This report discusses the method of the invention and various studies on lost circulation material. The aim of this project is to propose palm oil leaves as a drilling fluid additive to control the lost circulation during the drilling program. The report discusses the lost circulation problems, the lost circulation material and the characterization of the parameters of drilling fluid.

The experiment shows that palm oil leaves have characteristic as lost circulation material as compared to nut and corn cob. These problems can be addressed by adding or laying the lost circulation material to prevent the drilling fluid from entering the formation. The aim of this project is to develop a new lost circulation material which is more compatible with drilling fluid and the environmentally friendly.

So in this project we try to use the palm oil leaves as the lost circulation material in the oil field. If we can simultaneously produce the lost circulation material by using palm oil leaves, it can increase the socio-economic for the farmer.

Hamilton Beach mixer

Pycnometer

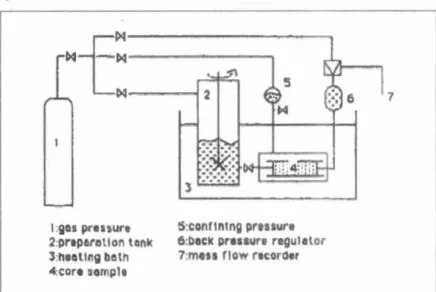

The instrument is useful for performing filtration tests on clogging materials without the interference of particles deposited on the filter media during the heating process. The pressure cell is similar to that of the standard HTHP filtration tests, but is inverted with the filter media and back pressure receiver on top of the assembly.

LITERATURE REVIEW

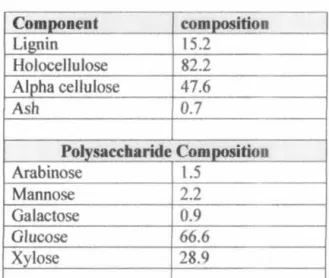

Palm oil Frond composition

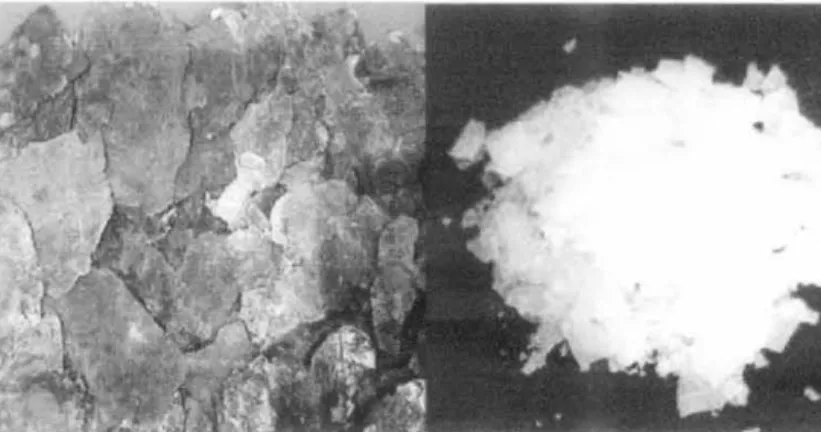

A palm branch or palm leaves usually refer to the leaves of the Arecaceae. The palm oil leaves are mainly composed of cellulose, hemicellulose and lignin. These components include cellulose and hemicelluloses, polysaccharides, which are simply broken down and metabolized by wood rot fungi. In the analysis of the constituents of wood, when lignin is selectively removed, holocellulose is formed.

Holocellulose can be considered the sum of cellulose and all hemicelluloses (KOZUMA Y osei et a/.,). Lignin from oil palm leaves was characterized by the existence of significant amounts of esterified p-hydroxybenzoic acid along with small amounts of etherified p-hydroxybenzoic acid. Some stretches of these ester bonds and beta-0-4 inter-unit bonds of lignin were cleaved during steam explosion, in addition to large condensation of guaiacyl nuclei, as revealed by 1H and 13C-NMR spectra of isolated lignin from the steam explosion pulp, the yield of which was quite high , suggesting that lignin has been released from other wall polymers.

The wall polysaccharides of oil palm leaves consist of cellulose and a rather high concentration of arabinoxylan, which produces a large amount of 5-hydroxymethyl-furfural or furfural during steam explosion or even hot pressing at 125 °C to prepare boards without a binder. It is believed that the released lignin and furfural derivatives formed during the steam explosion cause the self-bonding of the steam-exploded cellulose. It is an agricultural plant native to West Africa and cultivated in Malaysia for its oil-yielding fruits.

