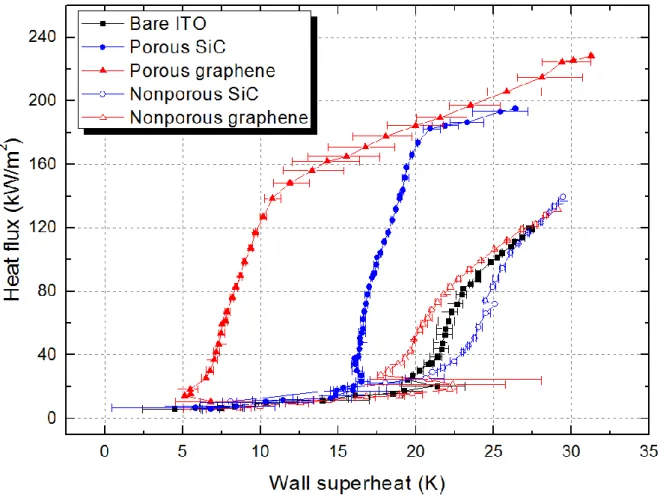

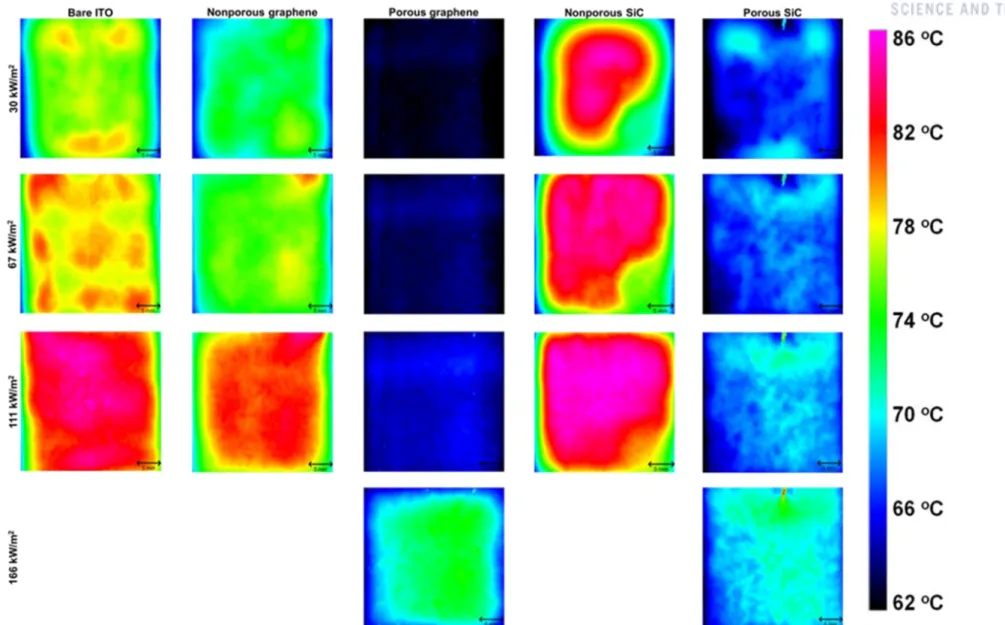

In the current CHF enhancement study, the deposition of nanoparticles (SiC and graphene) on a plain heating surface was used for the porous heating surfaces. The current approach assumes the change of the critical vapor velocity due to the change of heating surfaces.

Research Background and Motivation

General Literature Reviews

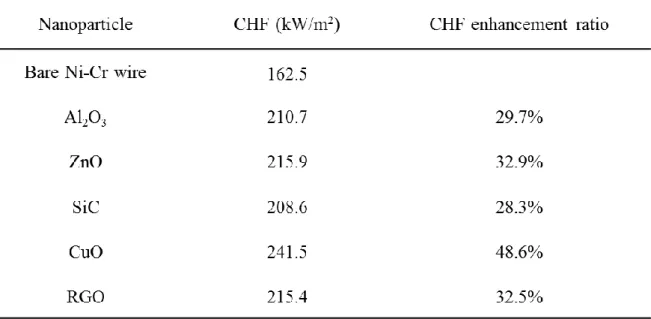

Changing the material and dispersion conditions of the nanoparticles would bring about a significant increase in CHF. Different types of nanofluids (Al2O3, ZrO2 and SiO2 Nanoparticles.) were examined in a boiling pool and the results showed that the surface wettability due to the deposition of nanoparticles on the heating surfaces was changed5.

