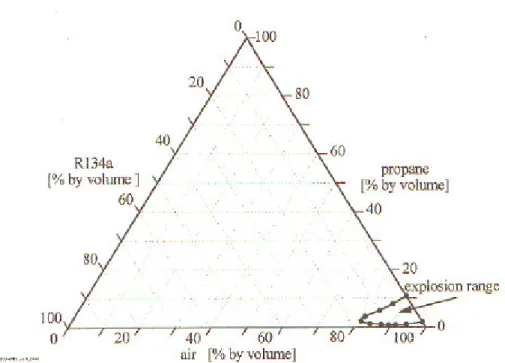

Too many variables exist (presence of lubricant, additives and hot metal catalysts) to determine with certainty the exact mechanism for the cause of the Tua Tona explosion. Flammable gas such as methane, when mixed with an HFC134a/air mixture, lowers the lower flammability limit of the mixture and thus requires a smaller ignition source before the gas becomes flammable at standard temperatures and pressures.

Problem statement

Objectives

Research design

The lack of literature regarding the flammability of HFC134a/lubricant mixtures indicated the need for experiments to provide these answers. Section 3 describes experimentation to provide qualitative answers for the flammability of HFC134a/lubricant mixtures as opposed to pure HFC134a (with known flammability limits).

Deployment of study

The work presented in the interim report fully defines the flammability of pure HFC134a under both normal and abnormal operating conditions. Finally, an attempt is made to understand what contribution the lubricant makes to the flammability of the mixture.

HFC134a

- Flammability of HFC134a

- Lubricants used with HFC134a

- Thermal stability of refrigerant - oil mixtures

- Flammability of refrigerant – oil mixtures

In refrigeration systems, the refrigerant is miscible with the compressor lubricant and therefore it is important to determine the flammability of the resulting refrigerant/lubricant mixture. In the case of converted systems, the compatibility of the new coolant with the previously used coolant and lubricant is important. All of the listed lubricants and their associated additive packages can oxidize or thermally degrade.

Chemical and thermal stability of lubricants is evaluated using ANSI/ASHRAE test method 97-1989. Equal volumes of lubricant, coolant and metal coupons (aluminum, steel and copper) are sealed in glass tubes and aged at 175°C for a period (from 7 to 56 days). This discrepancy may be due to several factors: different hydrolytic stability and acid number of tested lubricants, presence of air during the test, etc.

Adding flammable gases to HFC134a leads to an expansion of the lower explosive limit (LEL). Even small fractions of flammable substances in HFC134a can lead to flammability of the mixture.

Plant specific considerations

Retrofits

In a properly maintained cooling system, there is no air to form an ignitable coolant/lubricant/air mixture. The process involves isolating the CFC refrigerant from the compressor and replacing the original mineral oil with a polyol ester of the appropriate viscosity. The system then operates normally and the action of the CFC refrigerant traveling through the system flushes the remaining oil back into the compressor sump.

Through repeated oil changes, the contamination level of the mineral oil in the system is reduced to an acceptable level (usually 3-5%). Since HFC134a lubricant blends are more effective scavengers than the CFC mineral oil blends, there is a danger that particles (that accumulated while the system used the CFC working fluid) will be dislodged and contaminate the compressor oil and plug the expansion. devices and other components. Care must be taken to minimize exposure of the lubricant to humidity or to water entering the system directly through leaks in condenser or evaporator heat exchanger tubes.

Mixing CFC12 and HFC134a must be avoided, as the presence of CFC can result in chlorine attack by the synthetic lubricants. In addition, the resulting refrigerant azeotrope has a higher vapor pressure than either of the two individual components and can cause frequent high-pressure and engine overload stalls.

Leak detection

Unacceptable lubricant moisture content can lead to the formation of corrosive acids that will attack compressor parts. A solution of soap is brushed or poured on joints and other spots where leakage is suspected. Leaks are also determined by pressurizing or evacuating and observing for any change in the pressure or vacuum over a period of time, but this method does not determine the position of the leak.

If halogenated vapors are present, they decompose, and the color of the flame changes to blue-green.

SABS 0147 (1995) Code of Practice

A system poses a high risk if its basic design and location are such that a refrigerant leak from a defective part, seal or fitting could enter the service-classified area. Indirect closed systems typically used underground can only be considered low risk if all joints and connections are effectively isolated from the area classified for use. For any mining application, all systems must be referred to the Director General of the Department of Minerals and Energy Affairs.

