The fortieth annual conference of the South African Sugar Technologists' Association was held in S.A. Proceedings of The South African Sugar Technologists' Association - March 1966 9 a main variety with 13% plant cane; in the other.

Operation of the Milling Tandems I Boiling House Operations

Proceedings of The South African Sugar Technologists' Association—March 1966 11 This chapter would not be complete without man-. Up to this time the discussions had been limited to general remarks about the South African Sugar Crop and its prospects; from here on will follow more detailed discussions regarding all Mills, i.e.

Factory Control

It will be a melt carbonation refinery using a lime kiln for the production of CaO and COa like Sezela and Gledhow.

Operation of the Milling Tandems

12 Proceedings of The South African Sugar Technologists' Association—March 1966 and proper pressing of the first unit is therefore from. Returning to the topic of the importance of high juice extraction with the first pressing unit, ie.

Regarding Boiling House Operations (a) Purity

14 Proceedings of The South African Sugar Technologists' Association—March 1966 to the Boiling House Performance Figures the following. i) the purity of the final molasses, (ii) the sucrose lost in final molasses, (iii) the undetermined lost sucrose, (iv) the purity of mixed juice, and. v) the reducing sugars/sucrose ratio of mixed juice. Regarding the high molasses purity, the accompanying table shows a very low crystal content of the C-m.c.