Objectives and scope

The measured RT instability wavelength as a function of the surface characteristic was validated and the surface roughness parameter was also examined for validation of the CHF model. By comparing the prediction model with the experimental results, the modified CHF model was validated.

POOL BOILING CHF ENHANCEMENT EXPERIMENTS

Experimental Setup

- Experimental apparatus

- Fabrication procedure of various heating surfaces

- Test procedure

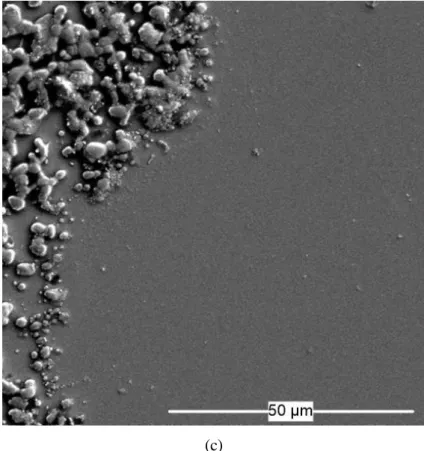

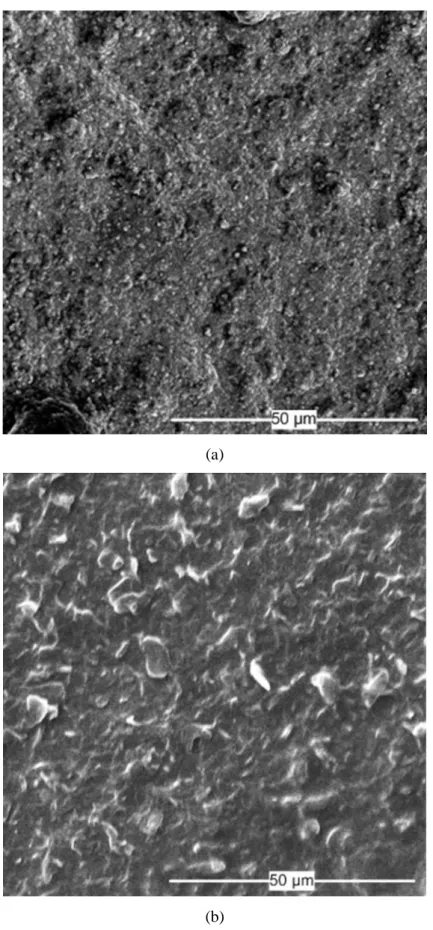

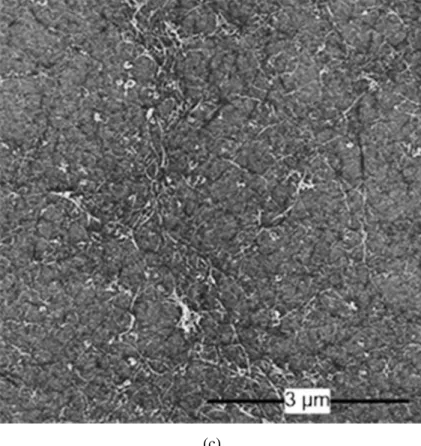

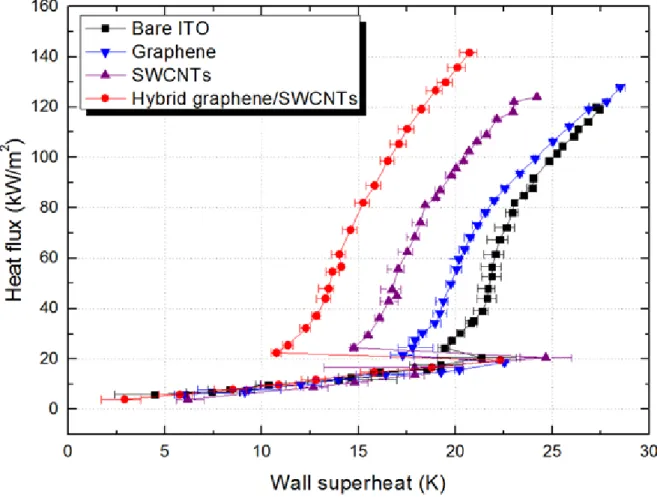

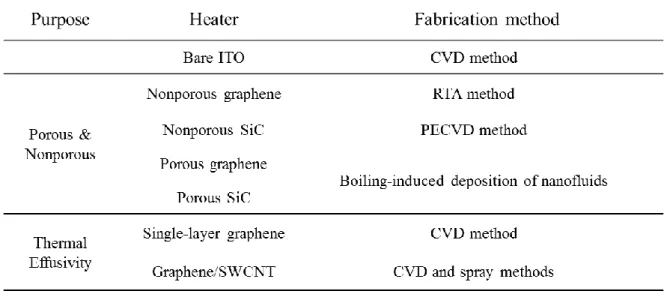

The amount of SWCNTs of 4 μl was used based on the optimized sheet resistance of the hybrid films. As shown in the SEM image of the single-layer graphene, there were wrinkles or interrupted areas on the graphene surface.

