COURSE PORTFOLIO

(an e-book for KC32603 Process Simulation and Integration)

BLENDED-COOPERATIVE LEARNING ENVIRONMENT FOR IMMERSIVE LEARNING EXPERIENCES IN PROCESS SIMULATION COURSE

Mohd Kamaruddin Abd Hamid*, Sivakumar Kumaresan, Mariani Rajin

Chemical Engineering Programme, Faculty of Engineering, Universiti Malaysia Sabah, Jalan UMS, 88400 Kota Kinabalu, Sabah, Malaysia

3rd Year of Universiti Malaysia Sabah (UMS) Chemical Engineering Students Semester 2 Session 2021-2022

QR code for Dr. Mohd Kamaruddin’s website

TABLE OF CONTENT

HIGHLIGHT 1

1.0 INTRODUCTION 2

1.1 KC32603 Course Information 3

2.0 BLENDED-COOPERATIVE LEARNING ENVIRONMENT USING TPACK FRAMEWORK

7 2.1 Accessing Micro-Credential Process Simulation 10

2.2 Accessing UMS SmartV3 Moodle Platform 10

2.3 Blended-Cooperative Learning Class implementation (Face-to-Face)

11 2.4 Complex Engineering Projects Implementation

(Industrial-Based Projects)

13

2.5 Aspen HYSYS Application (Team Hands-On) 18

3.0 TRANSFERABLE AND SCALABLE FRAMEWORK 20

4.0 STUDENTS INVOLVEMENT 23

4.1 Students’ Learning Reflection Journal 25

5.0 IMPACTS ON STUDENTS’ LEARNING 31

5.1 Students’ Learning Skills Improvement 31

5.2 Students’ Learning Behaviour Improvement 35

6.0 CONCLUSION 38

REFERENCES 38

BLENDED-COOPERATIVE LEARNING ENVIRONMENT FOR IMMERSIVE LEARNING EXPERIENCES IN PROCESS SIMULATION COURSE

Mohd Kamaruddin Abd Hamid*, Sivakumar Kumaresan, Mariani Rajin

Chemical Engineering Programme, Faculty of Engineering, Universiti Malaysia Sabah, Jalan UMS, 88400 Kota Kinabalu, Sabah, Malaysia

*e-mail: [email protected]

HIGHLIGHT

The purpose of this innovation is to increase student engagement experiences in a blended- cooperative learning environment (BCLE) for chemical engineering process simulation course.

Getting students engagement in a hands-on engineering class involves not only the exact and suitable pedagogical knowledge but also technological knowledge on top of the content knowledge. In this learning environment, students are encouraged to participate in routine chemical engineering process simulation activities, helps them for constructing their process simulation knowledge based on cooperative learning (CL) activities with the help of several Learning Management System (LMS) and process simulation software. The application of Moodle for asynchronous CL activities delivery as well as OpenLearning for a micro-credential implementation of process simulation introductory course using Aspen HYSYS, combined together with the face-to-face CL classes has enriched student learning experiences. This can be observed by the higher value of active index in Moodle as well as higher CLO achievement. In addition, students learning behaviour also shows positive changes from independently individual practice into interdependently cooperative practices that confidently encouraged team-working principle. Therefore, it can be concluded that students’ meaningful learning experiences by exposing them to BCLE able to improve not only students’ achievement in CLO but also their learning experiences.

Keywords: Blended Learning, Cooperative Learning, Process Simulation, Students Engagement

1.0 INTRODUCTION

Blended-Cooperative Learning Environment (BCLE) is the environment which included asynchronous online cooperative learning (CL) activities and face-to-face CL classes. Avgerinou (2008) defines BCLE as “learning environment in which students try to fulfil the assigned tasks in teams with the support of computer-aided or web-based applications.”

El-Deghaidy & Nouby (2008), in their study, mention three types of interaction in BCLE: Social, Content and Teacher. The first interaction type is the teacher that allows face-to-face interaction and active learning for a social environment. In addition, the teacher can plan and manage the learning parts and chooses appropriate communication tools before establishing communication with students. The second interaction type is content. Content is related to cognitive interaction regarding the skills and concepts presented in the course module. And the last type; social interaction refers to students’ ability to perceive themselves as a community supporting positive interdependence. Such an interaction in the learning process occurs when students achieve cooperative tasks and share the sources.

