The study focused on identifying the best possible contact angle measurement method to determine the contact angle for agricultural materials. Sugarcane (Saccarhum Officinarum), kapok (Ceiba Pentandra) and rice husk (Oryzae Sativa) are selected to be tested for their contact angle and then compared to the established synthetic oil sorbent, polypropylene. The device used is an interfacial tensiometer which measures the contact angle based on a picture taken of the drop of liquid on a solid surface.

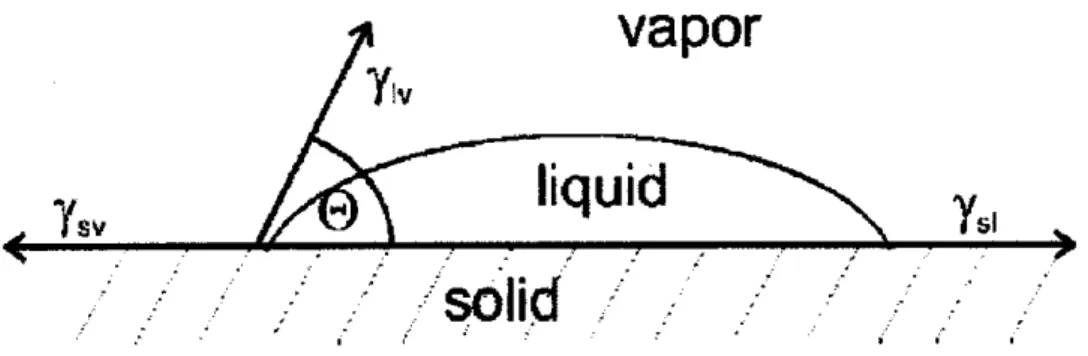

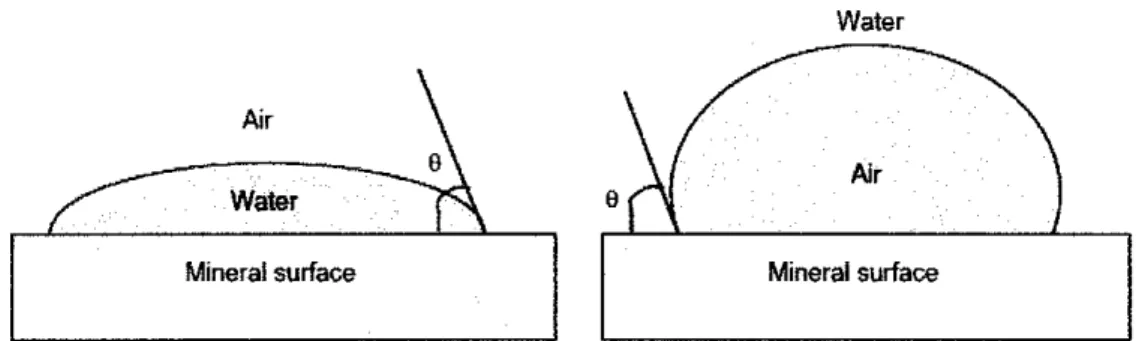

In general, however, the contact angle values for agricultural materials are lower than for polypropylene. The contact angle is specific to a given system and is determined by the interactions across the three interfaces. There are a number of techniques used to measure the contact angle currently in use.

Contact angle measurement for natural sorbent fibers such as rice husks, sugarcane bagasse and kapok is a new field that has not yet been fully explored using some of the few methods available. In this research work, experiments will be conducted to determine the best contact angle measurement methods for agricultural materials using the liquid penetration method.

Problem Statement

Objective

Scope of Study

The Relevancy of the Project/Project Significance

Feasibility of the Project within the Scope and Time Frame

In the second semester, experiments are performed to determine the best contact angle measurement method, followed by contact angle measurements for different types of agricultural materials with different types of liquids (water, oil).

CHAPTER2

LITERATURE REVIEW

Agricultural Materials

- Kapok

- Sugarcane Bagasse

- Rice Husks

However, it is usually divided into three main categories; physical methods, chemical methods and also biological methods (Bordosern, 2004). One of the most economical and effective methods for removing oil contamination is oil sorption with sorbents. Preferably, sorbent materials should exhibit a rapid oil sorption rate, high oil sorption capacity (oleophilicity or lipophilicity), low water absorption, high oil retention capacity during transfer, high recovery using simple absorbed oil methods, good reusability, high buoyancy, and excellent physical and chemical resistance to deformation, photodegradation, and chemical attack (Lim and Huang, 2007).

