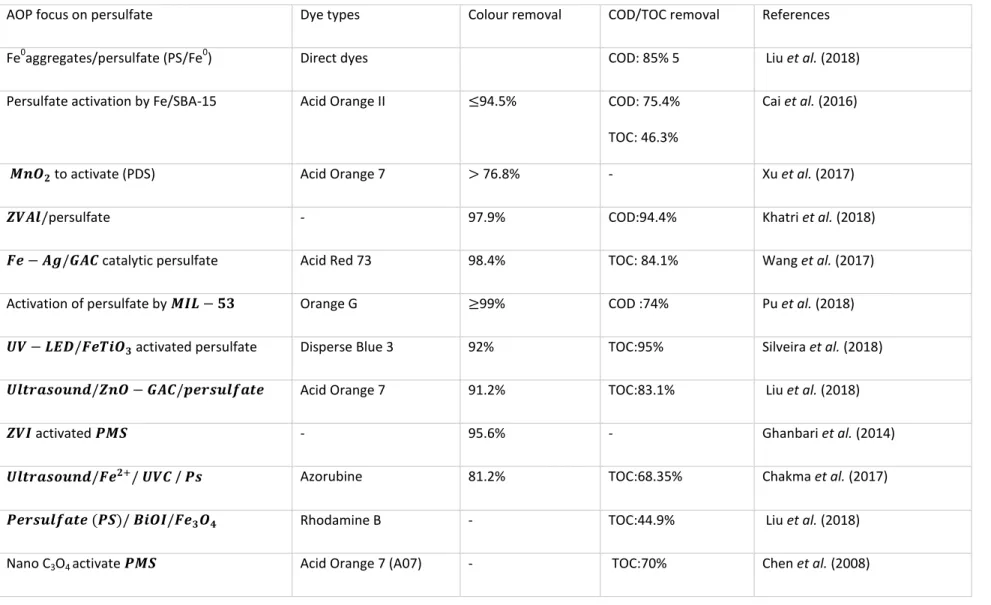

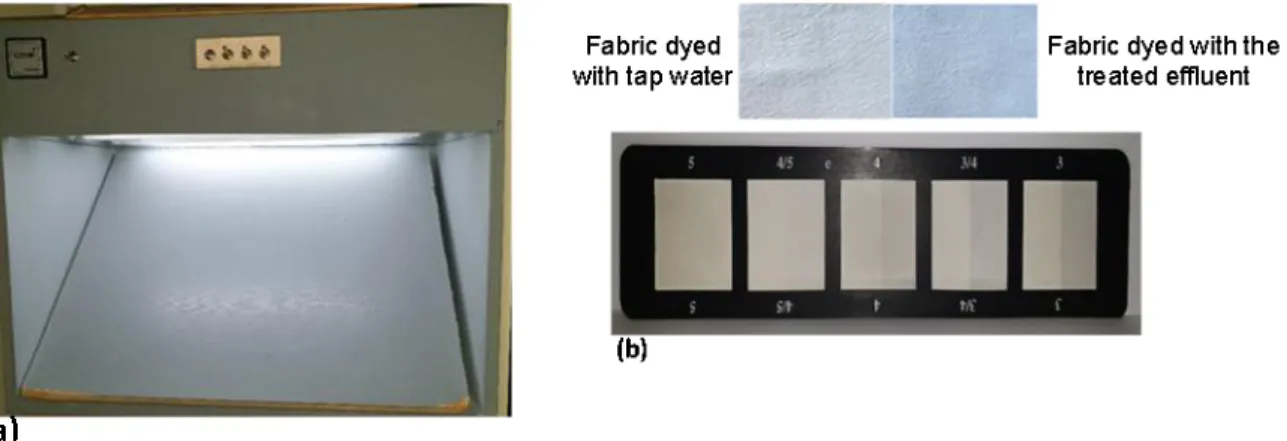

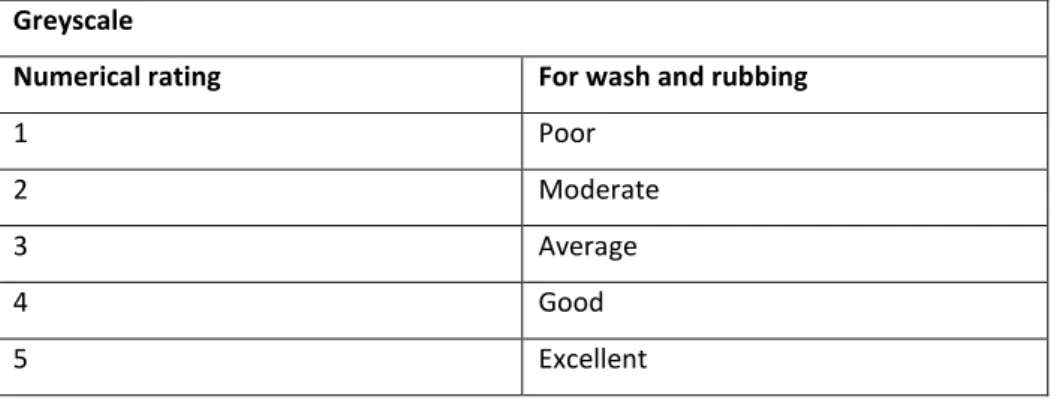

47 Figure 4-14: Color fastness of dyed fabrics after 5 hours of pre-treated effluent. 48 Figure 4-15: Color fastness of dyed fabrics after 48 hours of standing of the treated stream. 49 Figure 4-17: Color fastness of dyed fabrics to 50% dilution of treated effluent before reuse.

Introduction

- Background

- Research problem

- Aim and objectives

- Significance

- Delineation

- Thesis structure

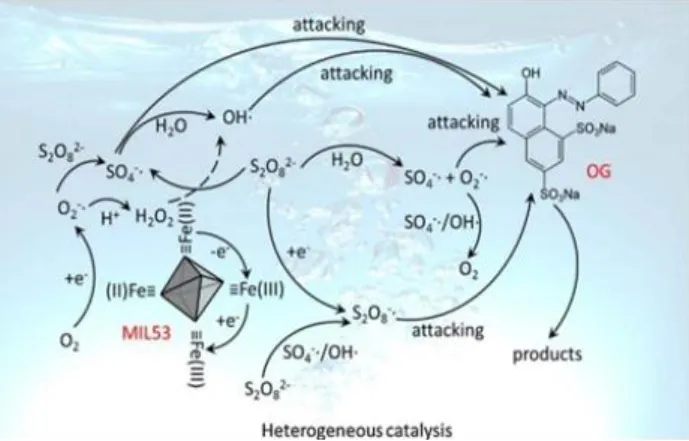

The effects of various parameters such as dye concentration in the dyeing process, oxon concentration during the treatment process and number of reuse cycles in the reuse dyeing process on the treated effluent and dyed fabrics were all evaluated. The treated effluent resulting from the CO-SR-AOP has not been evaluated for reuse in