The environmental sustainability of PRB has been tested by performing a life cycle assessment (LCA) of PRB when used in cooking and industrial applications. In the present research, the environmental assessment of PRB is also carried out when it is used in industrial applications.

Contents

5 Technological-economic evaluation of cooking plates based on a porous radiant burner 104 5.1 The need to perform TEA on cooking devices based on PRB 104.

76 4.9 Performance of BGSPRB under various biogas and digestate spills 78 4.10 System boundary and scope of the study of LPG based stoves 81 4.11 Midpoint and endpoint assessment categories 83 4.12 Damage assessment categories - manufacture and recycling of.

List of Tables

Introduction

- Porous Radiant Burner

- Application of Porous Radiant Burner

- Possibilities of further studies on Porous Radiant Burner

- Structure of the Thesis

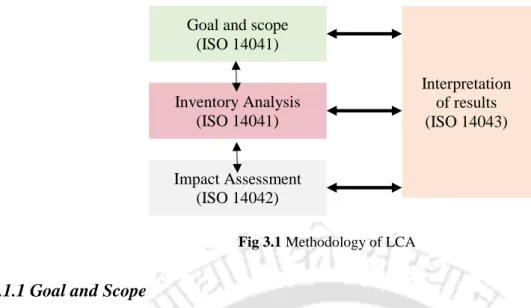

Only one study has been conducted on the environmental justification of PRB, and the study focused on the energy efficiency of the product (Kaushik and Muthukumar, 2018). The definition of LCA as given by ISO is "the collection and evaluation of inputs, outputs and potential environmental impacts of a product system throughout its life cycle" (ISO_354 2003).

State-of-the-art

Literature on Porous Radiant Burner based cook-stoves

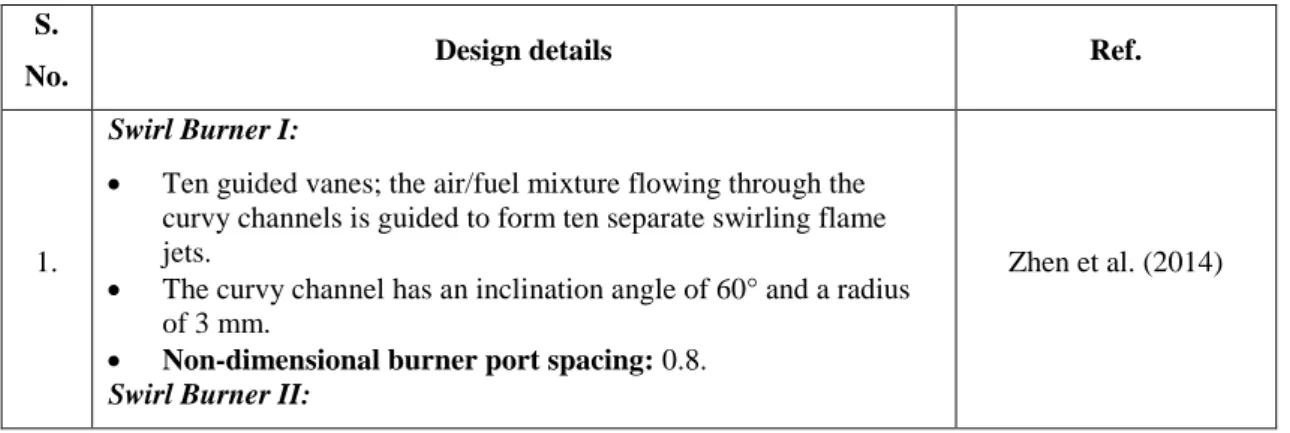

A further improvement of the thermal efficiency of the burner was achieved by combining the PRRB with the swirling central flame ring burner (SB), i.e. the PRRB(SB). 2020) achieved a thermal efficiency of 67%, which was higher than the efficiency of the locally available burners.

