It is the connecting pin between supply chain processes and partners that must work in tandem to ensure a complete order. Therefore, it is important that they understand the basics of transport management and use them in strategic decision-making.

THE VOICES

Studies have shown that supervisors are aware of most of the problems that workers face, but they do not know all of them. At the beginning of the day, the first workers have a call with their superiors, a little later there is a call between superiors.

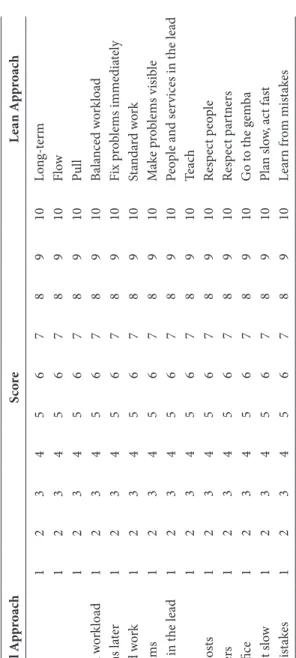

LEAN THINKING

Most of the total lead time from order to delivery is taken up by non-value adding activities such as waiting. Non-value adding activities are defined as work that costs money that the customer is not willing to pay.

LEAN PRINCIPLES

LEAN CULTURE

Taiichi Ohno said, “All we're doing is looking at the time from when the customer gives us an order to when we collect the money. We're reducing that time by removing non-value-added waste.” Lean started within one company, but the scope has expanded to the enterprise level.

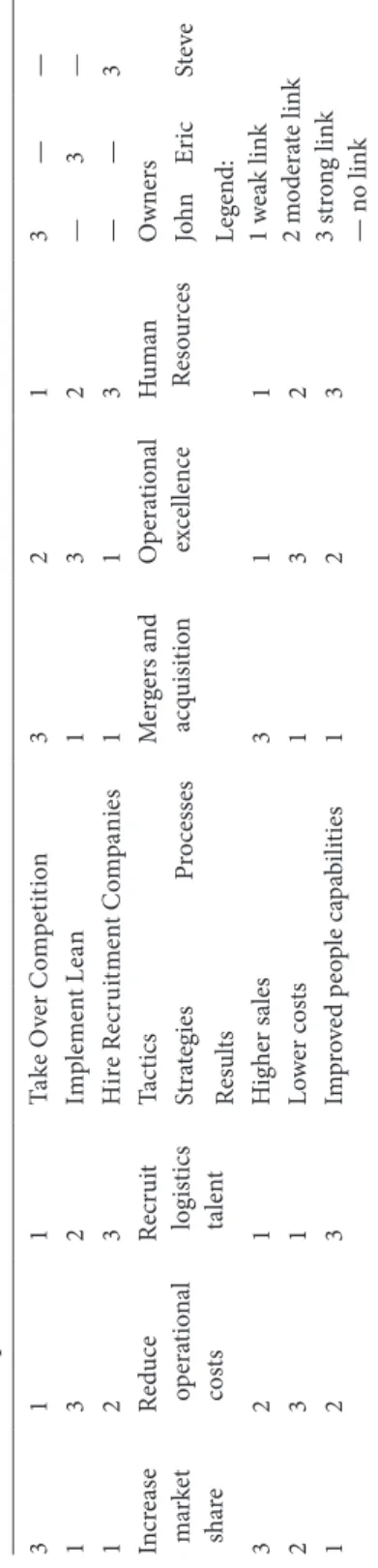

LEAN LEADERSHIP

Lean leaders are humble and take the time to plan and direct all improvements and employees in the same direction to ensure that their activities align well with strategic goals. Convis explains in their book “The Toyota Way to Lean Leadership” that Toyota expects their leaders to work on their self-development by maturing themselves in the Lean philosophy, applying the Lean tools and leading by example .

