Experimental dried products were produced and the efficiency of the solar dryer to produce quality products at a small farmer level was evaluated through three tests. First, the quality of the dried fruits and vegetables was assessed by sensory evaluation of color, taste, texture, and moisture content by members of a rural solar project. To study the effectiveness of a solar dryer in producing quality products at a small farmer level by assessing the quality of the dried fruits and vegetables against

Sub-problems

Hypothesis

Study Limits

Study Assumptions ~ 3

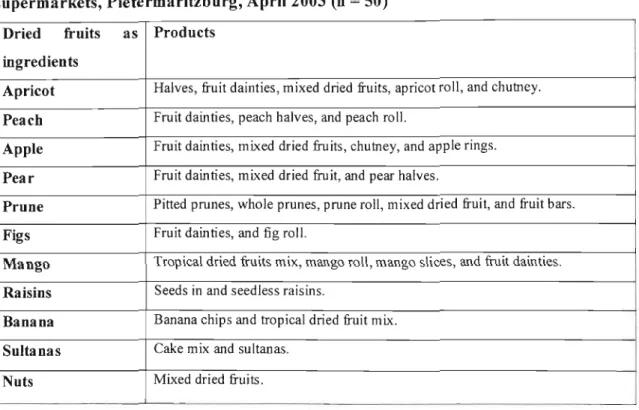

Of the 50 dried products identified, 10 (20 percent of the total number of items) were apricots or contained apricots as an ingredient (Appendix A). The lemon juice preserved with sulfur dioxide could also keep the natural color and flavor of the fruit unchanged (Mason et al., undated, University of Georgia, undated). Furthermore, the results of LSD showed that the flavor of the lemon juice-treated sample was preserved with sulfur.

REVIEW OF RELATED LITERATURE

Fruit and vegetable preservation

- Principles of drying. 6

- Pre-treating fruits. 8

The browning process, called oxidation, robs the fruit of flavor, color and vitamins A and C (Harrison 1993). Browning or oxidation is the result of a reaction between oxygen and a pigment in the fruit (Scholl undated). The fruit slices should be soaked in the solution for 3 to 5 minutes and then the slices should be placed on drying trays.