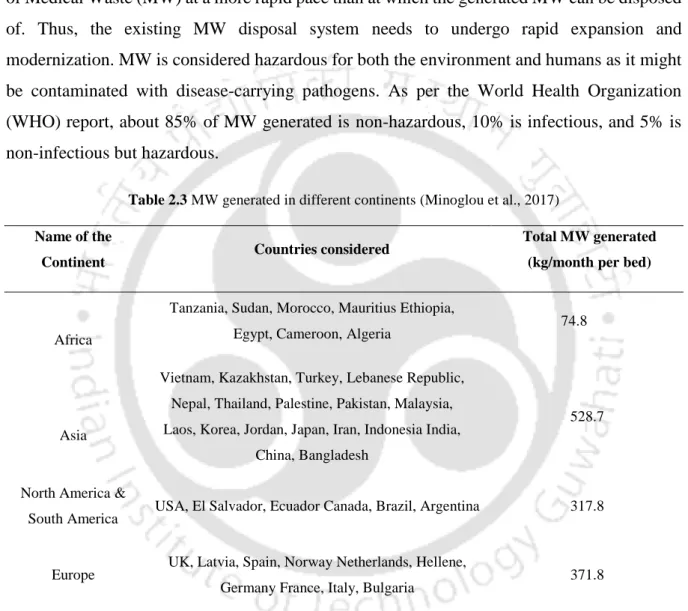

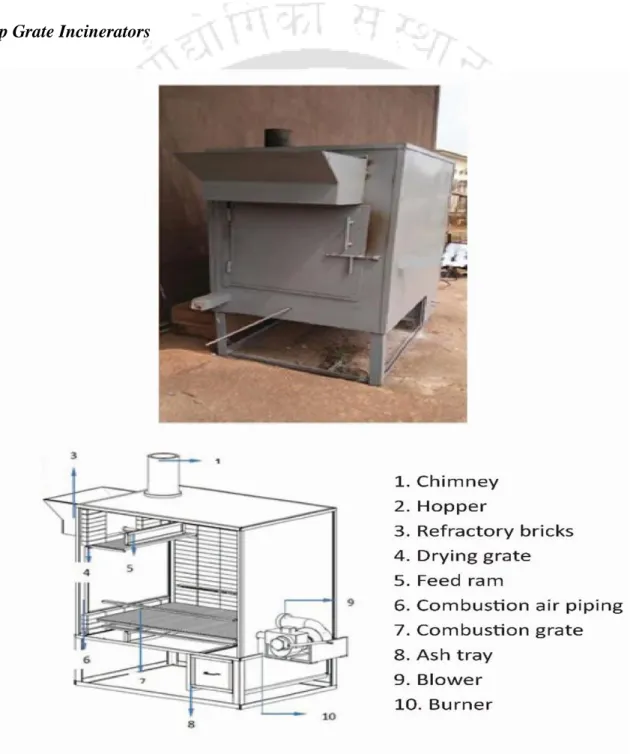

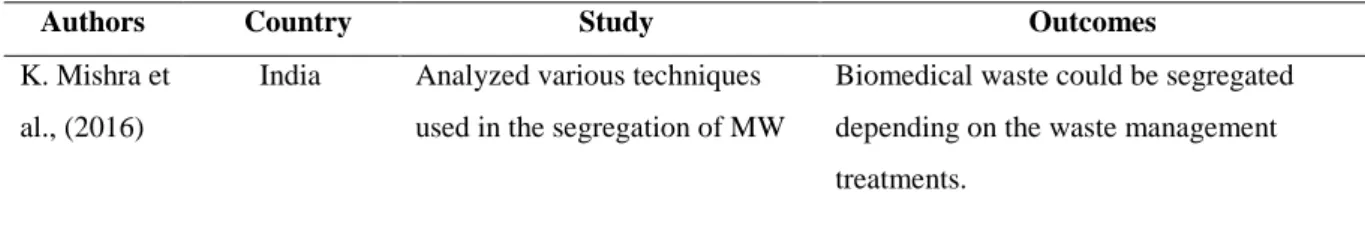

Literature on Medical Waste Incinerators

According to BMWM rules (2016), the permitted limit values for suspended particulate matter (PM), the residence time in the secondary chamber of the incinerator and the criteria for dioxin and furans are 50 mg/Nm3, 2 s and 0.1 ngTEQ/Nm3 respectively ( Datta et al., 2018). During the calculations, heat build-up in the construction materials of the two chambers and heat losses.

Literature Closure .1 Cook-stoves

Spain Assessment of information on health effects, including cancer incidence and cancer mortality, for the people living near the incinerator. Several authors have tested different incinerator configurations and reported an improvement in overall efficiency.

