I hereby declare that the work incorporated in this thesis entitled Aerobic Granulation in Sequencing Batch Reactors for Treating Wastewater Laden with Phenol, Thiocyanate, Ammonium and Nitrogenous Heterocyclic Compounds carried out by me in the Department of Civil Engineering, Indian Institute of Technology Guwahati, Assam, India, under the supervision of Prof. Shweta Singh for their selfless love, care and support during my research work and for creating an innate atmosphere in the laboratory to work.

Introduction

On the other hand, the AGS technology does not need any additional settling tank, which reduces the area requirement, which ultimately reduces the cost of installation and can also retain abundant biomass (Sengar et al., 2018). Aerobic granules are the self-immobilized microbial aggregates which can maintain high biomass and possess a regular, denser and stronger microbial structure with good settling properties along with the ability to tolerate toxic and high organic load compared to conventional activated sludge process (Marques et al. ., 2013 ; Tay et al., 2005).

Organization of the thesis

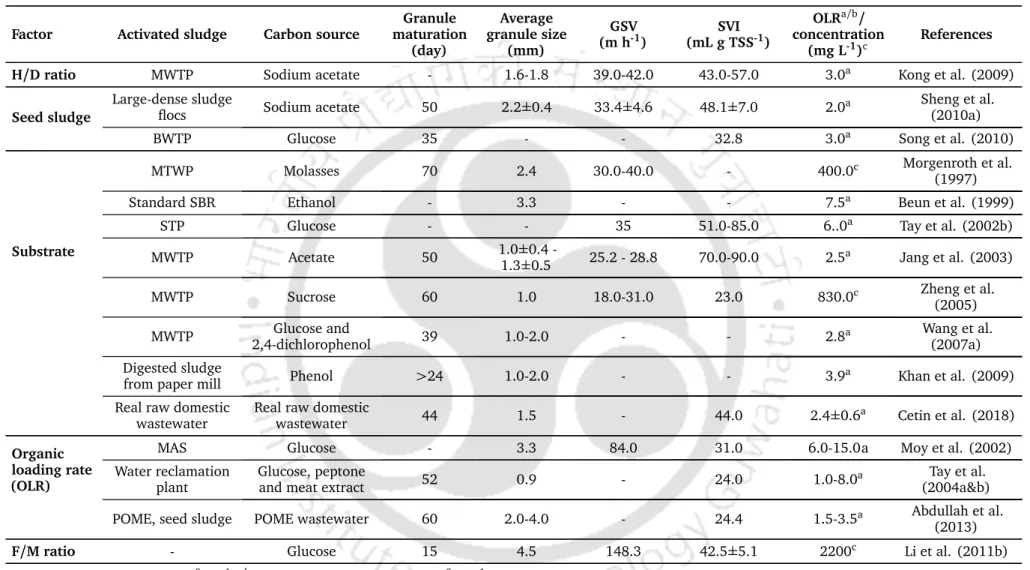

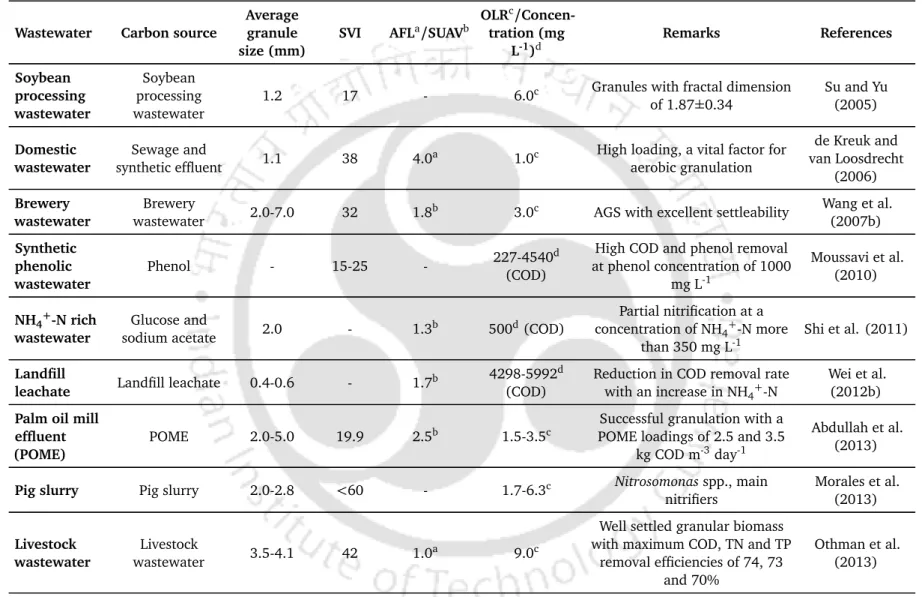

Due to the unique properties discussed above, AGS has been adopted to treat high-load wastewater containing toxic organics, nitrogen and phosphorus (Corsino et al., 2018; Hamza et al., 2019; Liu et al. , 2011). Many factors such as substrate loading, type of substrate and inoculum and operational parameters such as cycle time, settling time, feeding strategy, starvation regime, aeration intensity, etc., affect aerobic granulation (Corsino et al., 2017; Lee et al., 2010).

