In June 1998, a waste reduction club for the metalworking industry was established in the DMA. In addition to successfully raising awareness and promoting the concept of waste reduction, the waste reduction club has also resulted in improved relations between the metalworking industry and Metro, and among club members.

- WATER: THE SOUTH AFRICAN SITUATION

- SUSTAINABLE DEVELOPMENT

- AGENDA 21 AND LOCAL AGENDA 21

- ENVIRONMENTAL PROBLEMS IN THE DURBAN METROPOLITAN AREA The Durban Metropolitan Area (DMA) covers an area of approximately I 300 square kilometres

- WASTE MINIMISATION AND WASTE MINIMISATION CLUBS

- PROJECT OBJECTIVES

- HYPOTHESIS

- RESEARCH PROCEDURE

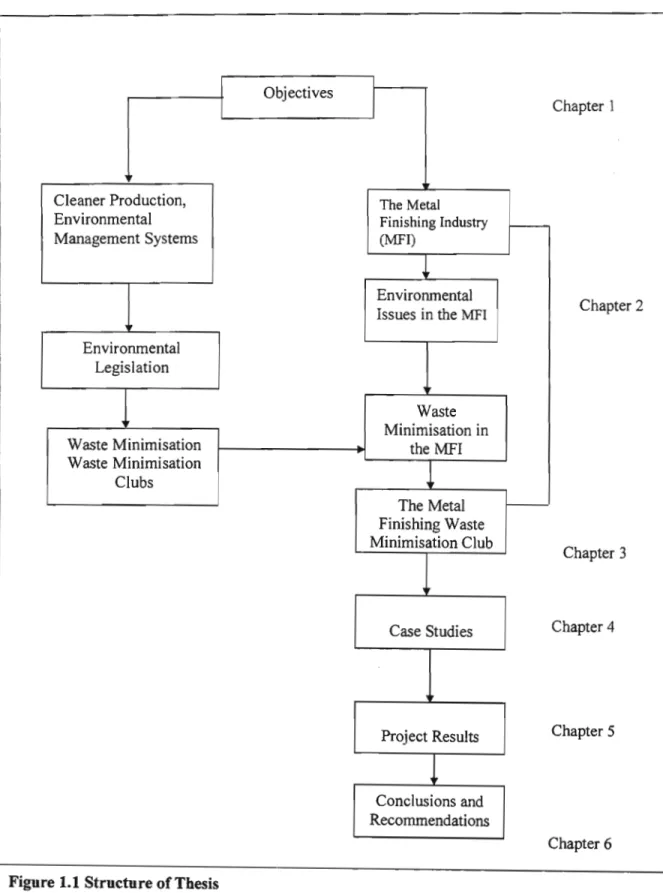

- THESIS STRUCTURE

The Management Strategy (1998) has identified waste minimization as an important instrument to assist sustainable development in the country. The main source of information was books, followed by publications and manuals dealing with the metal finishing industry and waste minimisation.

LITERATURE SURVEY

CLEANER PRODUCTION

Cleaner production can be the most efficient way to operate processes, produce products and deliver services. The basis of cleaner production is the reduction of water, resource and energy consumption and the reduction of waste.

ENVIRONMENTAL MANAGEMENT SYSTEMS

This will ensure the efficient operation of a company's cleaner production program and make it possible to achieve the program's goals. Emphasis is placed on policy as this provides the direction for the rest of the management system.

ENVIRONMENTAL REGULATIONS

However, the funding of the individual projects is the responsibility of the Council for Recycling and Cleaner Technology. The implementation of these legislative documents is the responsibility of the country's relevant supervisory bodies.

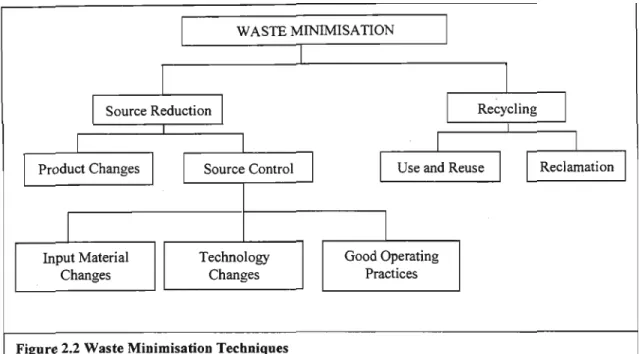

WASTE MINIMISATION

The waste reduction program IS an organized, comprehensive and continuous effort to systematically reduce the generation of waste. The official management directive policy statement is used to inform the company's employees about the waste reduction program.