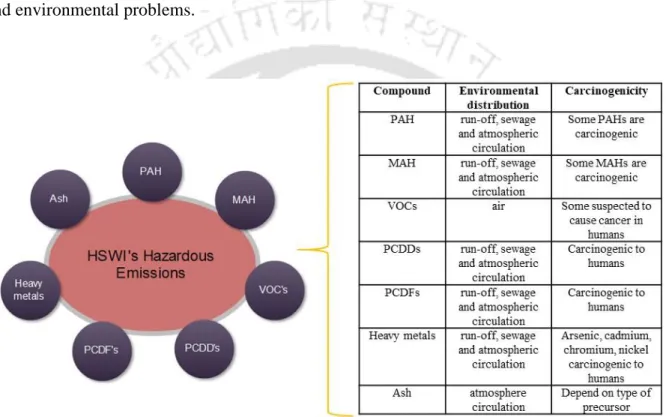

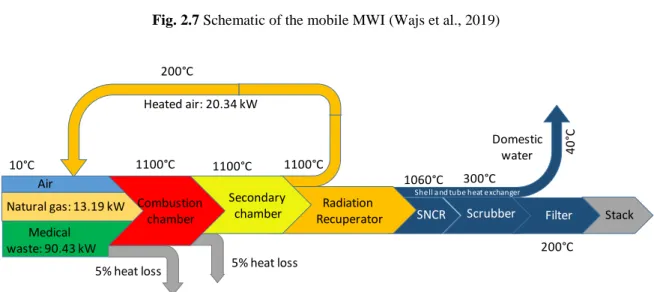

Research Questions and Objectives

The excess heat produced during the combustion process can also be effectively used for power generation, water heating purposes and so on, if the design and method of operation of MWIs are slightly modified with the right equipment. CO, NOx, PM, PCDD, PCDF, PAH, PCB, REE and heavy metals in the bottom ash are identified as the main emissions from MWIs. Complete combustion of MW within the incinerator indicates the efficiency of the incinerator in getting rid of the MW and such improvement in efficiency can be achieved by changing the design of the incinerator.

Also, no work has been reported so far on the performance of the combustors combined with the heater/burner, which is important since the thermal performance of the heater/burner influences the overall performance of the MWIs. Use of Porous Radiant Burner (PRB), which is highly efficient and produces less pollutants in the atmosphere, can be explored as an alternative to the conventional burners used in MWIs. b) Medical waste incineration plant.

Methodology

- Methodology for LCA

- Methodology for Organizational Design

- Summary

To make an accurate comparison of the considered studies defined in the purpose and scope, a clear functional unit should be defined for them (DeMarco and Fortier, 2021). In the Life Cycle Inventory (LCI) stage, the embodied energy involved in the material required for the product setup. Factory costs are the costs incurred for other expenses of the factory related to the product or service other than direct costs.

Like factory costs, administrative costs are not directly related to the production of the product or service. After the categorization of the skills, questionnaires were drawn up to gain insight into the working methods of the production department.

