A thesis submitted in partial fulfillment of the requirements for the degree of Master of Technology. Mahabir Panda, Head of the Department of Civil Engineering for his valuable suggestions during the synopsis meeting and necessary facilities for the research work. Swelling pressure (SP), differential free swelling index (DFS) and consolidation test were performed to understand the swelling behavior and consolidation behavior of the treated soil.

Chapter- 1

INTRODUCTION

General

Various methods such as physical, chemical and polymer processes are adopted to improve soil properties. Drainage is an efficient way to remove ground water using a pump, channel and pipes. The main goal of these physical processes is to reduce the amount of water in the soil and increase the effective load on the soil.

Expansive Soil

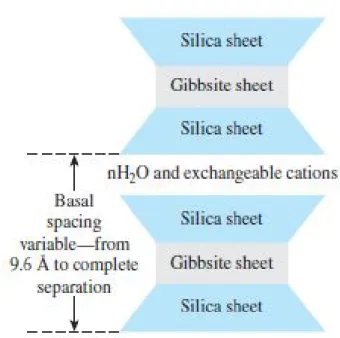

Compaction is a very common process that artificially rearranges and packs soil particles into a closer state of contact. On the other hand, the chemical process involves chemicals or emulsions to compact the soil or reduce the hydraulic conductivity of the soil. Due to this special soil mineral, the free swelling of the soil increases up to fifteen times its original volume.

Definition of Problem

This project is an attempt to investigate the behavior of expansive soil treated with xanthan gum biopolymer. Plasticity, swelling, strength properties, durability and microstructural investigations were carried out to understand the behavior of expansive soil treated with xanthan gum. The effect of curing periods on plastic properties of compressive strength and swelling pressure was studied with different concentrations of xanthan gum biopolymer.

Chapter-2

LITERATURE REVIEW

Introduction

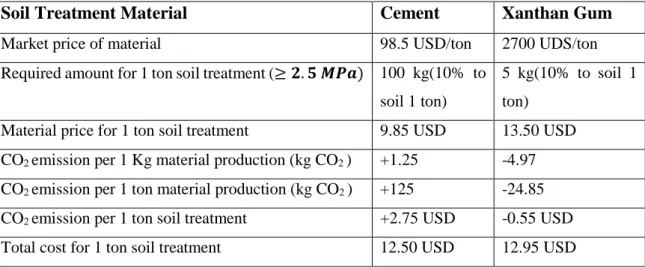

-time durability was evaluated to verify the usability and sustainability of Xantangom biopolymer treated soil. In the paper, they focused on improving the compaction and unconfined compressive strength of pond ash by incorporating xanthan gum and guar gum. The xanthan gum mixed 2-3% of the weight of the soil for optimal performance in terms of strength and durability.

Critical literature review

Objective and Scope

One rewarding area he put forward that decomposition and binding action will be concerned with the recovery of the soil polysaccharides. Then it can be used for binding, aggregation and adsorption on clay, sand or metal. 2007) conducted series of permeability tests to investigate the pore plugging effect by xanthan gum, guar gum and sodium alginate of highly permeable silty sand and soil. However, some literature on xanthan gum properties shows that this biopolymer has noticeable swelling nature on its own.

The current study therefore focuses on the stabilization of expansive soil by xanthan gum biopolymer. Assessment of compaction properties of untreated and biopolymer treated expansive soil by heavy and light compaction test. Detailed investigation of swelling characteristics of treated soil by differential free swelling index, swelling pressure test.

Strength and durability behavior of xanthan gum-treated soil has been evaluated by performing unconfined compressive strength and freeze/thaw tests, respectively.

Chapter-3

MATERIALS AND METHOLOGY

Introduction

The expansive soil has been prepared in the laboratory to achieve the necessary properties of black cotton soil. This synthesized expansive soil was then stabilized by adding biopolymer (commercially available xanthan gum powder) at different concentrations and with different curing period.

Materials .1 Expansive soil

- Xanthan gum

It has a rheology-modifying tendency of liquid and was discovered in the 1950s, is a natural anionic polysaccharide consisting of D-glucuronic acid, D-mannose, pyruvylated mannose, 6-O-acetyl D-mannose, and A 1,4-linked glucan ( Garcia-Ochoa et al. 2000, Hassler and Doherty 1990). The best known characteristics of xanthan gum are pseudoplasticity (Milas & Rinaudo 1986) & high shear stability (Chen &Sheppard 1980) even at low concentration. In addition, it has several desirable properties, including pH stability, storage stability and ionic salt compatibility (Hassler & Doherty 1990).

