Many of the implications for the technical, economic and environmental performance of recycled concrete have been identified through dynamic research on the subject. Many of the implications for the technical, economic and environmental performance of recycled concrete have been identified through the highly dynamic research on the subject.

Performance of Recycled Aggregate Concrete in Very Aggressive Environments

All four existing models failed to accurately predict RPC shrinkage and creep. However, good agreement was observed between the experimental results and the proposed numerical models for shrinkage and creep.

Reliability of Recycled Aggregate Concrete Structures

9] performed an analysis and modeling of shrinkage and creep of reactive powder concrete (RPC) with different steel fiber contents. It was revealed that the compressive strength and modulus of elasticity increased with increasing steel fiber content, in contrast to shrinkage and creep.

Life Cycle Assessment of Recycled Aggregate Concrete

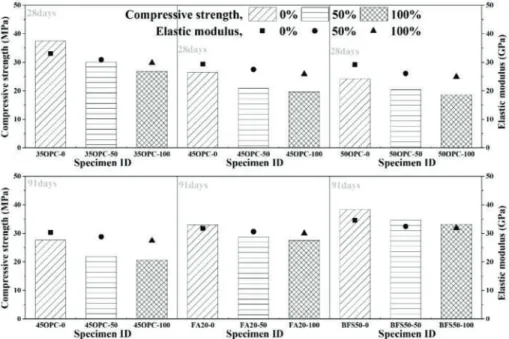

For 100% replacement, Young's modulus increased up to 10% and drying shrinkage increased up to 8%, while for 50% replacement, Young's modulus decreased up to 8% and drying shrinkage decreased up to 4%.

New Applications of Recycled Aggregate Concrete

Effect of recycled aggregate quality on bond behavior and shear strength of RC members.Appl. Using neural networks to determine the importance of aggregate characteristics affecting the mechanical properties of recycled aggregate concrete.

Performance Evaluation of Reinforced Recycled Aggregate Concrete Columns under Cyclic Loadings