WASTE MINIMISATION CLUBS

Site reviews were conducted by consultants who identified a number of waste minimization options resulting in an improved environmental condition and significant financial savings for club members. The development of such a methodology would be useful for the further establishment of waste minimization clubs.

MONITORING AND TARGETING

Montage then identifies the parts of the site that are performing better than expected and those that are underperforming. Enviros March, 1999] Thus, the use of a monitoring and targeting program could form an integral part of a waste minimization program.

SMALL AND MEDIUM SIZED ENTERPRISES

Montage, the software developed by the United Kingdom (UK) consultancy, Enviros March, is a management tool used to control utility and material consumption in commercial and industrial sites. Reports and charts enable identification and analysis of the underlying causes of good and poor performance.

THE METAL FINISHING INDUSTRY

- METAL FINISIDNG PROCESSES

- ENVIRONMENTAL ISSUES RELATED TO THE METAL FINISHING INDUSTRY

- WASTE GENERATED FROM THE INDUSTRY

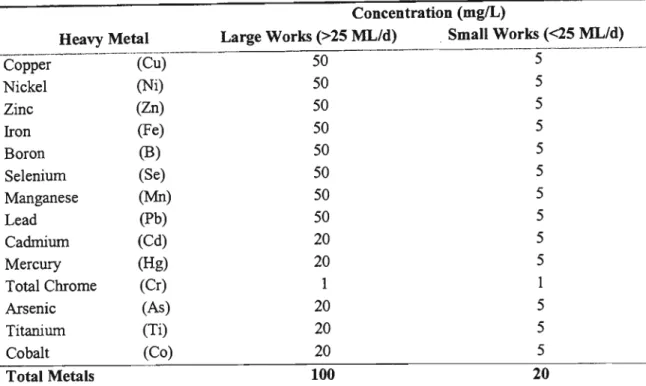

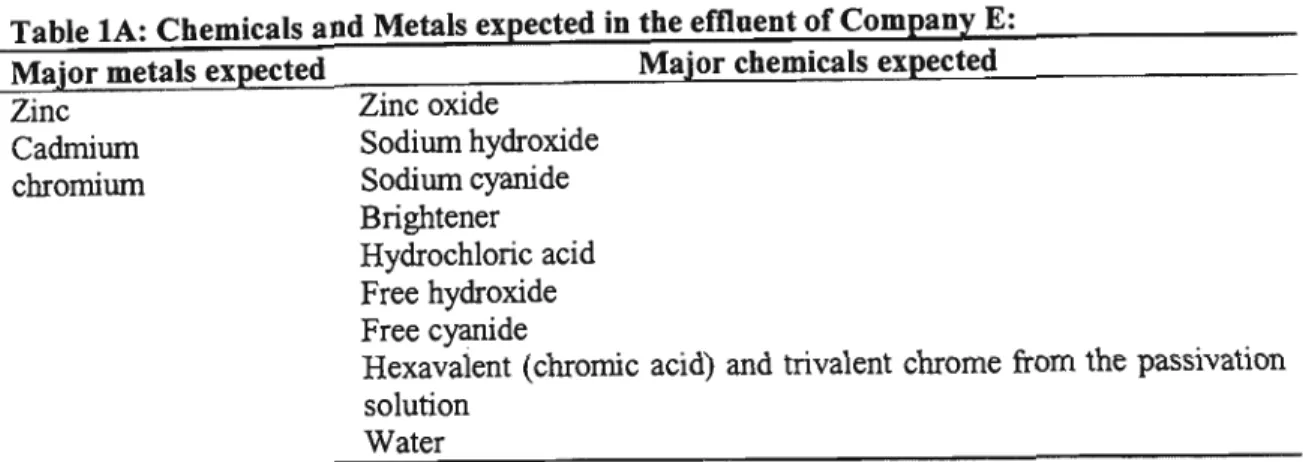

A large proportion of the chemicals used in the plating industry end up as waste due to inefficient rinsing. The free cyanide found in electroplating wastewater is one of the most toxic pollutants in the industry.

