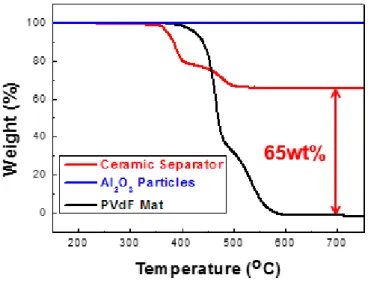

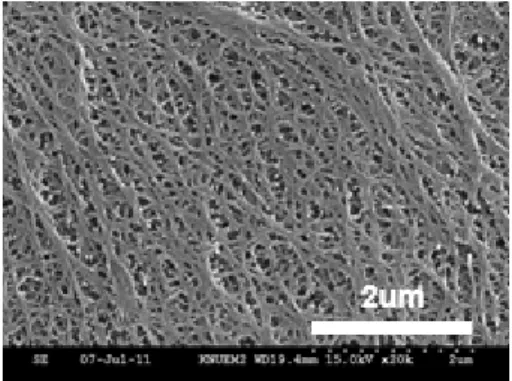

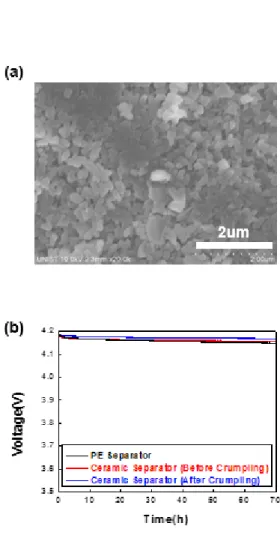

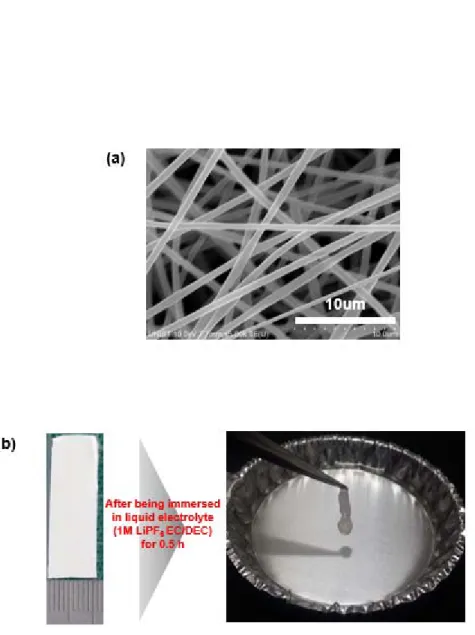

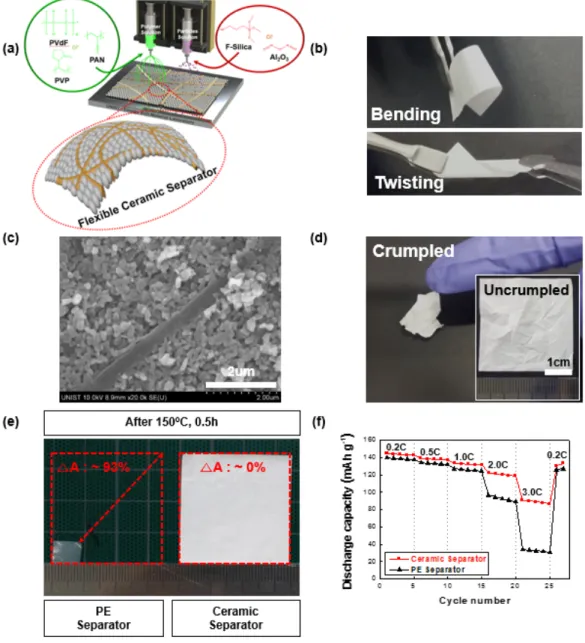

As a result, the 2F ceramic separator enabled unprecedented improvements in high-performance lithium-ion batteries. A TGA profile used to estimate the composition ratio of a model ceramic separator (based on Al2O3/PVdF). Fabrication and characterization of a 2F ceramic separator: (a) a SEM image of F-silica particles (insets show the chemical structure of F-silica particles and the physical appearance of the F-silica particle solution, respectively); (b) an SEM image of an electrospun PVP/PAN nanofiber mat (an inset shows the chemical structure of PVP and PAN); (c) an SEM image (an inset = cross-section); (d) photographs and an SEM image showing the structural tolerance after being subjected to an extreme deformation test (here: wrinkling).