Introduction

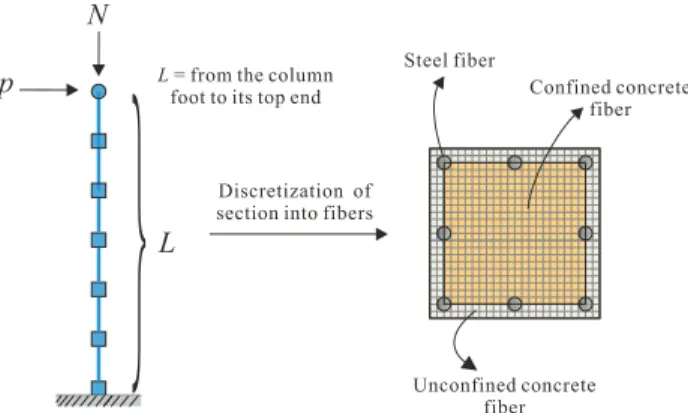

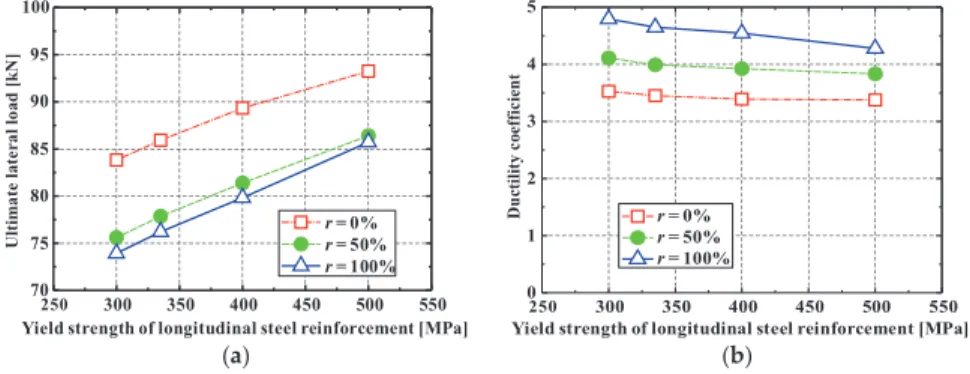

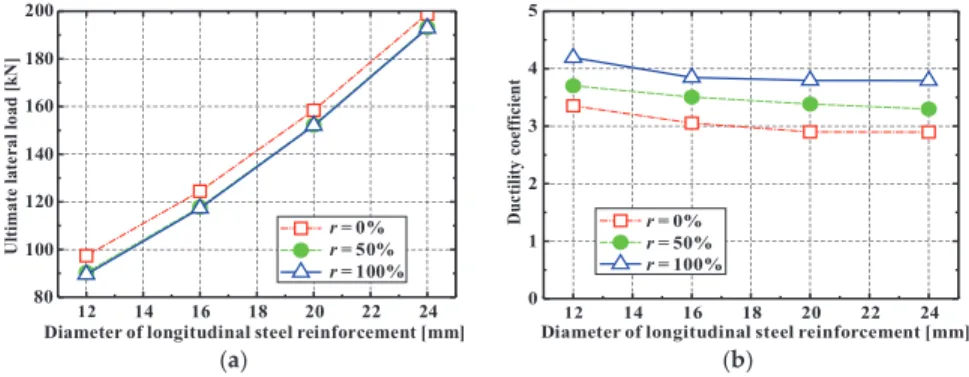

The main objectives of the present study are therefore twofold: (i) to investigate the modeling method of RRC columns under combined action of constant axial load and cyclic lateral load, based on a fiber-based numerical approach; (ii) to investigate the effects of a series of variables (such as the replacement ratio of RCAs, the mixing method of RAC, and the yield strength and area ratio of longitudinal reinforcing bars) on the seismic performance of RRC columns. The research outcomes presented in this study provide valuable insights into the seismic design of RRC columns.

Numerical Modelling

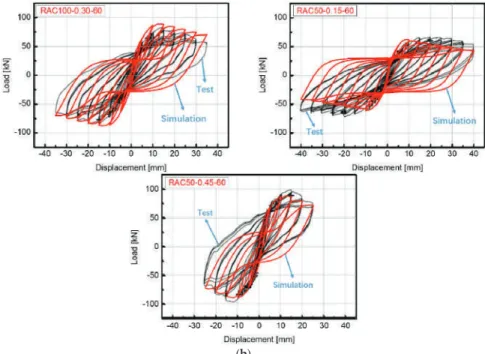

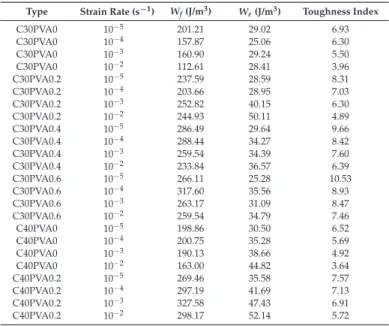

Figure 4 compares the lateral load-displacement hysteresis loops obtained from the experiments and the simulations. The lateral load carrying capacity and the ductility in Figure 4 are respectively defined as the maximum lateral load (Pu) and the displacement ductility coefficient (μ).

Parametric Investigation

The influence of area ratio of steel reinforcement (ρs=As/A) on the seismic performance of RRC columns was also discussed. A bidirectional loading scheme was used herein to investigate the seismic performance of RRC columns.

Grey Relational Analysis (GRA)

Figure 15 shows the hysteresis loops of RRC columns with different values of a, and the influences of a on Pu and μ are plotted in Figure 16. 1)α had no remarkable influence on the initial stiffness of RRC columns, (2)Pu of RRC columns subjected to the loading angle of 45◦ was lower than that of RRC columns with a loading angle of 0◦, and (3)μ of RRC columns with the loading angle of 4 5◦ was larger than ◦0 bars.

Conclusions

Indirect evaluation of the compressive strength of recycled aggregate concrete with high fly ash ratios.Mag. A database on the bending and shear strength of reinforced recycled concrete beams and comparison with predictions from Eurocode 2.Constr.

An Experimental Study on Flexural Behaviors of Reinforced Concrete Member Replaced Heavyweight

