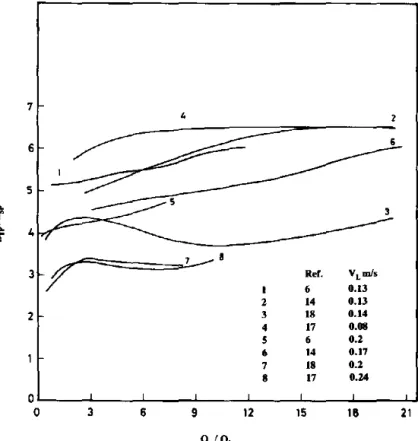

In general, the two-phase heat transfer coefficient increased with the increase in gas rate. The published data of many investigators [2,3,5,6] have shown that at very high liquid rates (much higher than 1 ml) the effect of gas addition on heat transfer coefficient is not significant. This may also explain the high jump in heat transfer coefficient when the first amount of gas is added (Figs. 2 and 3).

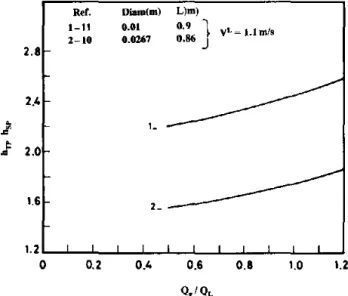

The effect of the exchanger diameter on the heat transfer coefficient in a two-phase system is similar to that in a single-phase system, i.e. an inverse relationship. As with single phase, the heat transfer coefficient in a two phase mixture increases with the increase in liquid velocity, with the gas velocity remaining constant [H~]. As with single phase, the heat transfer coefficient in a two phase mixture decreases with the increase in viscosity of the fluid as reported by some research.

The effect of increasing gas rate was generally not significant on the heat transfer coefficient [4]. Gas physical properties effect on two-phase heat transfer (,:effective has received very little attention in the literature. This is almost certainly due to the less pronounced effects of the gas properties on the heat transfer coefficient (which is very low) compared to the effects of fluid properties.

Aggour [22] was the only investigator who studied the effect of gas properties on the heat transfer coefficient.

![Fig. 3. nata of Mlsblyoshl [8] wllb air mhed with water prior the healed suction.](https://thumb-ap.123doks.com/thumbv2/azpdfco/8998263.146876/4.553.50.493.75.518/fig-nata-mlsblyoshl-wllb-water-prior-healed-suction.webp)

ANNULAR MIST I

It is actually a major (dependent) factor because many researchers correlated or plotted their heat transfer data according to different flow regimes. In contrast to the findings of others, the results of Johnson [13) in the horizontal pipe show a maximum in the heat transfer coefficient in the transition from the slug to the annular regime. Singk-pha!>c convective heat transfer can be easily treated as laminar, transient or turbulent flow.

It is always advisable to separate heat transfer in horiwntal tubes from that in vertical tubes because of its significant effect on the flow pattern [3,4J. Until the exact definition of the mixture Reynolds number is found, it is advisable to refer to the individual Reynolds numbers of the phases and combine the transition region with the laminar region where almost the same heat transfer trend has been discovered by some researchers [15 ,29]. Three different distinct regions according to the discharge arc adopted to explain the heat transfer trend in the two-phase mixture and the development of the heat transfer coefficient as a result of continuous gas addition.

By exploring some of the researchers' data, it has been concluded that the increase in the heat transfer coefficient is mainly due to the vortex mechanism of the flow from the gas bubbles. The heat transfer coefficient will increase here as a result of the thinning of the liquid film and will continue to increase with greater thinning of the liquid film as a result of increasing gas rate. The decrease in coefficient will continue with increasing gas void until single-phase gas is present, where the heat transfer coefficient is approximately less than that of the single-phase liquid initially present (Fig. 17 of 18).

The heat transfer trend here is undecided because this is basically a transition region from bubble to annular flow. In churn flow, a decrease in the heat transfer coefficient is expected because the presence of large: gas volumes in the bulk of the tube of undefined shape will result in dead gas pockets which will temporarily prevent the heat transfer to the mixture. If slug flow is present, the increase in heat transfer coefficient will depend on the type and shape of the slugs present.

For very long gas slugs, nearly annular type flow is present with liquid film thinning, leading to enhancement in heat transfer rate. While for short small slugs a decrease in heat transfer coefficient is found (Fig. 21) at low liquid rates, which is attributed to the resistance added by the gas phase to the original resistance of liquid phase while at high liquid levels. a continuous increase in heat transfer coefficient is detected [7,12]. It is worth mentioning here that Veda [20] itself did not provide an explanation for such a decrease in heat transfer coefficient.

Correlations of two-phase two-component heat transfer coefficient Correlations available in the literature can be divided into two sets based on the method of predicting the heat transfer coefficient of the two-phase mixture. Meanwhile, Kat~uhara [6] proposed a dimensionless correlation for two-phase heat transfer coefficient prediction in terms of.

