JOINTS

PROSES MANUFAKTUR I

MACAM-MACAM SAMBUNGAN

Las

Paku keling

Baut

Lem

Sambungan Las

Definisi Las

LAS ADALAH IKATAN METALURGI PADA

SAMBUNGAN LOGAM ATAU LOGAM PADUAN YANG DILAKSANAKAN DALAM KEADAAN LUMER

ATAU CAIR

- DIN -

Macam – Macam Pengelasan

Pengelasan cair

Pengelasan tekan

Pematrian

Welded Joints Design

Butt joint

Corner joint

Edge joint

Lap joint

Tee joint

Bevel Groove J Groove Vee Groove

U Groove Square Groove

Butt Joints

Open Corner Closed Corner

Corner Joints

1 2 1 2 3

4

Some considerations in selecting a type of joint to use on a fabrication

Accessibility for welding

Strength requirements

Cyclic or static loading

Material thickness

Welding process to be used

Material type

Code Requirements

Cost

Weld Quality (Size)

Effective Throat

Actual Throat Leg Size2

Leg Size1

Theoretical Throat

Convexity

Weld Quality

After selecting specified size gauge from set, measure Leg1

Measure Leg2

Verify throat with other side of gauge (face of gauge should touch weld)

L

1L

23/8

Weld Quality (Fault)

Undercut – most predominant weld fault

◦ Fix: Short arc length, proper amperage and speed

Weld Quality (Fault)

Porosity:

Lack of shielding gas Wet electrode

Greasy material

Weld Quality (Fault)

Slag Inclusion:

Improper cleaning / removal of slagWelding Joint Design & Welding Symbols – Chapter #5

Weld Quality (Fault)

Porosity

Undercut

Poor Fitup

Lack of Penetration

Weld Quality - Review

Weld Position (Plate)

F = Fillet G = Groove 1 = Flat

2 = Horizontal 3 = Vertical 4 = Overhead

Weld Position (Pipe)

G = Groove

1 = Horizontal Rolled 2 = Vertical

5 = Horizontal Fixed 6 = 45 Incline

Welding Symbols

Arrow

Reference Line

Tail

3 parts of the welding symbol body:

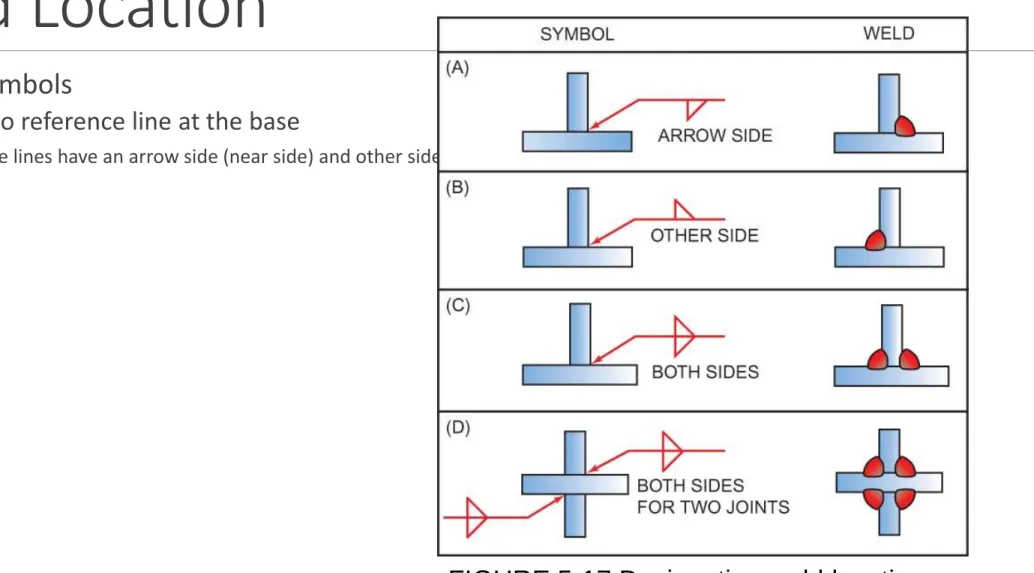

Weld Location

Welding symbols

◦ Applied to reference line at the base

◦ Reference lines have an arrow side (near side) and other side (far side)

FIGURE 5-17 Designating weld location.