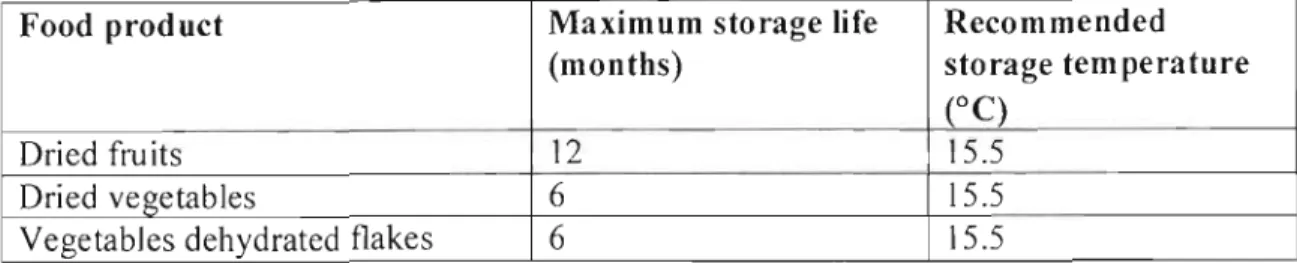

Solar drying for improved storage

- Principles of solar drying

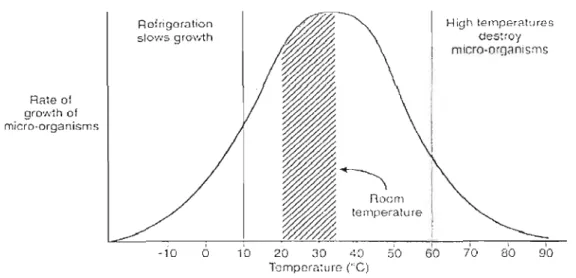

- Control offruit and vegetable spoilage through solar drying

- Moisturecontentoffoods..................................................... IS

- Benefits of solar drying for nutrition

Fellows 1997b, p. 8), but seasonal fruits and vegetables make them plentiful for only a few months (Minnaar udat). Drying fruits and vegetables using direct sun drying reduces the nutritional value of the dried products, especially vitamins A and C (FAO 1997 b, FAO 1989, Minnaar undated, Rodriguez-Amaya 2003). The Tanzanian Food and Nutrition Center (Mulokoziet0/2000) introduced an improved solar dryer for drying fruits and vegetables among rural women living in the semi-arid region of central Tanzania to assess the effect of solar drying on availability, micronutrient intake and nutritional quality. dried foods and the impact on household economic status (Mulokoziet0/2000). The study showed that vegetables dried with a closed sun dryer retained more of their beta-carotene (20-30% more) than those dried with traditional open sun dryers (Mulokoziet0) /2000).

