Chapters Four: This chapter focused on the performance evaluation of upflow expanded granular sludge bed (EGSB) reactor coupled with anoxic and aerobic bioreactors in the treatment of poultry slaughterhouse wastewater. Chapter Five: This chapter focused on the performance evaluation of static granular low flow reactor (SGBR) coupled with an ultrafiltration membrane system for the treatment of poultry slaughterhouse wastewater.

INTRODUCTION

Background of the research problem

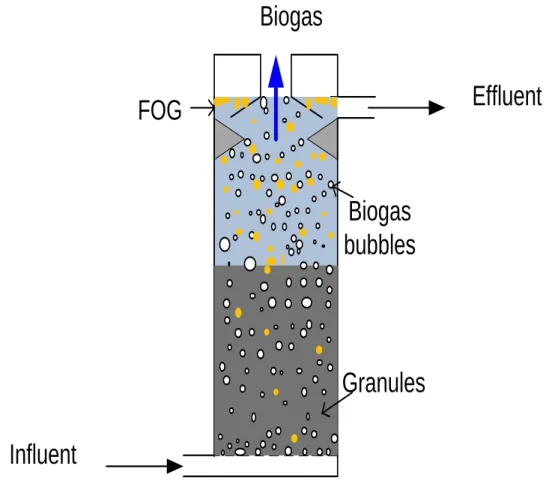

In addition, the performance of UASB and EGSB reactors depends on a well-designed gas-liquid-solids (GLSS) separation system that separates the biogas phase from the wastewater and biomass. Unlike UASB and EGSB reactors, which require gas-liquid-solids (GLSS) separation, SGBR uses an underwater effluent system to contain biomass (Oh, 2012; Park et al., 2012).

Problem statement

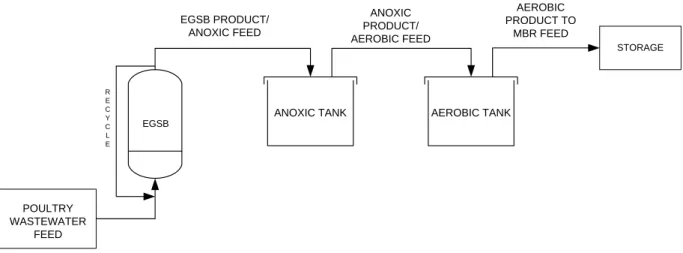

For this study, both an upflow EGSB coupled with anoxic-aerobic bioreactors and a downflow SGBR coupled with a UF membrane system were evaluated for the performance of the reactors in reducing organic matter in poultry slaughterhouse wastewater. . A poultry processing company located in the Western Cape Province of Cape Town, South Africa, was selected for this study as the industrial partner for the poultry slaughterhouse wastewater supply.

Research questions

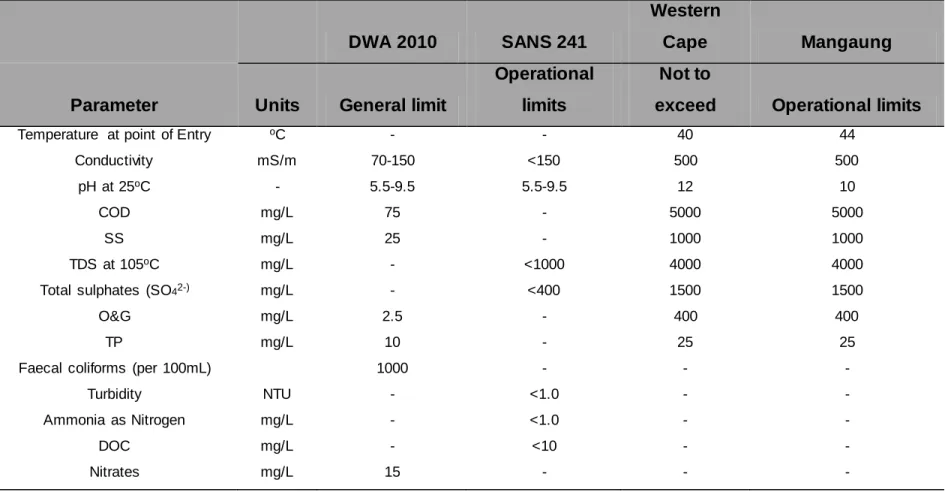

Does the quality of wastewater treated, or reclaimed from an upflow EGSB with an anoxic-aerobic configuration or a low flow SGBR with a UF system meet the South African municipal discharge standard. Once treated, is it possible to reuse reclaimed water from upstream or downstream EGSBs and SGBRs.