In addition to palm oil, the industry also produces huge amounts of lignocellulosic residues, such as trunks, leaves and empty fruit bunches, with an estimated amount of 30 million tons (MPOB, 200 l. Most of the leaves are taken from waste palm oil, which is usually Cellulose humans cannot eat and is often called "dietary fiber" or "cable" because it acts as a hydrophilic agent to increase the volume of the stool.

So if we refer to the palm oil leaf, it contains the cellulose which means it can help control the mud filtrate in the field.

CHAPTER3:METHODOLOGY 3.1 Research Methodology

Obtain RIIW Data of Expertment

Discussion Report Writins •

For this study, we need to do research on the current lost circulation material they use in the drilling fluid. Conduct research on the properties of palm oil leaves that can be used as a loss-circulating material. Test the properties of the drilling fluid using a viscometer and compare the properties of the two drilling fluids.

When we finally have all the data from the experiment, we begin to create the report. Mudder will design with the same amount of lost circulation material and see the result of the test. The image below is the spreadsheet for calculating additives for 1 0.5 ppg mud weight.

I~TAOLHT

Checking mud weight

Replace the cap and twist until it is tight, making sure some of the mud is expelled through the hole in the top to release any trapped gas. Place the beam on the base support and balance it using the rider along the graduated scale. The hydrostatic pressure produced by the mud in psi is = 0.052 x G x H where G = mud density in ppg.

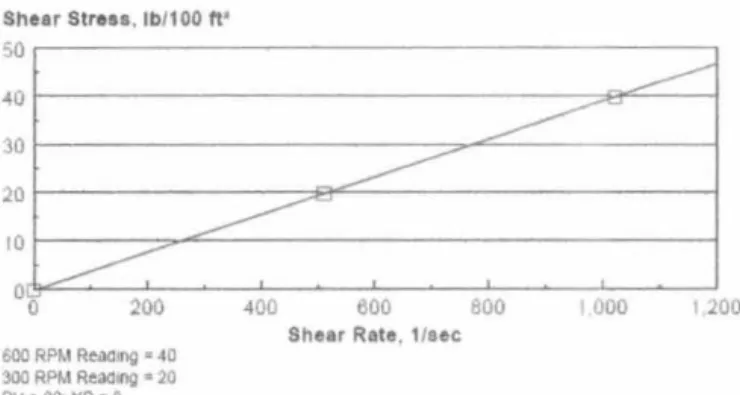

Place the sample in the thermo cup of the rheometer and adjust the cup until the level of the mud surface is equal to the drawn line on the rotor surface. Set the thermometer cup to 120°F and wait for the temperature to reach the set temperature. 120°F is API standard for drilling fluid rheology testing. High PV means the mud is not clean and there is a problem with the solids control equipment.

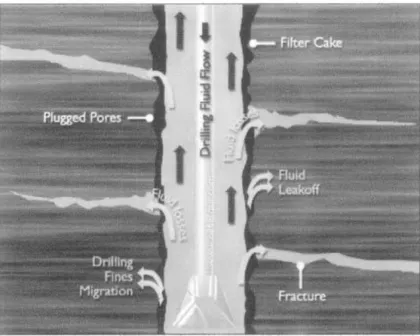

Knowing the fluid loss is important because it is bad to have mud with high filtrate loss as this contributes to high fluid invasion and also thick mud cakes. After drilling the fluid with an API filter press, we perform the next filtration test, which is the blockage permeability test. It has been suggested that PPT provides a better representation of the static state in the borehole [24]. Basically, PPT is an HPHT fluid loss modified to better simulate wellbore conditions.

Pressure is applied from the bottom of the cell using nitrogen gas and filtrate will collect from the top of the PPT cell. Gantt charts illustrate the start and end dates of the terminal elements and summary elements of a project. Terminal elements and summary elements consist of the work breakdown structure of the project.Ghant chart is important for a project to make sure the task or the fork structure feasibility with the time frame.

Each phase has the specific time frame and we have to follow the timeline to ensure that the end of the due date can produce or execute our project.

