Further, the market opportunities and the potential of AGV integration into the SC context using the S2C2 tool are discussed. Third, the distinct contribution of AGVs relates to the social impact and improvement of human safety (Bostelman et al., 2014;. To this end, it is necessary to create ergonomic workplaces where people can participate and communicate with machines, the creation of skilled jobs, and the use of AGVs in hazardous environments are also discussed in this context (Gómez et al., 2015; Shukla and Karki, 2016).

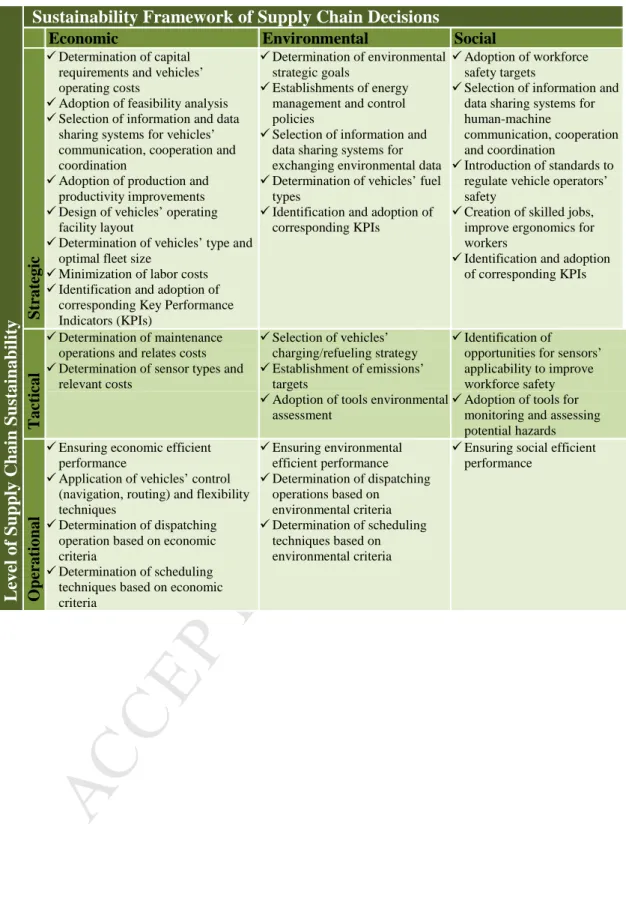

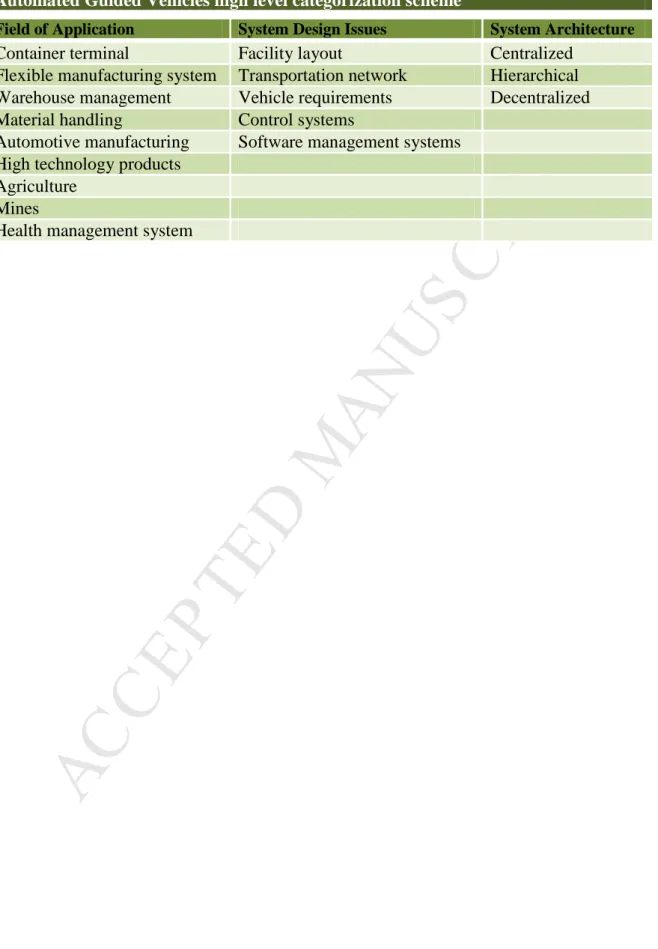

Overall, the proven ability of AGVs to ensure sustainable performance in a SC context at strategic, tactical and operational levels motivates new research in the field (Giret et al., 2015). To this end, this study maps the existing research questions onto a comprehensive framework for incorporating AGVs into SC management following the natural hierarchy of the decision-making process. The many types of AGVs and the many embedded systems can explain the diversity of the application areas (Ullrich, 2015).

