Introduction

Background and motivation of the study

Rational of the study

Problem statement

Research question

Objectives of the study

Location of the study

Significance of the study

Thesis outline

Summary

Introduction

The purpose of this literature review is to summarize various areas around lean and SMEs.

Lean

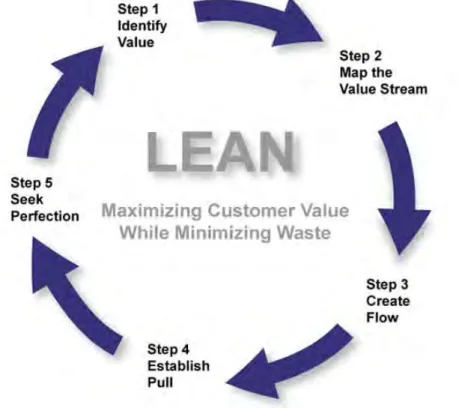

Weele (2005) states "Lean management is a philosophy of how to run a manufacturing organization which involves all aspects of the business system in general and design, manufacturing and supply management in particular". Based on the descriptions of these authors, Lean production is a competitive practice that reduces costs, improves the environment and the quality of the products.

Origins of Lean

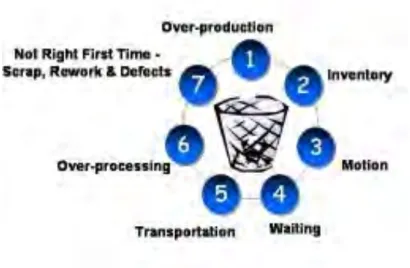

Sood (2010) believes that everything that does not add value to the production system should be eliminated. The wastes shown in the diagram are often labeled as activities that do not add any value to the production system.

Lean production system

The goal of the Lean Toyota Production System involves several technological terms and activities required to achieve the system's objective. Ensures a substantial improvement in the productivity of the organization. 2.5 Five principles of the Toyota Production System (TPS).

Lean manufacturing tools

- Value stream map

- Continuous or Smooth Flow Processing

- Continuous Improvement

- Just in time

- Production Smoothing

- Standardisation of work

- Flexible Workforce (Shojinka)

- Other Waste Reduction Techniques

The current status map is the first step in working towards the ideal state of the organization. Maintaining a buffer or safety stock between the production process is part of the Just-in-Case system.

Benefits of implementing Lean

However, Feld (2000) identifies that the purpose of Poke yoke is to observe the defective parts at the source, detect the progression of the defect, and avoid moving the defective part to the next workstation.

Challenges to successful Lean implementation

Initially, organizations can hire temps to free up some of the full-time staff to implement the system. These people can be used to implement Lean as well as maintenance later.

Lean manufacturing abroad

With proper execution of the general work area, organizations should be able to free up people to fill these roles. Understanding the full implications of lean and ensuring that everyone involved in the lean process knows what is required of them is essential to avoid lean implementation and management challenges (Mwacharo, 2013). But in the last five years, there has been a significant effort to use lean practices, and the results show it. 2012) further states that the Indian automobile sector is far ahead of the other sectors in the implementation of lean manufacturing principles.

It is noted that the Indian companies have forged ties with reputed foreign companies (which is common in the automotive sector), made progress in lean practices or become aware of the lean concepts through company-wide training programs.

South Africa's manufacturing industry

The demand for cars has increased drastically in India over the past two decades. Many global automakers and Tier-1 suppliers have already set up research, development and manufacturing facilities in India. According to the Boston Consulting Group's research, the United States currently serves as a benchmark for the year 2014. According to StatsSa's (2015) preliminary report for the third quarter, seasonally adjusted industrial production increased by 1.4%. % in the third quarter of 2015, compared to the second quarter of 2015.

The main contributor to the increase of 1.4% was the division of oil, chemical products, rubber and plastic products (4.3% and contributed by 0.9 percentage points) (StatsSa, 2015).