Results and Discussion

- Experimental results

- Surface parameter study

- Comparison between CHF results and CHF prediction models

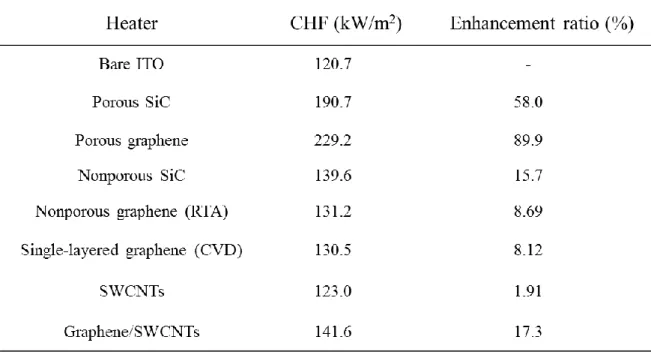

In addition, the high-temperature properties of the heating surface can improve the boiling performance based on the graphene/SWCNT hybrid surface. Most studies of improvement in heart failure claimed that the change in surface wettability was the main parameter of CHF performance. Previous studies have shown that capillarity trend can support the improvement of CHF.

The surface roughness parameter is also considered as one of the most important surface parameters in the CHF performance. Compared to the bare ITO and non-porous heating surfaces, higher values of Ra and Rq were observed in the porous heating surfaces. Porosity and permeability parameters are related to the fluid's ability to transport into the porous heating surfaces.