![Figure 2.4: Waste Generated from a Metal Finishing Enterprise [UNEP WG, 1998]](https://thumb-ap.123doks.com/thumbv2/pubpdfnet/10631163.0/39.816.106.745.120.596/figure-waste-generated-from-metal-finishing-enterprise-unep.webp)

WASTE MINIMISATION IN THE METAL FINISHING INDUSTRY

- Product and Input Material Changes

Accumulation of contaminants in electroplating baths reduces the effectiveness of bath solutions. This can be achieved by mixing the rinse water or mixing the workpieces during the rinse.

THE METAL FOOSHING WASTE MINIMISATION CLUB

- THE SOUTH AFRICAN METAL FINISHING INDUSTRY

- CHALLENGES FACING THE METAL FINISHING INDUSTRY

- ESTABLISHMENT OF THE METAL FINISHING WASTE MINIMISATION CLUB

- PROFILE OF CLUB MEMBERS

- INITIAL ASSESSMENTS

- CLUB MEETINGS AND TRAINING

- CLUB CONSTITUTION

- FOLLOW-UP SITE VISITS

- DATABASE

- IDENTIFICATION OF BARRIERS AND DRIVERS

- SURVEYS

- NEWSLETTER

- MONITORING AND TARGETING

- CASE STUDIES

- EXTERNAL ASSISTANCE

- SUMMARY

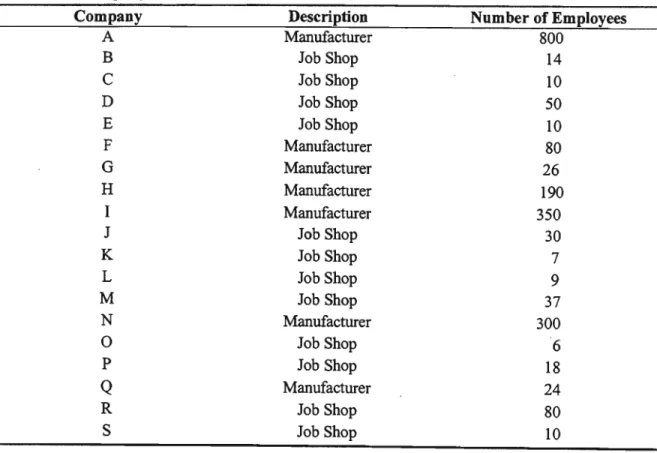

The Metal Finishing Waste Reduction Club (WMC) was formed in the DMA in June 1998 as a result of a meeting between local government authorities and 81 representatives of the local metal finishing industry. The main goal of the declaration was the commitment of the members to the implementation of the waste reduction program.