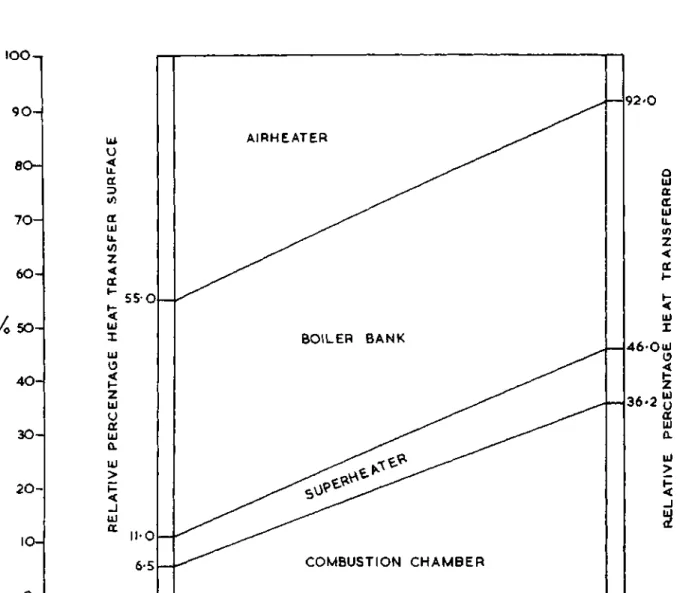

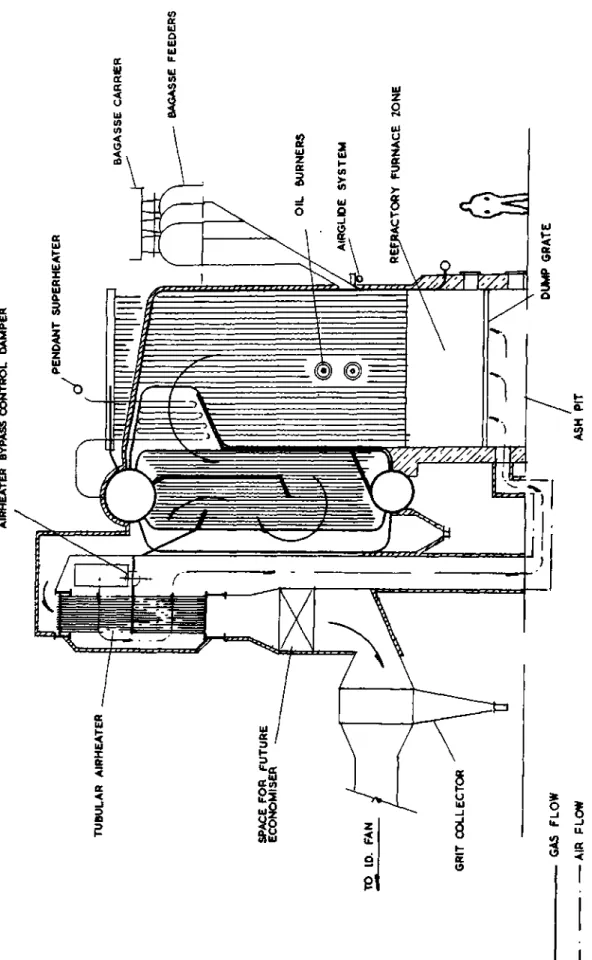

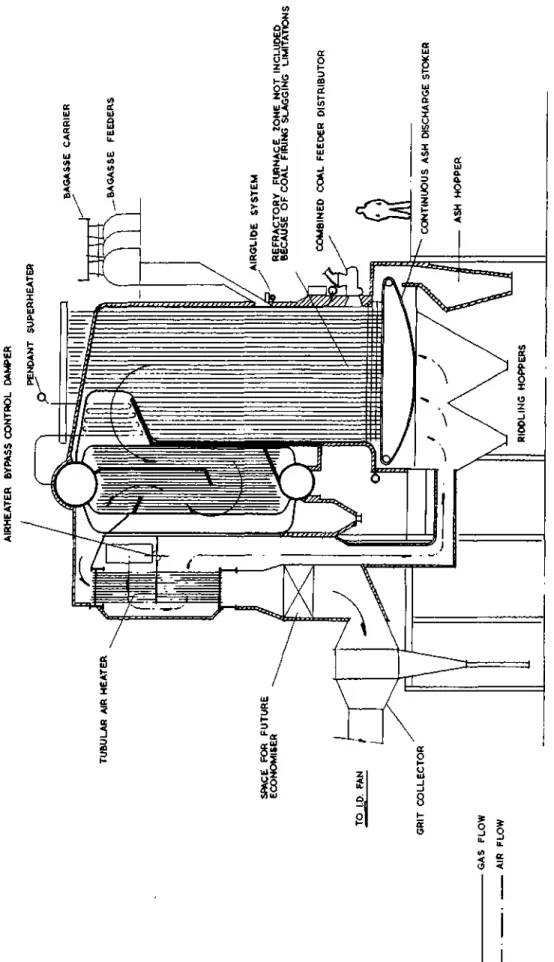

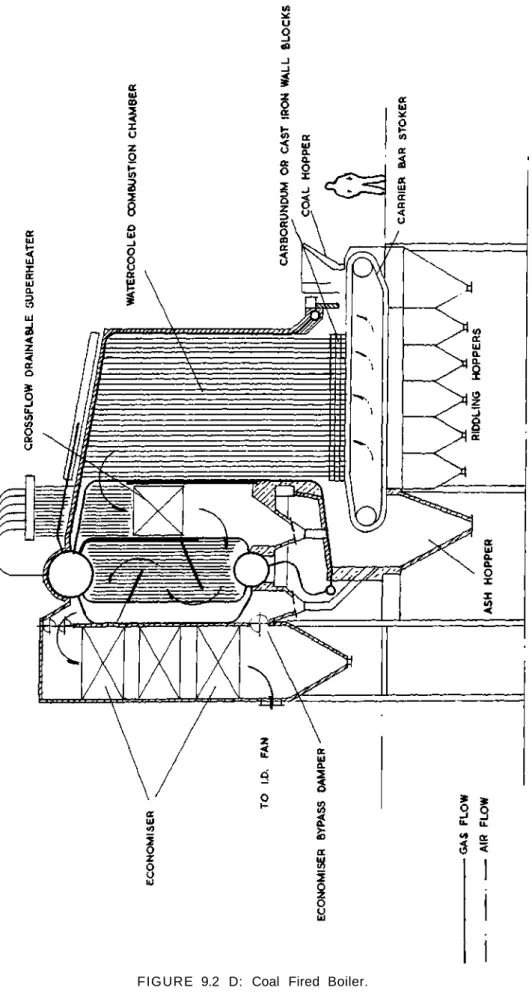

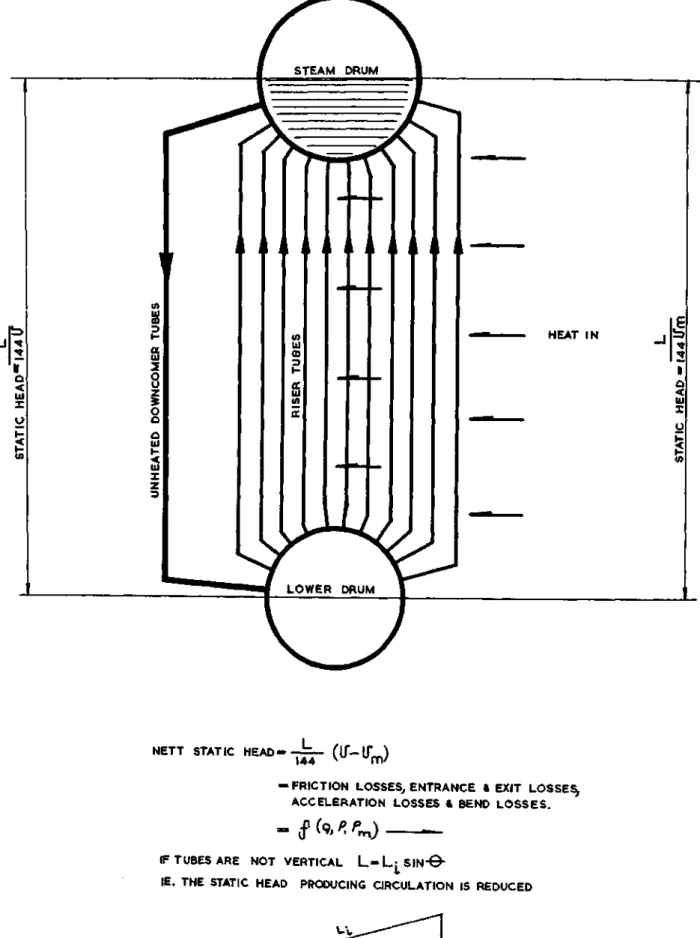

BOILER DESIGN AND SELECTION IN THE CANE SUGAR INDUSTRY

34 Proceedings of The South African Sugar Technologists' Association – March 1966 that heat transfer is greater for smaller diameter rubes. Proceedings of The South African Sugar Technologists'1 Association - March Disposition of boiler heating surface and Ta Ambient air temperature.

FUELS AND FURNACES

At the very high temperatures maintained in the combustion cell, the moisture in the fuel is carried away and most of the fuel is ignited from the bottom edge of the cone upwards. This results in rapid drying of the fuel, which loses a large proportion of its moisture before it lands on the grate. It is therefore desirable to have a means of varying the speed of the rotors over a wide range depending on the fuel being burned.