The course learning outcome (CLO) that is related to this innovation is CLO4: Apply the applicable process simulation concept of Aspen HYSYS process simulator in designing individual chemical engineering unit operations as well as complete and complex chemical engineering process design problems. This CLO is mapped with the PLO5: Modern Tool Usage – Create, select and apply appropriate techniques, resources, and modern engineering and IT tools, including prediction and modelling, to complex engineering activities, with an understanding of the limitations, refer to KC32603 Course Information.

Increasing meaningful student learning experiences especially for engineering courses is one of the learning issue that needs to be solved in this innovation. Engaging students is one of the challenging tasks especially for engineering process simulation course which requires students to do hands-on learning activities. Getting students engagement in a hands-on engineering class involves not only the exact and suitable pedagogical knowledge but also technological knowledge on top of the content knowledge. In addition, improving students learning behaviour from independently individual practice into interdependently cooperative practices based on team- working principle is also another learning issue that needs to be solved.

The objective of this innovation is to increase student engagement experiences in a BCLE for chemical engineering process simulation course (KC32603 – Process simulation and Integration).

Engaging students is one of the challenging tasks especially for chemical engineering process simulation course which requires students to do hands-on learning activities. Getting students engagement in a hands-on engineering class involves not only the exact and suitable pedagogical knowledge but also technological knowledge on top of the content knowledge. Thus, BCLE has been designed based on TPACK framework and successfully implemented in creating meaningful learning experiences in a chemical engineering process simulation course.

Faculty: Faculty of Engineering

Programme: Chemical Engineering

Course code: KC32603 Academic Session/Semester: 2021-2022/2

Course name: Process Simulation and Integration Pre/co requisite (course name and code, if applicable):

Credit hours: 3

Mapping of the Course Learning Outcomes (CLO) to the Programme Learning Outcomes (PLO), Teaching & Learning (T&L) methods and Assessment methods:

No. Course Learning Outcomes PLO Taxonomies Level

T&L Methods Assessment Methods CLO

1

Systematically analyze complex chemical engineering process design problems using the applicable chemical engineering process simulator.

PLO 2

C4 (analyze) Active learning, Cooperative Learning,

Blended Learning

In-Classs Exercises, Mid-Term Test, Final Exam CLO

2

Design solutions for complex chemical engineering process design problems that able to improve process

productivity and energy saving.

PLO 3

C6 (design) Active learning, Cooperative Learning,

Blended Learning

Quizzes, Progress Reports, Project Report 1.1 KC32603 Course Information

Course Synopsis

This course has been designed to illustrate the use of process simulation as a tool for the analysis of chemical processes and for the conceptual design of unit operations. In the last years, chemical process simulation has become of significant importance due to the evolution of computing tools, which have opened a wider spectrum of possibilities in the use of applications for process integration. The abovementioned application added to the need of performing calculations in a fast way in order to focus in the analysis of the obtained information and on other relevant aspects such as safety, green engineering, economic profitability, and many other factors that make the solutions of engineering more competitive. This course is divided into third parts. The first part is about fundamental of process simulation and application of process simulation for individual unit operations. Then in the second part, all the fundamental knowledge of process simulation will be applied in the complete chemical process. The third part is where the application of process integration will be applied in order to design complex chemical engineering process with specific aspects as mentioned above. This course implements active learning, cooperative learning as well as blended learning in all teaching and learning activities.

Course Learning Outcomes (CLOs)

At the end of this semester, students will be able to:

1. Systematically analyze complex chemical engineering process design problems using the applicable chemical engineering process simulator.

2. Design solutions for complex chemical engineering process design problems that able to improve process productivity and energy saving.

3. Design solutions for complex chemical engineering process integration design problems that able to improve process productivity and energy saving.

4. Apply the applicable process simulation concept of Aspen HYSYS process simulator in designing individual chemical engineering unit operations as well as complete and complex chemical engineering process design problems.

Course Schedule

Thursday 14:00 – 16:00 (Makmal Umum 2, FKJ) Friday 8:00 – 10:00 (Makmal Umum 2, FKJ)

Course lecturer Name Office Contact no. E-mail

Assoc. Prof. Ts. Dr. Mohd Kamaruddin bin Abd Hamid

A-11 0137790426 kamaruddinhamid@ums .edu.my

Faculty: Faculty of Engineering

Programme: Chemical Engineering

Course code: KC32603 Academic Session/Semester: 2021-2022/2

Course name: Process Simulation and Integration Pre/co requisite (course name and code, if applicable):

Credit hours: 3

CLO 3

Design solutions for complex chemical engineering process integration design problems that able to improve process productivity and energy saving.

