The heat capacity also showed a large dependence on the moisture content of the sample, but it was not a linear relationship. The big challenge that most municipalities face is to find an efficient and sustainable faecal sludge management for disposing of the sludge that has been emptied from the full pits.

Purpose of the study

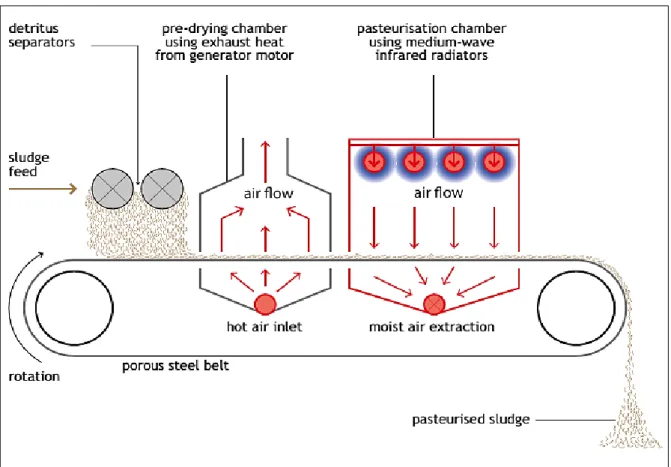

Janicki Industries Electricity production facility that uses fecal sludge as a fuel source for steam generation. Understanding, characterizing and modeling the drying kinetics of fecal sludge is essential for the design, operation, control and optimization of the drying process.

Objectives of the study

Nevertheless, the information regarding drying of fecal sludge from local sanitary facilities is not readily available in the literature, thus forming the basis of this particular study.

Dissertation outline

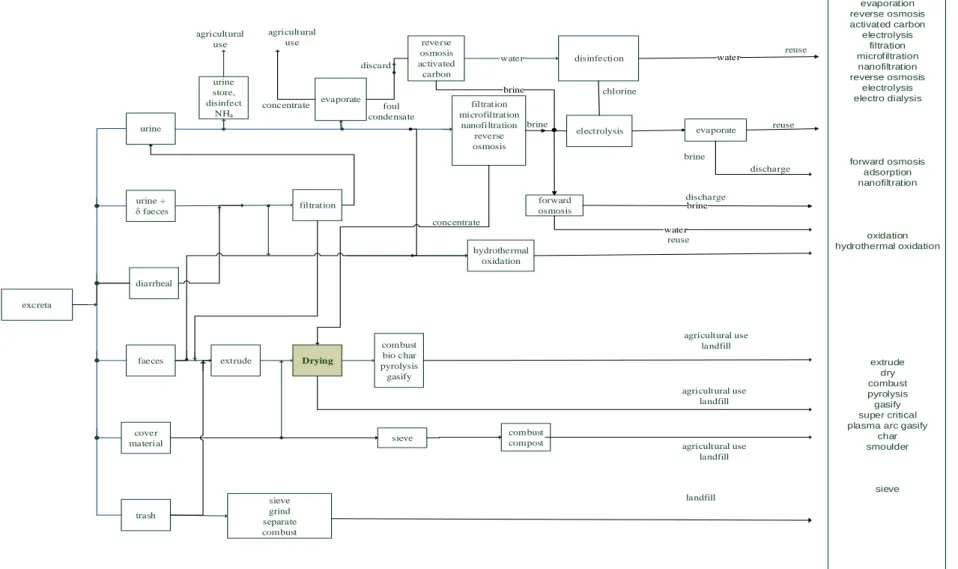

This chapter aims to outline the relevant literature needed to achieve the desired goals. In the first part of this chapter, sanitation systems and the management of fecal sludge from VIP latrines are briefly introduced.