The sorbent materials can be further divided into three main classes: inorganic mineral products, organic products and also organic vegetable products. One of the most commonly used commercial synthetic absorbents is polypropylene due to its sorption capabilities and physical properties. This is particularly useful as it can be used to absorb oil but not water during oil spills in the ocean.

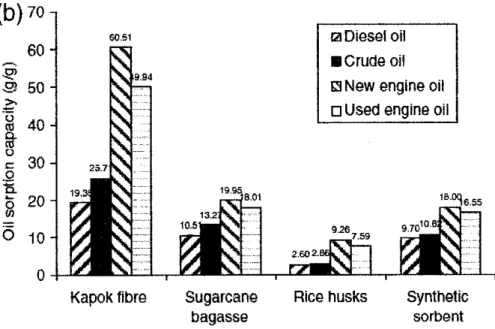

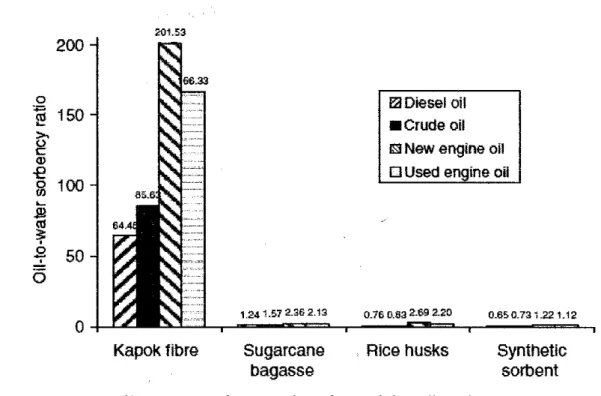

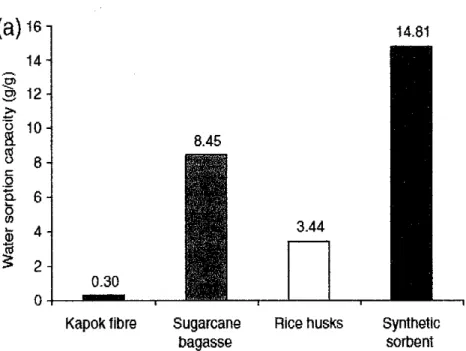

According to Ali et a, both kapok and sugarcane bagasse exhibit excellent oil absorption capabilities for diesel, crude oil, new engines and used engine oils, which can be used as alternatives to synthetic materials in use . This is supported by Figures 2.1-2.3 on the water and oil absorption capabilities of these materials. The production of sugar from sugarcane is one of the main agricultural industries in Malaysia.

Generally, 1 ton of sugar cane produces about 280 kg of sugar cane, which is about 28% of the total weight (Sun et al., 2004). Currently, the use of cane is still limited to use as animal feed. The fairly regular shape of spongy core particles with a length to width ratio close to unity can be approximated by a spherical shape.

Some fibers are often attached to the inner wall of the skin particles (Rasul et al., 1999). Rice husks have presented a major disposal problem for the rice milling industry in Malaysia, and also worldwide. The unique cell-skeleton structure of the rice husk cell means that it can be used to absorb oil (Lim and Huang, 2007).