PLO 3

C6 (design) Active learning, Cooperative Learning,

Blended Learning

Quizzes, Progress Reports, Project Report CLO

4

Apply the applicable process simulation concept of Aspen HYSYS process simulator in designing individual chemical engineering unit operations as well as complete and complex chemical engineering process design problems.

PLO 5

C3 (apply) Active learning, Cooperative Learning,

Blended Learning

In-Class Exercises, Mid-Term Test, Final Exam

Details on Innovative T&L practices:

No. Type Implementation

1. Active learning Conducted through in-class activities.

2. Cooperative learning Conducted through design projects. Students in a team of five will be given two design projects that require chemical engineering process design solutions involving the application of process simulator. Compliance to the design specifications need to be given in the form of written reports.

3. Blended learning Conducted through Learning Management System (LMS) of UMS SmartV3.

All information as well as materials related to teaching and learning activities will be given prior to class through this system. Some for formative assessments will be also conducted using this system.

Weekly Schedule:

Week 1 Introduction

Introduction to Process Design, Simulation and Integration Week 2 Process Simulation Using Aspen HYSYS

Part 1: Equation of state, pressure-related equipment, temperature-related equipment Week 3 Process Simulation Using Aspen HYSYS

Part 2: Reaction systems

Week 4 Process Simulation Using Aspen HYSYS Part 3: Separation systems

Week 5 Reaction Systems in Series Conversion-Equilibrium Reactions Week 6 Separation Systems in Series

Flash-Distillation Column, Distillation Columns Sequence Week 7 Reaction-Separation Systems

Reaction-Separation Systems Week 8 Mid-Semester Break

Week 9 Chemical Engineering Process Design: Simulation Project 1 Chemical Engineering Process Design

Week 10 Chemical Engineering Process Design Week 11 Chemical Engineering Process Design

Faculty: Faculty of Engineering

Programme: Chemical Engineering

Course code: KC32603 Academic Session/Semester: 2021-2022/2

Course name: Process Simulation and Integration Pre/co requisite (course name and code, if applicable):

Credit hours: 3

Week 12 Chemical Engineering Process Integration Design: Simulation Project 2 Chemical Engineering Process Integration Design

Week 13 Chemical Engineering Process Integration Design Week 14 Chemical Engineering Process Integration Design

Transferable skills (generic skills learned in course of study which can be useful and utilised in other settings):

Team working Life-long learning Communication

Student learning time (SLT) details:

Student Learning Time (SLT)

Teaching and Learning Activities

TOTAL Guided Learning SLT

(Face to Face)

Guided Learning (Online)

Guided Learning Non-Face

to Face

Independent Learning Non-Face to

face

CLO L T P O L T P O

CLO 1 3h 6h 6h 3h 5h 23h

CLO 2 6h 3h 10h 19h

CLO 3 6h 3h 10h 19h

CLO 4 8h 26h 8h 5h 47h

Total SLT 3h 26h 32h 17h 30h 108h

Continuous Assessment CLO Percentage Total SLT

1 Quiz 1 CLO 2 5 2h

2 Quiz 2 CLO 3 5 2h

3 In-Class Exercises CLO 1

CLO 4

15 2h

3 Mid-Term Test CLO 1

CLO 4

15 3h

4 Project Report 1 CLO 2 10 As in CLO 2

5 Project Report 2 CLO 3 10 As in CLO 3

Final Assessment Percentage Total SLT

1 Final Examination CLO 1

CLO 4

40 3h

Grand Total 100 120h

Special requirement to deliver the course:

Computer lab with Aspen HYSYS

Learning resources:

Main references

Ivan Dario Gil Chaves, Javier Ricardo Guevara Lopez, Jose Luis Garcia Zapata, Alexander Leguizamon Robayo, & Gerardo Rodriquez Nino (2016), Process Analysis and Simulation in Chemical Engineering.

Springer. ISBN: 978-3-319-14812-0.

Juma Haydary (2019), Chemical Process Design and Simulation: Aspen Plus and Aspen HYSYS Applications. AIChE-Wiley. ISBN: 978-1-119-31143-0.

Faculty: Faculty of Engineering

Programme: Chemical Engineering

Course code: KC32603 Academic Session/Semester: 2021-2022/2

Course name: Process Simulation and Integration Pre/co requisite (course name and code, if applicable):

Credit hours: 3

Nayef Ghazem (2018), Modeling and Simulation of Chemical Process Systems. Taylor & Francis. ISBN: 978- 0-203-70508-7.

Dominic Chwan Yee Foo (Eds.) (2017), Chemical Engineering Process Simulation. Elsevier. ISBN: 978-0- 128-03782-9.