Sanitation systems

Ventilated improved pit (VIP) latrines

Description and characterisation of the contents of VIPs

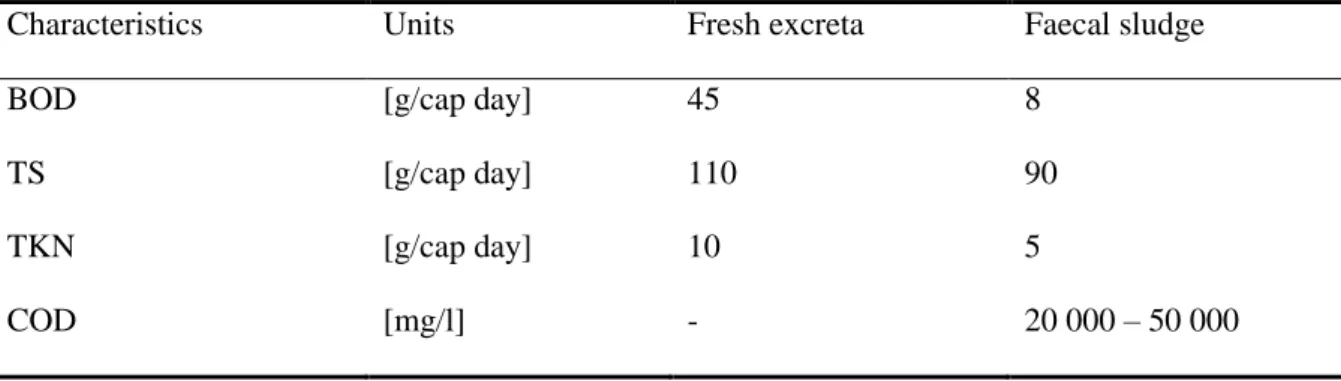

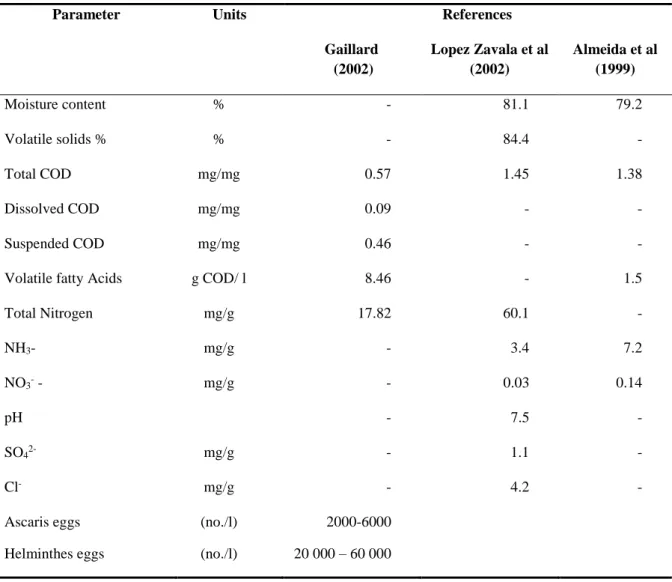

Fecal sludge consists of water-soluble and insoluble nutrients, most of which are essential for the proper growth of plants. The composition of fresh feces (urine and feces) and fecal sludge collected from VIP latrines varies widely.

Collection and Disposal of Faecal Sludge

Currently, the use of fecal sludge as a biofuel is at a premature stage and is much less utilized than sewage sludge from wastewater treatment plants (Muspratt et al., 2014a). 2014a) reported that the average calorific value of fecal sludge obtained from the cities of Kumasi (Ghana), Dakar (Senegal) and Kampala (Uganda) was 17.3 MJ/kg.

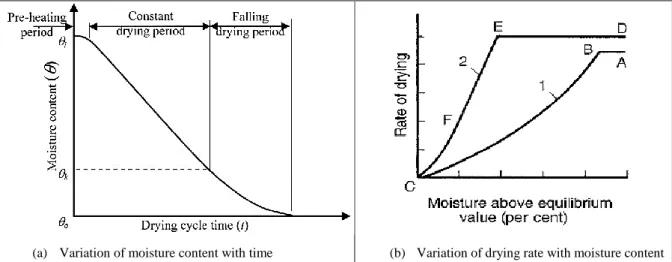

Concept of drying

- Drying technologies for sludge treatment

- Moisture in solids

- Convective heat and mass transfer

- Drying kinetics

- Process and material related factors that influence convective drying

- Drying Models

In the case of infrared (IR) drying, the surface of the solid is heated by exposure to IR radiation. In equilibrium, this means that the moisture activity in the material is equal to the relative humidity of the air (Coumans, 2000).