Methodology .1 Specific gravity

- pH test

- Grain size distribution

- Atterberg limits

- Compaction Characteristics

- Differential Free swelling index (DFS)

- Swelling Pressure

- Consolidation

- Unconfined compressive strength (UCS)

- Freeze/Thaw durability

- X-Ray diffraction (XRD)

- Scanning electron microscope

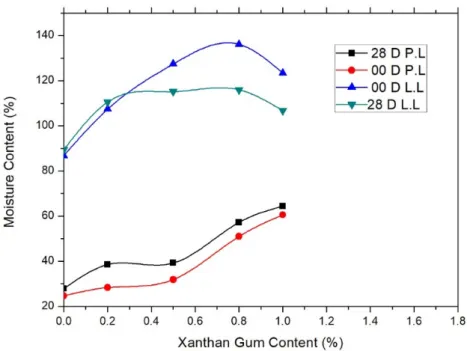

The granularity of expansive soils is determined as per IS: 2720- Part 4 (1975). In the graph, the moisture content corresponding to 25 blowing numbers is taken as the liquid limit of the mixture. At least 3 numbers of samples are prepared for each mixture to better identify the plasticity limit.

Subsequently, the volume of the wet soil and the dry soil was calculated using the mercury displacement method. Distilled water is then added to the soil sample until it becomes a smooth homogeneous mixture, with a moisture content of 2% above the liquid limit of the treated and untreated soil. Then, using a knife or spatula, the top surface of the mold is leveled.

The liquid limit, plastic limit and shrinkage limit of the virgin soil are given in Table 5. After compaction, the collar of the instrument is removed and the upper part of the soil is properly trimmed. The optimum moisture content and dry density of the virgin soil are tabulated.

The DFS value of biopolymer treated and untreated soil was determined as per IS 2720: Part 40: 1977 guidelines. The swelling pressure of treated and untreated soil samples was calculated following IS 2720 part 41 (1977). An initial 0.05 Kg/cm2 (seated load) is applied to the loading frame of the instrument.

Chapter-4

Results & Discussion

- Introduction

- Specific Gravity

- pH test

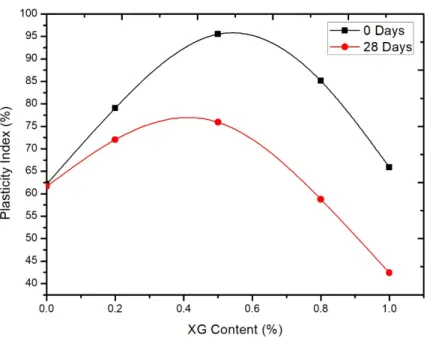

- Atterberg Limits

- Compaction characteristics

- Unconfined compressive strength

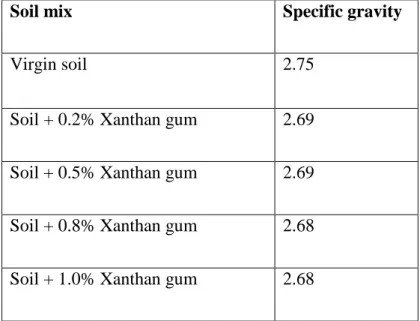

This chapter presents the experimental outcome of the stabilized expanse of land by xanthan gum biopolymer. The specific gravity of the different xanthan gum biopolymer blends expansive soil and virgin soil is given in the table. As the xanthan gum concentration increases, the density of the pore fluid increases; results in an increased density of the diffuse bilayer.

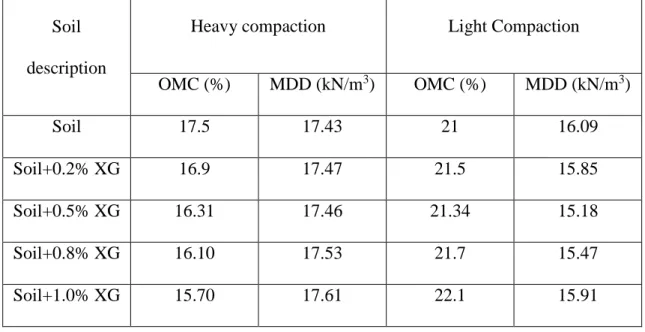

The plasticity index of treated soil has been calculated from liquid limit and plastic limit data for all xanthan gum and soil mixture. Light and heavy compaction curves for xanthan gum-treated expansive soil are shown in Figure 27 and Figure 28. Maximum dry density and corresponding optimum moisture content are assessed with increasing xanthan gum concentration in the expansive soil.