This would go a long way towards increasing the efficiency of the use of bagasse and effect a saving in the use of auxiliary fuels.

STEAM AND VAPOUR DISTRIBUTION

Horizontal runs can be supported on rollers which will allow free movement of the pipes. 76 Proceedings of The South African Sugar Technologists' Association — March 1966 valve are accepted as figures of the butterfly type. The life of the pipes will be significantly extended and in the long term financial savings will accrue.

This not only causes a lot of noise, but is also disastrous for the pump itself and may require complete replacement of the unit.

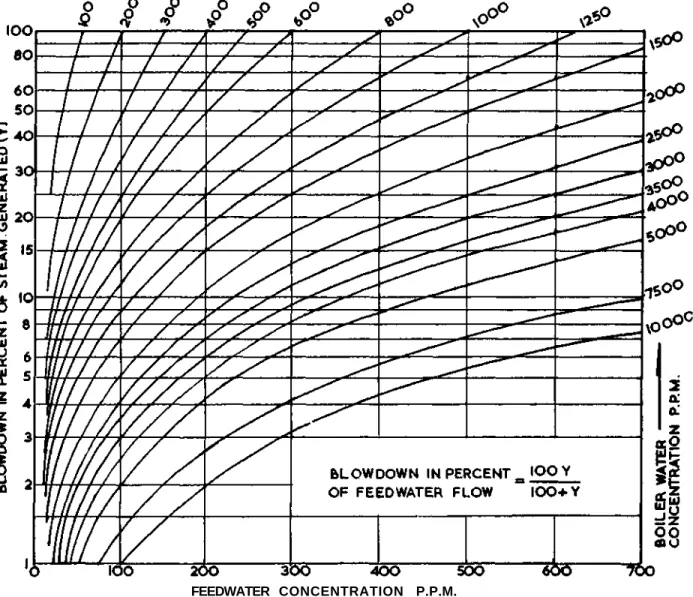

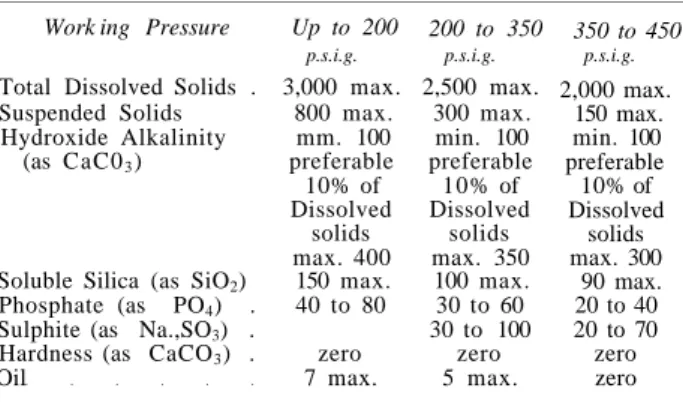

CONDITIONING BOILER FEEDWATER FOR THE SUGAR MILL

As the gases flow through the boiler, they are cooled by transferring their heat to the water in the tubes. Proceedings of The South African Sugar Technologists' Association—March 1966 which can be made available to the boiler is de-. Calcium and magnesium ions enter the ion exchange material and are replaced in the water by sodium ions.