Academic honesty and plagiarism:

It is contrary to justice, academic integrity, and to the spirit of intellectual inquiry to submit another’s statements or ideas as one's own work. To do so is plagiarism or cheating, offenses punishable under the University's disciplinary system. Because these offenses undercut the distinctive moral and intellectual character of the University, we take them very seriously.

Proper acknowledgment of another's ideas, whether by direct quotation or paraphrase, is expected. In particular, if any written or electronic source is consulted and material is used from that source, directly or indirectly, the source should be identified by author, title, and page number, or by website and date accessed.

Any doubts about what constitutes "use" should be addressed to the instructor.

Copying of work (texts, simulation results etc.) from other students/teams or from other sources is not allowed.

Existing texts should be reformulated with your own words used to explain what you have read. It is not acceptable to retype existing texts and just acknowledge the source as a reference. Be warned: students who submit copied work will obtain a mark of zero for the assignment and disciplinary steps may be taken by the Faculty. It is also unacceptable to do somebody else’s work, to lend your work to them or to make your work available to them to copy.

Other additional information:

All teaching and learning activities are team tasks unless explicitly indicated as individual tasks. During those activities, all students are required to actively participate. Peer rating will be implemented at the end of each activity especially for design project to measure students’ participation.

All students are required to attend the class unless given a notice in advanced. Attendance will be taken in the first five minutes before the class started either face-to-face or online.

All given assignments must be submitted through UMS Learning Management System (LMS) SmartV3 before the deadline. The marks of the late submission will be deducted. It is advisable for students to consult the instructor in the case of late submission.

Disclaimer:

All teaching and learning materials associated with this course are for personal use only. The materials are intended for educational purposes only. Reproduction of the materials in any form for any purposes other than what it is intended for is prohibited.

While every effort has been made to ensure the accuracy of the information supplied herein, Universiti Malaysia Sabah cannot be held responsible for any errors or omissions.

2.0 BLENDED-COOPERATIVE LEARNING ENVIRONMENT USING TPACK FRAMEWORK

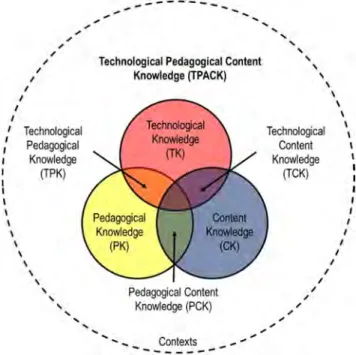

In this innovation, CBLE for process simulation course has been successfully developed based on the original TPACK framework (tpack.org) as shown in Figure 2.1. TPACK (technological pedagogical content knowledge) framework is a framework of teacher knowledge for technology integration which is critical to effective teaching with technology (Koehler & Mishra, 2009).

Figure 2.1: TPACK framework (tpack.org).

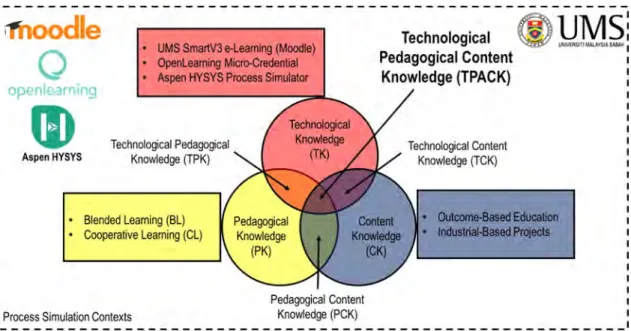

The original TPACK framework has been redesigned by including Outcome-Based Education (OBE) and Industrial-Based Projects in Content Knowledge (CK), as shown in Figure 2.2.

Figure 2.2: BCLE for process simulation course using TPACK framework.

In addition, Blended Learning (BL) and CL have been included for redesigning Pedagogical Knowledge (PK). The application of the UMS SmartV3, a Moodle-based LMS for asynchronous CL activities delivery as well as OpenLearning for a micro-credential implementation of process simulation introductory course of Aspen HYSYS process simulator has redesigned the Technological Knowledge (TK).

It has been known that engaging students is one of the challenging tasks especially for engineering process simulation course which requires students to do hands-on learning activities.

Getting students engagement in a hands-on engineering class involves not only the exact and suitable pedagogical knowledge but also technological knowledge on top of the content knowledge. Thus, BCLE has been proposed based on TPACK framework and successfully implemented in an engineering process simulation course at the Faculty of Engineering, UMS.