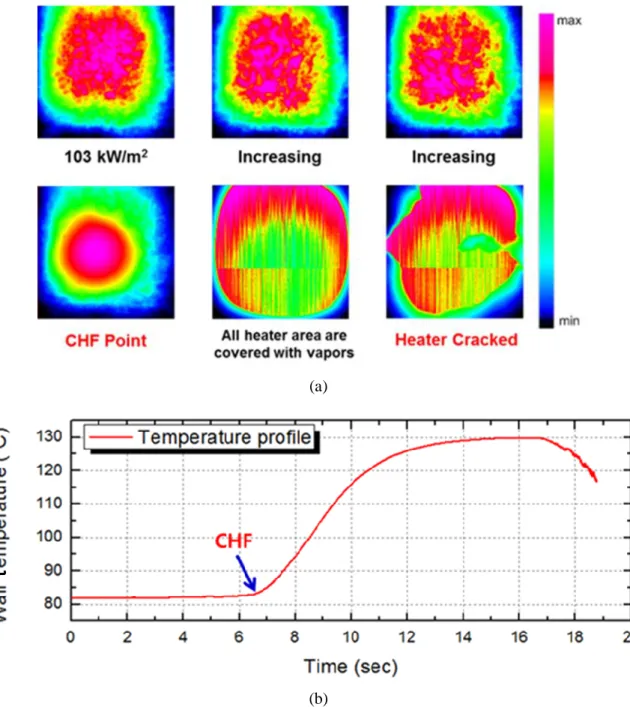

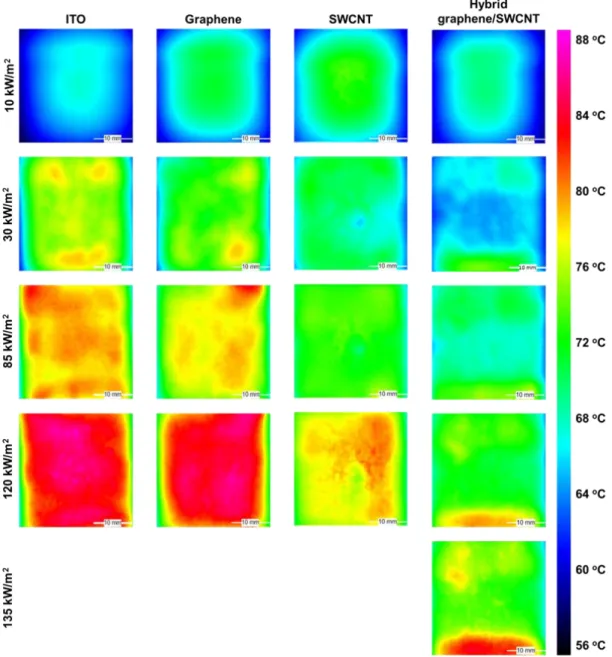

This means that the permeability of the porous graphene would be higher than the porous SiC heating surfaces. One of the material parameters used in the studies on CHF improvement mechanisms is the thermal effusion. 2-19 shows series of IR images in the base fluid and the nanofluid in the CHF region.

Instead of using surface roughness (actual surface/projected surface area), the average roughness value (Ra) of the heating surfaces obtained by the measuring device. To deal with the problem, the new approach of the CHF enhancement mechanism model based on the hydrodynamic instability theory is proposed in the present study.

Conclusions

However, it was difficult to quantify the growth ratio of CHF by comparing existing CHF models. Instead of existing CHF models, a modified hydrodynamic approach was proposed for CHF prediction. The detailed description for supporting the modified hydrodynamic approach will be described in Chapters 3 and 4.

CHF EXPERIMENTS BASED ON HYDRODYNAMIC INSTABILITY THEORY

Experimental Setup

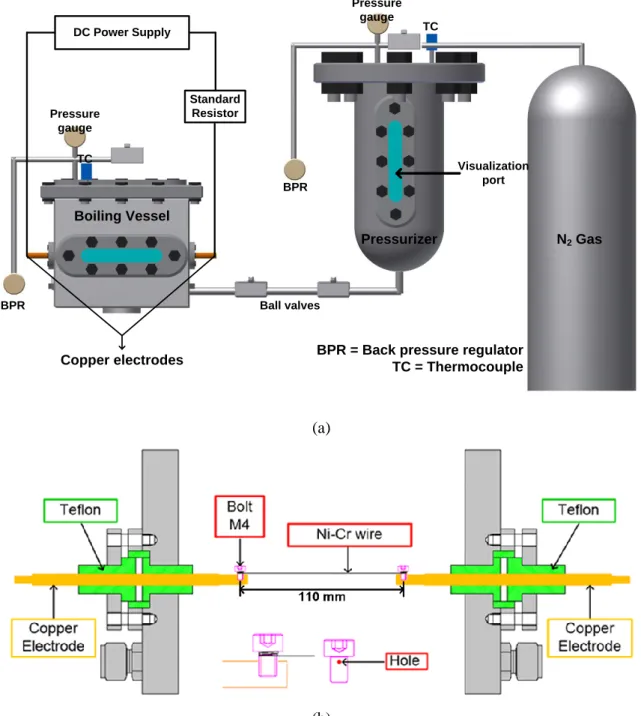

- Pressurized wire pool boiling facility

- Patterned plate heating surfaces

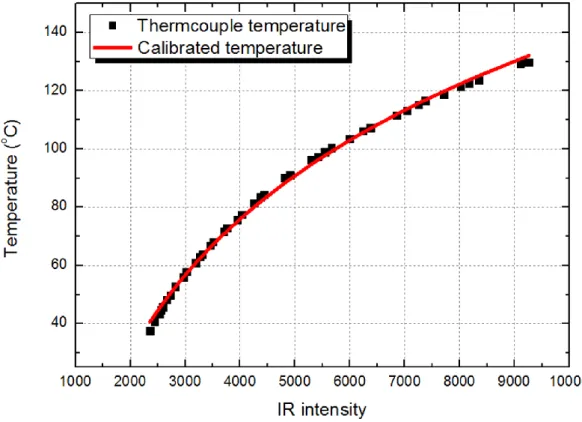

This means that it was easy to maintain the saturation state of the R-123 even at high pressure, compared to water. When there was a significant margin for the CHF, the heat flow was controlled at ~20 (kW/m2)/min. Calibration of the HSV was obtained simultaneously with a calibration sheet located on the visualization port.