CASE STUDIES

- METHODOLOGY

- Obtaining Management Commitment

- Electing the Project Champion

- Assessment

- Feasibility Analysis

- Implementation of Waste Minimisation Options

- COMPANY A

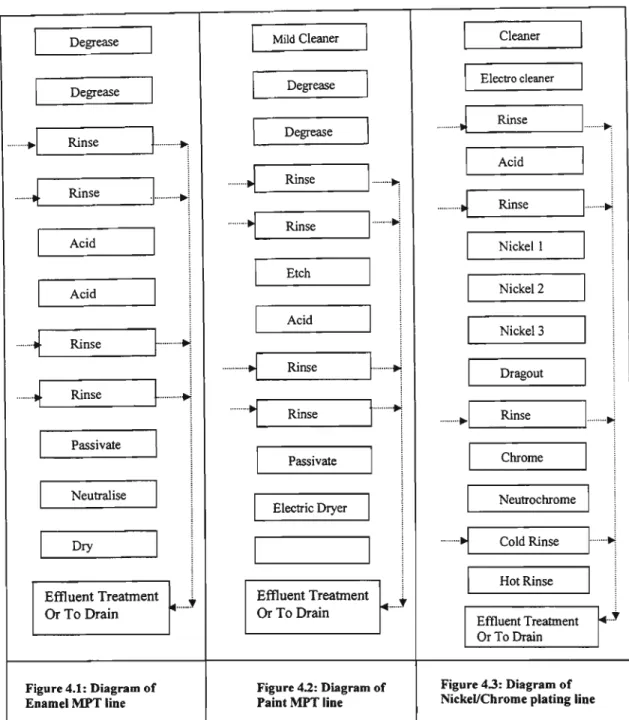

- Process Description

- Waste Minimisation Programme

- ECONOMIC BENEFITS

- COMPANY B

- COMPANY C

- COMPANY D

- DISCUSSION

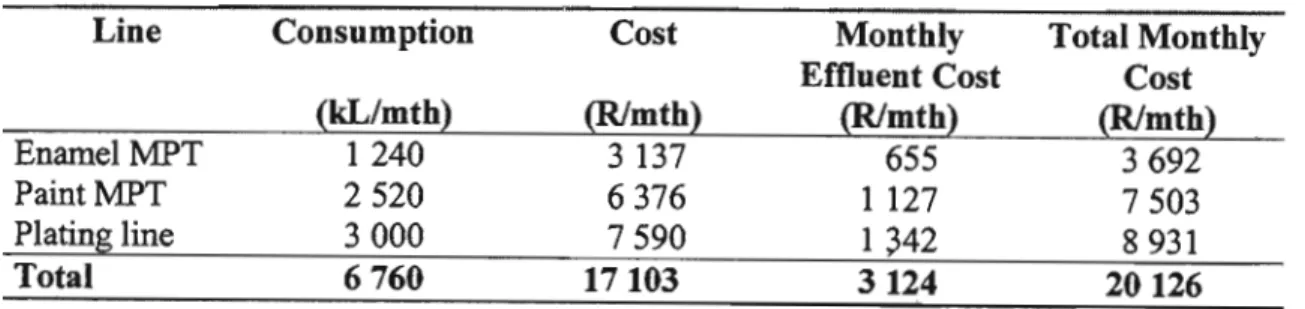

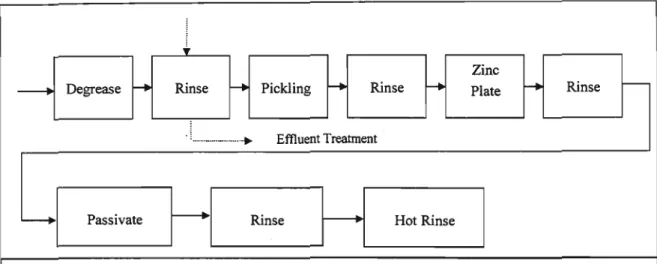

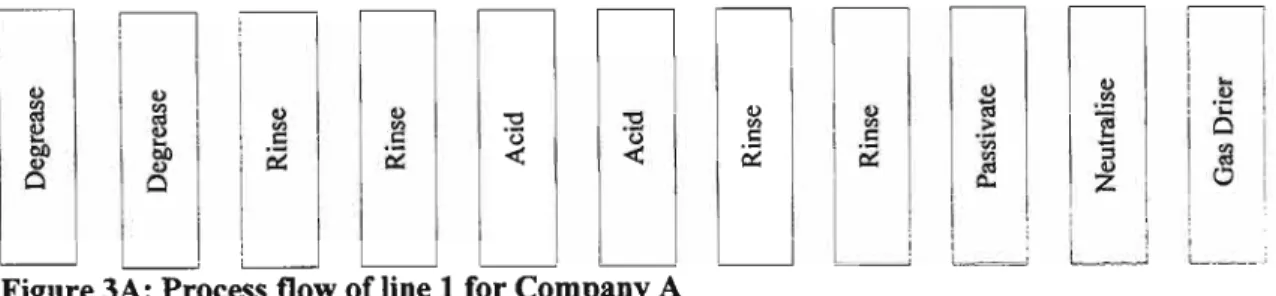

Most of the waste water generated by the company came from the on-site metal finishing processes. The company had two project managers (the plating manager and a maintenance officer) who worked together to coordinate waste minimization activities. Water, chemical and energy consumption and wastewater management were of great importance to the company.