KwaZulu-Natal manufacturing industry

Definition of Small Businesses in South Africa

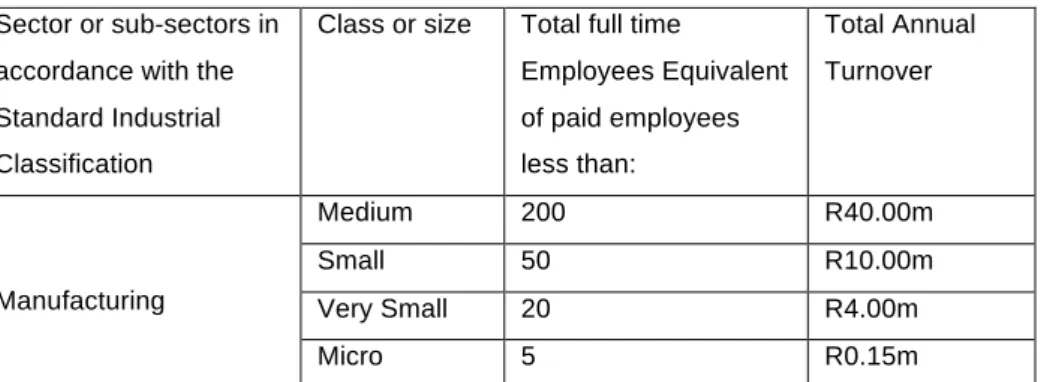

According to the National Small Business Act 102 of 1996, a medium-sized enterprise is defined as an enterprise with less than 200 full-time employees with an annual turnover of R, a small enterprise employs less than 50 full-time employees with an annual turnover of R , Very small enterprises employs less than 20 full-time employees with a turnover of R per annum, and finally a micro-enterprise employs less than 5 full-time employees with a turnover of R150 000. This breakdown of National Small Business Act categories is depicted in Table 2.2. Again, the researcher considered the total number of full-time employees as the main indication of SME and for the purpose of this study, the term SMEs has been used.

According to the National Small Business Act 102 of the establishment of the Advisory Body and the Agency for the Promotion of Enterprises; to provide instructions to state bodies for the promotion of small business in the Republic; and to ensure.

The Economic Contribution of SMEs

Challenges faced by SMEs

Conclusion

Introduction

Aim and Objectives of the Study

Participants and Location of the Study

Survey Population

From this population, the researcher focused only on manufacturing companies and further screened small and medium-sized manufacturing companies. However, the directory does not specify whether a business is small or medium, but the researcher was guided by the National Small Business Act 102 of 1996. The Act states that a small business has 21 to 50 full-time employees, and a medium-sized business is one that has between 51 and 200 full-time employees (Government, 1996).

Thus, the researcher found a target population of approximately 500 SMEs in the manufacturing sector by screening the directory.

Sample Size

31 The Durban Chamber of Commerce and Industry Directory has approx. 3 500 companies, which included all sectors of the economy.

Research Design and Methods

On the other hand, a quantitative approach is one in which the researcher mainly uses post-positivist claims for the development of knowledge, uses research strategies such as experiments and surveys, and collects data on predetermined instruments that yield statistical data (Daniel, 2010). The quantitative method was deemed necessary to achieve the aim of the research: to assess the level of Lean management practices among SMEs in the manufacturing sector.

Data Collection Strategies

- Construction of the Research Instrument

- Recruitment of Study Respondents

- Pretesting and Validation

- Administration of the Questionnaire

Most of the questions in the questionnaire used a five-point Likert interval scale and closed questions. Content validity, which is the measurability of questions in a questionnaire to adequately provide an analysis of fact-finding hearings. Internal validity, which is the ability of a questionnaire to accurately measure what the researcher wants to measure.

The ability of the questionnaire to accurately measure the predictions of the study, which is criterion-related validity.

Analysis of the Data

The purpose of the study was explained before the administration of the questionnaire so that the respondents were more informed. However, achieving a target of 218 recommended sample size was difficult due to several problems encountered, which include: some of the respondents refused to participate, difficulty in locating some physical addresses, and the distance and costs of business location among others. In this study, meaningful data and numerical models were found and used as primary data that formed the basis of the study and aimed at achieving the objectives of the study and answering its research questions.

Quantitative data were transformed into qualitative understanding to answer the objectives and research questions of the study.

