Flow Process Improvement Through Simulation In Electrical Part Manufacturing.

Teks penuh

Gambar

Dokumen terkait

Further improvement on the simulation process in areas such as queue analysis on the time and number of parts waiting time could add greater complexity to the

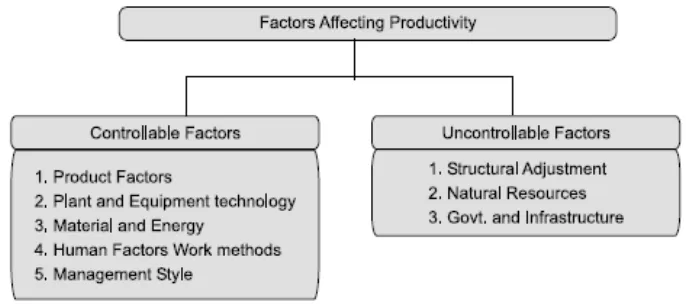

This methodology will consist of productivity improvement procedures such as problem identification in an assembly line, methods for pilot study, and applying improvement

This tools and techniques also take as knowledge that all their employees must have it to make quality life in organization and also to increase the productivity.. But, most of

Investment Opportunity Set as the Mediation Effect of Capital Structure, and Corporate Dividend Policy on Firm Value: A Study on Manufacturing Firms in Indonesia Stock

การปองกันการเกิดของเสียในกระบวนการผลิตชิ้นสวนยานยนต โดยประยุกตใชเครื่องมือทางดานคุณภาพ PREVENTION OF DEFECTS IN MANUFACTURING PROCESS OF AUTOMOTIVE PART BY APPLYING QUALITY

Thus, this study approaches small and medium scale business focusing in manufacturing industry to examine their productivity and efficiency in Malaysia.. The measurement of productivity

Adding the flow rate parameter to the simulation of this parameter can increase the certainty of the simulation results.For this reason, in this study, random forest, CARMA and CARMA-

Application of Phet Simulation to Electrical Circuits Material in Online Learning Nufus Choirum Masruroh1*, Amelya Vivianti 2, Putri Maulida Anggraeni3, Siti Nailil Waroh4, Nur