Aim of the study

Is there a need for an additional treated water processing unit to meet discharge standards or for reuse.

Hypotheses

Objectives

Delineation of the study

Review: Upflow and underflow anaerobic digester reactor configurations for treating fat, oil, and grease-laden poultry abattoir wastewater: Submitted to Water Journal, Manuscript ID: Water-190978. REVIEW: ANAEROBIC REACTOR CONFIGURATIONS FOR UPFLOW AND DOWNFLOW REACTORS FOR THE TREATMENT OF FAT-OIL-FAT POULTRY WASTEWATER.

Introduction

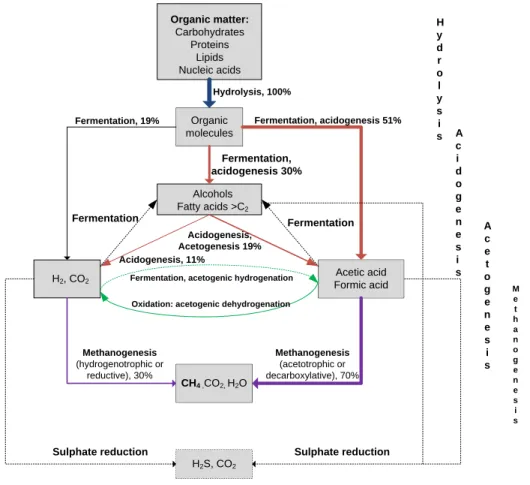

In addition, the AD process can play a vital role in waste management and in the reduction of greenhouse gas emissions (Harris & MaCabe, 2015) and the digestate can be used as a value-added organic fertilizer for soil improvement (Lim, 2009). While the AD process is effective in the degradation of other substrates in PSW, FOG poses several challenges, such as its accumulation in pipe walls leading to pipe blockages (Harris et al., 2015).

Overview: poultry slaughterhouse water usage, wastewater generation and

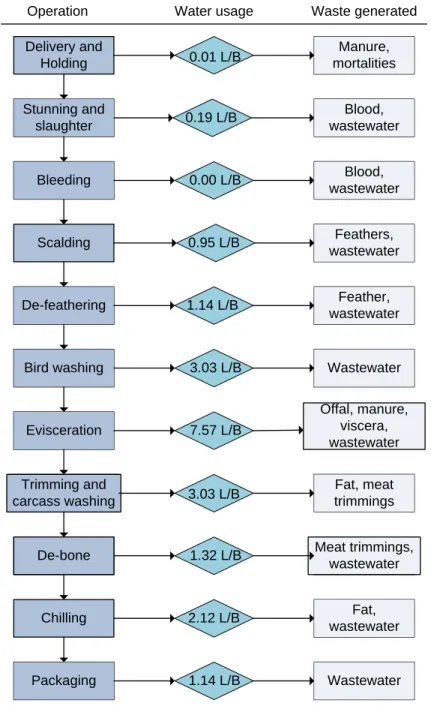

The critical control point in the poultry processing facility for reducing the contamination of the products is the evisceration process, especially for limiting and/or eradicating leakage from the guts of the birds as they contain pathogens. In addition, temperature should be controlled to minimize the spread of pathogens in the edible parts of the bird (Avula et al., 2009).