American Welding Society

Sambungan Mur - Baut

Nuts and Bolts

Threaded Fastener Issues:

Types

Materials/Grades

Tightening Torque

Threaded Fasteners

Did you know that?

the Boeing 747 uses about 2.5 million fasteners

◦ 70,000 titanium costing $150,000

◦ 400,000 other fasteners costing about $250,000

◦ 30,000 squeeze rivets, 50cents each installed

In certain applications (such as an engine head), you should tighten the bolt as much as possible, if it does not fail by twisting during tightening, there is a very good possibility that the bolt will never fail

Why are fasteners used?

Advantages

Removable

Easy to install

Wide variety of standard parts Disadvantages

loosening

failure

cost

Types

Machine screws

Wood screws

Tapping screws

Standard Thread Systems

Unified or American ACME

SI (ISO)

Pipe Whitworth (UK)

Typical Designation

1/2” - 13 UNC - 2 A

external thread (B means internal)

Class of fit

(1 is loosest tolerance, 3 is tightest) Thread Series

UNC (Unified Coarse) UNF (Unified Fine) Pitch (threads/inch)

Nominal Diameter

(also shown as decimal or screw #)

Terminology of screw threads Sharp vee threads shown for clarity; the crests and roots are actually flattened or rounded during the forming operation.

Bolt Grades

Grade indicates the tensile strength of the bolt Determined by bolt material and heat treating

Tightening Torque

It is typical on engines for bolts to have a specified tightening torque. Why?

It results in a quantified preload on the bolts Insures that parts never separate

Maintains friction (no sliding to shear forces) Insures even distribution of loading

◦ prevent warpage of mating parts

◦ uniform pressure distribution over seal or gasket

Prevents bolt from loosening Reduces fatique effects

Bolt Manufacturing Processes

Forging (upsetting)

Rolling

Thread-rolling processes: a) reciprocating flat dies; and b) two-roller dies.

Threaded fasteners, such as bolts, are made economically by these processes at high rates of production

a) b)

Manufacturing Processes - continued

Turning on screw machines

(a) Differences in the diameters of machined and rolled threads. (b) Grain flow in machined and rolled threads.

Unlike machining, which cuts through the grains of the metal, rolled threads have improved strength because of cold working and favorable grain flow.

Sambungan Paku Keling

Sambungan paku keling

Bagian-bagian paku keling

Pemasangan paku keling

Sambungan paku keling

Standard:

AISC (American Institute Steel Construction)

ASME (American Society of Mechanical Engineers) Parameter Desain:

Diameter

Material Desain:

Menurut Indian Standard, IS : 2998-1982 (ditetapkan 1992), Tensile strenght > 40 N/mm2

Elongation = 26 %

Keling dibuat dengan cold heading atau hot forging.

Sambungan paku keling

Aplikasi:

Sambungan kuat dan rapat, pada konstruksi boiler ( boiler, tangki dan pipa-pipa tekanan tinggi )

Sambungan kuat, pada konstruksi baja (bangunan, jembatan dan crane )

Sambungan rapat, pada tabung dan tangki (tabung pendek, cerobong, pipa-pipa tekanan)

Sambungan pengikat, untuk penutup chasis (mis ; pesawat terbang)

Sambungan paku keling

Kelebihan:

Tidak akan longgar karena adanya getaran atau beban kejut Relatif murah dan pemasangan yang cepat

Ringan

Lebih tahan korosi dibandingkan sambungan baut Kekuatan fatigue lebih baik dari sambungan las

Sambungan keling lebih sederhana dan murah untuk dibuat.

Pemeriksaannya lebih mudah

Sambungan keling dapat dibuka dengan memotong kepala dari paku keling tersebut.

Sambungan paku keling

Kelemahan:

Tidak dapat dilepas

Pencekaman tidak sekencang sambungan baut

Tipe kepala keling

Kepala keling secara umum (di bawah diameter 12 mm)

Tipe kepala keling

Kepala keling secara umum (diameter 12mm sampai 48mm)

Tipe kepala keling

Kepala keling untuk ketel

Tipe sambungan keling

Lap Joint (sambungan 2 lapis)

Tipe sambungan keling

Lap Joint (sambungan 2 lapis)

Tipe sambungan keling

Butt Joint (sambungan 3 lapis)

Kegagalan sambungan keling

Keretakan pada sudut plat

Retak pada seluruh plat

Pergeseran keling

Perubahan bentuk (crushing) pada plat atau keling