Literature background

History of aerobic granulation

Anaerobic granules have been recognized worldwide and were first observed in the anaerobic sludge reactor (UASB) for the treatment of industrial wastewater in the late 1970s (Lettinga et al., 1980). The production of aerobic granules and their applications using a sequential batch reactor (SBR) was discussed by Morgenroth et al.

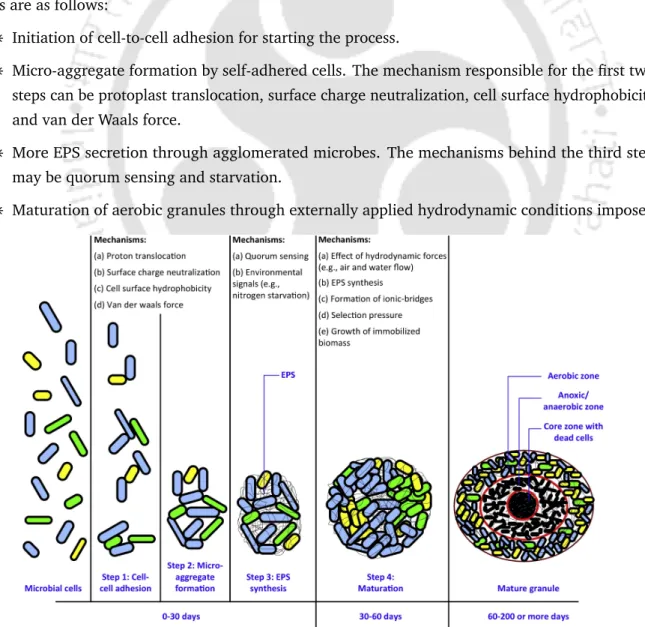

Formation of aerobic granules

Mishima and Nakamura developed the first aerobic granules in the aerobic sludge blanket reactor in 1991 (Mishima and Nakamura, 1991). The International Water Association (IWA) clearly defined AGS during the first workshop on AGS at the Technical University of Munich (Germany) in 2004, as the granules that make up aerobic granular activated sludge should be understood as aggregates of microbial origin, which do not coagulate under reduced hydrodynamics. shear, and which settle significantly faster than the activated sludge plume (de Kreuk et al., 2007).

Factors affecting aerobic granulation

- Reactor configuration

- Seed sludge

- Substrate composition and organic loading rate

- Food to microorganism (F/M) ratio

- Free ammonia (FA) and free nitrous acid (FNA)

- Operating conditions

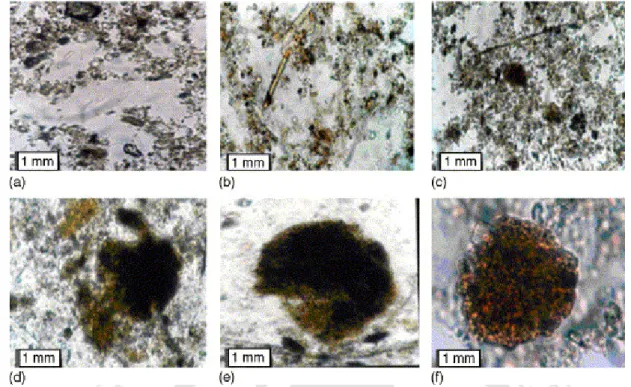

Micrograph of the aerobic granulation process: (a) seed slurry; (b) the stage of microbial multiplication; (c) hair appearance stage; (d) hair cohesion phase; (e) mature hair stage; (f) aerobic granule phase (Hailei et al., 2006). 1 min fixation time was also sufficient to achieve rapid granulation with better characteristics (Gao et al., 2011).

Aerobic granular characteristics

- Physical characteristics

- Chemical characteristics

- Biological characteristics

The hydrophobicity of acetate fed pellets (73%) was almost two times higher compared to suspended sludge (39%) (Tay et al., 2002b). Although the mechanism responsible for the effect of hydrophobicity on granulation is still unclear (Adav et al., 2008a).

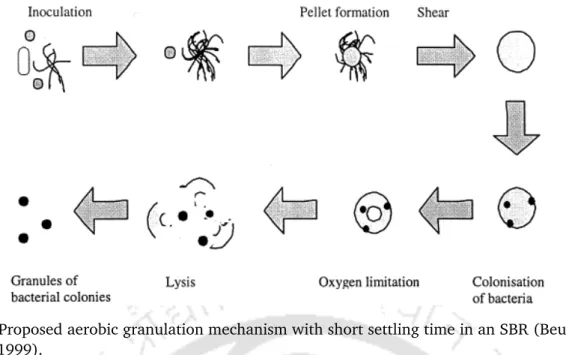

Mechanism of aerobic granulation

Despite all the above information, ESP secretion mechanism in AFM is still ambiguous (Zhang et al., 2019b). EPS presence on the surface of the bacterial cell can change the physicochemical properties of the cell surface, including surface hydrophobicity and surface charge ( Muda et al., 2014 ).

