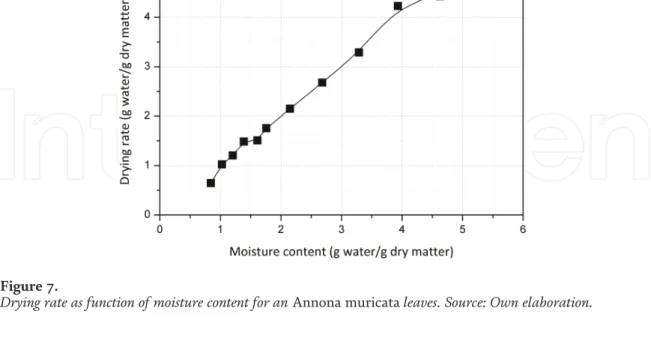

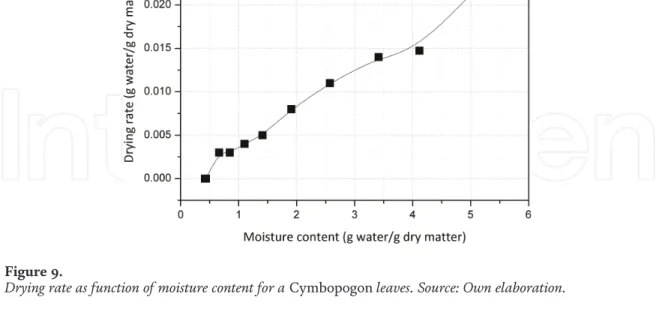

Moisture tests were performed on fresh and dehydrated leaves; in all cases the average initial humidity was 73.8%, the maximum readings were 79.58% and the minimum readings were 68.2%. It can be seen in Figure 4 that the moisture content started at 2.93 g water/g dry matter, and ended between 0.201 and 0.256. Figure 5 shows the moisture content as a function of the drying rate; in this case no constant rate period was observed.

Computational analysis

Figure 11 shows the thermal behavior of the dehydrator, which can be separated into three zones: left, middle and right. The temperatures achieved in the solar hybridization dryer remained stable for most of the day, fluctuating between 45 and 50 °C (Figures 3 and 12), which, as indicated in the reviewed literature, is optimal for preventing the loss of important vegetable and medicinal properties. plants [46, 50].

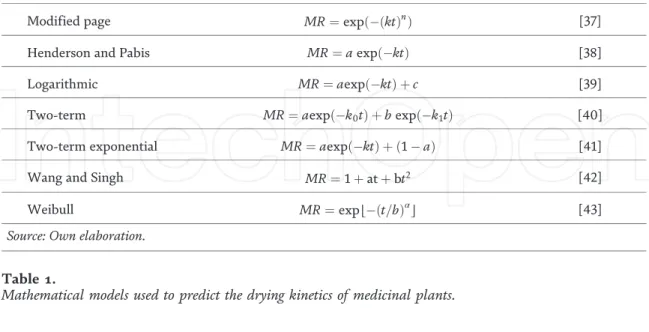

Mathematical modeling

Conclusion

The average final moisture content of the three medicinal plants varied between 0.8 and 1.5 g water/g dry matter. Experimental investigation of the performance of a new solar dryer for drying medicinal plants in the Western Himalayan region.