The research conducted included all AGV categories and no exclusion was made as the focus was on identifying the sustainability impacts of AGVs.

ACCEPTED MANUSCRIPT

AGVs in the literature

The annual distribution of publications represents a continuously increasing trend for the sustainable context of AGV systems. Notably, in 2016 the results are encouraging as already available papers account for 70% of the total publications in 2015. Notably, the collected journals cover a wide range of scientific fields highlighting the distributed nature of the use of AGVs.

However, the distribution is quite uneven given that the Journal of Cleaner Production accounts for the vast majority of articles included in the taxonomy, indicating the journal's dominant role in the rapidly advancing field of sustainability. As a next step, all collected articles were systematically grouped by specific sector or industry, as depicted in Figure 4. Further, the sectors of agriculture, energy, health, materials handling and transport, and mining comprise an equal 5% of case works. in study.

Few studies focus on the application of AGVs in mass consumer markets, high-tech products and the automotive industry.

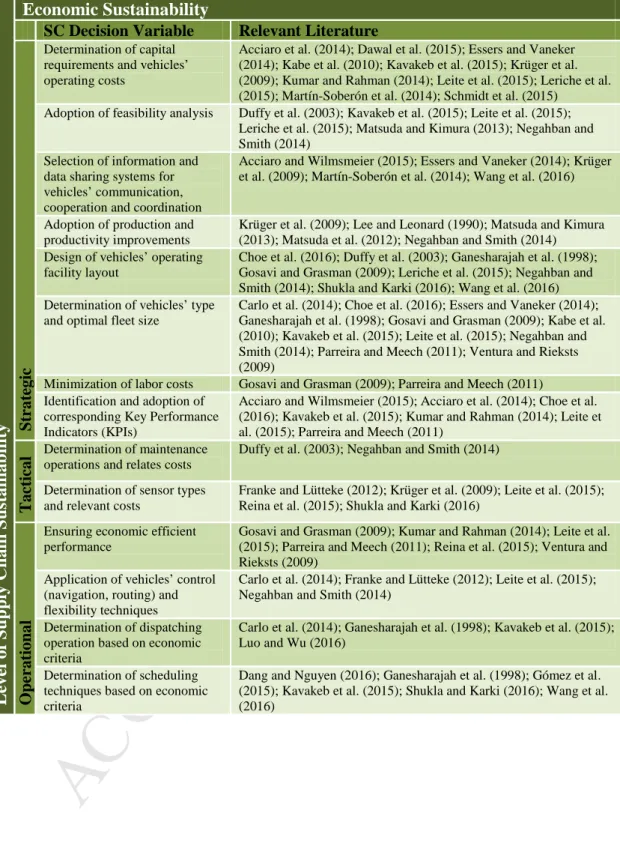

Hierarchy of decision-making process

- Economic sustainability

- Decision-making at the strategic echelon

- Decision-making at the tactical echelon

- Decision-making at the operational echelon

- Environmental sustainability

- Decision-making at the strategic echelon

- Decision-making at the tactical echelon

- Decision-making at the operational echelon

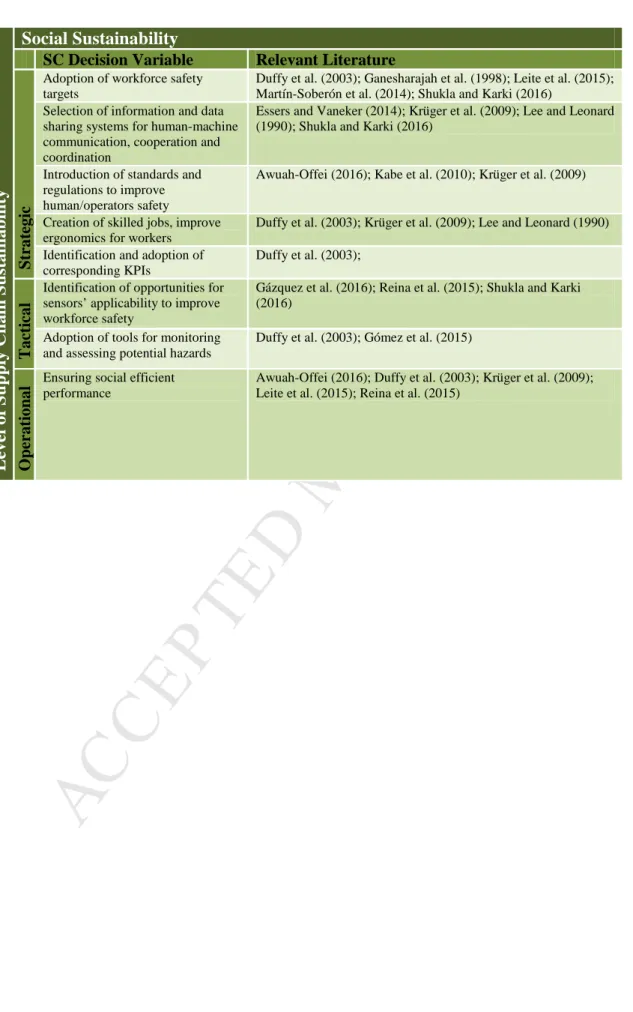

- Social sustainability

- Decision-making at the strategic echelon

- Decision-making at the tactical echelon

- Decision-making at the operational echelon

Following the triple-helix sustainability model, the authors discuss in the following three subsections all the decisions involved at the strategic, tactical and operational levels of the natural hierarchy along with a taxonomy of related research efforts. In addition, the authors describe the operational mechanism of the proposed architecture, including: (i) smart shop floor artifacts, and (ii) big data analytics. The authors conclude that simulation in manufacturing system design and operation is expected to continuously evolve to promote competitiveness in the manufacturing sector, as it is an important part of the global economy.

The authors discuss that multi-sensory perception systems increase the environmental awareness of agricultural vehicles operating in crops. Therefore, the authors identify determining the types of sensors that lead to the corresponding cost reduction as a crucial decision-making parameter. Specifically, the authors provide an integrated mixed-integer programming model for minimizing ship lay-up time through the determination of AGV and yard crane dispatching rules.