the dyeing process. The purpose of this study was to evaluate whether textile wastewater from reactive dyes in the dyeing of cotton fabric, and treated using the cobalt oxide-mediated advanced sulfate radical oxidation process, would be suitable for reuse in dyeing processes in the textile industry.

Literature review

Introduction

Textile industry: An overview

- Classification of dye

- Textile fabric types

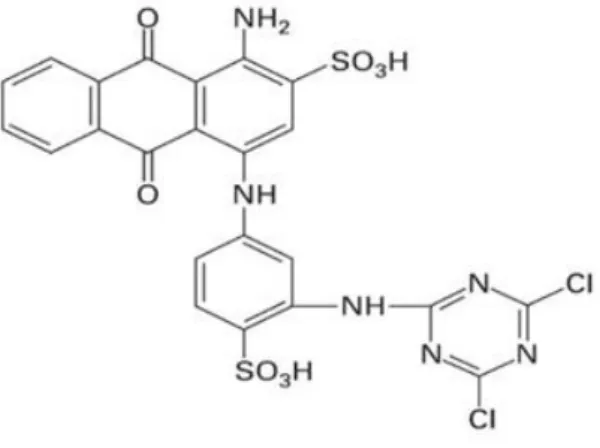

Some examples of azo dyes are: acid, basic, direct, disperse, mordants, reactive and solvent dyes (Vastag et al., 2018). Therefore, dyeing of wastewater from reactive dyes is one of the main sources of many environmental pollution problems (Karim et al., 2018). Reactive dyes are used to dye most cotton fabrics due to the fact that they produce a full range of lustrous colors with a high degree of color fastness to washing (Khatri et al., 2015).