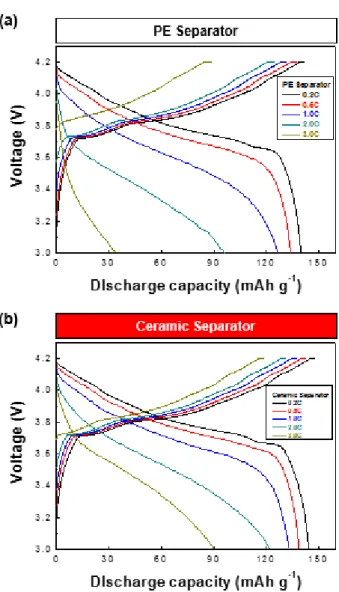

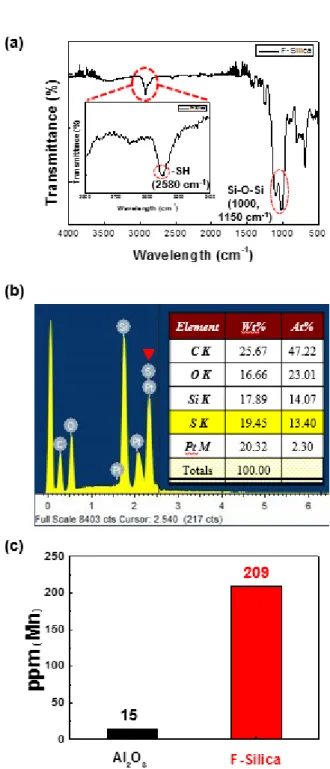

Comparison between 2F ceramic separator and PE separator; (e) amount of Mn2+ ions captured by the separators (estimated from ICP-MS analysis); f) cycling performance at high temperatures (60 oC). Comparison in cycle performance between 2F ceramic separator and PE separator: (a) charge/discharge profiles as a function of cycle number; (b) Change in AC impedance spectra before/after 100 cycles. a)-(c) Structural analysis of LMO cathode and Li metal anode after 100 cycles at 60 oC: (a) metallic Mn deposited on lithium metal anode (from ICP-MS analysis); (b) an SEM image of an LMO cathode surface assembled with a 2F ceramic separator, where an inset shows the LMO cathode surface assembled with a PE separator; (c) XPS F 1s spectra of LMO surface. Structural analysis of a 2F ceramic separator after 100 cycles at 60 oC: (a) EDS spectra (focused on the Mn element); (b) XPS F 1s spectra.

INTRODUCTION

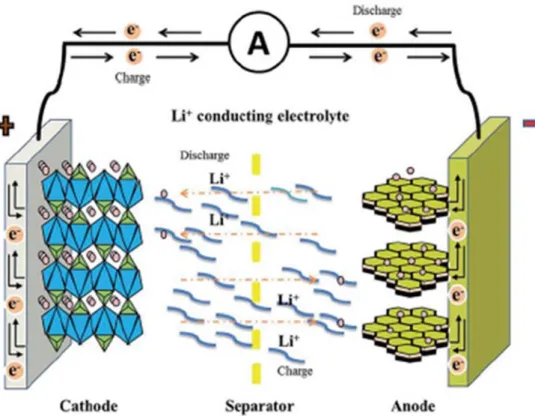

Operating principle of lithium-ion batteries

In a lithium-ion battery, the separator is one of the essential components, it is able to transport ionic phenomena such as porous channels filled with electrolyte. In this regard, the characteristics of the separator should concern a wide range of use in lithium-ion batteries. Lithium-ion battery separators are divided into two classes as polyolefin separators and non-woven mat separators.

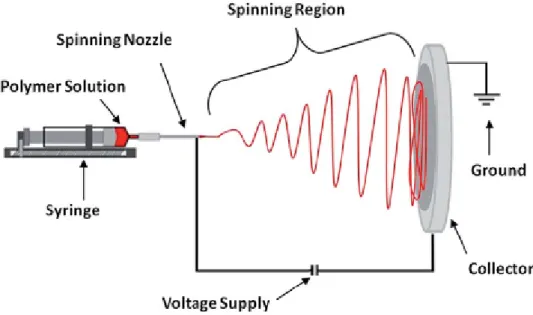

There are the materials for the preparation of non-woven carpets, such as polyethylene (PE), polypropylene (PP), polyamide (PA), poly(tetrafluoroethylene) (PTFE), polyvinylidene fluoride (PVdF), and polyvinyl chloride (PVC) .[ 1, 2] However, it is not good for them to use the lithium-ion batteries because of the physical characteristics related to unsuitable pores, large fiber diameter and difficulty in thinning. To improve the disadvantages, the electrospinning method (Figure 2) was used to produce highly porous structure non-woven mat separators suitable for lithium-ion batteries. The electrospinning method has a reputation for being a simple and efficient technique for producing non-woven carpet separators.