Application of aerobic granules

Limitations

- Long startup period

- Granular instability during operation

It was also investigated whether grain stability and organic loading are related and a high loading appeared to be beneficial for the stability of grains (Wang et al., 2009). However, the enzyme AHLs acylase degraded the AHLs and decreased the protein and polysaccharide content of EPS, ultimately worsening the granular stability (Li et al. observed a reduction in the stability of granules by algal growth.

Type of wastewater

In addition, the role of N-acyl homoserine lactones (AHLs) in granular stability has been reported in the literature. Recently, the interaction between layered double hydroxide (LDH) and EPS was studied for improving granular stability.

Pollutants

- Phenol (C 6 H 5 OH)

- Thiocyanate (SCN - )

- Ammonia-nitrogen (NH 4 + -N)

- Pyridine (C 5 H 5 N)

- Indole (C 8 H 7 N)

Indole toxicity can cause animal hemolysis, temporary skin irritation and tumor formation (Ma et al., 2018). However, a universally accepted bacterial community responsible for the aerobic biodegradation of indole has not been reported so far (Ma et al., 2015).

Summary of literature review and lacunae

Indole is a nitrogen-containing heterocyclic aromatic environmental pollutant that is generally found in livestock and coke wastewater (Ma et al., 2019). Among several treatment methods, the biological approach has been considered a sustainable and economical treatment technology for indole-contaminated systems (Ma et al., 2019).

Objectives of the study and methodology

Effect of food-to-microorganism ratio (F/M) on formation and grain size of aerobic sludge. Compared to the findings of Tay et al. 2008a), the present study was found to be more favorable in terms of granule size. The SRT values of R1 and R3 were in the range of standard values for achieving nitrification (10-30 days) (Tchobanoglous et al., 2003).