The average distance of paired columns was taken as the RT instability wavelength, and multiple images were considered to obtain the average RT instability wavelength. Observations of RT instability wavelength for different heating surface conditions were used to investigate the relationship of RT instability wavelength with CHF outcomes. A 100 nm thick oxidation layer was applied to the Si substrate to passivate the test sample.

Electrodes with an area of 5 mm × 20 mm were deposited on the end of the Pt layer through an E-beam evaporator with a Cr adhesion layer. A preliminary heating surface test was conducted to demonstrate the effect of patterned heating surfaces in areas of low heat flux. Higher temperature fields existed on the patterned heating surfaces compared to the plain heating surface.

Results and Discussion

This inferred that the reliability of the mean RT instability wavelength increased as the RT instability wavelength decreased. This means that actual measurement of the RT instability wavelength is a valid approach for the CHF prediction. This inferred that the RT instability wavelength can be correlated with the critical vapor velocity; the assumption of the hydrodynamic instability theory is proved.

The RT instability wavelength measurements were performed to find the correlation with the CHF results. 3-14 shows the measurement of the RT instability wavelength at the CHF region for all heating surfaces. The measurement results indicated that the change of the RT instability wavelength supported the CHF performance.

This means that changing the wavelength of the RT instability affects the critical vapor velocity. In this study, we assumed that the KH instability wavelength is related to the RT instability wavelength. The modified hydrodynamic instability model and the experimental results based on the measured RT instability wavelengths.

Conclusions

MODIFIED HYDRODYNAMIC INSTABILITY CHF PREDICTION MODEL

Reviews of Hydrodynamic Instability Theory CHF Models

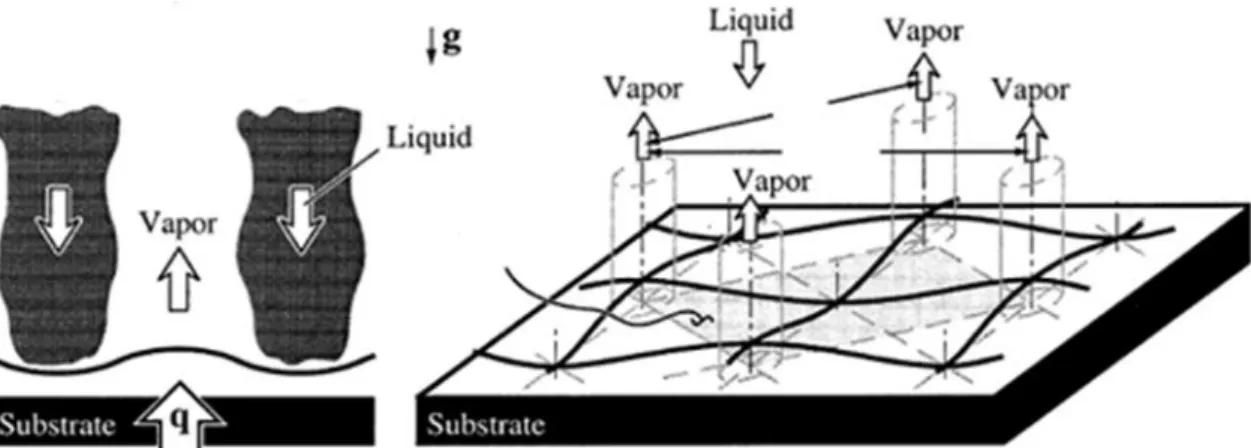

The diameter of the vapor column is assumed to be half of the RT instability wavelength, so the area ratio of the vapor columns on the heating surface is . 4-4 shows, the CHF phenomenon can be determined by taking the critical vapor velocity through the vapor column diameter as half the RT instability wavelength. In the hydrodynamic instability theory proposed by Zuber, the KH instability was considered the RT instability.

Instead of measuring the KH instability wavelength, Zuber used the RT instability wavelength instead of the KH instability wavelength. For the infinite and finite heating surfaces, the most dangerous wavelength was considered to be the RT instability wavelength. The KH instability wavelength for the infinite and finite heating surfaces was adopted as the most dangerous RT instability and the perimeter of the heating surfaces, respectively.