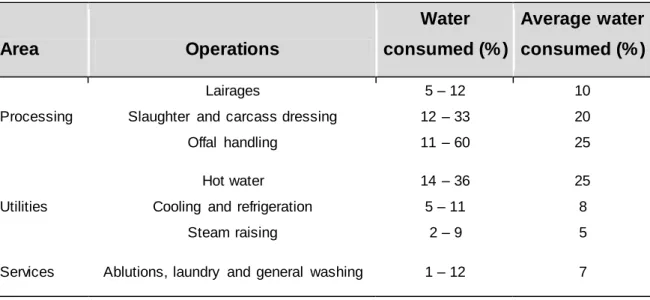

Average water usage per bird

Furthermore, water is also used as a transport medium for the by-products of slaughter (e.g. for mobilizing offal, including feathers, heads and entrails) (Avula et al., 2009). Yet another important contaminant in poultry process water is protein residues from carcass residues, blood, fats, oils and grease (FOG) and feathers (Avula et al., 2009; Yordanov, 2010).

Poultry wastewater generation and its impact on environmental health

Composition of poultry slaughterhouse wastewater

Legislation governing discharge of poultry slaughterhouse wastewater (PSW)

Anaerobic digestion treatment

- Anaerobic degradation pathways and biogas generation

- Up-flow configured anaerobic digesters: UASB and EGSB

- Impact of up-flow reactor configuration for the treatment of FOG-laden

- Down-flow configured anaerobic digesters: SGBR

- Impact of a down-flow reactor configuration for the treatment of FOG-laden

- Performance limitations of the SGBR

The poor performance of the reactor is believed to be due to intermittent sludge leaching caused by high FOG loading rates. Del Nery (2007) reported the success of the up-flow reactor in handling FOG-loaded PSW.

Summary

Characteristics, treatment and management of waste water from slaughterhouses in the meat processing industry: an overview of trends and progress. Use of the Static Granular Bed Reactor (SGBR) with anaerobic sludge for poultry slaughterhouse wastewater treatment and kinetic modelling. Overview of pre-treatments used in anaerobic digestion and their possible application in fat-rich wastewater from cattle slaughterhouses.

2005 A full-scale UASB reactor for the treatment of pig and beef abattoir wastewater with a high oil and fat content.

SUBSTRATE REMOVAL KINETIC MODELS FOR ANAEROBIC BIORECTOR

- Introduction

- Monod kinetics

- Modified Stover-Kincannon model

- Grau-second-order model

- Summary

By making the specific growth rate ( of AD biomass the subject of the formula, Eq. Where is the growth yield coefficient as a quantifiable measure of the biodegradability of the organic matter in the PSW. whereas the variability of the rate of organic material in the AD is minimal, cf.

The periodic change of soluble substrate can be represented using a simple modification of the Stover-Kincannon model, as in Eq.

PERFORMANCE OF AN EXPANDED GRANULAR SLUDGE BED (EGSB)