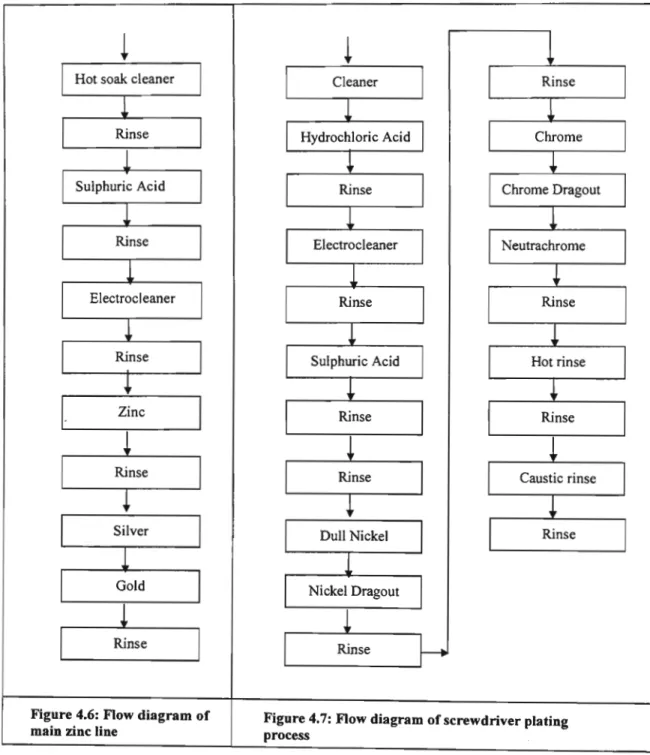

The high consumption of process chemicals and the loss of metal to drain were of particular concern to the company. The company has also investigated the use of ultrafiltration to extend the life of the degreasing baths. The investigation focused on the main sink line as the consumption of water and chemicals and the generation of waste water were of concern to the company.

The company has been a member of the waste minimization club since its inception, and its management has signed a declaration of commitment to waste minimisation. The company was approximately 20 years old and had 50 employees at the time of the study.

CHAPTER. 5 - PROJECT RESULTS

- INITIAL ASSESSMENTS

- Hypothesis

- Observations and Suggestions from Initial Audits

- SITE VISITS

- MEETINGS

- BARRIERS AND DRIVERS

- SURVEYS

- CASE STUDIES

- WASTE MINIMISATION OPTIONS FOR THE ENTIRE CLUB

It provided a better understanding of each company's capacity to implement a waste minimization program. It was noted that the companies that put the most effort into waste minimization programs attended more meetings. As the club progressed, it became clear that the lack of information or knowledge was not a major barrier to implementing waste minimization.

Further general agreement focused on the issue of the role of waste minimization clubs within the arena of. This was mainly due to the fact that the project champion was also the owner of the company and was very involved in implementing waste minimization. This slowed down the progress of the waste minimization program and made monitoring and targeting difficult.

It was therefore suggested that the bulk of the options implemented by the club members would be household improvements. For companies T to Z, it was not known whether the identified waste minimization options had been implemented in November 2000.

- FINANCIAL BENEFITS

- ENVIRONMENTAL BENEFITS

- MONITORING AND TARGETING

- ADDITIONAL OUTCOMES FROM CLUB ACTIVITIES

- PROMOTING WASTE MINIMISATION AND WASTE MINIMISATION CLUBS

- ANALYSIS OF CLUB APPROACH

- SUMMARY

- CONCLUSIONS

- SUMMARY OF FINDINGS

- REALISATION OF OBJECTIVES

- RECOMMENDATIONS

One of the main drivers for companies implementing waste reduction options has been the incentive to achieve savings. The purpose of the association was to deal with issues of common importance to metalworkers, such as waste reduction and waste treatment. In the beginning, it was difficult to convince companies about the benefits of waste reduction for their companies.