Effect of drying on nutrient content and thermal properties of excreta

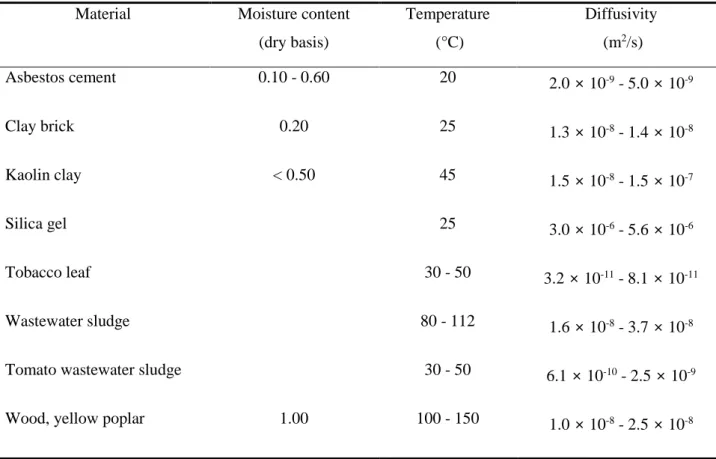

Thermal diffusivity provides an indication of the rate at which the temperature of a material changes when subjected to a temperature gradient (Bergman et al., 2011). Thermal properties are greatly influenced by the composition of the material, water content and temperature. All the authors came to the same conclusion that thermal conductivity and heat capacity increase as the moisture content of the material increases.

The same effect on thermal conductivity is observed as the temperature of the material increases. This chapter details the type of mud used for this study as well as the custom designed apparatus used to determine the drying kinetics. This section also describes the experimental protocol for characterizing the chemical and thermal properties of sludge before and after drying.

Sludge source and processing

Description of the Drying rig

Experimental procedure

Sample preparation

Operating conditions

Physico-chemical characterisation of sludge

Moisture content and ash content

Thermal analysis of faecal sludge

Nutrient analysis

Data analysis

Moisture ratio

Where 𝑀, 𝑀0 and 𝑀𝑒 are the mass of the sample at a given time, the initial mass and the mass at equilibrium moisture content, respectively.

Drying curves

Evaluation of the effective moisture diffusivity

Where 𝑀, 𝑀0 and 𝑀𝑒 are the mass of the sample at a given time, the initial mass and the mass at equilibrium moisture content, respectively. d) Negligible shrinkage of the sludge sample during drying. These assumptions mean that the effective moisture diffusivity can be considered independent of the local internal moisture content. For the purpose of this study, the equilibrium moisture content was considered as the moisture content of the sample after the drying experiment was completed.

Me is the final mass of the dried sample (equilibrium mass) (g), M0 is the initial mass of the sample (g). Plotting a plot of ln MR vs t produces a straight curve from which the effective moisture diffusivity can be determined by manipulating the slope of the plot. The variation of the effective diffusivity of water with temperature is classically represented by the Arrhenius equation (Chemkhi and Zagrouba, 2005), taking into account the fact that the molecular kinetic energy increases when the temperature increases.