Methods for Contact Angle Measurement

Direct measurements of contact angle

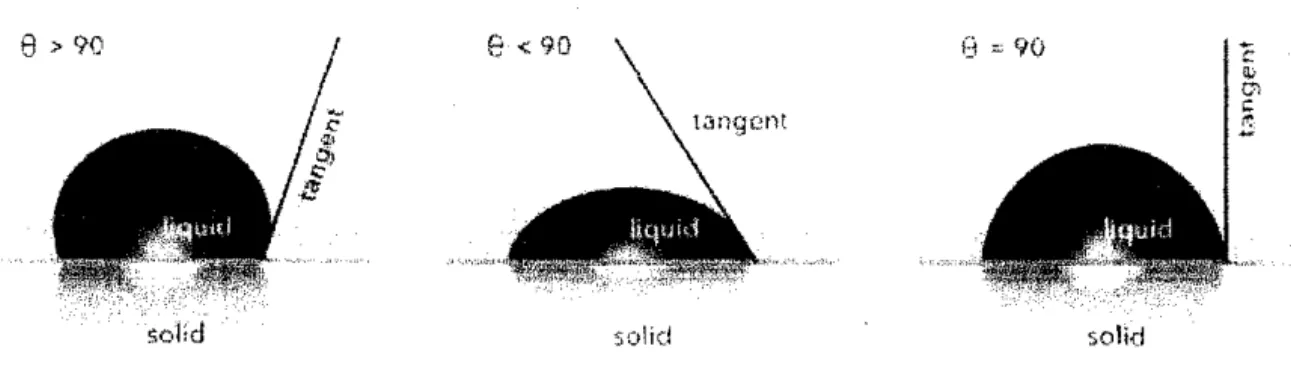

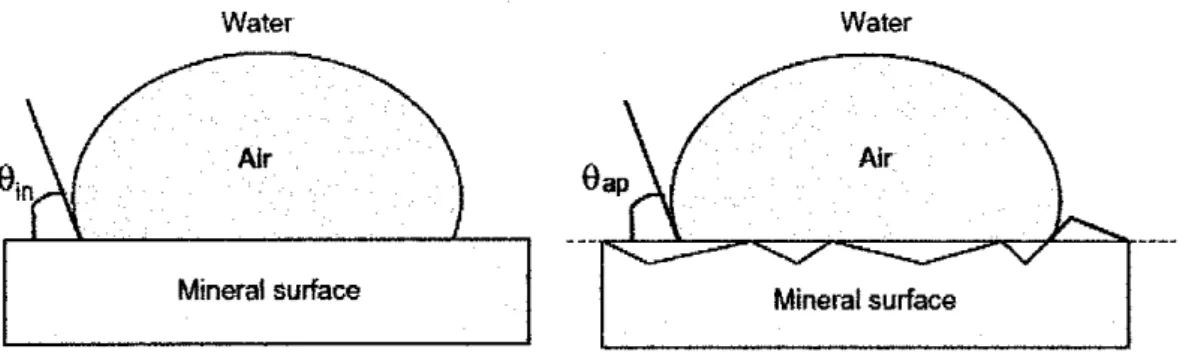

It is observed that in most cases, when a liquid is placed on a solid surface, it will not become wet, but will remain as a droplet with a specific particular contact angle between the liquid and solid phases (Adamson, 1967). The direct measurement of the contact angle can be useful for large samples of solids. The tilting plate method has provided the most reproducible and probably the most accurate contact angle values.

A plate several centimeters wide of the solid is immersed in the liquid and its position is changed by means of an adjustable mount to such an angle that the liquid surface appears to remain perfectly flat to the surface of the solid (Adamson, 1967). . For this measurement the surface of the solid must be smooth and clean before the substance is immersed in the liquid and a bubble, the angle, forms on the surface.

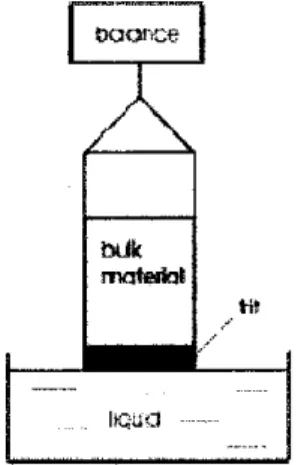

Column wicking method

Thin layer wicking method

However, methods based on the Washburn equation only give advancing contact angles and not equilibrium contact angles. However, this method is not recommended, as surface properties such as surface roughness, liquid adsorption and porosity may change during the compression phase, so contact angle measurement using pellets will be mostly based on assumed values.