General requirements for battery separators

FLEXIBLE/FUNCTIONAL POROUS CERAMIC

Experimental

- Synthesis of thiol-functionalized silica (F-silica) particles and PVP/PAN blends

- Structural design and fabrication of 2F ceramic separator

- Structural/physicochemical characterization of 2F ceramic separator

- Electrochemical properties of 2F ceramic separator and its application to

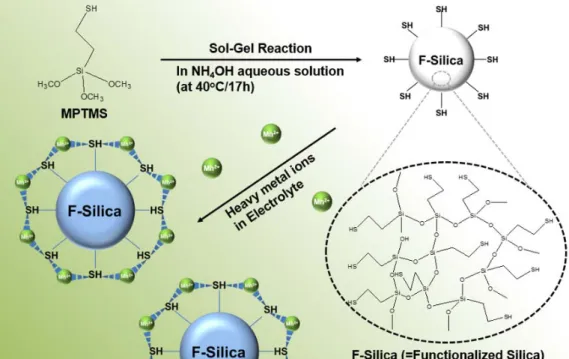

As an essential component of 2F ceramic spacers, thiol (-SH) functionalized silica particles (F-silica) were synthesized by the sol-gel process using 3-mercaptopropyl trimethoxysilane (MPTMS) as a precursor. To fabricate the 2F ceramic spacer, we utilized the simultaneous electrospraying (for densely packed ceramic particles)/electrospinning (for nanofiber scaffolds) technique followed by roll pressing. For a ceramic separator model comprising densely packed Al2O3 particles and PVdF nanofiber skeletons, colloidal Al2O3 solution (5 wt.% Al2O3 in acetone/n-butanol (= 7/3 v/v)) and PVdF solution (25 wt. ). % PVdF in dimethylacetamide/acetone (= 7/3 v/v)) were respectively prepared and then dispersed in simultaneous electroplating/electroplating through two different nozzles at room temperature.

The detailed experimental conditions were 10.0 kV with a feed rate of 5 μL min−1 (for electrospinning) and 17.5 kV with a feed rate of 70 μL min−1 (for electrospinning). After spin-molding at room temperature, a self-supporting and flexible ceramic spacer (thickness ~ 30 m) was produced. The 2F ceramic separator (thickness ~30 m), which consisted of F-silica particles and PVP/PAN blend skeleton, was fabricated by simultaneous electrospraying (14.0 kV at a feed rate of 50 μL min−1)/electrospinning ( 8.0 kV with a feed rate of 3.5 μL min−1) process used for the ceramic separator model.

The surface and cross-sectional porous morphology of the 2F ceramic separator were analyzed with FE-SEM (S-4800, Hitachi) and EDS (JSM 6400, JEOL). The thermal shrinkage of the separator was investigated by measuring their area-based dimensional change after exposure to 150 oC/0.5. The composition ratio of the separator was determined from the TGA measurement (SDT Q600, TA Instruments) at a heating rate of 10 oC min-1 under air atmosphere.

The Mn2+ chelating ability of the separator and its components was quantitatively estimated by measuring the amount of the trapped Mn2+ ions using ICP-MS analysis (ELAN DRC-II, Perkin Elmer), in which the samples were immersed in the manganese perchlorate solution[ 22 ] (10 mM Mn(ClO4)2-containing 1.3 M LiPF6 in EC/PC = 1/1 v/v) for 2 h at room temperature. The electrochemical stability window of the 2F ceramic separator was investigated using a linear sweep voltammetry experiment performed on a stainless steel working electrode and a lithium metal counter/reference electrode at a scan rate of 1.0 mV s-1. The OCV drop of the fully charged cell (at a current density of 0.2 C) was monitored as a function of time.

The ionic conductivity of the separator was investigated by an AC impedance analysis (VSP classic, Bio-Logic) over a frequency range of Hz.