Materials and Methods 1. Materials

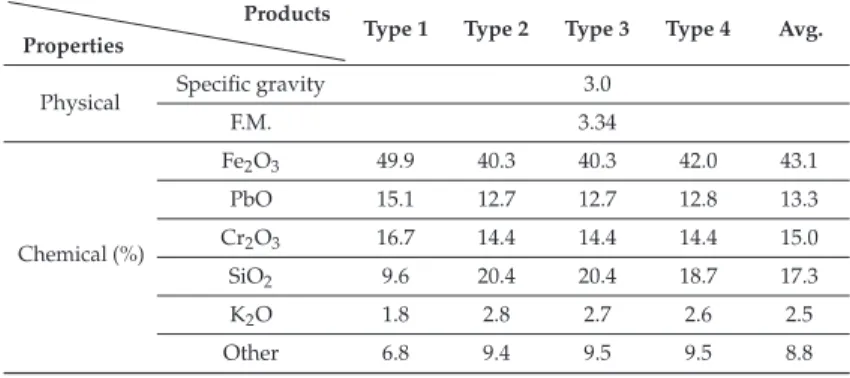

The physical and chemical compositions of the heavy glass waste are shown in Table 2, as determined by X-ray fluorescence. RC members were prepared to investigate the effect of the substitution ratio of heavyweight waste glass on the flexural behavior.

Results and Discussion

Meanwhile, the maximum load of the RC element was affected by the replacement ratio of heavyweight waste glass. The load-displacement curves of the RC members were affected by the replacement ratio of heavyweight waste glass.

Conclusions

Finally, the moment-curvature curves for the RC member were significantly reduced as all the fine aggregate was replaced by heavyweight waste glass. This trend is observed in all RC members, regardless of the ratio of water to binder and the substitution ratio of heavyweight waste glass. However, the neutral axis depth increases with the replacement ratio for heavyweight waste glass and the ratio of water to binder.

Thus, the depth of the neutral axis of the rectangular tension block in the RC element is expected to increase with decreasing compressive strength. Therefore, the use of heavy waste glass as fine aggregate requires concrete with high compressive strength. Characteristics of volume change and leaching of heavy metals in mortar samples, recycled heavy waste glass as fine aggregate.Constr.

An Experimental Study on Dynamic Mechanical Properties of Fiber-Reinforced Concrete under

The Sample Preparation for the FRC with PVA 1. Experimental Materials and Production

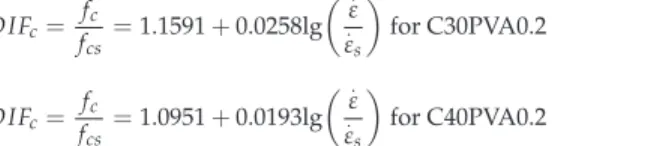

In the table, the types of concrete are named after two matrix strengths and different fiber contents. It was found that the key factor in the success of the experiment is the distribution of the fiber in concrete during the process of multiple adjustment of the fiber concrete. Based on a number of mixing experiments and the mixing experience of fiber concrete detailed in the literature, a fast and efficient laboratory mixing method is proposed.

Then the fiber and cement mixture is placed in the forced mixer for dry mixing with the coarse aggregate and fine aggregate mixture until the cement and fiber are evenly mixed, and the designated amount of water is added for wet mixing for 3 minutes. After the above process is completed, the fiber will be evenly distributed in the mixed FRC without knotting phenomena, which meets the construction requirements. In the experiment, a mm plastic mold was used to pour the concrete, and samples of the two different sized species were prepared by drilling out of the mold.

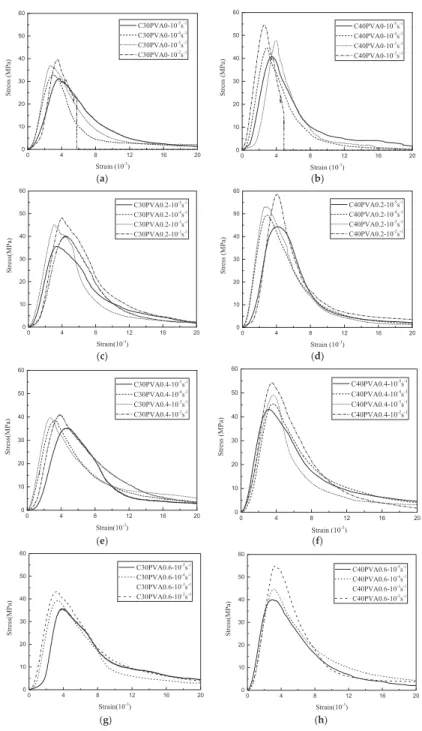

Experimental Results and Discussion 1. Compression Strength

The experimental results of the split tensile strength of fiber concrete at different strain rates are shown in Figures 6 and 7. Similar to the law of compressive strength, the addition of PVA can also increase the tensile strength of concrete. In general, the bridging effect of the fiber plays a major role at low strain rates.