![Fig. 18. Dala or Croolhlvs and Hend III].](https://thumb-ap.123doks.com/thumbv2/azpdfco/8998263.146876/19.546.54.487.60.324/fig-dala-croolhlvs-hend-iii.webp)

ANNULAA

When the physical properties of the mixture are correctly identified, this will lead to better correlation of the heat transfer data of such a complex mixture. The second trend in the relation of the two-phase heat transfer coefficient is in the form of improvement over that of the single-phase fluid (hTP / hsp). The main shortcoming in these correlations is the lack of fluid rate effect, where experimental evidence showed certain trends of increased heat transfer for certain fluid rates [4,14].

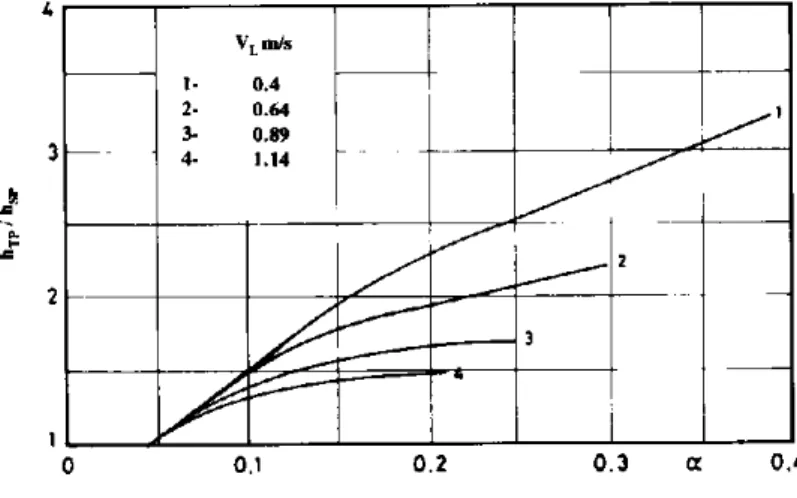

The correlation seems most promising for heat transfer improvement prediction because hot Gr and Re numbers have been considered in the correlation and are believed to have a significant effect on the heat transfer improvement. The scheme is identical to two-phase single-component mixture (boiling) .. dense from literature Fig. 15) shows that higher improvement in heat transfer coefficient is achieved for higher Prandtl number. Significant improvement in heat transfer can occur due to gas addition to flowing liquid phase.

The improvement in heat transfer is mainly due to the reduction of the thickness of the boundary layer; the increase in liquid velocity and the increase in the action of turbulence and mixing in the main stream, as a result of the addition of gas. The void fraction (gas holdup) is an important parameter to understand the mechanism of heat transfer enhancement in the two-phase mixture. Heat transfer is strongly related to the flow patterns that evolve under different gas and liquid phase flow conditions.

Available mixture heat transfer coefficient correlations lack satisfaction in accurately predicting the system. Flow model studies and two-phase hydrodynamics should be given more attention in future work to simulate the understanding of the heat transfer mechanism. The void fraction (gas holdup) approach needs further study as it is promising and may help in understanding and simplifying the two-phase heat transfer problem.

Factors influencing heat transfer improvement should be carefully studied with the same device, to minimize the expected errors of side parameters, to gain a full understanding of the effect of each individual factor under investigation. 34; Heat Transfer of a Cylinder in Cruss f'luw (Jf Buhhly Gus- Liquid Mixtures." Heat TransferSoviet ReuaI'ch, 14.34; Experimental Study of Heat Transfer in Upward and Downward Twn-Phase Flow of Air Hnd Oil Through 70mm Tubes ." Fountain Int.

34;Correlation of experimental data on local heat transfer during heating of air-l.liquid mixtures." Heal Traru!er-Sovlel ReSnlrrh. 34;Heat transfer in the inlet section of a pipe with two-phase flow." /leal Transfl!r-Soviet Resn1rch, 7, no.

![Fig. 11. Chut 110] results for air/water mixture flowJna upward.](https://thumb-ap.123doks.com/thumbv2/azpdfco/8998263.146876/12.554.141.446.148.505/fig-chut-results-air-water-mixture-flowjna-upward.webp)

![Fig. 12. Chue [10] reswu (or downRow.](https://thumb-ap.123doks.com/thumbv2/azpdfco/8998263.146876/13.549.95.433.60.434/fig-chue-reswu-or-downrow.webp)

![Fig. 13. Data of Kusorotov [18].](https://thumb-ap.123doks.com/thumbv2/azpdfco/8998263.146876/14.546.79.499.61.370/fig-data-of-kusorotov.webp)

![Fig. 15. AlaJunad [4] data for \'Uutll!~ liquids.](https://thumb-ap.123doks.com/thumbv2/azpdfco/8998263.146876/15.549.67.487.72.477/fig-alajunad-data-for-uutll-liquids.webp)

![Fig. 19. Data ofOshinowo [17] ror npnow.](https://thumb-ap.123doks.com/thumbv2/azpdfco/8998263.146876/20.553.58.485.51.689/fig-data-ofoshinowo-ror-npnow.webp)