Life Cycle Assessment of Porous Radiant Burner-based applications

Need for conducting LCA on biogas-operated Porous Radiant Burner

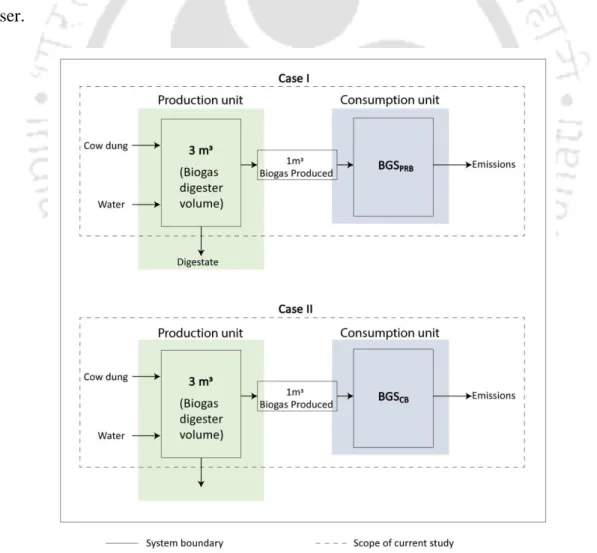

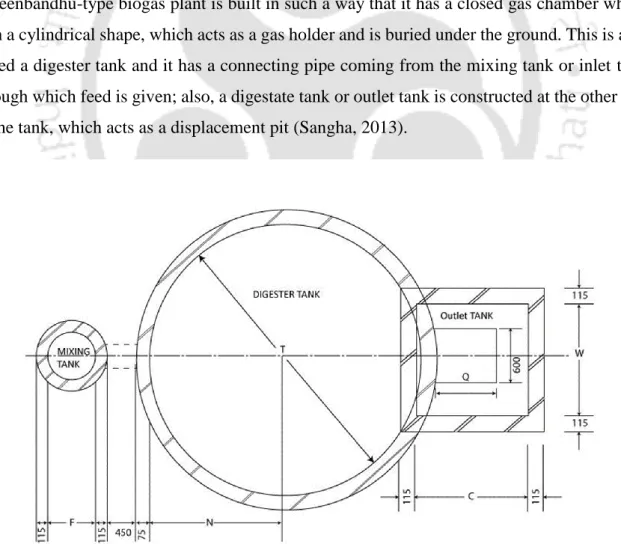

The biogas plant under consideration is part of the program of the Ministry of New and Renewable Energy (MNRE), entitled the New National Program for Biogas and Organic Fertilizer (NNBOMP). The water used for the construction of the plant also comes from the water readily available on the IITG campus. The biogas produced from this installation is used by the BGSPRB and BGSCB.

The environmental impact of the burners on the midpoint categories of the ReCiPe method is shown in table 4.5. The characterization categories of the influencing factors for the ReCiPe endpoint level leading to the damage assessment are shown in Fig.

Need for conducting LCA on LPG-operated Porous Radiant Burner

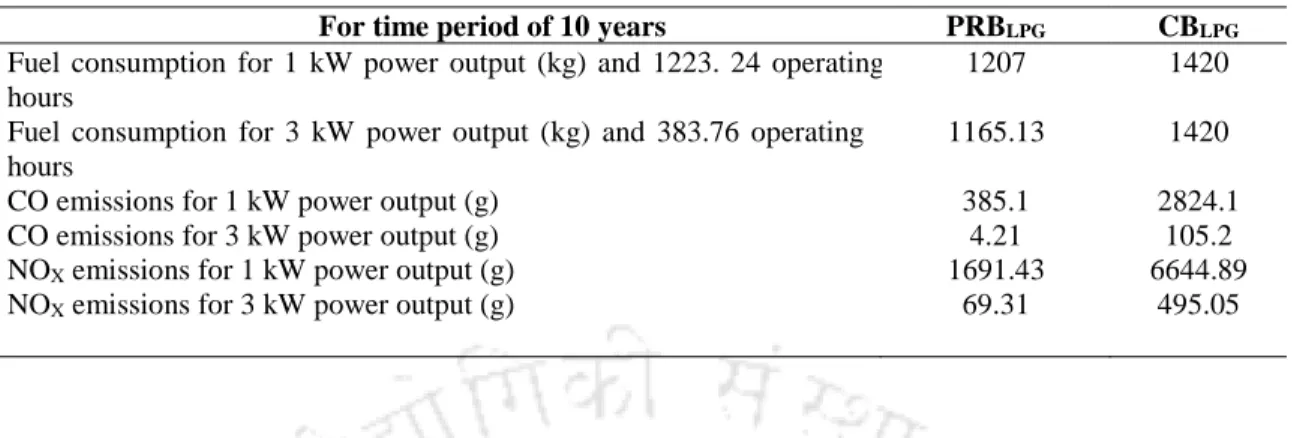

The results obtained show that the impact of PRBLPG cooker on most of the middle characterization values of environmental impact factors is smaller compared to CBLPG cooker. It is clear from the values obtained in Table 4.16 that the impact of PRBLPG cook-stove is decidedly smaller than that of CBLPG cook-stove on the human health and resource assessment categories. And also on human toxicity, where the impact of PRBLPG cooker is 153.16 kg 1,4-DB eq less than CBLPG cooker.