Finally, the authors illustrate the applicability of the proposed algorithm through a representative numerical experiment, concluding that the average usage percentage of an AGV is inversely proportional to the number of AGVs. To this end, the authors also propose the use of robotic vehicles as a means to simultaneously increase productivity, improve cost efficiency and effectively address HSE concerns in the offshore facilities of the oil and gas industries. The authors analyze data collected at the port of Hamburg, Germany, where a fleet of electric vehicles is used for loading and unloading container ships.

The authors examine three (3) alternative charging strategies: (i) optimization of energy procurement, (ii) trading of load-shifting potential in control markets, and (iii) use of a combination of the previous two. The authors apply an advanced energy information system in the context of a digital factory and use energy maps to provide energy consumption details on all parts of a production system, promoting visibility and visibility of energy consumption. In addition, the authors discuss the pros and cons of planning an automation system for port container terminals while emphasizing the resulting social sustainability ramifications.

The authors state that AGVs drive a gradual transformation in the nature of the human workplace through changing the work environment and occupational structure. The authors recognize the significant benefits of service robots in social culture and the inherent risks that occur in human-robot interaction. In particular, the authors examine transportation scenarios for AGVs for planning operations at the International Thermonuclear Experimental Reactor located at the Cadarache facilities in the south of France.

The authors focus on the role of operators in achieving social efficiency performance for loading and transport in the mining sector.

Results and critical discussion

- Key findings

- Sustainable supply chain cube

Furthermore, Figure 6 depicts that the majority (45%) of the reviewed publications, in relation to building AGVs into sustainable SCs, refer to strategic issues. The corresponding research scope focuses on high-level aspects of the investigated value chains, including capital expenditures (Schmidt et al., 2015), warehouse and port layout design, etc. After this, the 35% of the studies are classified to the operational level of the natural hierarchy, thus further confirming that for the specific case of AGVs, the strategic decisions are aimed at tackling operational challenges and creating additional opportunities for SC efficiency improvements (Kumar and Rahman, 2014).