An increase in the degree of deformation leads to an increase in the strength and modulus of elasticity of concrete. The increase in the effect of fibers on the toughness of concrete is more evident with increasing fiber content. The lower the strength of the matrix, the more obvious the reinforcing effect of the fibers on the concrete.

Effect of Recycled Aggregate Quality on the Bond Behavior and Shear Strength of RC Members

Experimental Program 1. Specimen for Bond Testing

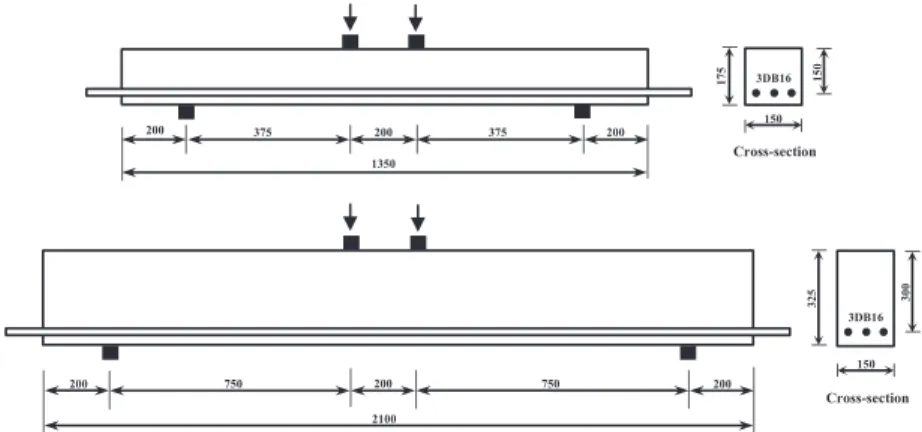

Sixty-four samples were prepared for pullout tests of steel reinforcement embedded in natural and recycled aggregate concrete. The shear behavior of AB beams using recycled aggregate concrete was investigated using two groups of AB rectangular beams without shear reinforcement. The length of the beam was extended by 200 mm at each end to prevent the steel reinforcement from collapsing due to the tension bond.

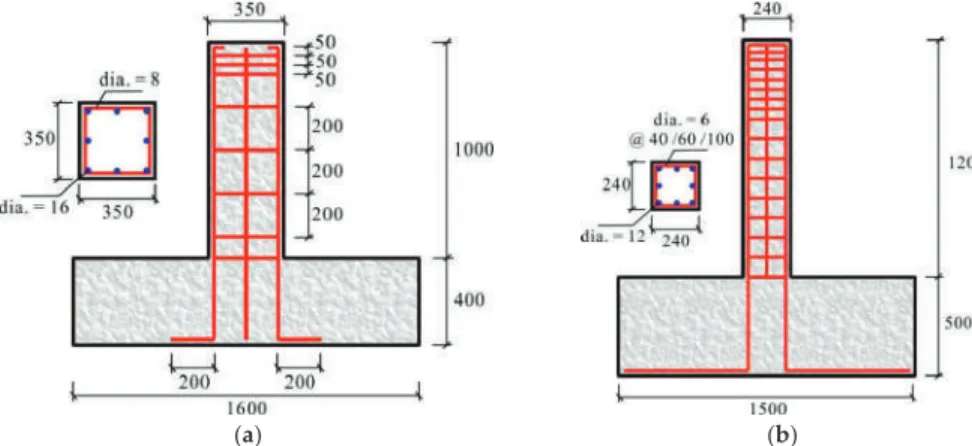

Although the density of natural and high-quality recycled coarse aggregate are very similar, the water absorption of high-quality recycled aggregate is slightly higher than that of natural aggregate. The texture of natural aggregate is very similar to that of coarse basalt aggregate, while high quality recycled aggregate is uniform and similar to marble stone. The strength of recycled aggregate concrete is controlled by (1) the strength of the aggregate, (2) the bond between the aggregate and the attached old mortar, (3) the bond between the aggregate and the new mortar, (4) the bond between the new mortar and the old mortar, and (5) the strength of the new mortar.