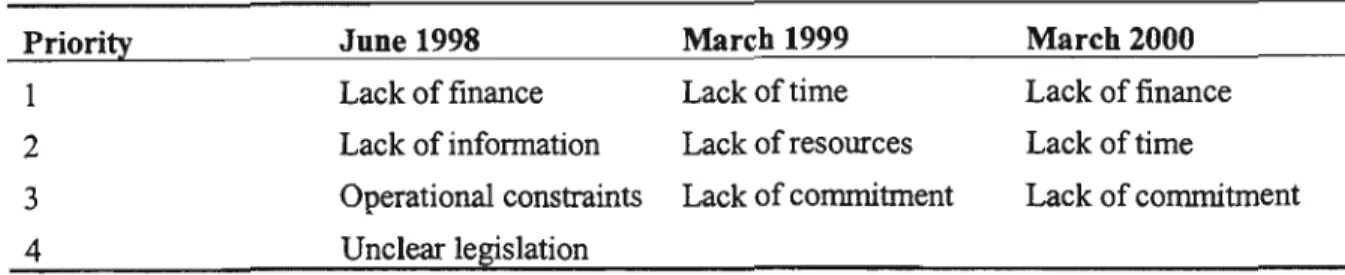

Thus, a major difficulty experienced while running the club was data collection during waste minimization assessments. The club helped build capacity for waste minimization within the metal finishing industry and other organizations. This is mainly a result of the lack of time available for waste minimization activities, especially in smaller enterprises.

The club successfully promoted and increased awareness of waste reduction in the metalworking industry. Waste reduction advocate, company management and store employees should be trained to implement waste reduction.

APPENDIX 1: INITIAL WASTE MINIMISATION

ASSESSMENT REPORTS FOR COMPANIES E TO Z

There is no evidence that the solution is • Finished concrete floors should be covered with a neutralized etc. Cracked bathtubs should be replaced as soon as possible before the cracks propagate and unnecessary spillage occurs. A fixed time must be set aside for maintenance where the plant is shut down, the contents of the baths, tanks are dumped and then the baths, tanks are cleaned.

A timer should be installed in each bath or one timer connected to all three tubs. Keep the baskets above the bath and not above the floor when dripping. The two flow rinse tanks in the galvanizing process (pipe coating) should be replaced with a countercurrent rinse tank system.

The water used in the cooling system should be stored in a tank and then used in the flushing tanks as needed. Efforts should be made to design lids that cover as much of the tank surface as possible.

SPIN

CASTING

BARRIERS AND DRIVERS

APPENDIX 3:. CASE STUDIES

Spraying or jet rinsing offers the following benefits: . a decrease in water consumption. b) the cost of concentrating the solution prior to recycling in the plating bath is reduced. The company has two project champions, the manager and the owner, who are committed to implementing waste minimization. The company was keen to implement waste minimization options and improve site conditions.

The project champion is the owner of the business who has committed to implementing waste minimization. A statement of commitment to waste minimization has been signed by the owner of the business, who was initially skeptical of the benefits of implementing waste minimization. As a result, the company has spent time and resources implementing a waste minimization program, and the project manager (owner) has convinced other club members of the benefits of waste minimization.

Municipal water consumption and costs prior to the implementation of waste minimization are given in Table 3J. Based on the above problems, a number of waste reduction options were proposed during initial company visits.

SURVEYS CONDUCTED IN 1999 AND 2000

- Company is 22 years old 3. -

- Joined when the club formed

- Good club to be involved in, beneficial for the company

- The representative is involved in various areas of management

- Didn't really know anything about waste min before being introduced to waste min in the club enviromnent

- Other benefits to the waste min club are increased knowledge and the practices that can help to

- Through the club theoretical and practical knowledge of waste min has been vastly increased

- Doesn't really know about how the club got started, motivation for starting

- Doesn't think there should be any changes

- Belonging to the club has meant that a great amount of knowledge and sharing of information so that waste min can take place. Meetings and consultants are a way of getting information

- Clubs are a good way of spreading information and they could be used to cut down on the wrong actions in other industries

- Relationships are very beneficial

- Clubs mean that industry can contribute to environmental causes by being involved in waste minimisation

- Since the Club was formed

- To avoid fines and prosecution form the law due to exceeding metro regulations, to help the environment

- Knows vaguely ofHammarsdale club beginning and possibly some waste minimisation being carried on in Pietermaritzburg

- Learnt a lot through the club and realises that waste min is a long term process that boils down to good housekeeping to make sure that your company maintains its waste min procedures,

- Metro was initially not veI)' interested and possibly a bit sceptical because they have their own agenda but now that they see the difference being made they view it as beneficial for them

- Sbaringofknowledge

- Thought it was a good idea for businessmen to get together and exchange ideas

- Works Director

- Believed that his company was always doing a good job in reducing waste

- Only considered cost reductions

- Views did not change after joining the club

- The potential for continuing is good since the club is vital for this industry

- If we cease to have facilitators in the future

- No suggestions for improvement 16. -

- Some relationships existed before joining the club, but none have formed since

- Customers

- Joined when the club first started.