Values obtained from the endpoint characterization tables of 1 kW and 3 kW LPG power clearly indicate that the impact on the respective endpoint factors for PRBLPG stove is less. in all categories other than CBLPG stove. Endpoint characterization values for operation of PRBLPG and CBLPG stoves at 3 kW LPG output.

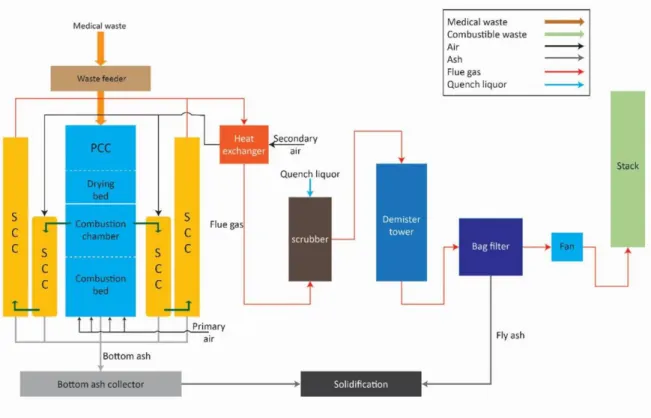

Need for conducting LCA on Small Scale Medical Waste Incinerator

In this section, LCA has been conducted to determine the environmental impact caused by SMWI, as it is a systematic analysis method to identify, evaluate and minimize the environmental impacts of SMWI. The environmental impacts caused by the construction of the SMWI and the operation of the heating device used in the secondary chamber are taken into account in the assessment in this study. The energy required for the materials used to manufacture the chamber is almost 90% of the total energy required to manufacture the SMWI.

The results indicated that the environmental impacts of SMWI-PRB are significantly lower than those of SMWI-EH in all categories. For example, the IMPACT 2002+ LCA analysis shows that SMWI-PRB is environmentally superior to SMWI-EH, as the impact of SMWI-PRB is smaller in all four damage categories compared to SMWI-EH.

Summary

There is a negative impact value of PRBLPG-based stove on ionizing radiation impact of midpoint characterization factors due to the use of refractory aluminum in the manufacture of the burner. The environmental impact of the work factor could not be taken into account for the impact assessment, as the metabolic rate of each human would be different and it cannot be generalized. A comparative assessment has been presented to find out the best option among PRBLPG and Electric heater as heating unit in the secondary chamber of SMWI.

In the present work, the LCA approach is limited to the construction of the SMWI and the operation of the auxiliary heating devices. The LCA approach is limited to the construction of the SMWI and the operation of the auxiliary heating devices.

Techno-economic Assessment of Porous Radiant Burner-based cook- stoves

- Need for conducting TEA on PRB-based cook-stoves

- Process flow of the cook-stoves

- Cost estimation and calculation of PRB-based cook-stoves

- Economic Analysis of PRB-based cook-stoves

- Benefit to the consumer

- Results of the Assessment

- Sensitivity Analyses

- Summary

In the current study, TEA from mass-produced PRB-based stoves of 1-3 kW and 5-7 kW is performed. The administrative costs for the production unit of the PRB-based cook-stove (ACPRB) are mainly for advertisements. Subsequently, the initial investment for the production of 250 PRB-based cookers is deducted from DCFPRB.

The IRR for the existing PRB-based cooking stoves (IRRPRB) is calculated using the forward method after calculating the NPVPRB. The return is estimated by calculating the payback period for the investment on the PRB-based stove (PBPPRB).

Proposed Organizational Design for Mass Production of Porous Radiant Burner-based Cook-stoves

- Need for the business model for PRB-based cook-stoves manufacturing

- Business Model for value proposition

- Organogram / Organizational Design

- Value chain analysis and Competency Mapping

- Results of Proposition

- Summary

After categorizing the skill set, questionnaires are designed to understand the work procedure of the stove manufacturing department of PRB. Technical skills of personnel for the assembly of PRB stoves and related training 16. The procurement department will purchase from the vendors the raw material required for the fabrication of PRB stoves.

Dimensions of the parts of the PRB and cooking stove About alternative materials of PRB. Ability to provide design specifications of the PRB cookstove to be assembled.