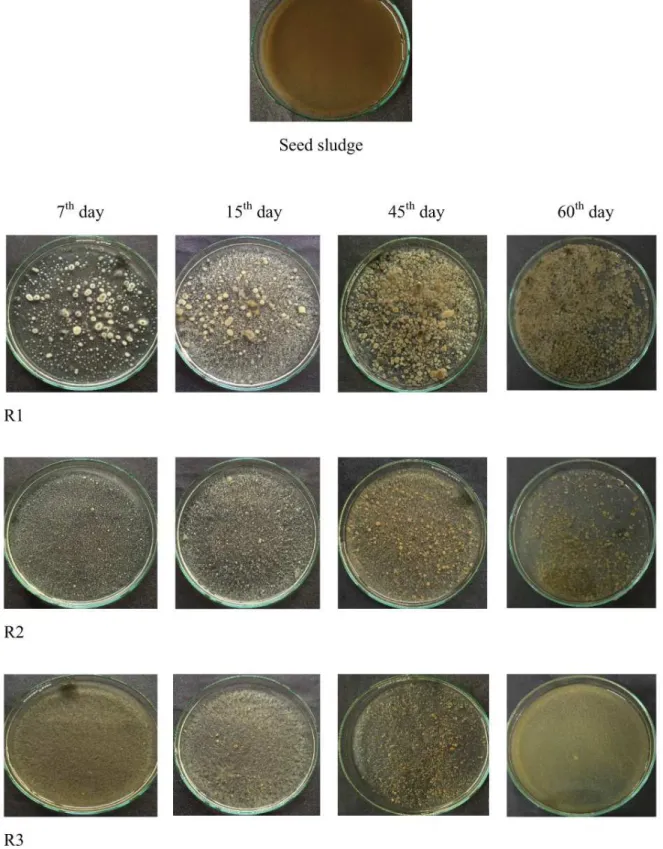

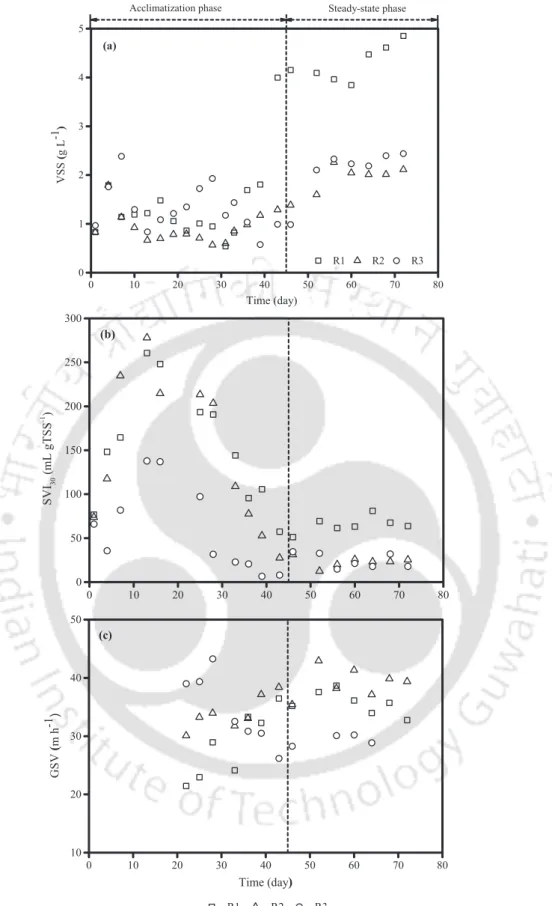

Previous research has shown that PN plays a similar role in glucose- and acetate-containing wastewater (Adav et al., 2007; Gao et al., 2011a; McSwain et al., 2005). The EPS secreted by microorganisms can also clog the pores in the water. the aerobic granules resulting in a decrease in permeation and settling rates (Basheer and Farooqi, 2014), as observed in the present study (R1 had low settling capacity than R2 and R3). However, an approach to grain reformulation after its disintegration is still very limited in the literature (Liu et al., 2014). The characteristics of the grains of R1 and R2 at different phenol concentrations are given in Table 4.4.

In batch tests, inhibition of nitrifying activity of aerobic grains above 10 mg L-1 phenol was observed (Liu et al., 2005). GSV values were quite higher in the present work (R1) from the study of Liu et al.