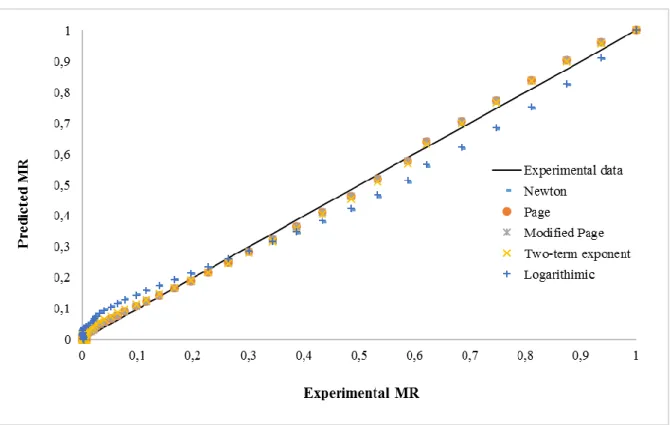

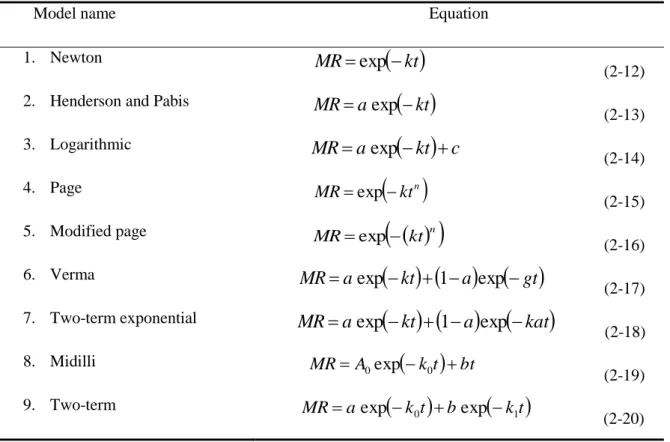

Fitting of drying curves to empirical models

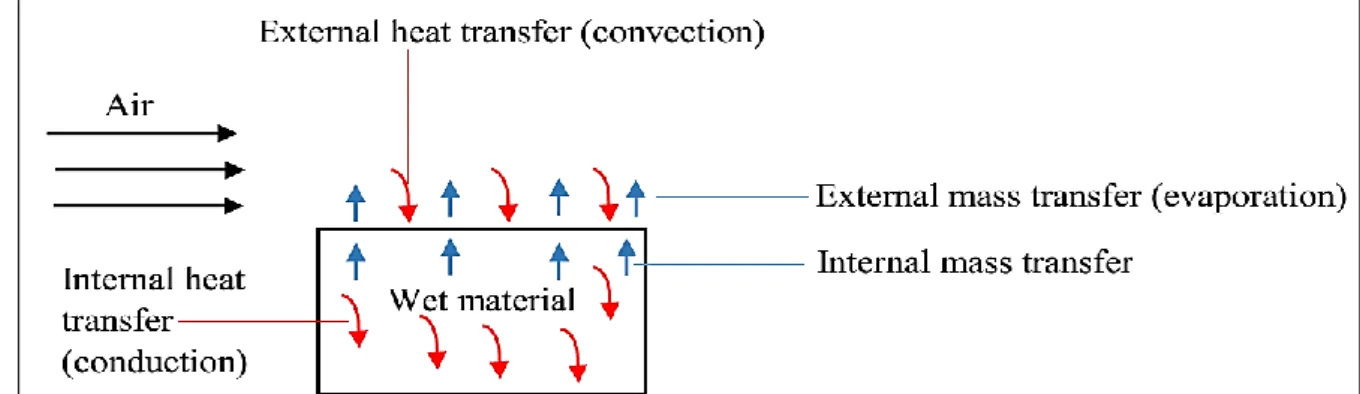

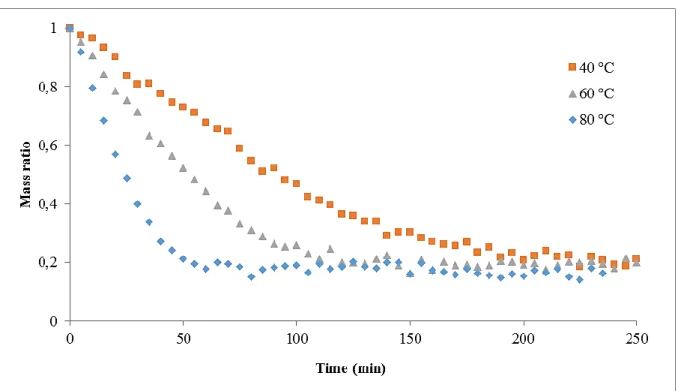

This chapter presents and discusses the experimental results obtained by convective drying of sludge from ventilated improved latrines. As explained in section 2.3.3, transport phenomena consist of internal and external resistance to heat and mass transfer. Therefore, resistance to transport phenomena controls the rate of moisture removal within the solid (drying rate).