Conclusion and Future Scope

Life Cycle Assessment of PRB

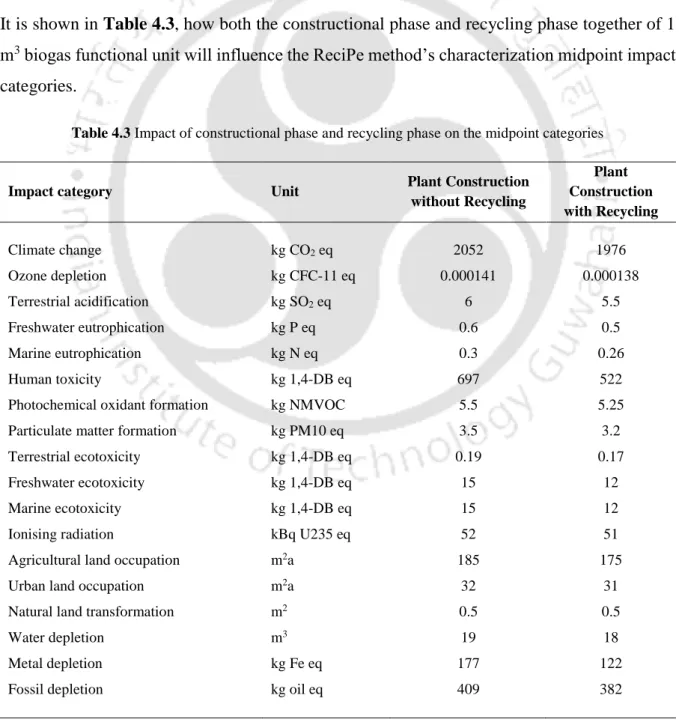

When performing an LCA for the manufacturing and recycling phase of LPG-operated Porous Radiant Burner Cookers (PRBLPG) and LPG-operated Conventional Cookers (CBLPG) for domestic use, it was found that the impact of PRBLPG-based cooktops is lower on all midpoint impact factors except the Fossil Depletion category. The endpoint assessment categories show that PRBLPG-based cookstoves reduce harm to human health and resources by 34% and 19%, respectively, compared to the harms of CBLPG-based cookstoves during their manufacture and recycling. When PRBLPG and CBLPG cooking stoves are used with a power of 1 kW LPG, PRBLPG cooking stove resulted in less harm to human health, ecosystems and resources by 15%, 15% and 15% than that of CBLPG cooking stove.

While PRBLPG and CBLPG cooking stoves are used with LPG power of 3 kW, the PRBLPG cooking stove resulted in less damage to human health, ecosystems and resources by 15% each than that of the CBLPG cooking stove. From the assessment results obtained, it can be concluded that PRBLPG cook-stove is a more sustainable product than CBLPG cook-stove.

Techno-economic Assessment of PRB-based cook-stoves After conducting the TEA, the following results are obtained

When performing the LCA of PRB and electric heating (EH) when integrated with a medical waste incinerator (MWI), the reduction of the impact on the damage category Primary energy use with PRB is almost 54% compared to electric heating. Over 82% of the total environmental impacts are due to the operation of heating devices, highlighting the importance of using an efficient heating device to mitigate the overall environmental impact caused by Small Scale Medical Waste Incinerator (SMWI).

Proposed Organizational Design for mass production of PRB-based cook-stoves The Organizational Design for the mass production of PRB-based cook-stoves has resulted in

Through the proposed business model, an organogram that is mainly mechanistic and slightly organic is proposed for any entity involved in the commercialization of PRB stoves. The focus is on the production department, and competency indicators have been identified for various hierarchical job positions in the production department. The survey will be useful in connection with recruitment, training and performance assessment and can serve as references for the respective job positions.

The same competency indicators can be further categorized into required and existing competency indicators to identify the exact gap for the futuristic human resource improvement.

Future Scope

Energy saving and technical-economic evaluation of a domestic LPG stove with self-suction and porous radiant burner. Life cycle assessment (LCA) and technical economic assessment (TEA) of a medium-sized (5-10 kW) LPG stove with a double-layer porous radiant burner. Life cycle assessment of an LPG stove with a porous radiant burner and a conventional burner - a comparative study.

Life cycle assessment of biogas fired porous radiant burner and conventional burner for cooking applications. Life cycle assessment of incinerator with porous radiant burner, conventional burner and electric heater - A comparative study.