RESULT AND DISCUSSION

Plastic viscosity and Yield point

Filtrtion and Mud Cake Thickness

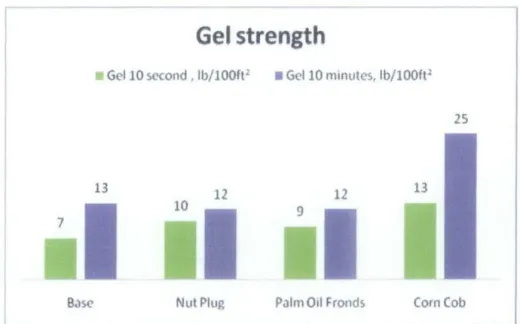

Gel strength

Plastic viscocity and Yield point

Based on the experiment result, nut plug is better in gel strength, it gives small changes in 10 sec and I 0 min. If we draw a graph, there will give a small slope value compared to based and comb head samples. An example of progressive gel strength is corn cob because the differences are quite large.

Filtration and Mud cake thickness

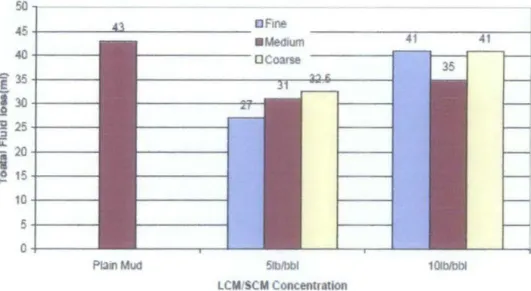

Comparison Between Size and Concentration of Palm Oil Fronds

CONCLUSION AND RECOMMENDATION

For this research, we are already testing the performance of palm oil leaves in drilling fluid as a lost circulation material. We attempt to compare their performance with current lost circulation materials such as nut plug and com cob. The first characteristic of palm oil leaves, which gives a better comparison with plugs from nuts and cobs, is the price.

This is because the palm oil leaves are a local product and easy to obtain and send to the field. From the test we can conclude that the palm oil leaves need to continue future studies. This is not to say that this product does not have the characteristics of lost circulation material, but before it is used in the oilfield industry, this product must have good properties and performance.

Based on the comparison, palm oil leaves give an approximate result with the nut plug product. For future studies, the author should recommend studies on the palm oil leaf in various aspects. Author should recommend that the palm oil leaves should roll at 170°F. This is to simulate in the drilling fluid in the actual well.

So from that test we can evaluate the rheological properties of our drilling fluid whether it changes that much or not. So from the test we can get the filtration that will penetrate our formation and how much our drilling fluid will affect our formation. I] http://www.drillfloor.com/Drilling_ fluid/Lost_ circulation.html [2]Method to reduce lost circulation in boreholes Heying, 2003.

3]Use cocoa bean shell as lost circulation material, Burts.Jr http://en.wikipedia.org/wiki/Lost_ circulation.

APPENDIXES

Instruction Manual

It attaches to the cell outlet valve stem and is secured with a retaining pin (Part No. Make sure the arrow on the cell cover lines up with the arrow on the test cell body. Turn the cell over and place it in the heating jacket with the inlet cover facing down.

The fluid level inside the cell should be flush with the bottom of the o-ring recess. Install and tighten the exhaust valve stem assembly with the em) ball valve into the exhaust cell cap on top of the cell. Hold the exhaust valve assembly with one hand and pull the stop on the heating jacket out of the way to lower the cell completely inside the heating jacket.

Rotate the cell until it clicks into place over the alignment pin on the bottom of the heating jacket. Insert a metal dial thermometer (Part No. 154-20) into the top of the cell, in the small hole. While the cell is heating to the desired temperature, open the inlet valve and apply the amount of pressure indicated in the 'Recommended Minimum Back Pressure' table.

When the closed cell is heated in the jacket, the pressure in the cell will increase rapidly due to the thermal expansion of the sample and the hydraulic fluid. After the cell has reached the required temperature, close the valve on the hydraulic pump and open the outlet valve. Use the pump to increase the pressure in the cell to the desired test pressure to begin filtration.

Repeat the process with the inlet valve, making sure all pressure has been released from the cell. Stroke the pump handle 1 to 3 times until the piston pushes the liquid out of the cell together with the ceramic disk. Remove the hydraulic pump manifold from the intake valve stem and remove the piston from the cell using the T-handle.