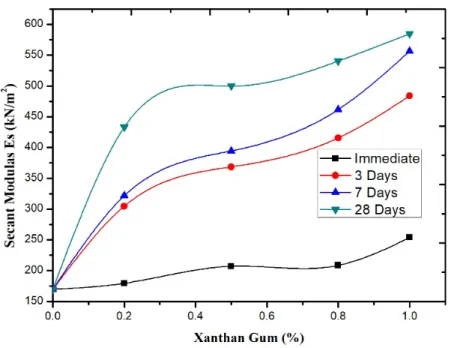

With an increase in the xanthan gum content, the density of the double layer of the soil particles increases, which in terms increases the undrained shear strength of the treated soil and flocculates the soil particles. In general, the strength behavior of the xanthan gum treated soil, shown in Figure 34, shows a remarkable increase in strength compared to virgin soil. This increase in strength of the xanthan gum treated soil depends entirely on the strength and density of the xanthan gum treated soil bond.

It shows that the UCS value of treated soil increases with increasing xanthan gum content and drying period.

Xanthan gum content

- Differential free swelling index (DFS)

- Swelling pressure

- One dimensional consolidation

- Freeze/Thaw Durability Test

- Scanning Electron Microscope Test

Swelling pressure is performed on untreated and xanthan gum-treated soil specimens with immediate and 7-day curing periods. From the experimental research, it was found that the addition of xanthan gum to the soil slightly increases the compressibility index (Cc) about 4.0%. While, from the discharge curve, it is found that the swelling index (Cs) of the treated soil increases by 116.12% of the virgin soil at a concentration of 1.0% of xanthan gum.

In Figure 42, the variation of Cc and Cs is given with variation in the content of xanthan gum. But the behavior in the discharge curve is due to the natural swelling tendency of xanthan gum hydrogels. The change in hydraulic conductivity (K) with increasing xanthan gum content and consolidation pressure is given in Fig.

In Figure 44, it is found that addition of xanthan gum reduces the loss of moisture content. On the other hand, the xanthan gum treated soil samples initially up to 4th cycle show this. So from this test it is found that xanthan gum treated soil sample offers good resistance to soil mass loss.

These results confirm that the strengthening mechanism and the improvement of the swelling characteristics of the soil treated with xanthan gum.

Chapter-5

Conclusion & Future Scope

Conclusion

While between 0.8% and 1.0% xanthan gum concentrations, particle accumulation is greater than the increase in pore fluid viscosity. As a result, the xanthan gum mixture soil shows a continuous increase in plasticity both for the immediate test and after the 28-day test with increasing concentration of xanthan gum. Which helps the soil by reducing the rate of volume change and reducing the volumetric shrinkage and increasing the linear shrinkage of the xanthan gum treated soil.

As the xanthan gum content in the soil increases, particle flocculation occurs with a highly viscous diffuse double layer. Xanthan gum has been shown to have an impressive strengthening effect on treated soil. At a 1% concentration of xanthan gum, it shows about a 93% increase in potency. This increase in strength is due to the direct interaction between the negatively charged soil particles and the carboxyl group of xanthan gum (i.e., hydrogen bonding, cation bridging).

Initially, the DFS value of soil treated with xanthan gum shows a slight increase in swelling of about 7.68. As a result, soil treated with xanthan gum absorbs less water than untreated soil and reduces swelling by 29.85%. The consolidation result also shows that adding xanthan gum to the soil reduces the hydraulic conductivity (K) and increases the time required for consolidation set with increasing xanthan gum content.

Due to the glue-like nature of xanthan gum, it accumulates soil particles and provides resistance to mass loss in the freeze/thaw test.

Future Scope

From the SEM image, it is found that the formation of gum-like cement products resulting from chemical reactions between xanthan gum and soil particles, which improves the strength behavior of the soil. Effects of xanthan gum biopolymer on permeability, odometer, unconfined compressive and triaxial shear behavior of sand. Introduction of microbial biopolymers into soil treatment for future environmentally friendly and sustainable geotechnical engineering.

Effect of liquid polymer and lime additives on the behavior of fine-grained soil at unfrozen and freeze-thaw conditions.