- Introduction

- Objectives

- Materials and methods

- Experimental set-up and equipment

- The EGSB laboratory bench-scale reactor set-up

- The anoxic and aerobic bioreactor set-up

- Slaughterhouse wastewater collection and storage

- Seed preparation

- EGSB operating conditions

- Analyses of poultry slaughterhouse industrial wastewater

- Combined EGSB-anoxic-aerobic system operational scheme and

- Results and discussion

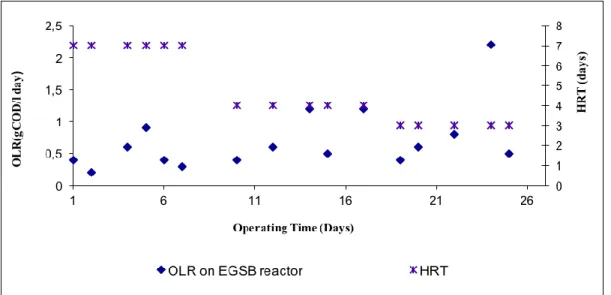

- Variation of OLR and HRT on the EGSB reactor salinity tolerance test

- EGSB performance and COD removal

- Overall COD removal of the EGSB, anoxic and aerobic bioreactor

- Variation in pH

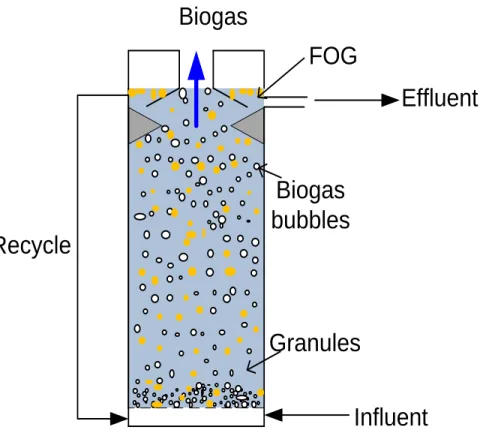

The goal of the EGSB reactor was to effectively reduce the organic load of the feed after the effluent was treated in the anoxic and aerobic bioreactors. The biogas produced from the EGSB reactor was collected at the top of the reactor with Tedlar bags. The influent was continuously pumped and fed from the bottom of the reactor using a Gilson (Germany) peristaltic pump, with the effluent withdrawn from the top at the same rate. The liquid phase of the effluent was split into two streams: 1) EGSB product and 2) the recycle stream.

The pH was used to monitor the stability of the EGSB reactor and the anoxic and aerobic bioreactors, as depicted in Figure 4.5.

TREATMENT OF POULTRY SLAUGHTERHOUSE WASTEWATER USING A

Introduction

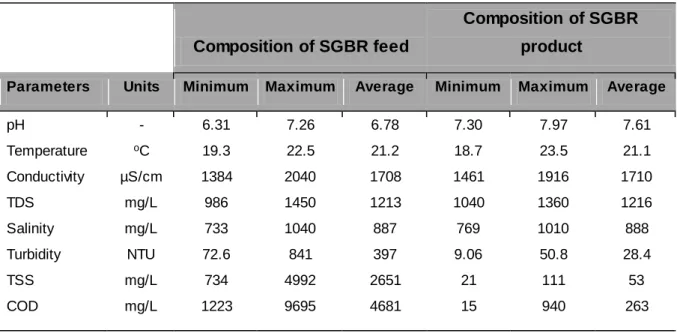

Treatment methods – such as physical, chemical and biological processes (Kiepper, 2001) – have been used to treat poultry slaughterhouse wastewater. Poultry slaughterhouse wastewater is suitable for anaerobic treatment because it contains a high concentration of organic compounds (Debik & Coskun, 2009). Yodanov (2010) reported tCOD removal greater than 94% for poultry slaughterhouse treatment using ultrafiltration membrane systems.

The use of this two-stage system has not yet been applied on an industrial scale in SA, particularly for the treatment of poultry abattoir wastewater.

Objectives

The up-flow anaerobic sludge bed (UASB) reactor is also widely used for the treatment of wastewater from poultry slaughterhouses. 2009), using the Static Granular Bed Reactor (SGBR) to treat the wastewater from poultry slaughterhouses, an average tCOD removal of 95% was achieved. De Nardi et al. 2008) investigated the use of a Dissolved Air Floatation (DAF) as a pretreatment prior to the UASB reactor to lower influent FOG and suspended solids, a strategy that improved UASB functionality. This study investigated the feasibility of using a two-stage process investigating a mesophilic Static Granular Bed Reactor (SGBR) coupled to a UF membrane system.

The aim of this study, therefore, was to evaluate the treatment efficiency of a laboratory-scale anaerobic digester SGBR coupled with a UF membrane system for effective tCOD reduction for poultry slaughterhouse wastewater, so that the treated wastewater matched Cape Town. City Bylaw Discharge Standards (CCT) for Industrial Wastewater Quality Assessment.