Optimization of Operational Strategies for Aerobic Granulation 33

- Materials and methods

- Chemicals and reagents

- Granular biomass activity (GBA) test

- Cycle time study

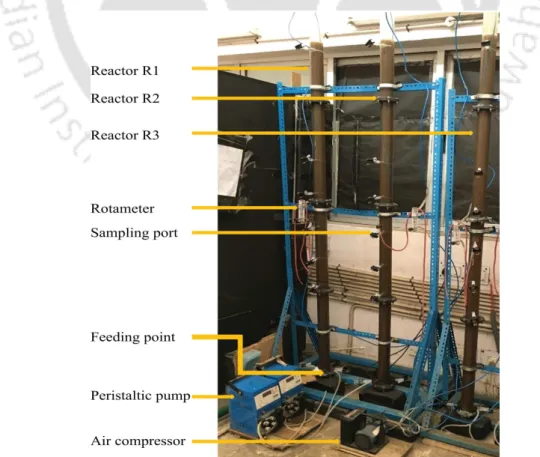

- Experimental set-up

- Seed sludge characteristics and composition of synthetic wastewater

- Operational strategy

- Results and discussion

- Conclusion of cycle time study

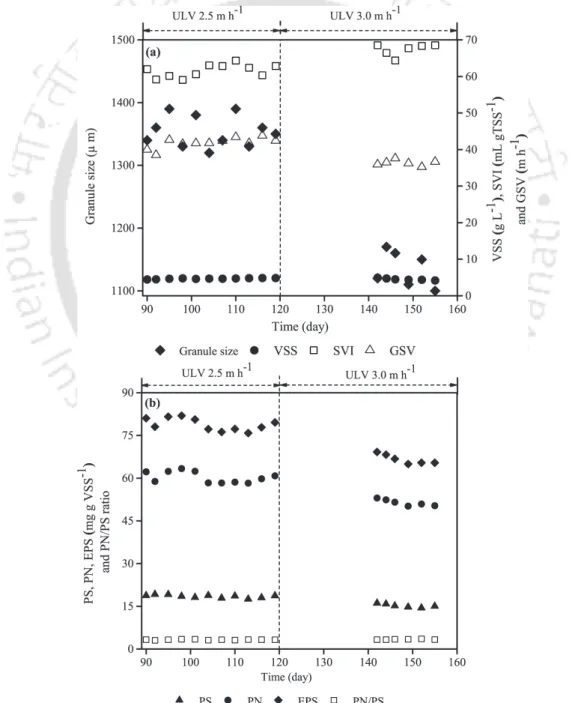

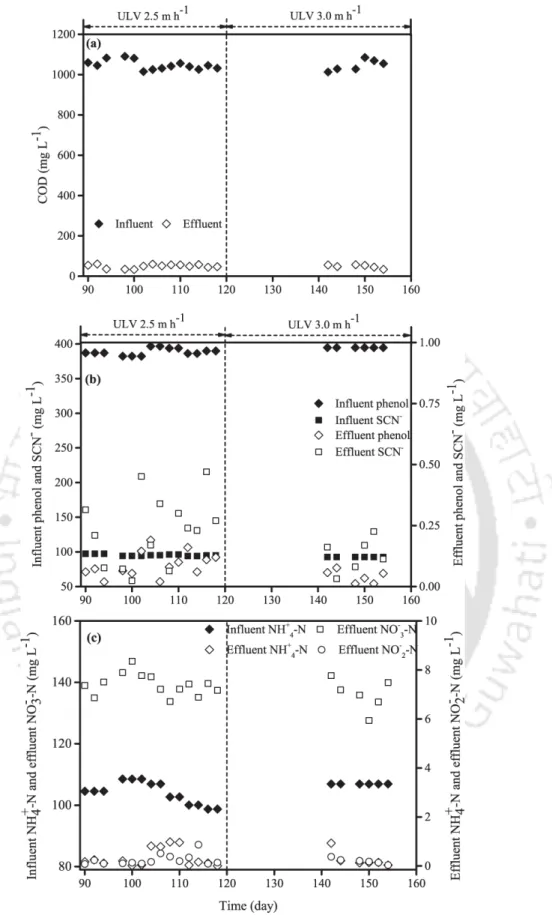

- Effect of ULV on characteristics and performance of reactor R1

- Air flow rate study

- Reactor and experimental set-up

- Characteristics of seed sludge and composition of synthetic wastewater

- Operational strategy

- Results and discussion

- Conclusion of the air flow rate study

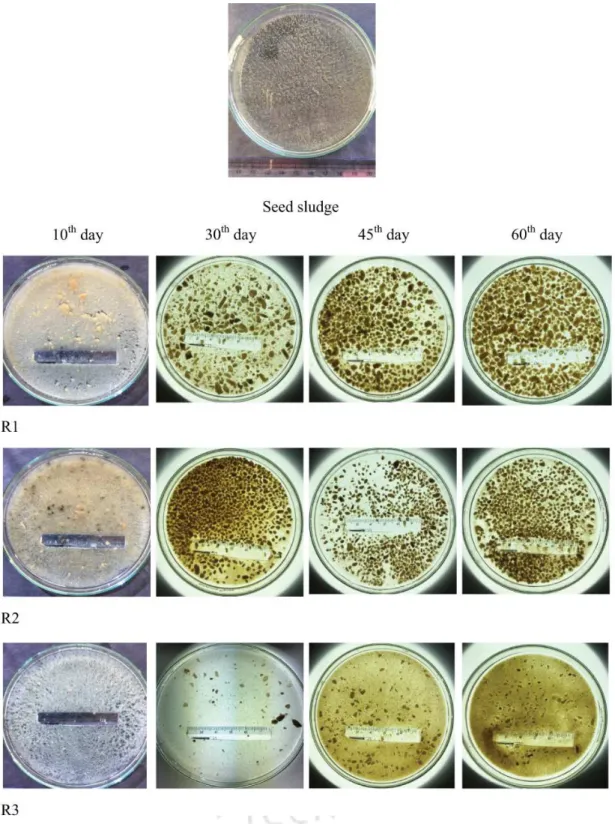

On the other hand, AGS was able to treat only pyridine up to a concentration of 5.0 mM. With a decrease (1.5 L min-1) and an increase (3.5 L min-1) in air flow rate, both granule characteristics and reactor performance deteriorated. Loose and porous granules were detected at lower air flow rate (R1, 1.5 L min-1), whereas higher air flow rate (R3, 3.5 L min-1) triggered the biomass leaching.

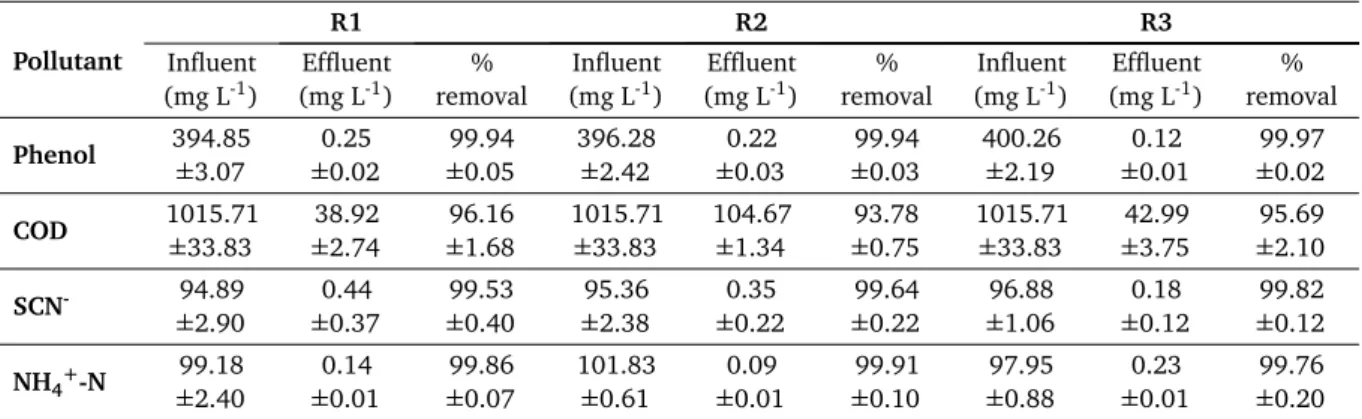

Removal efficiencies of 99, 98 and 95% were observed for phenol, thiocyanate and COD respectively at a min-1 air flow rate of 2.5 liters.

Effect of Substrates on Rapid Aerobic Granulation and Reformation of Aerobic

- Materials and methods

- Analytical methods

- Effect of substrates on aerobic granulation

- Experimental set-up

- Characteristics of inoculum sludge and synthetic wastewater

- Operational approach

- Results and discussion

- Conclusion of rapid granulation

- Reformation of aerobic granules

- Feed characteristics

- Reactor operation

- Results and discussion

- Conclusion of granule reformation

CLSM imaging illustrated the extensive fluorescence for active biomass, proteins and polysaccharides in R2 granules; however, a higher proportion of dead cells in R3 pellets. No inhibitory effect of SCN up to 340 mg L-1 was observed on pellet properties and reactor performance.