In particular, the research findings confirm that although port authorities are undoubtedly the main stakeholder that has actually realized the utilization of AGVs (Choe et al., 2016; Xin et al., 2015a,b), several other sectors that share common operational characteristics, like logistics/dispatch/planning/scheduling problems, they now recognize the potential of automated systems in their SCs (Bocewicz et al., 2014). Apart from providing insightful statistics, the scope of the provided taxonomy is to document the gaps in the existing literature that could highlight opportunities to integrate AGVs into the sustainable SC management field. Indeed, it is evident that published works related to sustainability ramifications of AGVs across SC levels have increased significantly over the last five years, indicating the new importance of automations in the design of SCs within the upcoming digitization era.

However, the analysis of the studies in an integrated SC context is rather challenging as AGVs are only myopically considered at different SC levels of operations, thus preventing a comprehensive evaluation of sustainability. Therefore, only a subset of publications refer to real case studies and provide a vision on the applicability of AGVs in SCs. To this effect, the authors of the present study identify the key regions that offer research opportunities to academics and practitioners in the adoption of AGV systems to a SC ecosystem, by considering the proposed hierarchical decision-making framework.

The functional dimension was further discussed in the SC matrix context (Meyr et al., 2002) and included purchasing, production, distribution and sales levels to integrate the flow of materials through the SC. In addition, the building blocks of the SC cube were later proposed as the FAMASS (FORAC Architecture for Modeling Agent-based Simulation for Supply chain planning) methodological framework for analyzing requirements (Santa-Eulalia et al., 2012) and identifying the possible schedule. and control functions of a typical SC. Regarding the structure of the cube, the three axes represent: (i) the fundamental SC level of operations, i.e.

Each building block of the cube represents: (i) a well-reported region in the existing literature, (ii) a gap identified as a mature region for the deployment of AGV systems, or (iii) a gap identified as an immature region. Finally, ripe regions for AGV integration can be found at the strategic and tactical levels and involve all SC stakeholders at all operational levels.

Conclusions

- Limitations

- Discussion beyond state-of-the-art

Existing efforts mainly refer to the economic consequences of AGVs in SCs and sometimes to environmental aspects. Social sustainability aspects resulting from the adoption of AGVs in SC management are rarely discussed. The governmental sustainability level and environmental regulations should also be included in future research (Schmidt et al., 2015) where researchers should focus on the creation of widely accepted standards (cross-section of suppliers, customers, academia and government) and to assess tax incentives for the adoption of AGVs in the markets that reinforce the commitment to sustainable manufacturing and corporate social responsibility.

Further research will also consider the use of fully autonomous, intelligent fleets that act as multi-agent systems in container terminals (Kavakeb et al., 2015; Using Battery Electric AGVs in Container Terminals - Assessing Potential and Optimizing Economic Viability. Energy-conscious control for automated container terminals using integrated flow shop planning and optimal control.

Selection of information and data exchange systems for environmental data exchange Determination of vehicle fuel. Ensuring efficient environmental performance Determining dispatch. operations based on environmental criteria Scheduling determination. techniques based on environmental criteria.

Tier 1Tier 2

Continue Database Selection (Scopus, Science Direct, Association for Computing Machinery Digital Library, Emerald Insight) Review list for abstract categorization. Annals of Operations Research Applied Soft Computing Autonomous and Intelligent Systems Biosystems Engineering Computer Integrated Manufacturing Systems Computers in Industry Control Engineering Practice IFAC-PapersOnLine Independent Journal of Management & Production Journal of Manufacturing Systems Procedia Social and Behavioral Sciences Procedia Technology Industrial Engineering Research Conference The International Journal of Life Cycle Assessment Robotics and Computer Integrated Production Safety Science CIRP Annals - Manufacturing Technology Energy Policy European Journal of Operational Research International Journal of Distributed Sensor Networks Research in Transportation Business & Management Robotics and Autonomous Systems Transportation Research Part C Transportation Research Part D Procedia CIRP Journal for Cleaner Manufacturing.

Economic 49%

Environmental 30%

Social 21%

Strategic 45%

Tactical 20%

Operational 35%

AGV referenced region AGV mature region AGV non-mature region

Involved SC stakeholders