The maximum concentration of HFC134a is 60,000 ppm (or 6% by volume) and applies to accidents or incidents that cause a large release of refrigerant and does not refer to daily exposure limits. When the concentrations of the coolant, in the event of a leak, may exceed this value, the temperature of any hot surface or flame must be at least 100°C less than the minimum ignition temperature. No openings are allowed that allow the escape of refrigerant to other parts of the building.

Plant rooms containing group 1 refrigerants (HFC134a) must be equipped with vapor alarms to ensure warnings against oxygen deficiency. A set of suitable protective clothing should be provided for each set of self-contained breathing apparatus.

Incident at Anglogold, Tau Tona underground chiller plant

Remedial action undertaken at Tau Tona

Fire detection sensors were installed in each of the five rooms located on level 100, Tua Tona, and are monitored and inspected daily. The sensors are connected to a control system that opens the flaps (self-closing) to divert air to the return air path (RAW) in case of smoke detection. At each plant start-up, safety devices are tested as part of the plant start-up sequence.

Procedures for small-scale and large-scale plant maintenance were implemented, and restrictions were placed on how cutting torches and welding equipment were used in refrigeration plants.

Investigation conclusions

However, no information was found to describe the contribution of the lubricant on the flammability range of HFC134a/lubricant/air mixtures. The literature has indicated that small amounts of flammable gas mixtures can drastically change the flammability of non-flammable gases such as HFC134a. To investigate and provide clarification, an experiment was designed to qualitatively evaluate whether the presence of the lubricant lowers the LEL of the coolant.

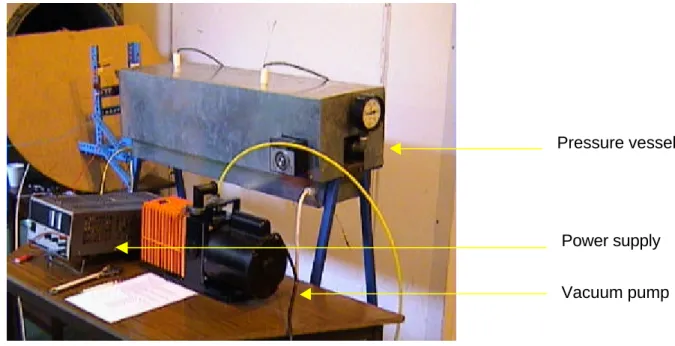

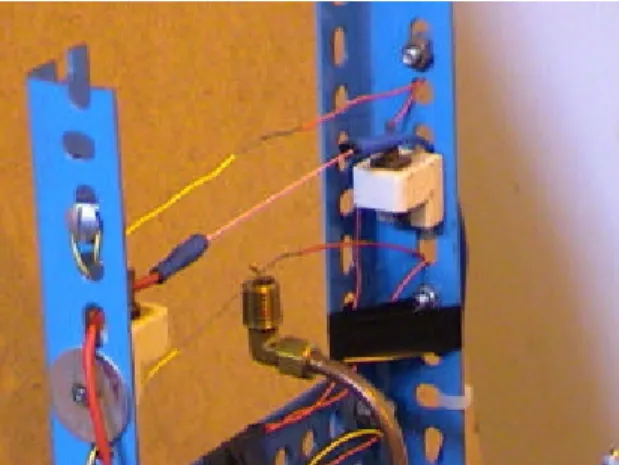

Apparatus

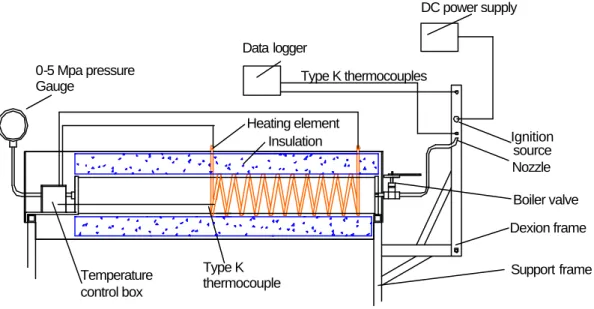

The test rig consisted of a pressure vessel arrangement with a boiler valve to fill the vessel with HFC134a or HFC134a/lubricant mixtures. A heating element looped over the outside of the cylinder allowed the refrigerant gas contained in the pressure vessel to be preheated (simulating the operating temperatures and pressures of the compressor) before being ejected over an ignition source by one of the to open boiler valves remotely. The heating element was controlled by feedback from a thermocouple located at the hottest part of the heating element.