Review of international studies of solar drying of fruit and vegetables

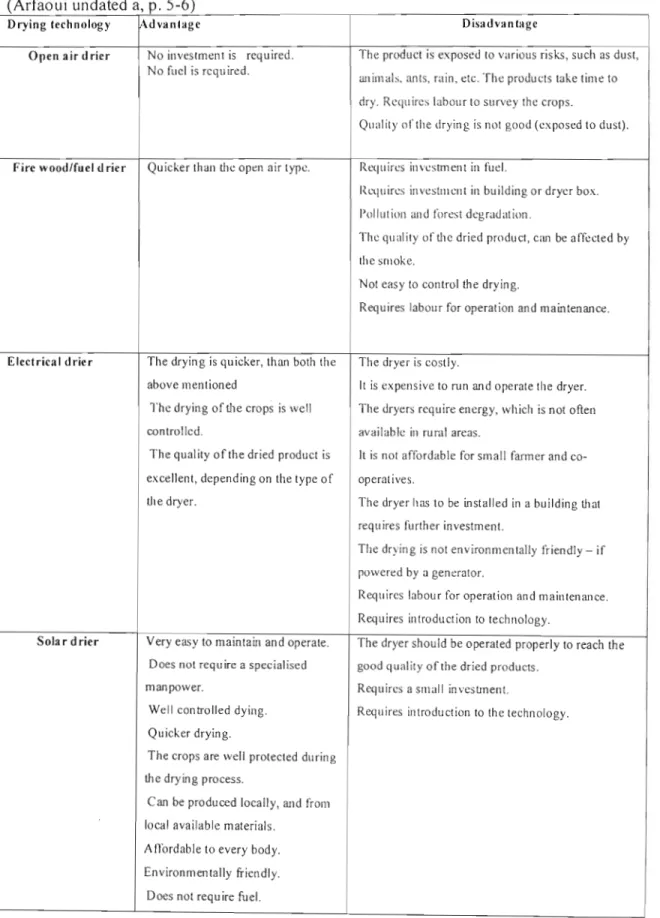

- Comparison of drier designs

- Nebbi Solar Drier

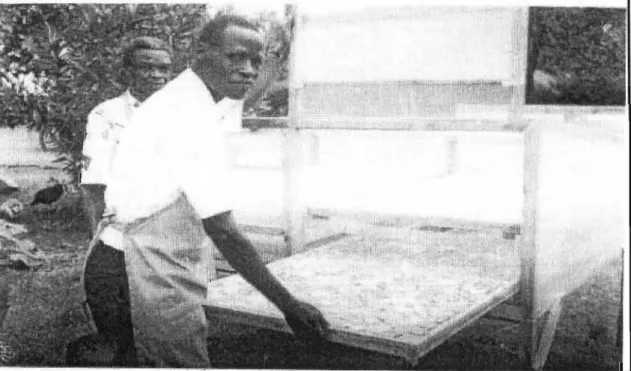

- Kawanda solar Cabinet drier

- Solar Tent Drier

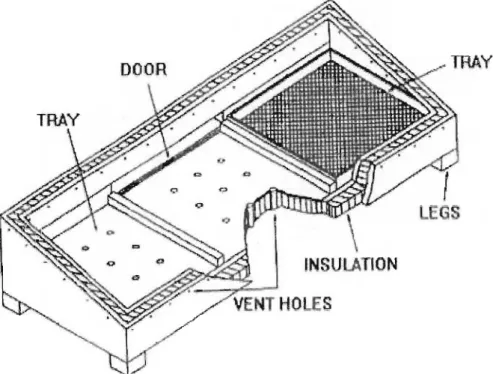

- Brace Solar Drier

This comparison of the solar drying technologies will be limited to: low cost solar dryers such as (Nebbi, Kawanda, Tent, and Brace solar dryer) and an electric solar dryer such as (AC and DC powered electric solar dryer). The moist air leaves the dryer through holes in the top corner of the tent (Figure 2.4). The inside of the dryer is painted black to act as a solar collector (Intermediate Technology Development Group 2002 a).

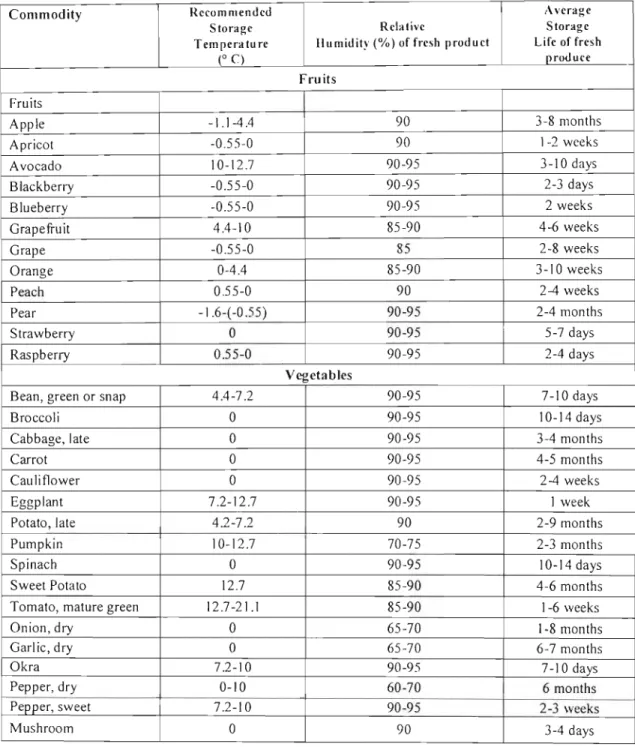

Overview of agricultural production by farmers in rural areas of KwaZulu-

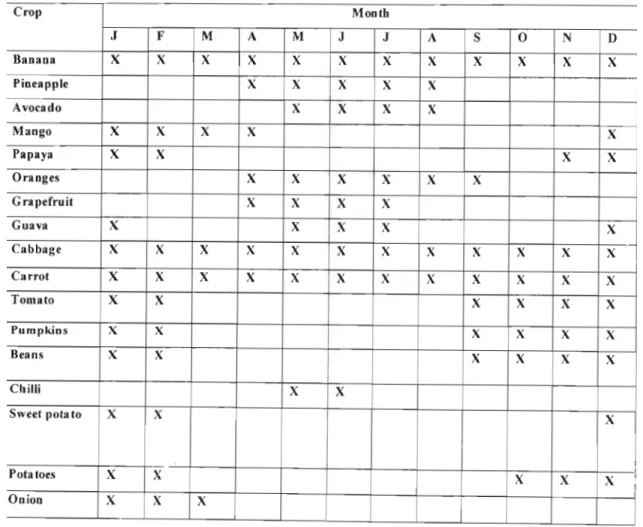

The various crop varieties grown in KwaZulu-Natal are: cabbage, tomatoes, squash, beans, chillies, potatoes, sweet potatoes, carrots and onions (Table 2.5) (Trade Partners 2003). Due to the seasonal nature of production, large quantities of fruit and vegetables are brought to individual markets at the height of the growing season, followed by shortages. By processing fruits and vegetables during periods of abundance into shelf-stable products, farmers could avoid food waste and loss of income (Minnaar undated).