As you know, fully demineralized water can be obtained with a special ion exchange system. the expense of obtaining this is rarely justified.

ECONOMIC DESIGN AND OPERATION OF PROCESS HEAT EXCHANGE EQUIPMENT

An estimate of the wall temperature can be achieved by trial and error using Eq.18. Their total values can be determined by comparing the total coefficients of pure and scaled heaters. For a preliminary estimate of h„, the outer wall temperature is chosen midway between the bulk temperatures on both sides of the wall.

For type 2-4 exchangers, graphical differentiation is most useful for evaluating P.

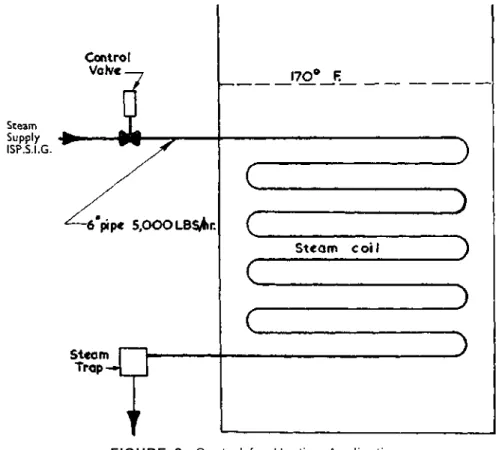

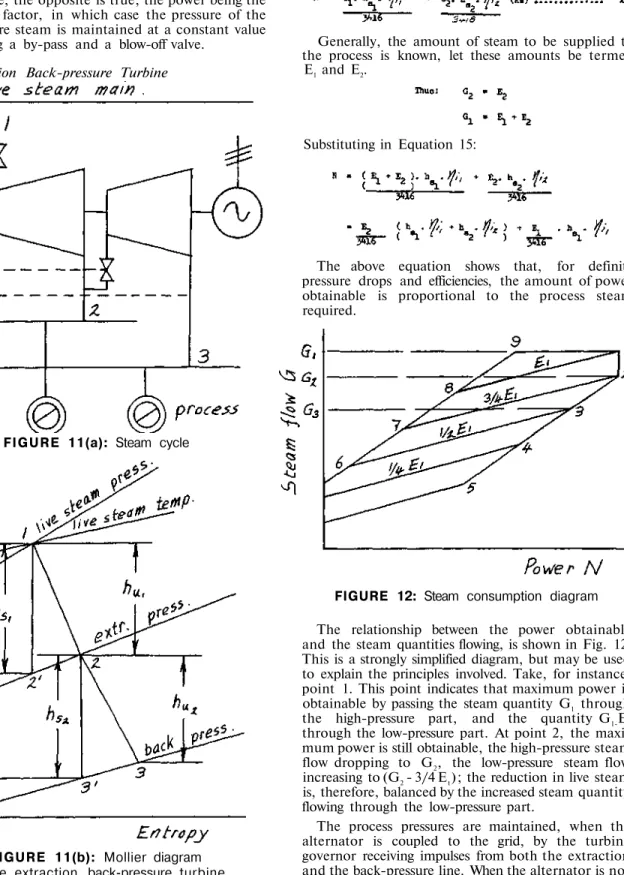

PROCESS STEAM

PRODUCTION USE AND CONTROL

These valves control the steam flowing to the lower pressure stages of the turbine or to the atmosphere, and not, as is commonly believed. the steam to the faint. If this is not properly controlled, there can be serious fluctuations in turbine speed and cut-out pressure. Proceedings of The South African Sugar Technologists' Association - March 1966 104. a) (b) Operating mechanism for pass-out control valves on a 10 M.W.

Proceedings of The South African Sugar Technologists' Association— March 1966 105 superheating in the steam fed to the unit gives.

BOILER OPERATION, MAINTENANCE AND TESTING

The intense heat at the edges of the grate accelerates the deterioration of the side wall of the oven. Temperature and pressure of air entering and gas exiting the main parts of the boiler. In a variation of this, the amount of feedwater supplied to the boiler is measured instead of the amount of steam.