Textile wastewater from the textile industry

- Dyeing process

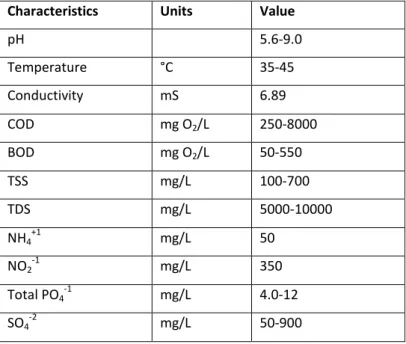

- Characterisation of textile effluent

- Effects of discharging the textile effluent into the environment

Textile wastewater is known to be one of the most dangerous wastewaters for the environment when it is released without any proper treatment (Hayat et al., 2015). Due to its characteristics, effluent from the textile industry can be considered harmful to both the environment and human health (Rajasimman et al., 2017). The azo-chromosphere in textile wastewater can be transformed into toxic, mutagenic and carcinogenic amines (Stagnaro et al., 2015).

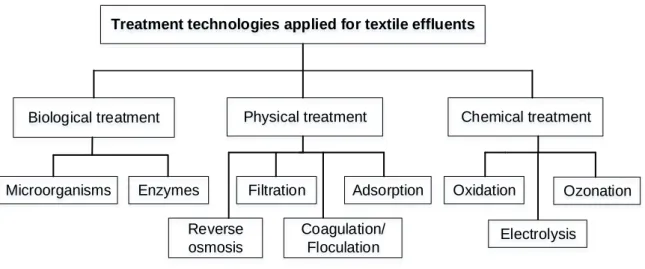

Treatment technologies applied to textile wastewater

- Biological treatment

- Physical treatment

- Chemical treatment

One of the most widely used catalysts is titanium dioxide (TiO2) as it is cheap, stable and highly reactive (Verma et al., 2012). However, it cannot be used for industrial textile wastewater treatment, as it has selective compatibility (Jorfi et al., 2016). Disadvantages of the oxidation process using ozone is the production of highly toxic and difficult to degrade by-products during the treatment process (Verma et al., 2012).