The thermocouple above the filament recorded the temperature of the gas after it passed over the filament. Two HFC134a gas canisters were manufactured, one with pure HFC134a and the second with HFC134a and 5 mass% SW68 Castrol lubricant (the same lubricant present in the Tua Tona refrigeration plant).

Experimental method

The video camera was set to record the scene on the exit side of the apparatus.

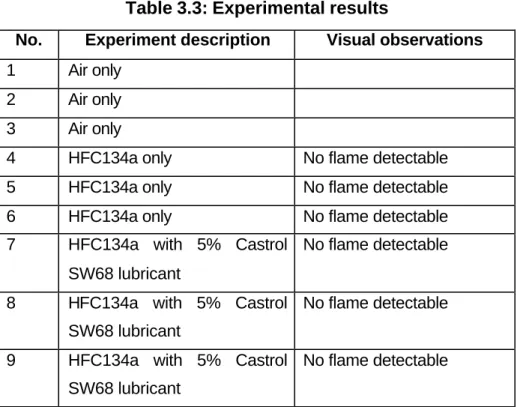

Results

Conclusion

Based on work undertaken in execution, HFC134a/lubricant mixtures are highly unlikely to ignite under normal and abnormal conditions (temperatures less than 180°C) except catastrophic conditions such as plant room fires and total mechanical failure of equipment. Based on the outcome of the accident report for the incident that occurred at Tau Tona, the most likely scenario put forward to explain the explosion was: coolant and lubricant escaping past superheated red-hot bearing surfaces mixed with air, thus providing a heat source and the oxygen needed for combustion to take place. The addition of small amounts of flammable gas to HFC134a/air mixtures has the effect of lowering the LEL.

At increasing (abnormal) temperatures, decomposition or thermal cracking of the lubricant will begin long before the thermal decomposition of HFC134a begins to occur. Thus, it is interesting to consider the effect of the decomposition of the lubricant and consequently the formation of flammable gases on the flammability of HFC134a by the described mechanism. Furthermore, the presence of rapidly worn aluminum and other metals could play a catalytic role in the reaction.

Whatever the exact mechanism, we must keep in mind that these conditions are highly abnormal and catastrophic and must be prevented in the first instance. Therefore, Chapter 5 of this report presents guidelines for a code of practice that recognizes conditions that can lead to ignition of HFC134a and ways in which these situations can be avoided or neutralized.

Scope

Guidelines

Cavestri RC, Munk J, and Menning M, (1994), Solubility, viscosity and density measurements of refrigerant-lubricant mixtures – part I: branched acid pentaerythritol polyol esters with R-134a, ASHRAE Transactions: Research, Vol. Cavestri RC, Munk J, and Menning M, (1994), Solubility, viscosity and density measurements of refrigerant-lubricant mixtures – part II: polyalkylene glycols with R-134a, ASHRAE Transactions: Research, Vol. Cavestri RC, and Schafer WR, Real-time determination of lubricant concentrations dissolved in alternative refrigerants, ASHRAE Transactions: Research, pp.

9] Cohen AP, (1993), Test Methods for the Compatibility of Desiccants with Alternative Refrigerants, ASHRAE Transactions: Research, Vol. 25] Lilje KC, Sabahi M, and Hamid S, (1995), Polybasic esters: novel synthetic lubricants designed for use in HFC compressors, ASHRAE transactions: symposia, pp. 32] Reyes-Gavilán JL, (1993), Performance evaluation of naphthenic and synthetic oils in reciprocating compressors using R-134a as the refrigerant, ASHRAE Transactions: Research, Vol.

41] Short GD and Cavestri RC, (1992), High viscosity ester lubricants for alternative refrigerants, ASHRAE Transactions: symposia, Vol. 46] Sunami M, Takigawa K, Suda S, and Sasaki U, (1995), New immiscible refrigeration lubricant for HFCs, ASHRAE transactions: symposia, p 47] Sundaresan SG and Finkenstadt WR, (1992), Polyalkylene glycol and polyol ester lubricant candidates for use with HFC-134a in refrigeration compressors, ASHRAE Transactions: symposia, Vol.

53] Yoon HK, Poppe CH and Cusano C, (1996), Predicting Lubricant Performance in Refrigerant Compressors: A Comparison Between Component and Bench Testing, ASHRAE Transactions: Research, Vol.

Interim report