BCLE is the environment which included asynchronous online learning CL activities and face-to- face CL activities. In this learning environment, students are encouraged to participate in routine engineering process simulation activities, which helps them for constructing their process simulation knowledge based on cooperative learning activities with the help of several LMSs and Aspen HYSYS, an engineering process simulation software.

The application of LMS such as Moodle for asynchronous CL activities delivery, OpenLearning for a micro-credential implementation of basic engineering process simulation as well as the hands-on of Aspen HYSYS, the industrial process simulator, combined together with face-to-face CL activities has enriched student learning experiences by opening wide range of resources to encourage engagement. In this learning environment, engagement is defined as the quality of efforts students themselves devote to educationally purposeful activities that is positively linked to student desired learning outcomes, including high grades, student satisfaction and perseverance as well as team-working skills. This can be observed by the high grades obtained by students and their learning outcomes achievements. In addition, students learning behaviour also shows positive changes from independently individual practice into interdependently cooperative practices which can be clearly observed from students learning reflection journals that confidently encouraged team-working principle.

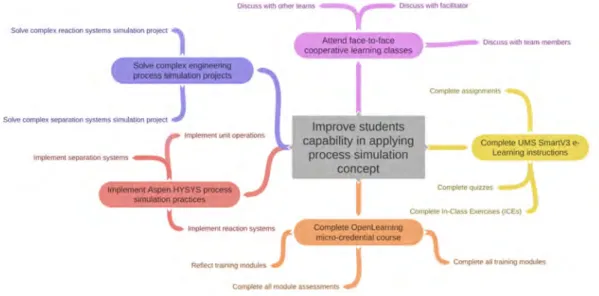

The BCLE innovation shown in Figure 2.2 has been successfully implemented in Semester 2, Session 2021/2022. Systematically, the implementation of this innovation has been designed and planned using Action Mapping model as shown in Figure 2.3.

Accordingly, BCLE innovation taking into consideration of these elements together with their dedicated activities:

1. Micro-Credential implementation (OpenLearning) – refer to Figure 2.4.

2. Asynchronous CL activities delivery (Moodle) – refer to Figure 2.7.

3. Blended-Cooperative Learning class implementation (Face-to-face) – refer to Figure 2.8.

4. Complex engineering projects implementation (Industrial-based projects) – refer to Figure 2.8.

5. Aspen HYSYS application (Team hands-on) – refer to Figure 2.9.

Figure 2.3: Action Mapping model for BCLE implementation.

Figure 2.4: Micro-Credential implementation using OpenLearning platform.

2.1 Accessing Micro-Credential Process Simulation

QR code shown in Figure 2.5 needs to be scanned in order to access the micro-credential course on the introduction to process simulation using Aspen HYSYS.

Figure 2.5: QR code for micro-credential of process simulation in OpenLearning platform.

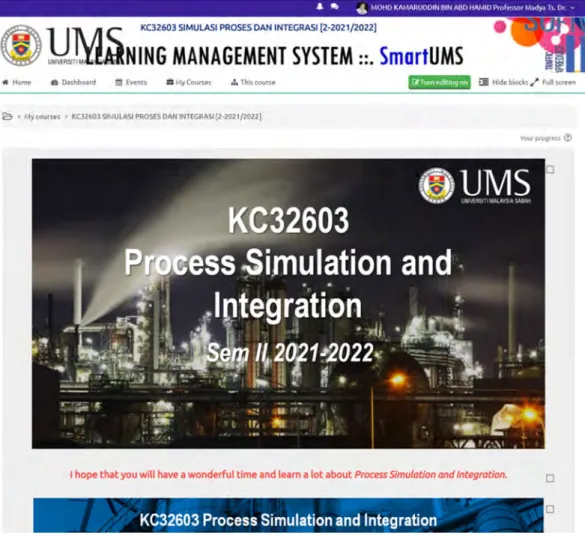

2.2 Accessing UMS SmartV3 Moodle Platform

CL asynchronous activities is delivered using UMS SmartV3, an e-learning LMS based on Moodle platform. This LMS can be accessed using QR code shown in Figure 2.6. The screenshot of the top page of this Moodle LMS is shown in Figure 2.7.

Figure 2.6: QR code for accessing CL asynchronous activities.

Figure 2.7: Asynchronous CL activities delivery using Moodle.