TOP 1%

Introduction

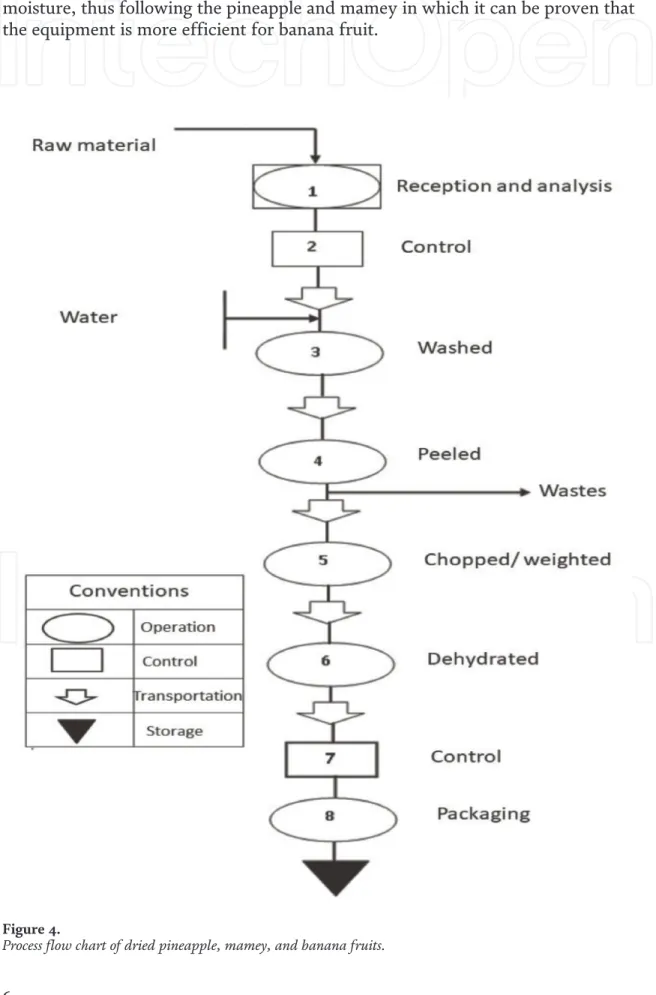

In the canton of Bolivar of the city of Calceta in the province of Manabí, Ecuador, the fruits pineapple (Ananas comosus(L.) Merr.), mamey (Mammea americanaL.) and banana (Musa paradisiacaL.) are abundant but due to a high sugar content and acid content have a limited shelf life and are in many cases wasted. Sunlight from past and present serves for fruit drying as a post-harvest treatment or preservation activity which, when purchased with other activities for the same purpose, such as chemical treatments, refrigeration, priority canning for use and collection, even with drying in the solar, results in a decrease in energy expenditures and could therefore reach areas where other energy supplies would not exist or would not even exist (see [3]). A conventional dehydrated fruit is inferior in organoleptic characteristics to that of the fresh fruit from which it is derived, affecting its color, texture and other peculiarities.

The industrial-scale study, a simple convective solar drying process of pineapple, such as a round or circular economy tactic for countries in progress, is specified, which is paramount to the tactic offered. It built a manual solar dryer that operates in indirect heat mode; it was also modified to improve its gain. According to these cases, the objective of the research was to design and develop an empirical and practical distribution for solar dryers and drying tests to preserve the fruits and prolong the shelf life, as well as organoleptic and nutritional properties with samples of pineapple, mamey and banana fruits in the city of Calceta, Bolívar Canton in the province of Manabí , Ecuador.

Climate data collection

Design and construction of solar dryer

- System dimensioning .1 Collector area calculation

RTDs were created at the inlet and outlet of the collector (Tin, Tout), outside to calculate the ambient temperature (Tamb) (see [8]). The tools treated in the test consisted of sterilization at 180°C for 60 minutes according to the Medical Research Council; the cutting of fruits was done in a sterilized part previously rinsed with neutral soap; to quickly immerse the fruits in water with ascorbic acid C6H8O6 to prevent oxidation and then put in the dryer, start the test by placing the dehydrator; feel this part of the dryer, facing north, so that the collector receives sunlight from east to west. Three repetitions are performed for each fruit, which are delayed from 3 to 5 days for each repetition.

At the end of each day, the samples are wrapped in foil and tightly sealed and stored. Statistical analysis was performed with a complete or randomized design with therapy in each of the treatments; The units are practical or experimental consisting of 4 kg of dried fruit. To identify significant differences in treatments, as well as statistical significance for all comparisons, p < 0.05 was used.

Results

- Bromatological analysis of fruits evaluated

- System efficiency in each of the fruits

- Microorganism tests to learn about fruit shelf life

- Sensory evaluation with scale 1–5

- Relationship and recoil tests concerning the access temperature in dryer with the receiver access sheet (collector), as well as the radiation with the

- Examination of the process by psychometric spread

- Through these ante-laid characterizations, the movement of the mass fluids was established using the following equations

So, according to this premise, the model exposes a variability of 61.3763% in the drying temperature °C, and the correlation coefficient is equal to 0.78343; therefore, it indicates a moderately strong relationship between the variables, and the standard error evaluation in the calculation shows that the standard deviation of the residuals is 2.51359. Therefore, depending on the p-value in ANOVA less than 0.01, there is a significant statistical relationship between the drying T°C and the T°C of the collector with a confidence level of 99%. The correlation coefficient is equal to 0.693408; therefore, it indicates a moderately strong relationship between the variables, and the sample standard error evaluation in the calculation shows that the standard deviation of the residuals is 23.4888 (Fig. 9a).

The R2, according to the model, states that there is 55.6423% variability in DMM, the correlation coefficient equals 0.745938; therefore, it shows a moderately dynamic relationship between the variables, and the standard error evaluation shows that the standard deviation of the residuals is 12.3989 (Fig. 9b), as is the mean absolute error (AAE) of 10.7287. Examination of the table in collector and solar dryer in the form of a psychometric chart. 2-3 into the inlet dryer, the humidification of the air and the easy cooling were carried out by the activities of water evaporation in the fruits of pineapple, mamey and banana.