Water reuse concept in the textile industry

- Colour conformity

- Colour

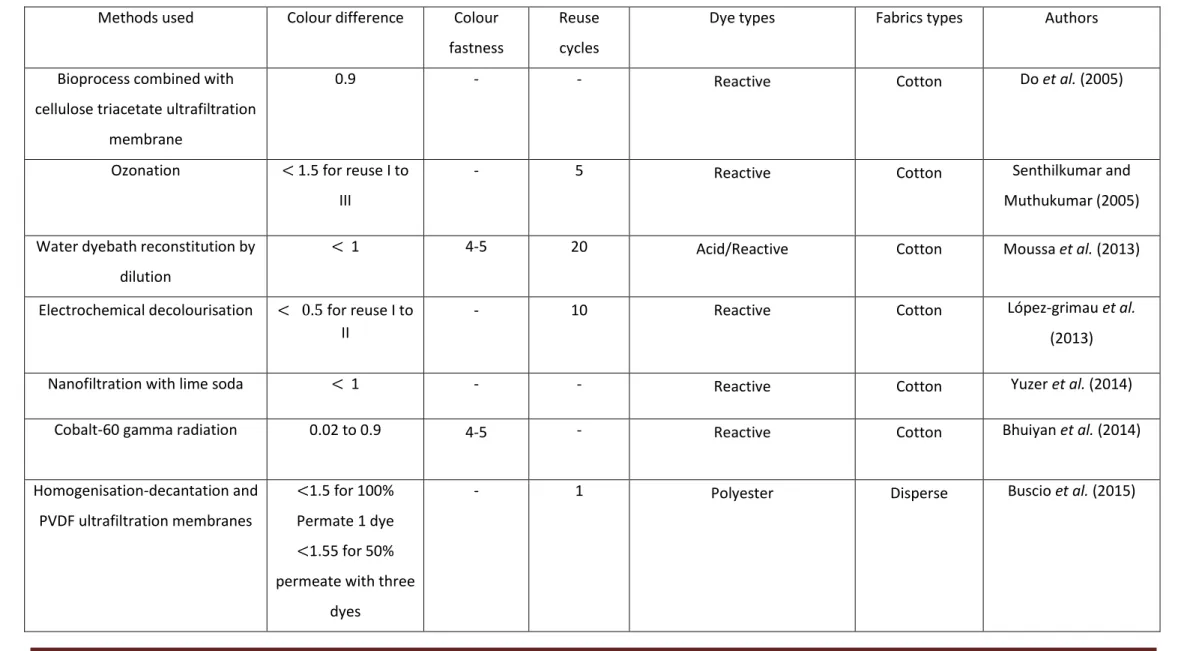

- Summary of fabric properties obtained with treated textile effluent

Quantification of the salt residues (NaCl and Na2SO4) to know how much salt still needs to be added. They explain that the waste water obtained from the fabric pre-treatment process can be reused without being filtered. The color difference of the fabrics showed that navy blue dyed fabrics had a color difference (E) of less than 1, while the yellow dyed fabrics had an E of more than 1 whether the water passed through the filters or not.

This was explained by the fact that during the cleaning process the whiteness index of the fabrics that were removed was lower. A laboratory continuous system was used to recycle the treated wastewater prior to dyeing without changing the quality of the fabrics. A comparison of fabric samples dyed with treated wastewater and those dyed with tap water revealed "good" to "excellent".

Senthilkumar and Muthukumar (2005) attempted to reuse the treated wastewater five times, using reactive dyes Red 5MR and Golden Yellow MR on cotton fabrics. When the dye concentrations were 0.5, 1.0 and 1.5%, the weight of the fabrics and the color difference from the standard were 0.7, 0.46 and 0.32, respectively, with thermally treated industrial wastewater. After purification of the wastewater with a sulphur-free agent, sodium borohydride and silver nanoparticles, the reuse studies were carried out 5 times without the addition of extra salt.

In the first cycle, E was equal to 0.6 and good color fastness 4; while the second dyeing gave a color difference of 1.08, with a color fastness rating of 3, due to the prohibition of protein adsorption of the dye by the fiber, leading to color failure.

Design of experiments (DoE)

- Response surface methodology (RSM)

- Analysis of variance (ANOVA)

The desirability of the response from numerical optimization is an objective function whereby the desirability of the response lies between 0 and 1, where 0 means least desirable and 1 most desirable.

Conclusion

Therefore, further studies should be conducted to evaluate the reusability of these effluents produced through the sulfate radical-based advanced oxidation process.