2.3 Blended-Cooperative Learning Class Implementation (Face-to-face)

In semester 2 session 2021/2022, the teaching and learning implementation is based on physical face-to-face mode. However, in this innovation, the face-to-face activities have been improved using BCLE in order to increase students’ engagements. Figures 2.8 – 2.11 show how the BCL activities have been conducted face-to-face. All the CL instructions were given before the face- to-face class using Moodle, usually a day before. Then, in team, students were required to prepare certain deliverables that will be further discussed in face-to-face meeting. For example, in solving any given process simulation problem, students will be asked to summarize the solution planning individually. Then, when they meet in face-to-face class, students will discuss in their team to cooperatively summarize their team solution planning. Once all team members agreed with their team solution planning, then the solution will be uploaded in UMS SmartV3 to be assessed. Then the activities will be continued until all teams able to solve the given process simulation problem.

Figure 2.8 Face-to-face blended-cooperative learning class implementation.

Figure 2.9 Face-to-face blended-cooperative learning class implementation.

Figure 2.10 Face-to-face blended-cooperative learning class implementation.

Figure 2.11: Team hands-on Aspen HYSYS application.

To see more photo of students in face-to-face class activities, please scan the QR code shown in Figure 2.12.

Figure 2.12: QR code for accessing photo of students conducting CL asynchronous activities.

2.4 Complex Engineering Projects Implementation (Industrial-Based Projects)

In this innovation, there are two industrial-based projects have been used in implementing the BCLE. These two projects have been designed to cover CLO 2 and CLO3 (Refer KC32603 Course Information). Although this innovation is systematically designed to cover CLO 4, but in the other hands, implementation of industrial-based projects also indirectly helps in increasing students’ engagement in this process simulation class. Figure 2.13 shows the project 1 that covers CLO2, whereas Figure 2.14 shows the project 2 that covers CLO3.

Figure 2.13a: Complex engineering projects implementation (Industrial-based project 1).

Figure 2.13b: Complex engineering projects implementation (Industrial-based project 1).

Figure 2.14a: Complex engineering projects implementation (Industrial-based project 2).

Figure 2.14b: Complex engineering projects implementation (Industrial-based project 2).

2.5 Aspen HYSYS Application (Team Hands-On)

The application of Aspen HYSYS is conducted through team-based (cooperative) learning.

Figures 2.15 – 2.17 show team hands-on Aspen HYSYS application activities.

Figure 2.15: Aspen HYSYS team-based hands-on activities.

Figure 2.16: Aspen HYSYS team-based hands-on activities.

Figure 2.17: Aspen HYSYS team-based hands-on activities.

For more photo of students’ activities, please refer to Figure 2.12.

3.0 TRANSFERABLE AND SCALABLE FRAMEWORK

The BCLE innovation is designed such that it can be transferable, can be applied for other courses such as shown in Figure 3.1. In Figure 3.1, the same BCLE has been successfully implemented for UMS engineering programming course in Semester 1, Session 2021/2022 (during COVID-19 pandemic). The objective of this innovation is to increase student engagement experiences in a BCLE for engineering programming class during online hands- on classes. This innovation won a Gold Medal in International University Carnival on e- Learning (IUCEL2022) under category of Invention, Innovation & Design on e-Learning (IIDEL).

Figure 3.1: BCLE for engineering programming course using TPACK framework.

For more details on competition participation and sharing session of BCLE during IUCEL 2022 can be referred by scanning the QR code in Figure 3.2.

Figure 3.2: QR code for more information on IUCEL 2022

In terms of scalability, this BCLE innovation can be scalable into Blended-Cooperative Problem-Based Learning Environment (BCPBLE) as shown in Figure 3.3, where BL, CL and problem-based learning (PBL) will redesign PK whereas UMS SmartV3, UMS MOOC, UMS Micro-Credential as well as industrial process software will redesign the TK for more meaningful learning experiences for engineering courses in the future.

Figure 3.3: Blended-Cooperative Problem Based Learning Environment (BCPBLE) using TPACK framework.

Previously, the same BCPBL environment has been developed for Process Control course at Universiti Teknologi Malaysia (UTM) in 2019 as shown in Figure 3.4.

Figure 3.4: Blended-Cooperative Problem Based Learning for UTM Process Control Course using TPACK Framework.

This innovation has been presented during New Academia Learning Innovation (NALI 2019)

UTM, and won a Gold Medal and NALI Award 2019, as shown in Figure 3.5. This shows that BCLE and BCPBLE developed using TPACK framework capable increasing students’

engagement in engineering courses, and has been implemented to several universities such as UTM and UMS.

Figure 3.5: BCPBLE for UTM Process Control Course won a Gold Medal and NALI Award 2019.