By analyzing the drying characteristics of faecal sludge, the dominant transport phenomena can be determined with the drying progress. This chapter is divided into 3 main sections, the first detailing the effect of air temperature, relative humidity and flow rate, as well as sample thickness on sludge drying kinetics. The second section highlights the effect of drying on the thermal properties as well as nutrient content of sludge, properties which are essential in the potential design of a sludge dryer and also vital for the agricultural sector.

Drying kinetics

- Effect of air temperature on drying rate

- Effect of temperature on the effective moisture diffusivity, (D eff )

- Effect of air relative humidity

- Effect of sample thickness

- Effect of air velocity

The existence of a period of decreasing rate in the drying kinetics obtained in this study is evidence that the drying of faecal sludge is influenced by internal resistance to mass transfer. Linear regression was performed only on the sections of the drying curves corresponding to the period of falling rate. From the drying kinetics curves, it was found that the relative humidity of the air has a great influence on the drying time of faecal sludge.

The influence of the relative humidity of the air on the variation of the drying rate with the humidity ratio was investigated and the results are presented in Figures 4-7. Both the constant speed period and the decreasing speed period are significantly affected by the change in the relative humidity of the drying air. Increasing the relative humidity reduces the difference between the water content of the drying air and the water content of the surface of the solid undergoing the drying process.

Analysis of thermal properties

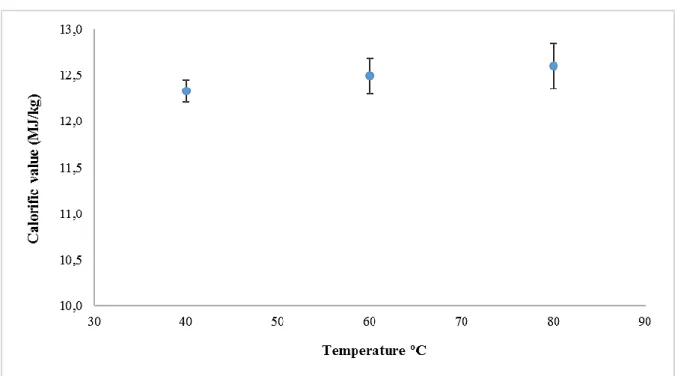

Calorific value

As shown in Figure 4-12, there was no significant variation in the calorific value of sludge dried with the different air temperatures with the average value around 12.5 MJ/kg wet solids. This observation may be confirmed by the amount of volatile solids contained by the dried product, which may affect the calorific value of a solid fuel. An investigation into the effect of drying air temperature on the volatile solids was carried out and the results are depicted in Figure 4-13.

This means that sludge exposed to temperatures higher than 105 ºC can lose a significant amount of volatile solids, which can result in a significant change in calorific value. The effect that relative humidity has on the calorific value has been investigated and the results are shown in Figure 4-14. As illustrated in Figure 4-14, it can be seen that the relative humidity under which this study was conducted has an effect on the resulting calorific value of the dried product.

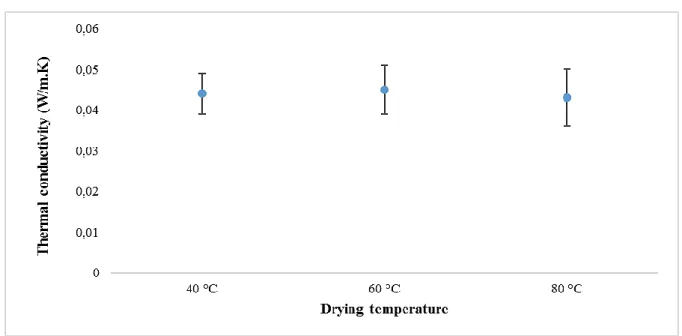

Thermal conductivity

This observation can be attributed to the fact that increasing the operating humidity of the drying air results in an increase in the equilibrium moisture content, therefore lowering the calorific value as part of the heat released during oxidation will be used to evaporate the remaining moisture. . There was no significant difference in the final thermal conductivity of the dried pellet at different air temperatures, as shown in Figure 4-15. This may be indicative of large void spaces in the solid which are occupied by air after the sludge has dried, leading to a decrease in the overall conductivity of the material (Hanson et al., 2000, Bart-Plange et al. ., 2009).