Impact of High Phenol Loading on Aerobic Granulation 99

Materials and methods

- Experimental set-up

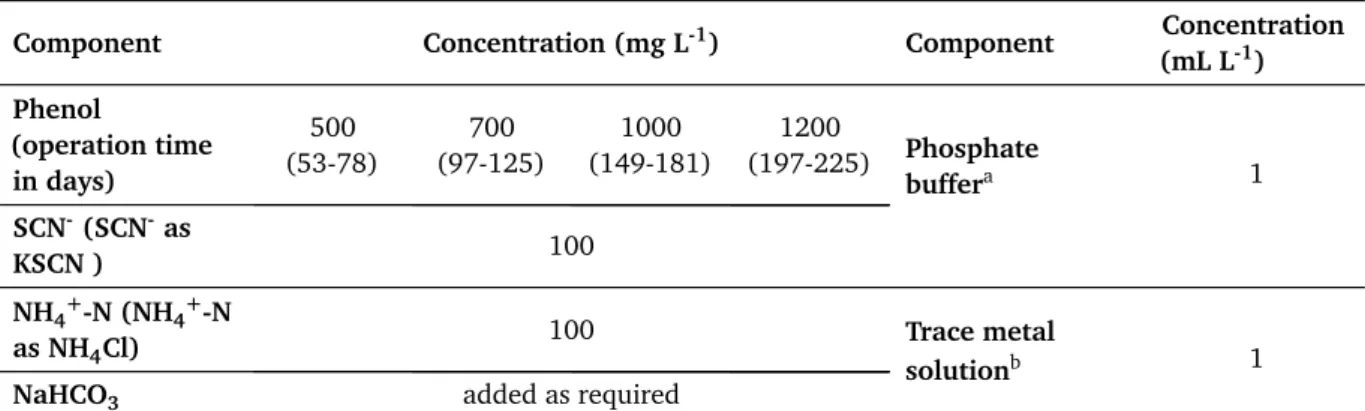

- Characteristics of seed sludge and synthetic wastewater

- Granular biomass activity (GBA) test

The pH in both reactors was between 7.5 and 8.0 and was maintained by phosphate buffer and NaHCO3. The phosphorus required for the growth of the micro-organisms was also supplied by the phosphate buffer. Initially, 1000 mg L-1 sodium acetate was added as a benign carbon source in both the SBRs.

The activity test was carried out in three cycles with the same feed concentration and the slope of the linear part of the third cycle was taken into account to calculate the activity of granular biomass.