CHAPTER3

Research Process

Project Activities

- Literature Review

- Materials for Experiment

- Experimental Procedure

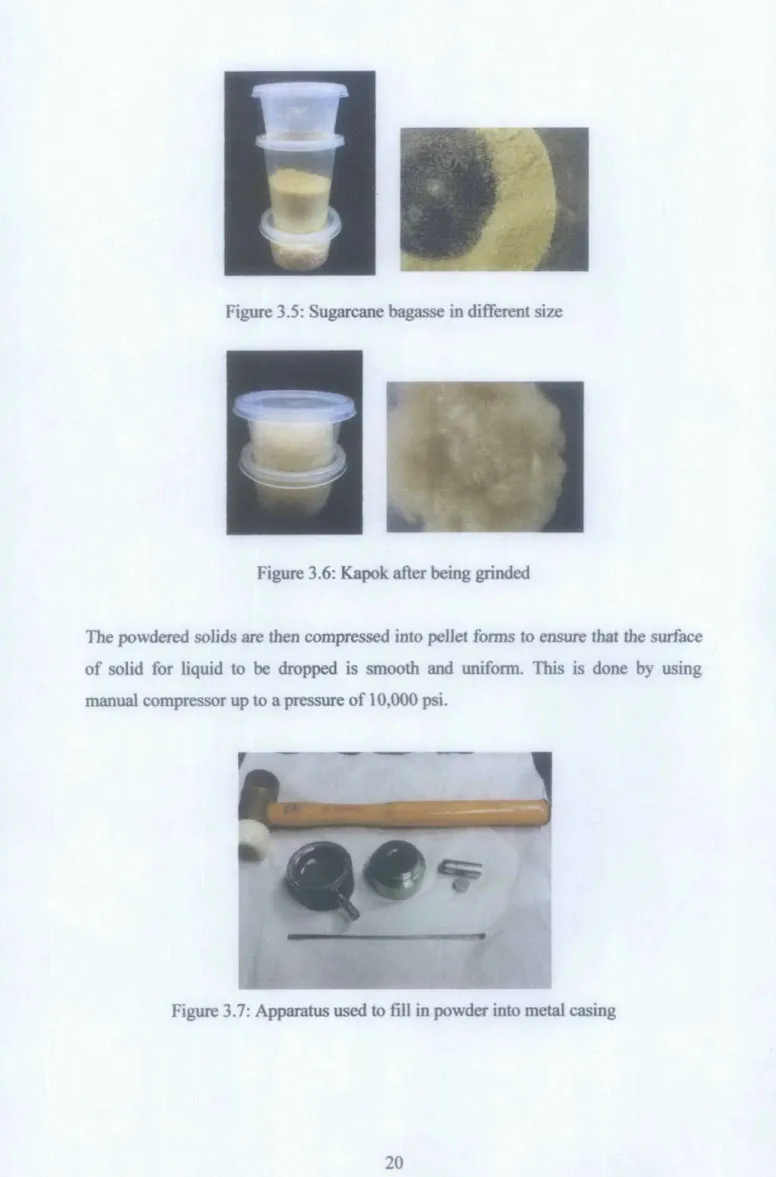

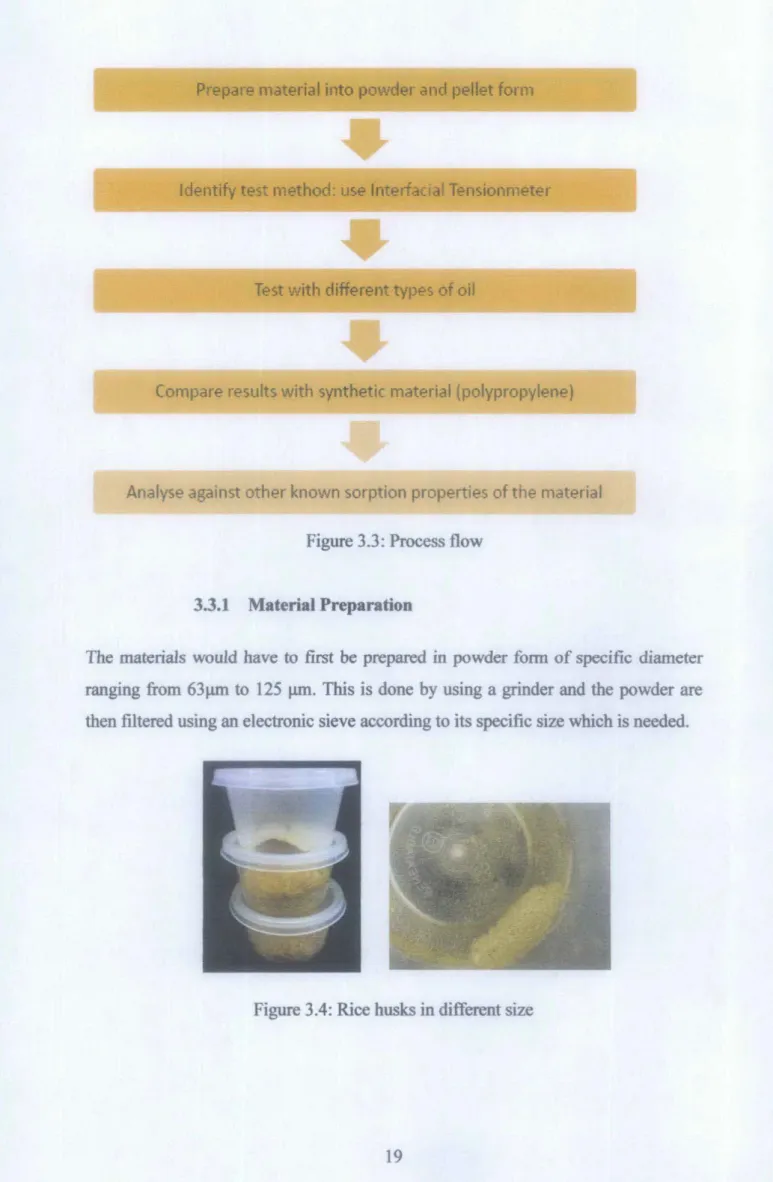

These solid materials will be tested with many different fluids such as crude oil, motor oil, used motor oil and also diesel. The materials should first be prepared as a powder of a specific diameter ranging from 63 J.LID to 125 J.LID. This is done with a grinder and the powder is then filtered using an electronic sieve according to its specific size that is required.

The pulverized solids are then compressed into granular forms to ensure that the surface of solid for dropping liquid is smooth and uniform. The resulting agricultural material in granular form is much easier to handle and therefore the experiment can be carried out more accurately. The chosen identified method to measure the contact angles of the agricultural material is by dropping a liquid onto the solid grain.

The pellet is first placed on a clean glass plate to ensure that it is free from contamination. The syringe with precision tips of internal diameter 1.54 mm is placed in its holder with the equipment. Make sure the camera alignment is correct to capture the best image of the liquid droplet on the solid.

This procedure is then repeated for different types of oil and also with different types of solids including polypropylene. The results can then be compared between the agricultural material and the synthetic sorbent material - polypropylene.

CHAPTER4

RESULTS AND DISCUSSION

Contact Angle Values for Different Material

Contact Angle Values for Different Oil

Discussions

From Figure 4.1 it can be seen that kapok generally has the lowest contact angle value of all oil types. Polypropylene, on the other hand, resulted in the highest contact angle values for each type of oil. This means that the sorption capacity of the agricultural materials is much better than the synthetic materials.

The values in Table 4.3 also confirm that the contact angle values for diesel fuel would also follow the same pattern from the lowest value to the highest value: kapok < sugarcane < rice husk < polypropylene. However, there are some conflicting values of contact angles for sugarcane and rice husk, as shown in Figure 4.2. For crude oil and used motor oil, the contact angle values for sugarcane were reported to be lower than for rice hulls, as demonstrated in other literature.