The modulation wavelength changes the RT instability wavelength, so the CHF can be changed by the modulation wavelength. The bubble force balance model presented by Kandlikar50 is similar to the hydrodynamic instability theory because the RT instability wavelength was used in positioning the bubbles on the heating surface. The critical vapor velocity was determined by the instability wavelength RT due to the ratio of the instability wavelength KH.

CHF Modeling with Change of RT Instability Wavelength

In the present work, the measured RT instability wavelengths and surface roughness factors were taken into account in the modified CHF hydrodynamic model. The obtained and additional CHF results that took into account the wavelength effect of the RT instability were used to validate the modified CHF hydrodynamic model. The observation of RT instability wavelengths and CHF results were incorporated into the modified CHF hydrodynamic model for validation work.

Therefore, the prediction of the CHF gain with the measured RT instability wavelength is valid. The CHF trends according to the surface roughness and the RT instability wavelength factors were obtained. The results indicated that the RT instability wavelength factor as the parameter of the modified CHF model was validated.

The results emphasized that the RT instability wavelength should take into account the surface characteristics to support the CHF variations. The modified hydrodynamic instability CHF model was developed based on the change of the RT instability wavelength with the surface characteristics. The results indicated that the surface roughness factor and the RT instability wavelength factor as parameters of the modified CHF model were valid in the present work.

Comparison of Modified Hydrodynamic Instability Model and Experimental Data

Conclusions

The modified hydrodynamic instability CHF prediction model was proposed by considering the effects of surface characteristics on the pressure balance of the wavy interface. Reviews of CHF models based on hydrodynamic instability theory were discussed and the originality of the modified CHF model was suggested. The derivation of the CHF model taking into account the surface curvature functions was performed and the validation of the procedure with existing CHF results that took into account surface roughness and RT instability wavelength factors.

For the surface roughness factor, it was defined by the ratio of the projected area divided by the actual surface area. Moreover, the RT instability wavelength factor was considered as the measured RT instability wavelengths under different heating conditions. Comparing the predicted CHF values with the experimental results, the modified CHF model with surface roughness factor is valid in the pool boiling experiments.

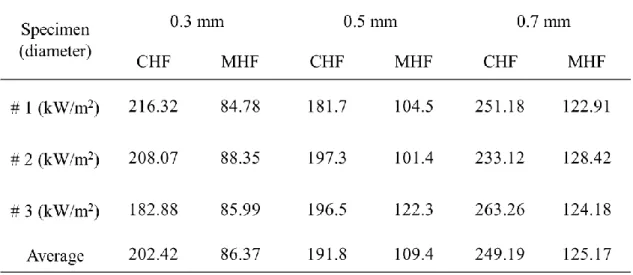

The RT instability results for the nanoparticle-coated surfaces were performed by the condensation method using water and the FC-72 coolant. For the pressurized wire pool boiling, the RT instability wavelengths were confirmed as the CHF variation parameter and the different heater diameters indicated that the CHF prediction model based on hydrodynamic instability theory should consider the heater surface properties. Various conditions of RT instability factor were used to validate the modified CHF model: the maximum of the RT instability factor and the CHF improvement results were 7.38 and 2.36 respectively.

CONCLUSIONS AND RECOMMENDATIONS

- Pool boiling CHF enhancement experiments

- CHF experiments based on hydrodynamic instability theory

- Modified hydrodynamic instability CHF prediction model

- Recommendations

Pool boils CHF of reduced graphene oxide, graphene, and SiC-coated surfaces under highly wettable FC-72. Effect of nanoparticle deposition on capillary drainage affecting the critical heat flux in nanofluids. Effect of fluid expansion due to nano/microstructures on the critical heat flux during pool boiling.

Effects of the thickness of boiling-induced nanoparticle deposition on the saturation of critical heat flux enhancement. An experimental study of the size effect in pool boiling critical heat flux on square surfaces. Simultaneous observation of dynamics and thermal evolution of irreversible dry spot at critical heat flux in pool boiling.

Effect of surface roughness on pool-boiling heat transfer at a heated surface of moderate wettability. A modified hydrodynamic model for pool boiling CHF considering the effects of heater size and nucleation site density. Enhanced pool-boiling heat transfer and critical heat flux on femtosecond laser processed stainless steel surfaces.