Thermal conductivity changes were analyzed by removing the sludge at different time intervals during the drying process, and moisture content and thermal conductivity were evaluated. The variation of thermal conductivity of VIP sludge with moisture content is shown in Figure 4-16. This is as a result of the contribution of water within the sludge. Thermal conductivity increased linearly with increasing moisture content (with coefficient of determination, R2 equal to 0.995).

Heat capacity

This trend is consistent with the results obtained by Hanson et al. 2000), on the study of drying material with high water content. It is clear that the moisture content has a significant effect on the heat capacity of the sludge.

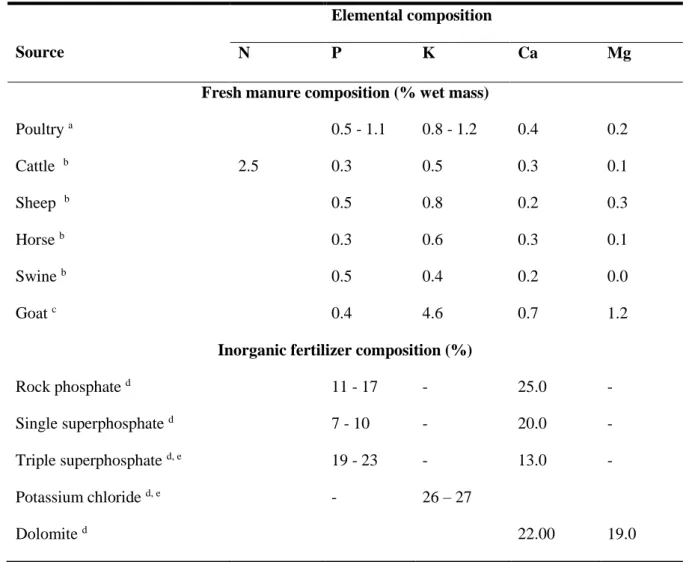

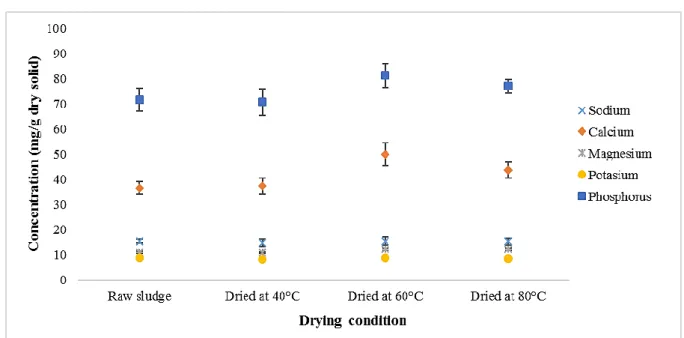

Nutrient analysis

The concentration of orthophosphates showed no difference between the initial concentration in the raw sludge and the concentration in the dried pellets. However, there was a decrease in nitrate and ammonia concentrations between raw sludge and dried pellets. The reduction in ammonia concentration was the most significant, dropping from 24 mg/g dry solids in the raw sludge to about 4.5 mg/g dry solids.

The concentration of nitrates decreased from 1.5 mg/g dry solid in the raw sludge to about 0.45 mg/g dry solid. The concentration of total phosphorus was significantly higher compared to that found in literature as shown in Table 4-1. Compared to popular manures used for agriculture, the concentration of nutrients in the sludge found in this study was greater as the same nutrients as detailed in Table 2-4.

Empirical modelling of the drying of VIP sludge

However, the constant n of the page model did not show any trend as temperature and pellet diameter changed as shown in Table 4-3. The validity of the model could be increased by increasing the temperature and diameter of the pellets. The effect of drying on the concentration of nutrients in the sludge was investigated in order to evaluate the potential reuse of the dried product in agriculture.

The effect of the drying procedure on excretory energy values for poultry and other species. Attach the spray chamber socket to the ball joint on the base of the torch and secure with the torch clamp. The temperature variation of the k-constant for the folded sheet and cylindrical configuration was evaluated and represented in the figure below.

It was assumed that the variation of the constant A with the diameter of the pellet follows a power relationship of the shape. 2 variation of the constant A with pellet diameter obtained by regressing k, the Page constant of the model with the temperature of the cylindrical configuration.