- Joined when the company was approached by the PRG. Was already aware of the need to be environmentally friendly and saw the club as a way of educating himself and as a way of

- The representative is the manager of the company

- Did not know too much about waste minimisation initially in terms of the practical activities that can be carried out to minimise waste

- Apart from cost, benefits were knowing what was going on in industry and getting suggestions and help to reduce the waste

- Nocomment

- Seems to think that the club began as a combined effort of Durban Metro and the University of Natal

- Thinks that the club has enormous potential for continuing into the future and is veI)' enthusiastic

- Feels that there are no constraints to the club continuing into the future

- Would make no changes to the functioning and structure of the club. Feels that the informal structure and functioning of the club is an advantage because it allows members to express their

- Owner

- Deposit waste in Joburg therefore less waste being produced will give financial benefits

- Members get benefits from each other through the club, including shared knowledge, which is in addition to benefits of waste minimisation

- Has been involved at the beginning but didn't explain how the club actually got off the ground

- Membership has been beneficial for companies therefore potential for continuing is great 12. Constraints are the time available for dedicating to the project by industry, which prevents

- No changes to structure but possibly meetings in the middle of the month rather than at month end

- Enabled finding out problems and procedure in other companies in beneficial and also other companies solutions

- Clubs are useful and positive mechanisms

- Club acts as a go-between between industry and the regulators such as metro and water affairs and enables wider monitoring of effluent etc

- So that compliance with regulations can be adhered to

- To improve processes and gain knowledge

- Did not quite understand what waste minimisation was

- Benefit from the sharing of knowledge and ideas

- Had a better understanding of the concept of WM

- Lack of manpower and time

- No need for improvement. The club is functioning quite well

- Previously did not have much knowledge

- No business relationships were formed

- Company is 55 years old 3. Durban

- Joined when the club started in mid 1998

- Joined the club in order to get abreast with information and with what is going on in industry as well as to find out the correct environmental practices and to hear the views of guest speakers

- The representative is the owner

- At the initial meeting the details of waste Minimisation were clearly explained by the PRG and this was the initial impression of waste minimisation that the representative bad

- An extra benefit of the club was the potential to gain broader technical knowledge about the industry

- Views have not changed much since belonging to the club. But it is felt that the smaller

- The club was started through the initial encouragement and ideas of the University

- Possibly constraints may be financial. At the moment the club is funded by research grants but in the future the members may have to pay to belong to the club and if they feel this is not worth

- The club structure and functioning is okay and the guest speakers are interesting but the information and suggestions need to be relevant for the small companies as well as the larger

- Cordial relationships have been developed amongst members

- Joined when the club started, approximately a year ago

- Joined as a founder member due to pressure from. the legislation and the need to decrease costs etc

- Club representative is the owner andIor the son-in-law of the owner who is also an employee

- Difficult to say if other benefits could be gained because the company is different from other metal finishers since it does paint finishing, mainly focus on benefits of cost reduction. It is good

- Yes and No. Feels that the club still has a lot of obstacles to overcome because Metro still maintains its own opinions and it would be nice to work hand in hand with them rather than them

- Club has a lot of potential to continue into the future It has progressed and grown and in the last meeting there was a huge response, so very good future

- No real obstacles to the club continuing

- Possibly the club needs to focus on aspects of waste min that are relevant to the metal finishers

- Yes, greater knowledge has been facilitated

- Mutual relatiooship. We all deal in the same industry

- If we didn't think the club could act towards improving the environment we wouldn' t be involved!