Material and methods

- Experimental set-up and equipment

- Slaughterhouse wastewater

- SGBR inoculation and start-up procedure

- SGBR operating conditions

- The ultra-filtration (UF) membrane system

- Analyses of poultry slaughterhouse wastewater

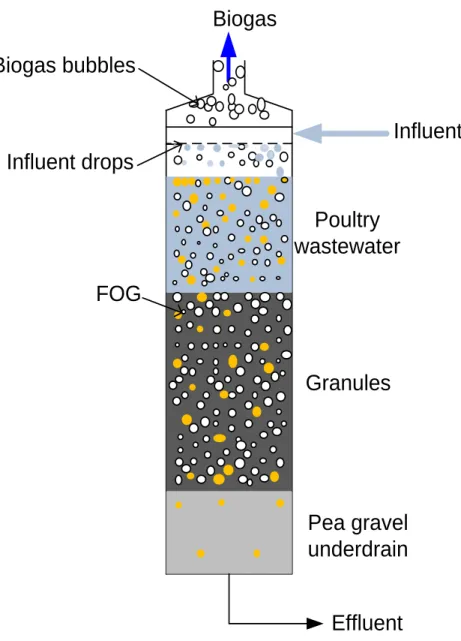

A 2 mm grain sieve was placed at the bottom of the SGBR to retain the pea gravel. Poultry slaughterhouse wastewater (collected from a slaughterhouse in the Western Cape, SA), with a volume of 0.43 L, was also added to the SGBR to initiate the process. During the last 36 days of SGBR operation, the bioreactor was fed with the undiluted poultry slaughterhouse wastewater.

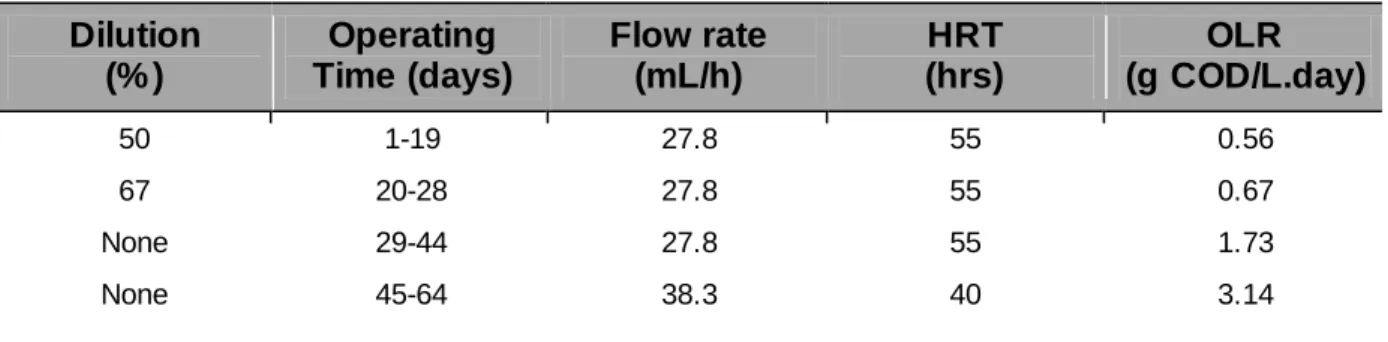

To start the process, the SGBR was fed with 50% of the diluted poultry slaughterhouse wastewater for the first 19 days (ratio 1:1), followed by diluted poultry slaughterhouse wastewater at a concentration of 67% (ratio 2:1) for subsequent 9 days.