Several innovations using general TPACK framework under blended-cooperative method received recognitions in teaching and learning (T&L) innovation such as:

1. Gold Award in International University Carnival on e-Learning (IUCEL 2022).

2. Award of excellence in active blended learning UTM 2017, 2018, 2019, 2020.

3. UTM New Academia Learning Innovation (NALI) 2019 award in recognition of excellence in T&L.

4. Gold Award in UTM NALI 2018, 2019 Exhibition and Competition.

5. Finalist AKRI 2018 for immersive learning experience (blended).

4.0 STUDENTS INVOLVEMENT

The application of BCLE has enriched student meaningful learning experiences by opening wide range of resources to encourage engagement especially in achieving CLO4. Students were meaningfully engaged in BCLE both in online and face-to-face CL activities. This can be clearly seen by higher students’ participation in OpenLearning (Figure 4.1) as well as higher students’ hits in UMS SmartV3 (Figure 4.3).

Figure 4.1: Students’ engagement in Openlearning micro-credential course.

Please scan the QR code shown in Figure 4.2 for more evidence of this participation.

Figure 4.2: QR code for accessing micro-credential of process simulation in OpenLearning platform.

Figure 4.3: Students’ engagement in UMS SmartV3 e-Learning CL activities delivery.

Please scan the QR code shown in Figure 4.4 for more evidence of this participation.

Figure 4.4: QR code for accessing CL asynchronous activities.

In addition, Figure 4.5 shows students’ engagement during face-to-face CL classes.

Figure 4.5: Students’ engagement during face-to-face CL class.

To see more photo of students’ participation in face-to-face class activities, please scan the QR code shown in Figure 4.6.

Figure 4.6: QR code for accessing photo of students conducting CL asynchronous activities.

4.1 Students’ Learning Reflection Journal

Several examples of students’ learning reflection journal showing their active participations in this BCLE are shown in Figure 4.7 – Figure 4.8. Figure 4.7 is the learning reflection journal written by Irene Rinai Ilias (BK19110216) after the mid-term of semester 2 session 2021-2022.

Figure 4.7a: Student learning reflection journal by Irene Rinai Ilias.

Figure 4.7b: Student learning reflection journal by Irene Rinai Ilias.

Figure 4.8 is the learning reflection journal written by Farah Leyana Daut (BK19110285) after the end-term of semester 2 session 2021-2022.

Figure 4.8a: Student learning reflection journal by Farah Leyana Daut.

Figure 4.8b: Student learning reflection journal by Farah Leyana Daut.

More students’ learning reflection journals can be referred in Figure 4.9.

Figure 4.9: QR code for accessing more students’ learning reflection journals.

5.0 IMPACTS ON STUDENTS’ LEARNING

In this learning environment, engagement is defined as the quality of efforts students themselves devote to educationally purposeful activities that is positively linked to student desired learning outcomes, including higher grades, student satisfaction and perseverance as well as team-working skills. This can be observed by the higher value of active index (AI) in Moodle as well as higher course learning outcomes (CLOs) achievements. Table 5.1 shows information of KC32603 implementation for two sessions, which were successfully achieved blended-learning (BL) level (1,7,3,2 concept). Session 2020/2021 was conducted as BL whereas session 2021/2022 was conducted as blended-cooperative learning (BCL). It can clearly be seen from Table 5.1 that BCL class received higher hits compared to BL class.

Table 5.1: Active Index calculation for KC32603 in UMS SmartV3 (Moodle).

In addition, the most important result is that BCL class obtains 110 value of AI compared to only 7 for BL class. AI is the average access for each student to e-learning platform. To be recognized as an active BL course, AI value must be greater than 28 during the semester, which is equal to at least two times per week for one student access to e-learning. Since the AI value for BCL class is the highest (and more than 28, refer to Table 5.1), it can be verified that BCL class is an active class which offered more opportunities for student engagement experiences.

Apparently, when students have better engagement experiences, their learning outcomes achievements will also increase. Tsai (2012) stated that use of CL and online activities together will increase the quality of learning. In literature, there are number of studies demonstrating the BCLEs increase academic achievement (Aladejena, 2009; Owston, York &

Murtha, 2013). These studies are supported by the results shown in Figure 5.1. Figure 5.1 shows CLO4 achievement (in terms of marks percentage) of KC32603 for two sessions (2020/2021 – BL; 2021/2022 – BCL).

Figure 5.1: KC32693 CLO4 achievements.

It can clearly be seen from Figure 5.1 that BCLE contributed more to the students’ CLOs achievements than traditional teaching methods did.