Potential benefits of solar drying for rural households and economIc

To measure the perceived quality of the dried fruits and vegetables in terms of color, texture and flavor, subjective sensory evaluation was used. The color, flavor and texture of the dried apple and banana pre-treated with sugar syrup with lemon juice preserved with sulfur dioxide had the highest acceptance level implying that the respondents liked the products (Figures and 5.4). While the color, flavor and texture of the dried apple and banana treated with lemon juice preserved with sodium metabisulphite had the lowest acceptance level of the respondents, which indicated that they liked the products (Figures and 5.4). a .. a) Dried apple treated with sugar syrup b) dried apple treated with lemon juice preserved with sulfur dioxide.

Nevertheless, the sample pretreated with sugar syrup with lemon juice preserved with sulfur dioxide was significantly greater than the sample pretreated with lemon juice preserved with sodium metabisulfite (3.62). The color, taste and texture of the dried tomato and pumpkin treated with steam blanching had a higher acceptance level than the control products (Figures 5.7 and 5.9). FAO/WHO Food Standards report that the moisture content of the dried apple treated with (soaking in sulfuric or ascorbic acid) should be less than 25% and the treated apple.

The moisture content of dried apple was found below the standard for all samples. Furthermore, quality characteristics such as color, taste, texture and moisture content of dried fruits and vegetables support that the solar dryer was efficient. Third, the efficiency of the solar dryer was studied by evaluating the quality of the experimental dried products in terms of color, aroma, texture and moisture content.

We studied the influence of different treatments on the quality of experimental dried fruits and vegetables. Sensory evaluation results showed that dried apple and banana treated with sugar syrup with sulfur dioxide-preserved lemon juice had the highest color score, followed by sulfur dioxide-preserved lemon juice and sodium metabisulfite-preserved lemon juice. Sensory data results for dried pineapple treated with sulfur dioxide from lemon juice scored higher for color, flavor and texture than for dried pineapple treated with lemon juice preserved with sodium metabisulfite.

Data analysis for the third subproblem showed that the solar dryer used was efficient. It is recommended that small farmers use solar dryer effectively to ensure high product quality.

COMPARISON OF SUPERMARKET SURVEY WITH

DRIER DESIGN, TRIAL AND METHODOLOGY FOR

Selection offruits and vegetables for solar drying experimentation

The fruits and vegetables selected for the study were selected according to types of fruit and vegetables that were available during the trial period (April–September 2003) and could typically be produced by small-scale farmers in KwaZulu-Natal. This period included autumn, winter and early spring, when humidity in the region is low, but daytime temperatures are still sufficient for solar drying. Unfortunately, the experiments could not be repeated in the summer months to compare the efficiency of the dryer with periods when there is more production, but temperatures and humidity are much higher.

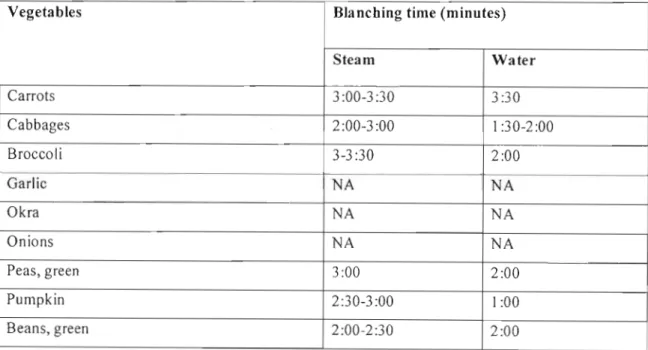

The selected fruits and vegetables were purchased from local supermarkets (Hayfields Pick'n Pay, Scottsville Shoprite Checkers and Woolworths). Half of the vegetable samples were left untreated and the others were pre-treated with steam blanching before drying (Appendix C). In general, vegetables have lower sugar content and are less acidic than fruits (Fellows and Hampton 1992, p. 4, University of Idaho 1995).