Results and discussion

- Variation of OLR and HRT on the SGBR reactor

- SGBR performance and COD reduction

- Compliance: COD Industrial discharge standard

- TSS removal efficiency

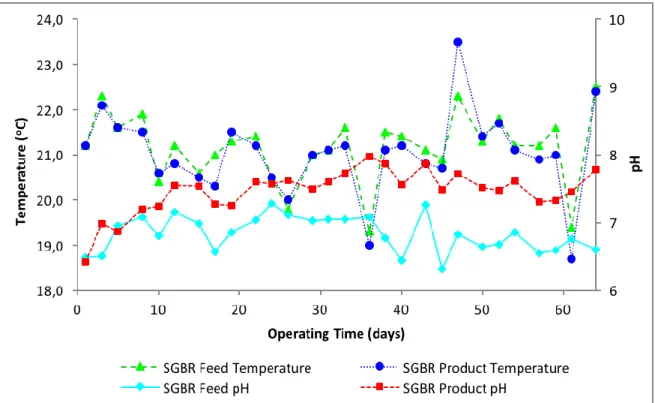

- pH and temperature variations

- VFA/Alkalinity ratio

- Ultra-filtration (UF) membrane system

- Overall tCOD, TSS and FOG removal of the SGBR and UF membrane . 71

The TSS was measured to determine the concentration of the insoluble organic and inorganic material suspended in the poultry slaughterhouse wastewater. On day 8, the TSS removal increased exponentially to 91% and remained relatively constant throughout the duration of the SGBR operation. The UF treatment of the poultry wastewater from the SGBR reactor was monitored using tCOD, TSS and FOG pollution indices.

Note: This section is a repeat of the SGBR reactor with different HRT and OLRs.