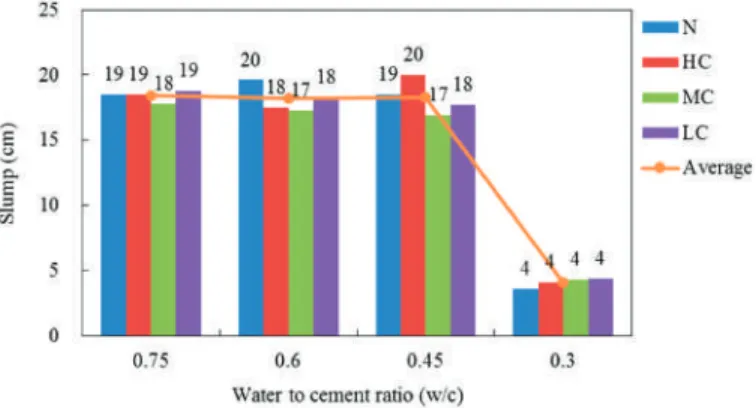

Experimental Results 1. Properties of Fresh Concrete

The compressive strength of the mortar with different water-to-cement ratios is shown in Figure 8. The effects of the recycled aggregate quality on the concrete tensile strength with different water-to-cement ratios are shown in Figure9. However, the split tensile strength of the natural aggregate concrete was very similar to that of the low-quality recycled aggregate concrete.

The results of the drying shrinkage of the natural and recycled aggregate concrete with different water-to-cement ratios are illustrated in Figure 12. The shear behavior of the RC beams with natural and recycled aggregate concrete was very similar. Experimental results of the shear strength of the RC beams using a natural and recycled aggregate concrete, without web reinforcement.

Discussions

The bond strength of the concrete with the low-quality recycled coarse aggregate is always the lowest, but the bond strength degradation can be ignored for the high- and medium-quality recycled aggregate concrete. The effect of high quality of recycled aggregate on shear strength should not be considered. In contrast, the effect of the high-quality recycled aggregate was almost equal to that of the 50% recycled aggregate replacement.

As a result, the workability is almost the same, regardless of the effect of recycled aggregate grades. In general, the strength of a high quality recycled concrete is the highest followed by a medium and low quality recycled aggregate concrete. The dynamic modulus of elasticity is always lower for lower grade recycled material, regardless of recycled material replacement.

Can We Truly Predict the Compressive Strength of Concrete without Knowing the Properties

Methodology

Then the geological nature of the aggregates (e.g. limestone, basalt, granite, sandstone) was considered to analyze the results. For example, the studies that did not provide the geological nature of the aggregates (Table 4—5th row) were still included in the analysis of the effect of the quality of the aggregates on the compressive strength of concrete when their WAs and densities were provided. The equation has been adjusted from the results of the table in the specification with R2 = 0.996.

In other words, w/cis is the ratio of water to cement; bfc is the average compressive strength of concrete in cylinders (150 mm diameter × 300 mm length) at 28 days (MPa). It is well known that the shapes and sizes of concrete samples (eg cube or cylinder) affect the results. Then the NA strength of the concrete was classified according to the quality of the aggregates.

Results

7] (Section 1), Figure 6 is drawn to show all the factors that can influence the influence of the aggregate on the quality of concrete. This shows that the quality of the aggregates can significantly affect the ultimate strength of concrete. Therefore, again, the quality of the aggregates, namely their LA abrasion, controls the ultimate strength of concrete.

Properties of concrete with recycled aggregates: Influence of properties of the aggregates and their interpretation. Rheological behavior of concrete made with fine recycled concrete aggregates—Influence of the superplasticizer.Constr. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr.

A Study on the Properties of Recycled Aggregate Concrete and Its Production Facilities

- Scope and Method of Research

- Development of the Technology to Improve the Recycled Fine Aggregate Quality 1. Outline

- Development of the Technology to Improve the Quality of the Mixed Aggregates 1. Outline

- Mechanical Properties of the Recycled Aggregates Using Concrete and Durability Characteristics

- Conclusions

Furthermore, the density and absorption rate of recycled fine aggregate varies depending on the mortar content attached to the aggregate surface. Furthermore, the density and absorption rate of recycled fine aggregate varies, depending on the mortar content attached to the aggregate surface. Air volume increased, in both the general strength and high strength territory, as the replacement rate of recycled coarse aggregate increased.

After replacement of the recycled coarse aggregate and recycled fine aggregate, before and after modification, the compressive strengths were measured. This confirmed that the quality of the recycled fine aggregate had improved. For the recycled coarse aggregate and the recycled fine aggregate after modification, the length variation ratio decreased as the volume of the recycled aggregate increased.

![Figure 1. Changes in the waste material volume in Korea [1].](https://thumb-ap.123doks.com/thumbv2/1libvncom/9201128.0/112.723.176.546.162.355/figure-changes-waste-material-volume-korea.webp)