Ethical considerations

37 This study was conducted without prejudice or bias towards data collection and data analysis.

Summary

Introduction

Response rate

Biographical data of participants

Age and gender distribution

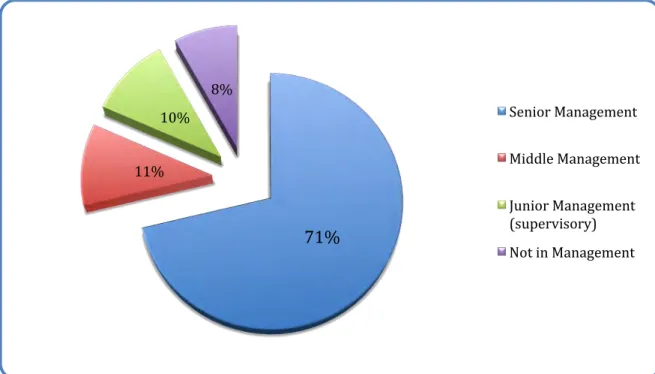

Employment position held

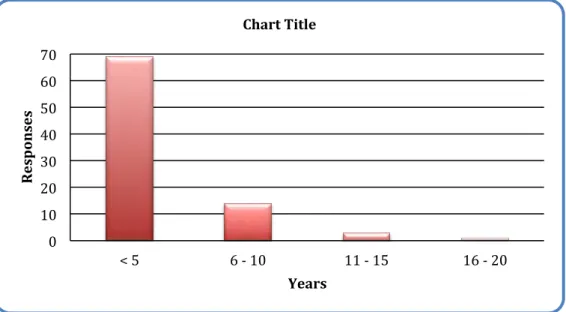

The findings of this analysis are presented in table 4.1, most senior management positions are held by men. This showed that for every top management position held by a female participant, there were approximately 2 males holding similar management positions. This group represented 79.3% of the 87 participants who indicated the number of years they had held their current positions.

Fourteen (16.1%) respondents indicated that they had been with their company for approximately 6 to 10 years, three for 11 to 15 years, and only 1 participant had been in the same position with their company for at least 16 years.

Company background

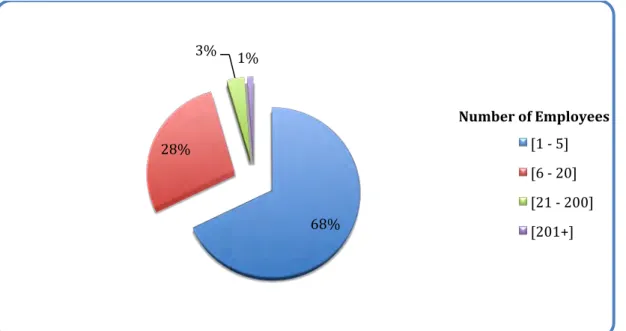

- Total Number of Employees

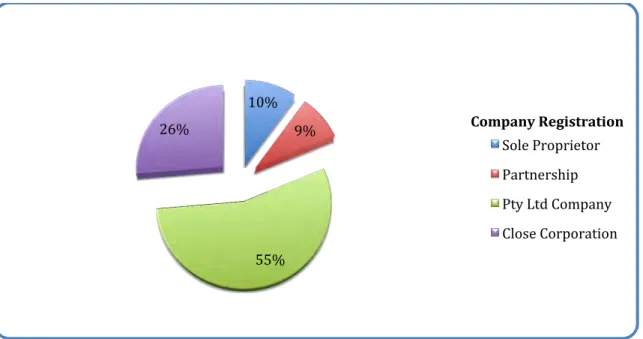

- Company registration Status

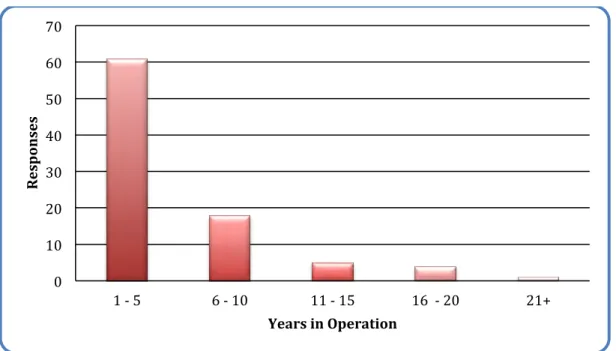

- Number of years in operation

- Business activity

- Annual company revenue

Of the 90 participants who indicated how many employees worked in their company, the majority indicated that they had a maximum of 5 employees. Based purely on size, it can reasonably be inferred that approximately 95% of the enterprises represented were micro or very small enterprises (i.e. had fewer than 20 employees). These companies represented 68.5% of the 89 participants who indicated the operational experience of their respective companies.