Figure 5.2: KC32603 grade analysis.

Figure 5.2 shows the KC32603 marks percentage analysis. About 60.87% of students, 28 students out of 46 obtain grade A and 9 students obtain grade A- (19.57%). It could be stated that the students’ levels of academic achievement was high because the BCLE included both online and CL activities; the online course-related materials were available through OpenLearning and Moodle; the students were prepared for the lessons; the students had the chance to revise wherever and whenever they wanted; they maintained interaction in the online environment; they studied for the course using a number of resources (in-class exercises, project, presentations, team-based activities, videos), the students fulfilled the tasks collectively; and because all assessments were administered. Therefore, BCLE is significant in increasing student engagement experiences.

5.1 Students’ Learning Skills Improvement

In this BCLE innovation, the skill in applying Aspen HYSYS process simulator for designing chemical engineering process is expected to increase. Previously, most of the students only had minimum process simulation experiences.

“In terms of technical skills, I felt unsure about myself at the beginning of the semester since I had only a little bit of experience and interest in process simulation. However, once I tried learning and using Aspen HYSYS based on OpenLearning courses and guidance from Dr.

Mohd Kamaruddin, I found out that process simulation is not as hard as I imagined previously”, Farah Leyana Daut.

Figure 5.3 shows the full version of learning reflection journal written by Farah Leyana Daut.

Figure 5.3a: Learning reflection journal by Farah Leyana Daut.

Figure 5.3b: Learning reflection journal by Farah Leyana Daut.

More students’ learning reflection journals can be referred in Figure 5.4.

Figure 5.4: QR code for accessing more students’ learning reflection journals.

5.2 Students’ Learning Behaviour Improvement

In BCLE, students learning behaviour also shows positive changes from independently individual practice into interdependently cooperative practices which can be clearly observed from students learning reflection journals that confidently encouraged team-working principle.

“By asking lots of questions, I was able to learn more about certain things that I did not understand and that has helped me greatly”, Aaron Yeap Wai Hung. Figure 5.4 shows the full version of learning reflection journal written by Aaron Yeap Wai Hung.

“Learning new things in this subject really surprises me and brings me joy”, Amira Natasha Shirlin.

“I'm grateful to be in this class as it really gives me knowledge and fun. I also learn how to communicate with my teammates and other classmates for any discussion.”, Pg Mohd Rafi Aiman.

“The team discussion has also been worthwhile where my team members and I could share our answers together and discuss the problem”, Joshua Rechard Mijong.

“Thankfully, I have the support of my teammates where we work together to solve the problem”, Jaclyn Ingu.

“I have to emphasize the significance of teamwork”, Abigail Bernardette Yong.

“…this course was very team-based”, Isaac Bernard Funk.

Therefore, it can be concluded that students’ exposure to BCLE able to improve not only students’ achievement in CLO4 but also their learning experiences.

Figure 5.4a: Learning reflection journal by Aaron Yeap Wai Hung.

Figure 5.4b: Learning reflection journal by Aaron Yeap Wai Hung.

More students’ learning reflection journals can be referred in Figure 5.4.

6.0 CONCLUSION

The BCLE is one of the innovation developed using TPACK framework to increase student engagement experiences in online hands-on engineering process simulation class. Engaging students during the online class is one of the challenging tasks. The application of BCLE has enriched student learning experiences by opening wide range of resources to encourage engagement. Therefore, it can be concluded that students’ exposure to BCLE able to improve not only students’ achievement in learning outcomes but also their learning experiences.

REFERENCES

Aladejena, F. (2009). Blended learning and technology-assisted teaching of biology in Nigerian secondary schools, Special Edition of the world Congress on Engineering and Computer Science, 133-140.

Avgerinou, M. D. (2008). Blended collaborative learning for action research training. The Journal for Open and Distance Education and Educational Technology, 4(1).

El-Deghaidy, H., & Nouby, A. (2008). Effectiveness of a blended e-learning cooperative approach in an Egyptian teacher education programme. Computers & Education, 51, 988- 1006.

Koehler, M. J., & Mishra, P. (2009). What is technological pedagogical content knowledge?

Contemporary Issues in Technology and Teacher Education, 9(1).

Owston, R., York, D. & Murtha, S. (2013). Student perceptions and achievement in a university blended learning strategic initiative. Internet and Higher Education, I18, 38-46.

Tsai, C. W. (2012). Do students need teacher’s initiation in online collaborative learning?

Computers & Education, 54, 1137-1144.