Research methods

- Introduction

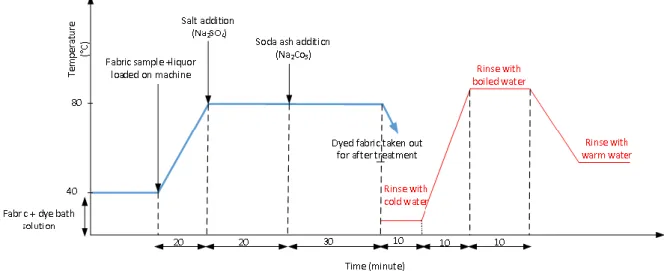

- Fabric dyeing process and characterisation

- Pre-treatment

- Dyeing procedure

- Colour fastness

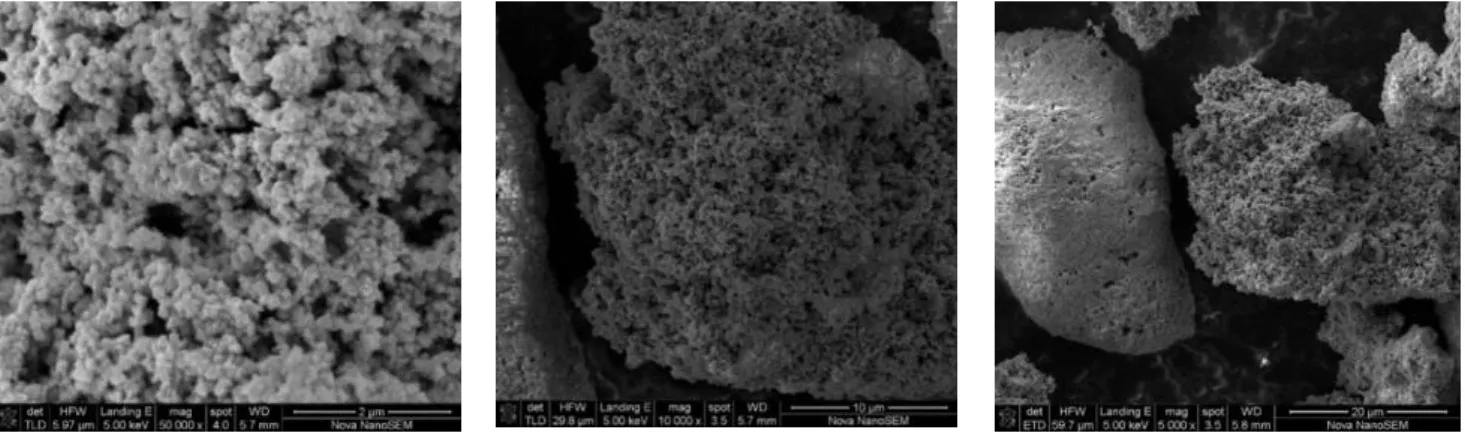

- Catalyst preparation and characterisation

- Water treatment reactor set up

- Colour, conductivity, COD, sulphate and cobalt analysis

- Reuse of treated textile effluent

- Factorial design analysis and presentation of results

- Conclusion

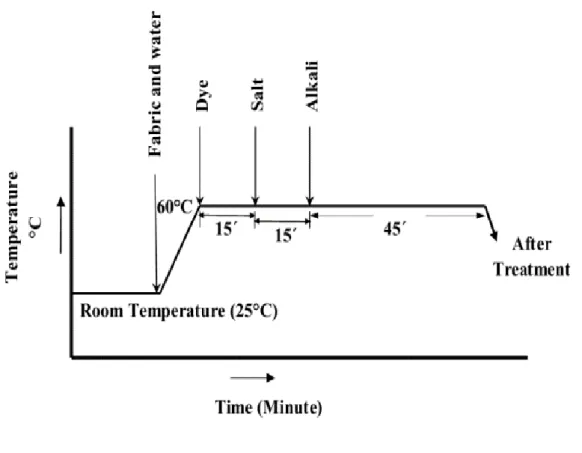

The calculated mass of the reactive dye was poured into a beaker with 150 ml of cold water and the temperature of the solution was adjusted to 40°C. After the rinsing step of the dyeing process, the fabric was allowed to dry at ambient temperature. The washing fastness evaluation by the WASHTEC-P machine was helpful to contrast the treated and untreated sample with shades of gray for the changing color of the painted samples.

The color of the wastewater was assessed by measuring the color degradation of the treated water using a portable color meter (Figure 3-11a). The color of the treated wastewater was measured the day after the treatment process to allow the sulfate radicals responsible for the color degradation to complete. The conductivity of the treated wastewater was analyzed after each treatment using the Lovibond SD320 Con waterproof hand meter.

This was done to see how the conductivity of the treated wastewater behaves during the treatment process. To prepare the blank, the cap was removed from the vial, the vial was held at a 45 degree angle. The effect of each factor on the color fastness of the dyed fabrics was studied.

Fifteen experiments were run for each combination of the factor levels selected by the software.

Preliminary studies

Introduction

Characterisation of the treated textile effluent from cobalt oxide and sulphate radical-

- Colour degradation and conductivity of the treated effluent

- Evaluation of the variation of dye concentration at constant Oxone concentration during

- Colour fastness of the dyed fabrics at each process condition

- Effects of recycling salt found in the treated effluent on the colour fastness of the fabric

- Evaluation of the effects of standing time of the treated effluent on colour fastness

- Evaluation of the effects of dilution of the treated effluent on colour fastness