Results and discussion

- A preliminary step for 2F ceramic separator: Fabrication of a model ceramic

- A main step for 2F ceramic separator: Fabrication and characterization of

- The functional influence of 2F ceramic separator: Chelating ability In-depth

Such structural tolerance of the ceramic separator was further verified by measuring open circuit voltage (OCV) drop of cells as a function of elapsed time (Figure 6b). Based on the understanding of the model ceramic separator mentioned above, we developed the chemically active 2F ceramic separator. The details about the fabrication procedure of the 2F ceramic separator were described in the experimental section.

The composition ratio of the 2F ceramic spacer was observed to be F-silica/(PVP/PAN) = 54/46 (w/w), by TGA measurement (Figure 13). The cell incorporating the 2F ceramic separator showed stable charge/discharge profiles at high temperature (60 oC) up to 100 cycles (Figure 15a). The capacity retention after 100 cycles was approximately 94 % for the 2F ceramic separator and 0 % for the PE separator (Figure 12f).

Comparison in cycle performance between 2F ceramic separator and PE separator: (a) charge/discharge profiles as a function of cycle number; (b) change in AC impedance spectra before/after 100 cycles. The Functional Influence of 2F Ceramic Separator: Chelation Ability In-Depth Analysis of 2F Ceramic Separator Ceramic Separator. The beneficial effects of the 2F ceramic separator on cycling performance were elucidated in great detail, with particular focus on its Mn2+ chelating ability.

Moreover, the relatively clean surface was observed at the LMO cathode assembled with the 2F ceramic separator (Figure 16b), while the LMO cathode combined with the PE separator was covered with a significant amount of byproducts (an inset of Figure 16b). In addition to the above results of Li metal anode and LMO cathode, the surface change of the 2F ceramic separator with the high temperature cycling was analyzed. A significant amount of byproducts was formed on the surface of the 2F ceramic separator (Figure 16d), compared to that of the PE separator with a relatively clean surface (Figure 17).

Such unusual chelating ability of the 2F ceramic separator was further elucidated by monitoring the change in the FT-IR peaks and XPS spectra of the 2F ceramic separator. The beneficial effect of the 2F ceramic separator on the high temperature cycling performance is conceptually illustrated in Figure 19. In comparison, a significant amount of Mn2+ ions are captured by the 2F ceramic separator (particularly thiol groups of F-silica particles and pyrrolidone groups of PVP) in the form of Mn(II) chelate complexes, ultimately suppressing the detrimental influence caused by Mn2+ ions on the electrochemical activity of the electrodes.

Conclusion

강원도 토박이로 생활하다가 울산광역시로 이사와 연구를 시작한 것이 엊그제 같은데 벌써 졸업을 앞두고 있다는 생각에 기분이 상쾌합니다. 아직 부족하고 부족한 점이 많지만 교수님께서 가르쳐주시는 방법을 배우며, 제가 맡은 분야에서 잘할 수 있는 사람이 되도록 늘 발전하고 노력하겠습니다. 제가 연구실을 떠날 때까지, 그리고 퇴원한 후에도 저를 도와주시고 돌봐주셔서 정말 감사드립니다.

대학원 선배로서 힘들고 지칠 때 해주신 말씀이 저에게 큰 도움이 되었던 것 같아요. 근호는 아직 충분히 잘하고 있으니 앞으로 더 좋은 결과를 만들어서 최교수가 되었으면 좋겠다. 준묵은 취업에 대해 아무것도 몰랐지만 그 덕분에 도움이 됐다. 많은 정보를 배울 수 있었고, 형 덕분에 연구실 생활이나 삶의 여러 측면에 대해 많은 것을 배울 수 있었던 것 같아요.

당신이 일자리를 찾기 위해 많은 스트레스를 받고 있다는 것을 알고 있었지만, 모든 일이 잘 되어 정말 다행입니다. 가시면 잘 되실 거라 믿고, 가시면 좋은 결과 많이 얻으셨으면 좋겠습니다. 함께 지내면서 그의 연구 방법, 작업 방법, 가공 방법을 가장 많이 보고 배운 것 같아요. 덕분에 석사과정을 좋은 성적으로 마칠 수 있었던 것 같아 정말 감사드립니다.

많은 배려와 도움을 주셔서 감사합니다. 계속 같이 가자고 해주셔서 감사하고, 끝까지 함께하지 못해 너무 아쉽다. 성주님도 좋은 결과 많이 얻으셨으면 좋겠습니다.

박사님 덕분입니다. 이 박사와 유씨는 석사님 연구에 많은 도움을 받았고, 사고력도 키울 수 있었던 것 같아요.