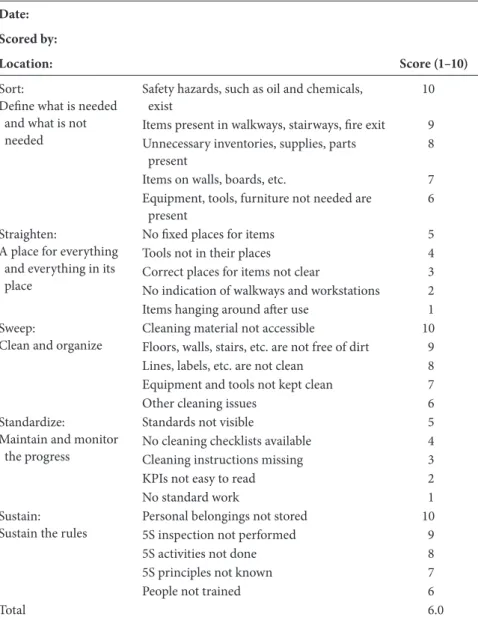

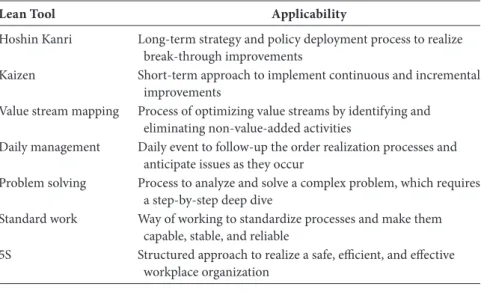

LEAN TOOLS

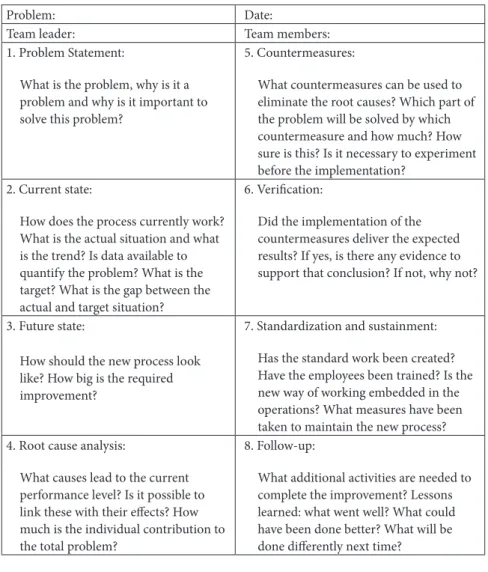

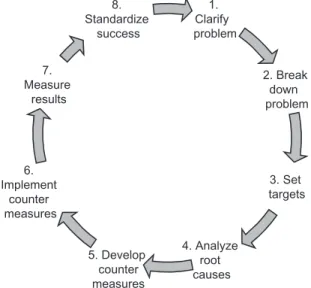

The waiting time is the time a part must wait before it is processed in the next step of the process. You have to dig a little deeper to find the root cause of the problem.

LEAN MATURITY

The model line is a limited scope of an organization or process where the first improvements are implemented and which can be used as a success story to market the Lean philosophy in the rest of the company. A company that manages the flow of goods on behalf of a customer by picking, packing and shipping them using their own, asset or non-asset-based, network or sub-suppliers: Logistics Service Providers (LSPs), service providers, Lead Logistics Providers (LLPs), xParty Logistics (xPL) where "x" can be one or "5". The xPL structure will be described later in this book.

LOCATION AND FLOW TYPES

Delivery locations can be customer sites, PUDOs, HFPUs, other DCs (also called rebalancing), or drop-off locations. Repair Center (RC): A location where returned goods can be repaired and sent back to DC or discarded. Market Warehouse: A national warehouse where stock may be owned and the warehouse managed by a local organization.

OUTBOUND PROCESS

Carrier selection can be done manually with simple tools or using a sophisticated Transportation Management System (TMS). Each shipment unit must have a carrier label with a tracking number so that it can be scanned through the transportation network for status updates on the carrier's track-and-trace websites and/or the shipper's ERP system. Such an advance alert can be made via telephone, e-mail or EDI message from a WMS/TMS to the carrier system.

INBOUND PROCESS

SHIPMENT PREPARATION

The unloader counts the number of pallets received, the types, their quality and the presence of the International Plant Protection Convention (IPPC) stamp on the pallet. Companies record any differences on the transport document and report them to the sender of the goods and the provider of the pallet pool. The number of pallets on documents, physically received and taken over is registered in the pallet administration tool.

TRANSPORTATION MODALITIES

Door-to-Door (DD): the goods are picked up by the carrier from the sender and delivered to the recipient's address. If the shipper is not certified as a “Known Shipper,” the shipper may submit its goods to a third party for a security scan before loading. The CMR is non-negotiable and is addressed to the recipient and the carrier.

COSTS AND TRANSIT-TIMES

In general, shorter transit times mean higher costs, but this is not the case in all cases. In fact, all of the aforementioned pricing strategies lead to shifts in market shares, since transportation is an indirect demand, meaning that lower prices will not result in higher prices. This is different from lowering the price of, say, TVs, which is likely to lead to more people being willing to buy a new one and create more demand for transport.