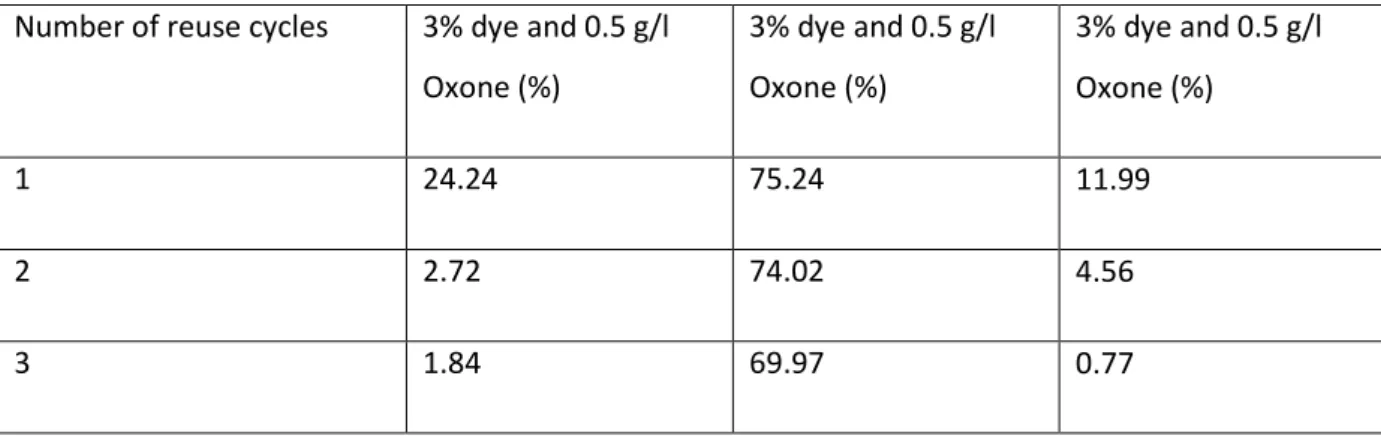

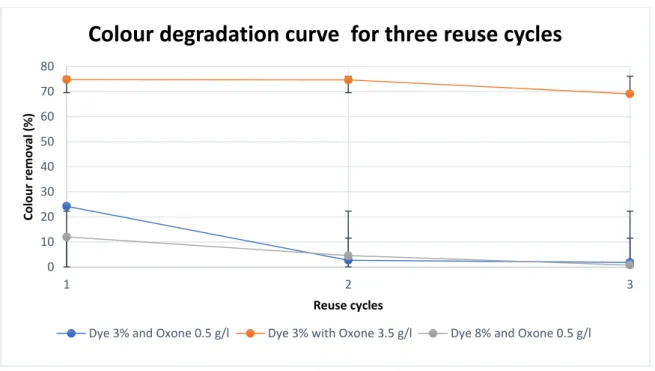

The conductivity (1.69 µs/cm) of the treated effluent increased to 2.6 µs/cm, 4.1 µs/cm for processes dyed with the same amount of dye (3% dye concentration) and treated with 0 .5 g/l and 3.5 g/l. respectively after the first treatment. Therefore, the increase in conductivity in the treated effluent corresponded to the increase in the amount of salt in the same effluent. It was observed that for both cases, the conductivity of the treated effluent increased as the treated effluent was reused.

However, the conductivity of the treated effluent dye reused in the dyeing process with the standard recipe is higher than the one dyed with the modified recipe. Before the first reuse cycle, the conductivity of the treated effluent in both cases was 2.6 µs/cm. Page Effects of COD of the treated effluent when reused three times with variation in dye.

Color fastness of the material dyed at each treatment process condition (discussed in section 4-2-1) is recorded in the following figures. The effects of the standing time of the treated effluent at treatment process conditions of 3% of dye concentration and 0.5 g/l, as well as treated wastewater that is reused three times, on the color fastness of the. The standing time of the treated wastewater had no effect on the properties of the colored substances in the reuse process.

Since it did not matter whether the treated effluent was reused after 5 or 48 hours after the effluent treatment, the color fastness of the dyed fabrics was still the same.

Conclusion

Finally, the number of reuse cycles that treated sewage undergoes is from one to three reuse cycles.