As illustrated in Figure 4.7, Rubber and Plastic Products accounted for almost 50% of the selected activities.

Objective 1: To assess the level of awareness of Lean practices within the small and medium

- Understanding of Lean Management

- Awareness of the Lean practice in their companies

- Which of the following have you implemented?

- Methods to successfully implement Lean practices

- If Lean elements have been implemented, did the improvements meet your expectations?

- Please indicate reasons why certain improvements did not meet expectations

As can be seen in Figure 4.10, 80% of the respondents indicated that they are familiar with the lean practices used in their companies. This is evidenced by 83% of respondents who indicated that they use them in their companies for each program. This is demonstrated by this method, which was selected 44% of the time compared to other methods.

Of the remaining responses, 6 (7%) strongly disagreed and 2 (2%) disagreed with their perceived expectations of Lean practices implemented in their companies.

Objective 2: To assess the challenges encountered when implementing Lean practices

Which of the following Lean management challenges do you face in your business?

To assess the challenges respondents face in lean management, participants were asked to select as many reasons as they could from 4 common or known challenges. As can be seen from Figure 4.14, among the challenges of lean management in the companies presented, technological challenges ranked highest. Supply chain, cultural issues and employee development were rated more or less equally in terms of the challenges they presented.

55 experience any problems with Lean management or, alternatively, the challenges they faced were not presented as options in the current survey.

Thorough training and support decreases the implementation challenges

Do you have a need for external support in order to improve your company’s performance?

Objective 3: The potential benefits gained from implementation of Lean practices

Lean Management Practice is beneficial to our business environment?

To assess participants' opinions about the usefulness of Lean management practices in their environment, they were asked to rate their degree of agreement or disagreement with the statement "Lean Management practice is beneficial to our business environment". Their combined responses indicate that 83% of them felt that Lean management practices were beneficial to their organizations.

Which of the following benefits do you achieve when implementing Lean management?

Did your organization get support from an external party?

Summary

Training and communication were rated as 2 of the most important methods for implementing bad practices. 70% of participants felt that the freelance practices in their organizations were effective and met their personal satisfaction levels. Employees not being given sufficient training and the short time frame for implementing lean practices were cited as two of the most important reasons why Lean implementation failed.

In addition, the majority of respondents also believed that outsourcing professional assistance to assist in the implementation of Lean practices would also contribute to reducing implementation challenges.

- Introduction

- Aims and objectives of the study

- Demographics of respondents

- Lean practices awareness

- Challenges in Lean practice implementation

- Lean Benefits

- Summary

Although the purpose of the survey was to assess the level of awareness and implementation of Lean, it is important to note that the majority of respondents (i.e. 71% of respondents) were senior managers. It was important to gain insight from respondents regarding the specific Lean tools implemented and training they received as this could assess implementation among SME manufacturers in KZN. Training programs, standard work, 5's and skills matrix were largely selected from the Lean tools list (FELD, 2000), this could explain the awareness of Lean practices.

It was established that the respondents had a basic understanding of the Lean tools that have been implemented in the organization.

- Introduction

- Summary and conclusions

- Implications of this research

- Recommendations

- Limitations and areas of further study

- Access to study sample

- Research Scope

- Demographic data

- Summary

This study therefore bridges the gap in the knowledge pool on lean management practices among small and medium-sized companies within the manufacturing sector. The study aimed to identify the challenges faced during the implementation of lean practices within SMEs in the manufacturing sector. It is recommended to involve employees in the selection of lean practice(s) that can be used within the organization.

The study sought to examine the level of lean management practices of SMEs within the manufacturing sector in KwaZulu-Natal.

RESEARCH QUESTIONNAIRE CONSENT

I………(full names of participant) hereby confirm that I understand the content of this document and the nature of the research project, and I agree to participate in the research project.

RESEARCH QUESTIONNAIRE

If No above: the purpose of lean manufacturing is to eliminate waste and increase the value of manufactured products, thereby increasing the company's competitiveness 11. Based on the following table, which of the following have you implemented (select all that apply). Which of the following lean management challenges do you face in your company (Choose all that apply).

Which of the following benefits do you achieve when you implement the practice of lean management (Select all that apply).

ETHICAL CLEARANCE

TURNITIN REPORT