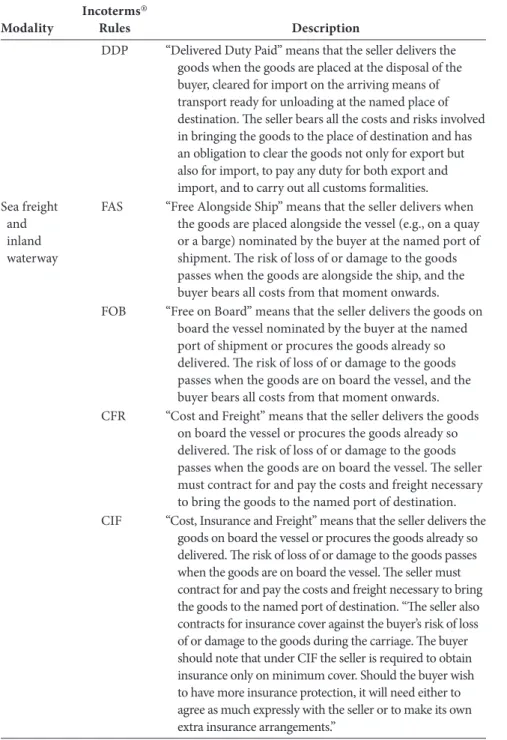

INCOTERMS ® RULES

FCA "Free Carrier" means that the seller delivers the goods to the carrier or another person appointed by the buyer at the seller's premises or another named place. FOB "Free on Board" means that the seller delivers the goods on board the vessel designated by the buyer in the named port of shipment or acquires the goods already so delivered. CFR "Cost and Freight" means that the seller delivers the goods on board the vessel or procures them already so delivered.

TRADE COMPLIANCE

The exact documents required depend on the country of origin, final destination and the nature of the items being shipped. Order: it is not possible to transfer the ownership of the goods to a third party. Letter of Credit (LC): a document from a bank to the buyer of the goods guaranteeing the payment of the seller's invoice.

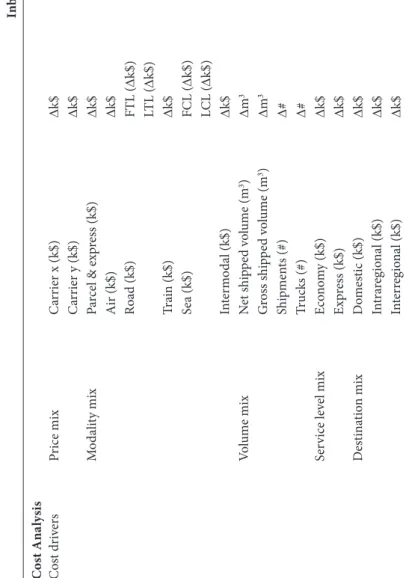

TOTAL COST OF OWNERSHIP

In the build process, people try to indicate what costs they can expect related to activities in the previous month, based on logistics indicators such as volume, weight and number of shipments. In the first case it is a loss-making shipment, in the latter case it is profitable. Payment: Transfer of money from shipper to carrier in the form of cash in advance, cash on delivery, check or from one bank account to another.

COMMODITY STRATEGY

Before doing this, it is possible to negotiate the terms and conditions with the carriers, based on a negotiation plan. Especially in difficult times, it is not recommended to beat suppliers and reduce their margins. It is important to explain the potentially bad situation of the shipper to suppliers and ask them for help by brainstorming improvement opportunities.

CARRIER SELECTION PROCESS

It is possible that some carriers will be eliminated from the shortlist, as their proposals do not meet the conditions. Since some gaps are more important than others, it's a good idea to assign a weight factor to them and score the brackets. Carriers may be required to quote prices for the entire allocation or only a portion of the quantity.