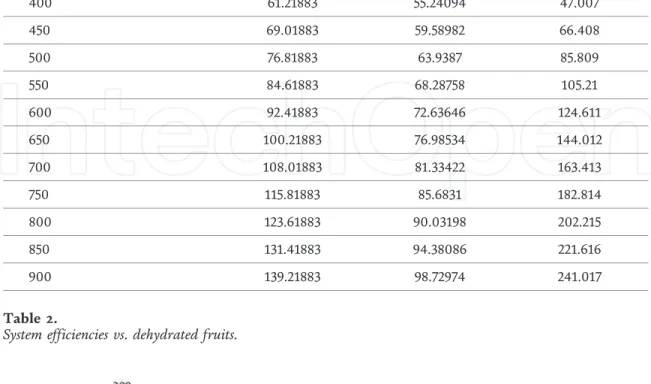

Debate

Having balanced everything, all this gives more accurate and complete assessments of the duration as useful life of dried fruits, in pineapple, mamey and banana separately, from 15-30 days of the dehydration process in repetitions, the amount of shelf life of banana fruit, by sample, see Figure 5, as fitted model linear regressions of banana fruit low humidity in this regard with radiation showed a duration of 109 days, the moisture content of pineapple was reduced from the amount or mean riginaria by 86.36% up to a final amount of 21.07%; mamey fluctuated between 79.3 and 21.13% and bananas fluctuated proportionally between 80.22 and 10.35%. The protein content, as well as fiber, was known to show a significant increase in the previous and subsequent periods of dehydration, is understood as a derivative of fresh pineapple fruit with 0.67% protein and fiber with 2.45% in the fresh phase, together , in dehydrated period, had an increase of 2.45 and 3.63%.

Termination

The main advantages related to the convective drying of the granular materials in the multi-stage dryers with inclined perforated shelves were presented. Convective drying is one of the most effective methods of dispersing material dehydration in the chemical, pharmaceutical, mining and other industrial sectors [1–6]. Therefore, drying is the only method for industries to achieve the required product quality.

Approximation of the hydrodynamic model of flows in the unit to the ideal displacement model. Therefore, it is necessary to make maximum use of the desiccant's thermal potential at every contact with dispersed material. It can be achieved by using the multi-stage drying devices with vertical cutting of the working area by means of the perforated shelf elements [7, 8, 11].

Theoretical basics

- Hydrodynamic calculation

- Calculation of heat-mass transfer

- Calculation of the kinetics and drying efficiency

The racks increase the residence time of the dried material particles, either thrown to the bottom of the device or carried upwards from it. The free space between the ends of the shelves and the walls of the device does not require special flow from the upper shelf to the lower one. Moisture of the desiccant inі stage of the dryer (kg water / kg material).

The empirical function of the effect of compression on the residence time of the particle in the working space of the device. It is responsible for displaying the main menu, for the main calculation of gas flow, and for. Let us use the following algorithm to calculate the kinetic parameter of the moisture removal (the moisture living capacity coefficient).

Visualization of results and discussion 1 Hydrodynamics

- Heat-mass transfer

The calculated values of the mass transfer coefficient β from Eq. 16) depending on the speed of the movement of the desiccant is shown in Figure 8. Influence of the desiccant recirculation method on the change of the moisture content of the disperse material. Influence of desiccant recirculation method on the change of desiccant moisture content.

Influence of the desiccant recirculation method on the temperature change of the disperse material. The organization of the movement of the desiccant can have a great influence on the quality indicators of the dried material and the characteristics of the drying. Block diagram of the algorithm to calculate the multi-stage gravity shelf dryer is represented in Figure 15.

Experimental research and practical implementation

Photograph of the hydrodynamic modes of the rack dryer: (а) "gravitational falling bed" regime and (b) "weighted bed" regime. Effect of gas flow rate on the intensity of interphase heat transfer: (1) "gravitationally falling layer". Fine crystalline potassium chloride containing 7-10% of the small fraction with a particle size of less than 100 μm in the initial mixture, according to

Coarse crystalline potassium chloride, containing 4-10% of the minor fraction with a particle size of less than 100μm in the initial mixture, had 2-. 5% of the small fraction in the final product (subduction) with a gas flow rate of 1.3-1.4 m/s and 58-65% of the small fraction in ablation. When the gas flow rate exceeds 1.5 m/s in the final product, the small fraction is practically absent, and the content of the coarse fraction (more than 100 μm) in the ablation is 3-5%.

Conclusions

The working path of the pneumatic pipe dryer, in which energy is expended to accelerate and lift the drying material, has a hydraulic resistance of 1600–2000 Pa. The small fraction was completely extracted from the polydisperse mixture of granulated superphosphate containing up to 20% of the small fraction with particle sizes less than 1 mm, after processing in the shelf device at a gas flow velocity of 3.5–3.8 m/s, in the ablation. To prevent the coarse fraction ablation by the gas flow and to increase the residence time of particles in the separation space for the drying of the ablative fractions, the upper part with a constant intersection was replaced with a conical free intersection [16] or with shelf contact elements [17].

Thus, rack dryers achieve a higher technological effect than typical designs of fluidized bed dryers and pneumatic tube dryers, with less energy, capital costs and size. Methods of Mechanical System Analysis," Cultural and Educational Agency of the Slovak Republic (KEGA) Project no. 3.0), which permits unrestricted use, distribution and reproduction in any medium, provided that the original work is properly cited.