The high acid and sugar content of fruit inhibits certain enzymes that cause loss of flavor and color and reduce the storage life of the products (University of Idaho 1995). For this reason, most vegetables can be blanched as this destroys the natural enzymes found in vegetables, which cause loss of flavor and color (Reynolds 1998 b). Blanching, especially steam blanching, allows vegetables to retain more water-soluble nutrients and will have better color and flavor than control (unblanched) produce (Anon 1998, Wolfet0/1990).

Drying experiments

Soaking the prepared fruits in a sugar solution or lemon juice did not require special equipment, additional time or work, but the sulphurous desire for a further process. Half of the vegetable samples (carrot, tomato and pumpkin) were pretreated with steam blanching, and the second half was left unblanched to evaluate the effect of the pretreatment and its suitability for small-scale production by small-scale farmers in KwaZulu. Natal (Appendix Band C). Twelve kilos of fruit or vegetables were dried in successive batches for eight weeks.

Kendall and Alien (1998) explain that fruits are considered sufficiently dry if they are pliable and leathery and no moist area is visible in the cores when cut. The apple and pineapple were considered dry when they were still soft, supple and leathery. Vegetables were considered sufficiently dry if they were brittle or leathery (Andress and Harrison 1999, Kendall and Alien 2002).

When dried, the products were packed in ziplock plastic bags (hermetic bags) and kept at room temperature until quality parameters were measured. The oldest products were 12-16 weeks old at the time the taste and moisture tests were conducted.

Efficiency of the solar drier

Quality evaluation (sensory evaluation)

Affective sensitivity tests, product acceptance and preference tests were used to evaluate the quality of sun-dried products. MI was the mass, in grams, of the dry glass and test piece before drying. The average values of sensory scores for acceptance regarding color, taste and texture are given in Table 5.4.

The least significant difference (LSD) test presented in Table 5.6 shows that there is no statistically significant difference between the dried banana treated with 35% sugar syrup and lemon juice and that preserved with sulfur dioxide, and the dried banana that treated with lemon juice treated with sulfur dioxide regarding the color, flavor and texture of the product. The sugar syrup counteracts enzyme action, which causes browning, and lemon juice preserves the natural color and flavor of the fruit (University of Idaho 1995, University of Georgia undated). As a result, the moisture content of the three samples was consistent with that reported by Dauthy (1995) and Eienaar (1998).

As part of the evaluation of the efficiency of the solar dryer, three tests were carried out. The results of the sensory evaluation of the dried products as discussed above indicated that panelists liked most of the dried products produced by the solar dryer. Second, to assess the quality of the sun-dried products, both objective and subjective methods were used.

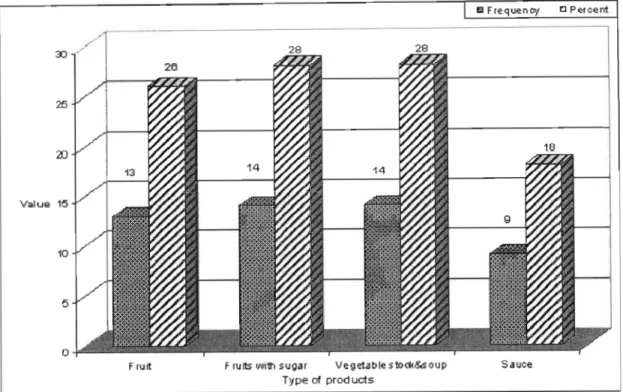

In addition, the selection of dried products identified in the market survey indicated that there is a market opportunity for smallholder products. The analysis of the second subproblem showed that the quality of dried fruits and vegetables could be improved by using a solar dryer and appropriate pretreatments before drying the products.