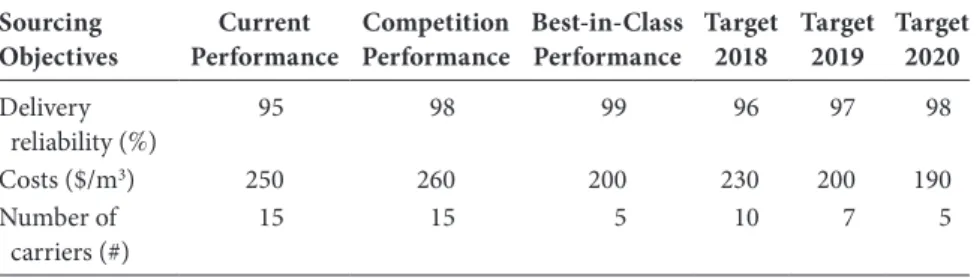

CARRIER REVIEW PROCESS

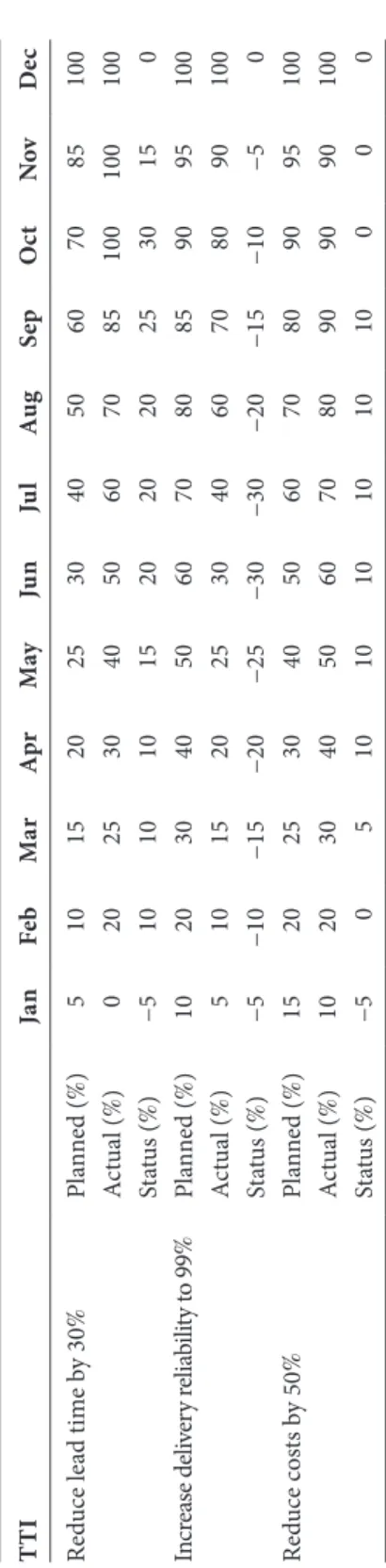

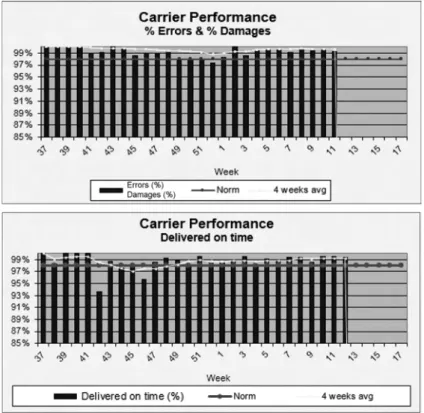

Therefore, on-time delivery, errors, damage and documentation services can be considered the most important. The performance delivered on time, also called delivery reliability, can be expressed in a net and gross performance. The same approach can be used to analyze the delivery quality (defects and damages) and documentation (Table 3.7).

COMPLAINT AND CLAIM HANDLING

The request must be sent out within the deadlines specified by the laws and regulations for the specific modality in the country in question. In the case of irregularities, photographs must be taken and the carrier and the sender must be notified at the same time within the time frames outlined for the specific mode of transport in the country in question. Transport invoices must be paid at all times, as it is not permitted to stop paying carriers as a result of a pending claim.

NETWORK OPTIMIZATION

Any discrepancy noticed upon delivery must be noted on the transport document and/or on the electronic device. The number of warehouses, their locations and size must be taken into account as they greatly influence transportation costs. The research is conducted using elements such as geography, supply and delivery points, modes of transportation, key metrics and seasonality.

BENCHMARKING

Carriers receive a lot of tender requests that cost a lot of time to process, and when they later find out there was nothing to win, it leads to frustration. Therefore, carriers are experienced in determining whether it is a real tender or just an attempt to obtain market information. Such a situation leads to carriers not accepting real tenders and seeing the shipper as a serious partner who provides standard prices, and more of these negative effects.

OUTSOURCING

The shipper has outsourced the day-to-day operational asset-based logistics activities to a third party, but management activities are still carried out by its own logistics department. The shipper has outsourced supply chain activities such as procurement, production and distribution of products to the market and their management to a third party that is not an asset. The relationship between the shipper and the service provider focuses on establishing a long-term cooperative partnership that covers all aspects of the supply chain and the sharing of risks and benefits.

SUSTAINABILITY

Congestion, a typical example of a process that does not flow, and loss of time lead to higher costs. It is also about committing to act fairly towards the stakeholders and respecting the applicable laws and regulations. It is not allowed to employ children, work with subcontractors who employ children, or force people to work for the company.

QUALITY MANAGEMENT SYSTEM

There must be instructions on what to do in case of fire, earthquake and injury. Define the quality policy to meet all requirements and realize a quality vision or mission. ISO 9001:2015 requires only three documented procedures, namely 'the scope of the quality system', 'quality policy' and 'quality objectives'.

TRANSPORTATION MANAGEMENT SYSTEM

The shipper agrees with the carrier which adjustment should be made in the next billing cycle. Rates and other relevant data are entered into the TMS for further dispatch and/or benchmarking purposes. Does the shipper want shipment status updates only in the TMS or also in the WMS and/or ERP system.

TRANSPORTATION MANAGEMENT MATURITY

Achieving a world-class level requires a documented process for measurement and management. Achieving excellence requires a global board that includes key stakeholders from different locations. Achieving excellence requires a documented process for measuring, collecting, aggregating, reporting and comparing KPIs against targets.