Results and discussion

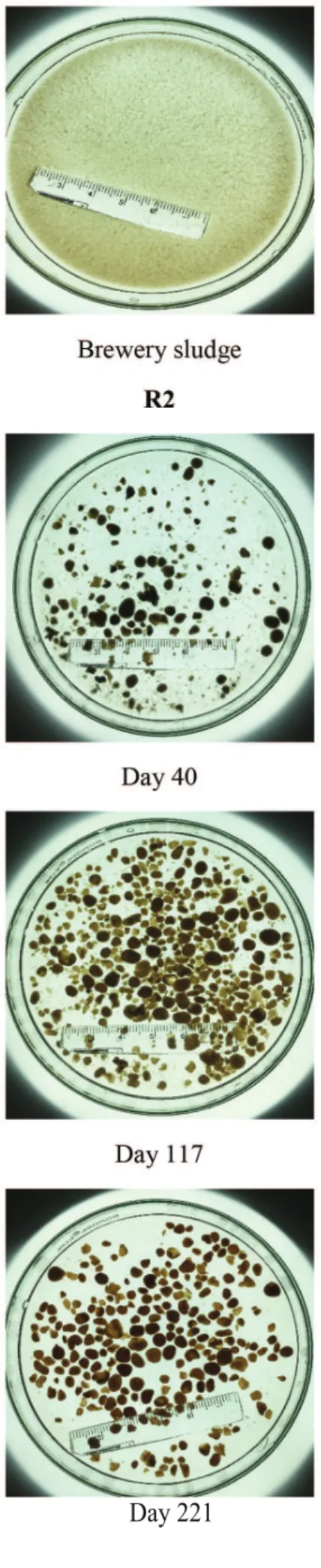

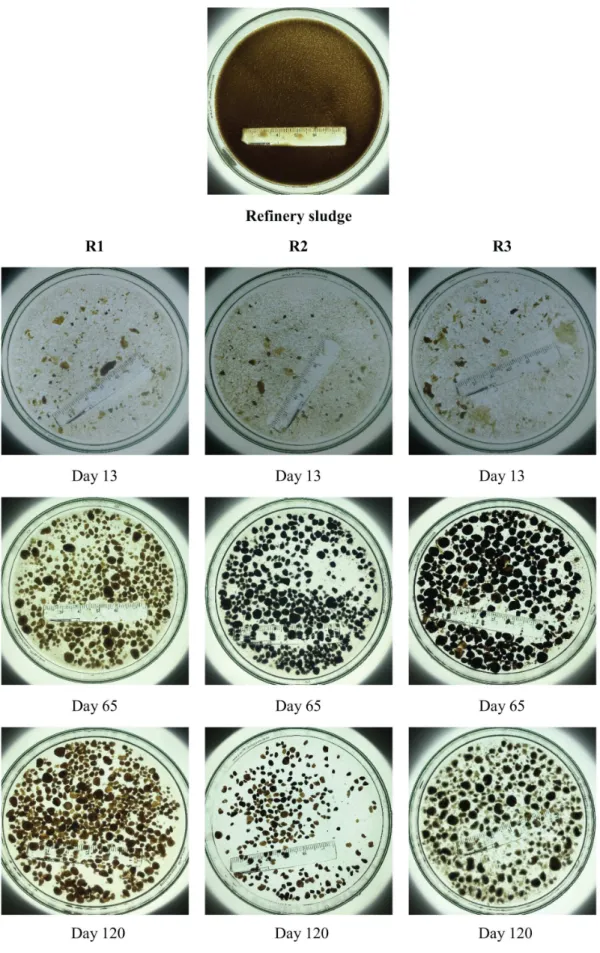

- Granule formation

- Granular characteristics

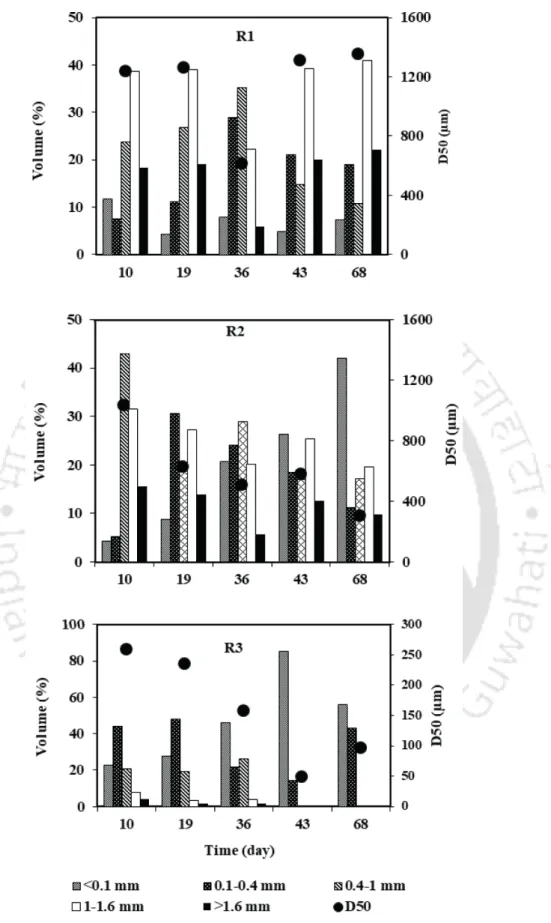

- Granule size

- Biomass (VSS) concentration

- Settling characteristics of the granules

- Extracellular polymeric substances (EPS)

- Strength of the granules

- GBA of the AGS

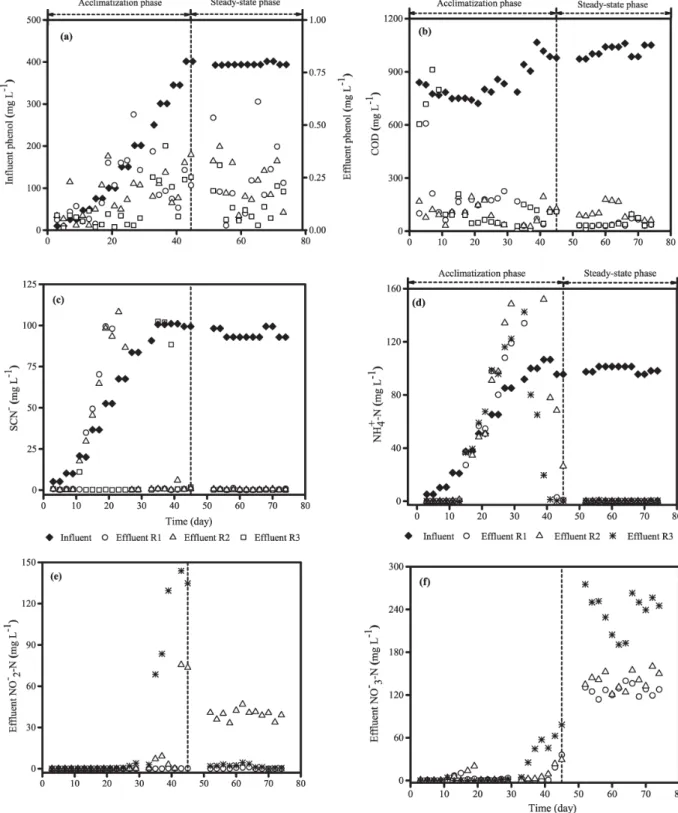

- Pollutants removal profile

The size of the granule with the operation for both SBRs is given in Fig. Up to a phenol load of 3.32 kg COD m-3day-1, no toxic effect of phenol on granular size was observed in both SBRs. The average VSS values for both SBRs for all four phases are given in Table 4.4.