- Company is 3 years old

- Phoenix Industrial Park 4. Joined the club when it began

- The company has a lot of effluent to dispose and the club seemed a way to help with this problem

- Company representative is the Operations Manager

- Idea that waste minimisation would mean that the company would have no more waste and that efiluent would be reduced

- Other ideas have been have come about through the club but some of these are not effective for this particular company

- The waste minimisation club was started at a meeting with Durban Metro - where the university introduced the idea of a waste minimisation club

- The club has grown from strength to strength and the potential for the club carrying on is great

- Possibly if participation and attendance becomes lower then the club may not be able to continue

- No changes were suggested. Feels that Susan Barclay is doing a great job

- The discussion in the club and the assistance offered through the club has increased the knowledge about waste minimisation

- Big industries may not need a club to help them because they have consultants etc. The smaller industries need a club to help them with their waste minimisation

- Relationships have been formed

- With knowledge sharing the companies relate

- Yes, the clubs can help with environmental management. The club can be a beginning and from this club members can branch out and join other conservation groups etc if they want to

- Was interested in other people's views

- No knowledge of waste minimisation before joining the club

- More people can get together to discuss problems

- No change

- The club is a good idea, and has good potential for continuing

- Can't think of any constraints

- No changes

- Became aware of the concept of waste minimisation

- Joined the club when it began last year

- Went to a meeting with Durban Metro and were encouraged at the meeting to join the club

- Representative is the owner-manager

- Did not think that waste minimisation was a big issue prior to joining the club

- There are benefits but often these are missed out on due to time constraints that prevent one from attending meetings

- It has potential to fit in with the environment issues

- The club was started at a meeting held by Durban Metro at which the university people attended and encouraged people to do waste minimisation through the club that was being formed

- The club has the potential to carry on

- Time constraints on company representatives are a major problem to the club carrying on. The small companies find it difficult to lose their representatives for business hours when they go to

- Changes made to the functioning of the club could be the timing of meetings. Possibly it would be convenient for smaller companies to hold meetings at the end of the day or outside of working

- The club has facilitated greater knowledge through the meetings and through the various documents that have been disseminated through the club. Discussion allows learning about the

- Clubs are a good mechanism because they promote awareness of the environment and of what people are doing in industry

- These relationships are business relationships but are mainly knowledge sharing. The strongest relationship has been formed with Company D

- The clubs can fit into environmental issues if they go wider than they are and move into a broader spectrum of enviromnental management

Yes, a lot of knowledge has been shared and wider knowledge and the club has facilitated the waste miD experience. He thinks the club has great potential to continue in the future and is very enthusiastic. The club has been a facilitator of much information sharing through discussions and suggestions of waste minimization practices.

An additional advantage of the club was the opportunity to acquire a wider technical knowledge of the industry. Informal discussion during tea hours, etc. among peers and on the club forum was useful. The formal presentation of knowledge among peers and on the club forum was helpful.

If necessary, the club must focus on aspects of waste mining that are relevant to the metal handlers. The discussion in the club and the assistance offered through the club has increased knowledge about waste minimization.

- To gain knowledge

- Did not know about waste minimisation before joining the club

- Thought it will enable him to look at things differently

- The club will continue nicely but not for this company

- The club is run quite well as it is

- No relationships have formed since joining the club

The club was formed at a meeting organized by Durban Metro where participants from the university encouraged people to reduce waste through the club that was formed. The club facilitated greater knowledge through meetings and various documents that were distributed through the club. The closure of the landfill (a result of the landslide) was the main reason I joined the club.

Reducing my company's pollution was the main reason I joined the club 0 0 0 0 0 Other plates. Before I joined the club: I had a fairly good idea of who the other saucers were, but I had never 0 0 0 0 0 spoken to them. I joined the club to buy time and delay Metro's new proposal 0 0 0 0 0 I joined the club to be in a better (Metro) light compared to companies that didn't 0 0 0 0 C join.

I joined because I saw an opportunity to negotiate relaxed terms with Metro 0 0 0 0 0 I wasn't very busy at the time, if business suddenly picked up I would just leave the club 0 0 0 0 0 I joined the club because I didn't know what waste minimization was and wanted. I joined the club because I thought it would help me save money 0 0 0 0 C What do you think of the Waste Minimization Club today.