PERFORMANCE EVALUATION AND KINETIC PARAMETER ANALYSIS FOR

- Introduction

- Materials and methods

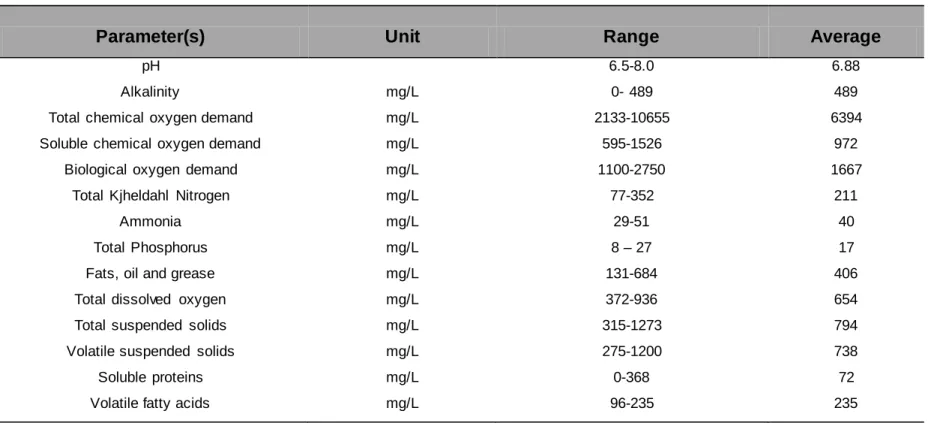

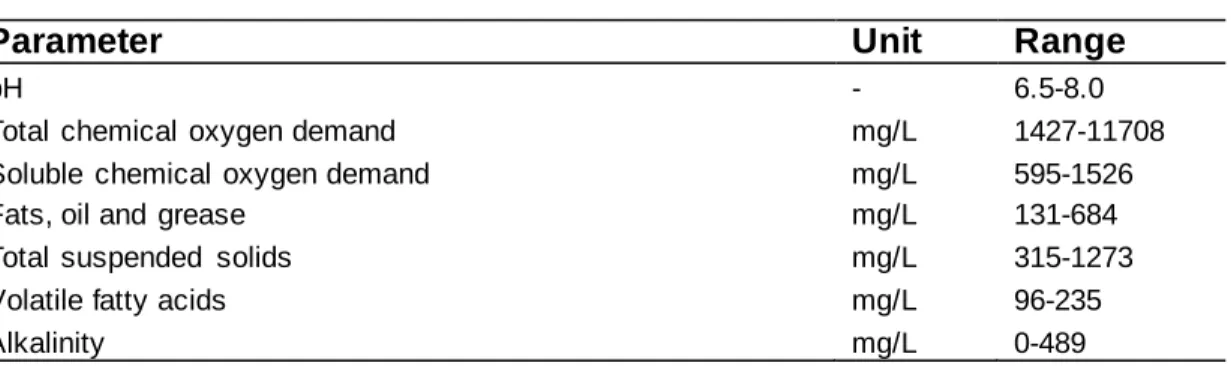

- Inoculum seed and wastewater characteristics

- The SGBR set-up and operation

- Results and discussion

- tCOD removal rates

- Kinetic model evaluation

- Grau second-order multicomponent substrate removal model

- Modified Stover-Kincannon model

- Summary

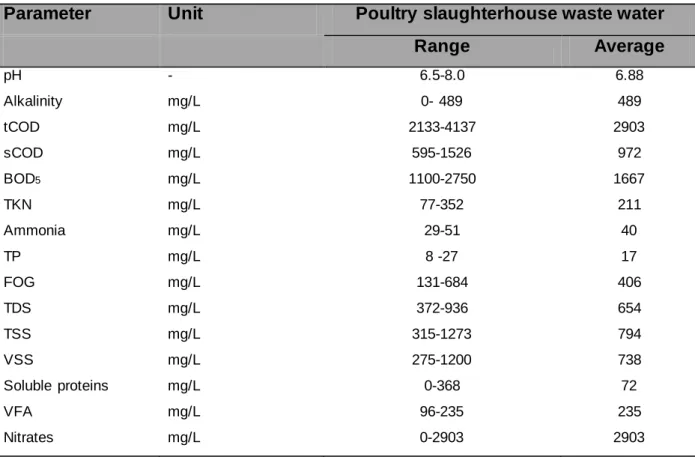

The PSW characteristics (Table 1) show a typical high strength wastewater (i.e. PSW in South Africa). A Gilson (Germany) multihead peristaltic pump was used to pump the influent to the top of the bioreactor. The tCOD utilization rate in this model is expressed as a function of organic loading rate (Yu et al., 1998).

The value of the maximum removal rate constant tCOD, Umax, including the saturation (affinity) constant, KB, as described in Eq.

SUMMARY AND CONCLUSIONS

- Summary

- Process engineering significance

- Significant contributions from this study

- Future studies and this study limitations

The quality characteristics of the treated effluent from the improved EGSB operation met the South African industrial discharge standards. Furthermore, the use of the post-treatment UF membrane system improved the quality of the SGBR reclaimed water, an indication that the treated water can be used for other facilities in the abattoir, thus reducing the intake of potable water, which is currently matter. Periodic backwashing to plug fine sludge particles from the underdrain was required to resuspend anaerobic biomass for maximum organic matter/biomass contact life and to increase total surface contact attributed to the fluidization, expansion of the sludge bed, which culminated in dead biomass shearing off.

This study was conducted in the context of university student unrest at South African universities (2015 and 2016), which resulted in reduced reactor operating times deemed unsatisfactory and culminated in a re-run of both the SGBR and EGSB experiments to collect sufficient data to be able to adequately assess the reactor. performance of both up-flow EGSB and down-flow SGBR AD for the treatment of poultry slaughterhouse wastewater.

BIBLIOGRAPHY

Book MBR: Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment, Elsevier. Performance evaluation of a pilot-scale static granular bed reactor (SGBR) for industrial wastewater treatment and biofilter treatment of septic tank effluent using recycled rubber particles (Doctoral dissertation, Iowa State University). Evaluation of a Static Granular Bed Reactor (SGBR) Pilot Plant for Abattoir Wastewater Treatment.

Antibiotic removal in conventional and advanced wastewater treatment: implications for environmental discharge and wastewater recycling.

APPENDICES

APPENDIX B: ADDITIONAL DATA FOR SGBR AND UF OPERATION IN

It can be seen from Figure B4 that the TSS and turbidity of the SGBR feed varied significantly throughout the study due to the variation in the SGBR feed. It is clear from Figure B4 that the SGBR successfully reduced the TSS and turbidity content of the poultry slaughterhouse wastewater. The tCOD was used to evaluate the performance and overall efficiency of the SGBR system throughout this study.

The total removal of tCOD, TSS, and FOG by the EGSB system was 65%, 71%, and 83%, respectively.