So far, no inhibition on the nitritation due to phenol loading has been observed in both reactors.

Conclusion

While a decreasing trend was observed in the VSS values with increases in the concentrations above 1.0 mM for indole and an equimolar mixture of pyridine and indole in R2 and R3, respectively. While the concentrations of indole and an equimolar mixture of pyridine and indole greater than 1.0 mM imposed an inhibitory effect on EPS secretion in R2 and R3, respectively. However, indole concentrations above 1.0 mM had an inhibitory effect on the granular features in R2 (alone) and R3 (present with pyridine).

Inhibition on NH4+-N removal was observed in R2 and R3, as the concentrations of indole and an equimolar mixture of pyridine and indole were increased to more than 1.0 mM.

Treatment of Aromatic, Inorganics and Nitrogenous Heterocyclic Compounds

Materials and methods

- Experimental setup

- Characteristics of seed sludge and influent feed

- Reactor operation

- Analytical procedures

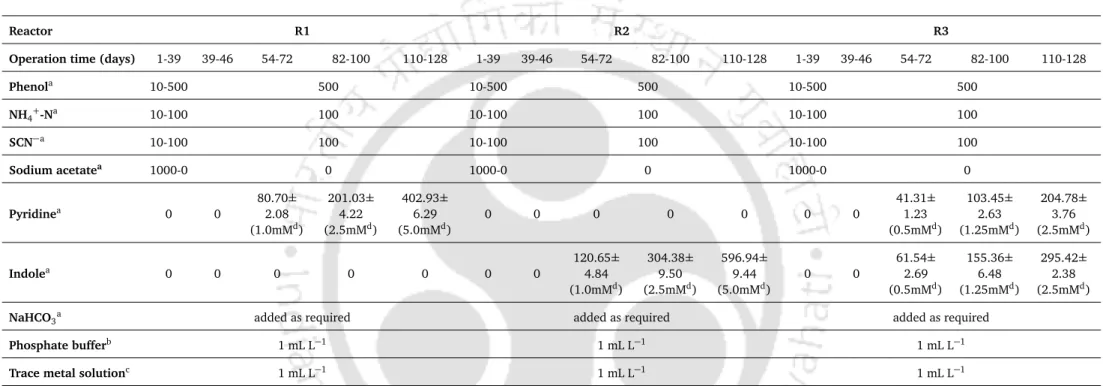

Pyridine and indole were purchased from Merck (India) and Hi-media (India). Three identical transparent acrylic sequencing batch reactors (SBRs) with the same configuration as given in Chapter 2 (Section 2.3.1) were used to grow AGS. R1, R2, and R3 were driven with pyridine, indole, and an equimolar mixture of pyridine and indole, respectively (Table 5.1). All SBRs were operated for at least 18 days with each pyridine and/or indole concentration to obtain steady-state data.

Concentrations of pyridine and indole were quantified using a high performance liquid chromatography (HPLC) (Prostar 210, Varian, USA).

Results and discussion

- Granule formation

- Granular Characteristics

- Granule size

- Biomass concentration

- Settling behaviour

- Extracellular polymeric substances (EPS)

- GBA test

- Pollutants removal profile

While like SVI30, the negative effect of indole on GSV was also observed in R2 and R3 with concentrations beyond 1.0 mM of indole and an equimolar mixture of indole with pyridine resulting in reduced values. The addition of pyridine to R1, indole to R2, and an equimolar mixture of pyridine and indole to R3 at a concentration of 1.0 mM did not impose any inhibition on phenol biodegradation, and all SBRs continued to exhibit greater than 99% phenol biodegradation. . In the present work, no inhibition was observed in SCN removal with a phenol concentration of 500 mg L-1 along with 5.0 and 1.0 mM of pyridine and indole, respectively (Fig. 5.8c).

No inhibition phenomenon was observed among all pollutants up to the NHC concentration of 1.0 mM.

Conclusion

Long-term stability of aerobic granular sludge for treatment of very low-strength real domestic wastewater. Effect of thiocyanate on the conversion of aerobic granules from the disintegrated granules treating phenolic wastewater along with recovery of nitritation efficiency. Effect of air flow rate on aerobic granule development, biomass activity and nitrification efficiency for phenol, thiocyanate and ammonium treatment.

Characteristics of aerobic granules treating phenol and ammonium at different cycle times and upflow liquid velocities.

Conclusions and Future Scope 143

Key findings

Limitations

Scope for future work

Impact of high phenolic loading on aerobic granules from two different types of industrial sludge, together with thiocyanate and ammonium. Simultaneous biodegradation of pyridine, indole and ammonium together with phenol and thiocyanate by aerobic granular sludge. Third International Conference on Sustainable Energy and Environmental Challenges (3rd SEEC), December 18-21, Indian Institute of Technology Roorkee, India.

Comparison of pellet properties developed from the same inoculum sludge with two different substrates in sequencing batch reactors.