The plausible explanation for this result is that there may be some pores between the particles of rice husks in the pellet. This would allow the test liquids to penetrate the pores, invariably resulting in unstable and unreliable contact angles (Constanzo et al., 1995). The waxy and separated particles of kapok fibers mean that liquid samples are able to penetrate the material more quickly. This means that the sorption rate of oil into kapok will be much faster than the other two materials.

The surface of sugarcane bagasse is also suitable for absorption compared to that of rice husks, since rice husks consist of silica (Si) as part of the elemental composition. On the other hand, kapok fiber and sugarcane bagasse are not made of Si, which means they are able to absorb liquid better than rice husks (Ali et al., 2010). From the findings, it is clear that the use of agricultural materials to replace synthetic materials as oil sorbent is a more promising alternative (refer to the Appendix for the suitability matrix for the use of agricultural materials for oil removal).

CHAPTERS

CONCLUSION AND RECOMMENDATION

Conclusion

Preparation of the powdered solids in pellet form must be done in a clean environment to ensure that there is no contamination from the equipment used to prepare the pellets. The capillary penetration method could be used to observe the effect of liquid penetration into powdery solids packed into a capillary tube. With the conclusion that kapok is the most suitable material to replace the synthetic material currently used, it is necessary to analyze the availability of kapok trees in the country and whether the number is enough to meet future demands.

Another alternative would be to synthesize materials similar in properties to kapok fiber that could provide enough supply to meet demand should kapok fiber be a viable a.

Investigation of oil sorption behavior of filled and structured fiber assemblies made from polypropylene, kapok and milkweed fibers.

APPENDICES