Effect of process parameters and their interactions on colour fastness of the dyed fabrics51

- Optimisation of parameters using Box-Behnken design with RSM and its validation

- ANOVA and estimated regression coefficients for colour fastness

- Model determination

- Model validation

- Interaction effect of variables on colour fastness of fabric dyed with treated effluent 56

- Interaction effect of Oxone level and reuse cycles on colour fastness of the dyed fabrics at

- Optimum conditions for colour fastness

- Criteria for optimisation

- Predicted values of colour fastness at the optimum settings

- Conclusion

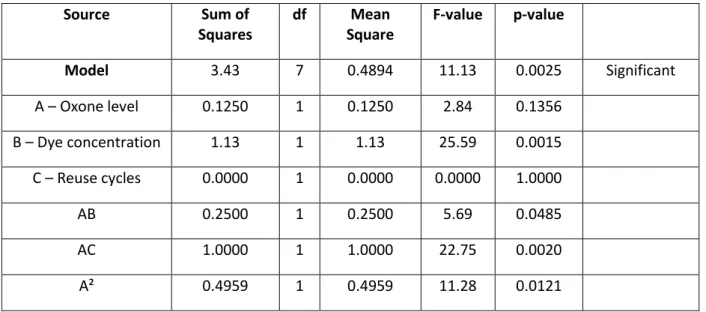

These binary terms show that there is an increasing effect between Oxone level and dye concentration (AB) and Oxone level and recycling cycles (AC) on the color fastness of the dyed fabrics. This section discusses the color fastness response surface as a function of the selected parameters. Finally, the effects of Oxone level and dye concentration on the color fastness of the dyed fabrics show that medium (0) levels of Oxone content (1 g/l), dye concentration (5%) and recycling cycles (2) resulted in the color fastness of the colored fabrics of Good (4).

The interaction effects of Oxone content and recycle cycles on color fastness with a constant dye concentration of 5% are shown in Figure 5.3. Therefore, with the increase in the number of reuse cycles of the treated waste water from -1 to +1 (1 to 3) level, a decrease of about 16% in color fastness of the dyed fabrics was observed. Finally, the combined effect of Oxone levels and recycle cycles shows that 1 g/l level Oxone level (0), 2 levels of recycle cycles (0) and 5% level of dye concentration (0) resulted in a Good (4 ) assessment of the color fastness of the dyed fabrics.

In order to determine the optimal conditions under which maximum color fastness of dyed fabrics could be found, the criteria shown in Table 5-5 were determined. Optimum conditions for color fastness of single-flow dyed fabrics treated with cobalt oxide catalyst and sulfate radical AOP are shown in Table 5-6. The effects of oxon level, dye concentration and reuse cycles at three levels (low, medium and high) on the color fastness of dyed fabrics were studied and the optimum process conditions were determined.

The interaction effects of all process parameters have a significant influence on the color fastness of dyed fabrics.

Conclusions and recommendations

Introduction

Conclusions

- Preliminary studies

- Colour fastness of the fabrics dyed with the treated effluent

Recommendations

Recycling of textile wastewater for dyeing using combined technology with ceramic microfiltration and surface-treated sugarcane bagasse:. toxicity evaluation using Channa punctatus as a model. The role of auxiliaries in the immersion dyeing of textile fibers: Part 6 analysis of conventional models describing the way in which inorganic electrolytes promote reactive dye uptake onto cellulose fibers. Development of a bioprocess combined with membrane technology for the treatment and recycling of textile wastewater.

Enhanced Coagulation-Photocatalytic Treatment of Acid Red 73 Dye and Real Textile Wastewater Using Synthesized MgO Nanoparticles UVA/. Electrochemical decolorization of cotton dye baths for reuse purposes: a way to reduce the salinity of textile wastewater. Combined anaerobic-ozonation process for textile wastewater treatment: Removal of acute toxicity and mutagenicity.

Biodegradation of wastewater from the textile dyeing industry using a modified anaerobic sequential batch reactor – Start-up, parameter optimization and. Treatment of a simulated textile wastewater in a sequencing batch reactor (SBR) with the addition of a low-cost adsorbent. Reuse of the purified textile waste water and membrane brine in the wet textile processes: disruptive effects on the cotton fabric.

The measurement of the percentage of color removal and conductivity of the treated effluent at different process conditions is shown in Appendix A.