If hourly readings of boiler performance are recorded, a reasonably consistent operating standard can be obtained.

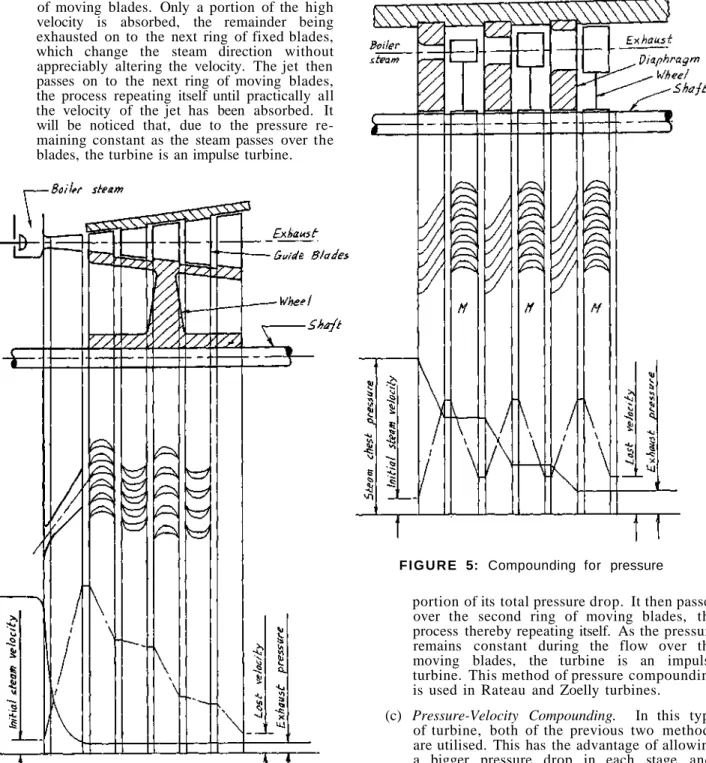

STEAM TURBINES-THEIR CONSTRUCTION, SELECTION AND OPERATION

Theory of Steam Turbines

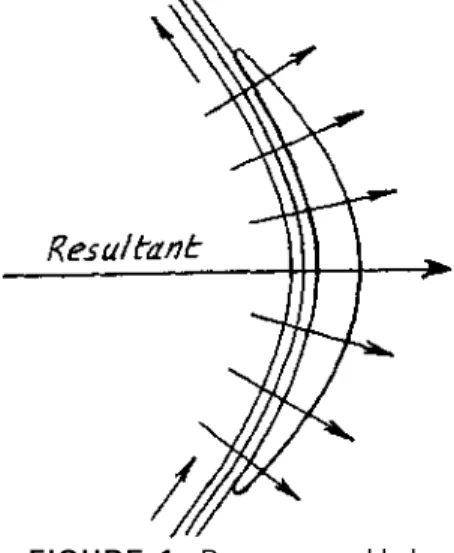

Only part of the high velocity is absorbed, the remainder is exhausted in the other ring of fixed blades, which change the direction of the steam without significantly changing the velocity. Fixed blades correspond to nozzles; they reverse the direction of the steam and, at the same lime, allow it to Proceedings of the South African Sugar Technologists' Association—March 1966 115. The adiabatic flow of steam through the nozzle may be approximately represented by the equation.

To maintain the efficiency of the blade, the energy E (see E q u a t i o n 2) must be divided by the kinetic energy of the jet emerging from the nozzle.

Selection of Steam Turbines

Extraction-condensing turbines are used where the required power is above the process steam. Proceedings of the South African Sugar Technologists' Association process in March 1966 where the flow was balanced due to the grid. For industrial turbines, an economic solution has been found in an intermediate speed, which is generally between 5,000 and 12,000 rpm, where the latter speed is for turbines with small power.

130 Proceedings of The South African Sugar Technologists' Association- March 1966. at full load according to the continuous line in Fig.

Summary

The causes of failure naturally fall into two groups, namely those that are part of the structure or material used in the construction of the turbine, and those related to operating conditions. Some of the former are interrelated with some of the latter; for example, blade erosion may be the result of unsuitable material or poor steam conditions. The causes of failure, which are inherent in the design and materials of the structure, can be classified as follows:

It would be far beyond the scope of this article to discuss each of the above points.

STEAM TRAPPING AND CONDENSATE CONSERVATION

A little venting, some chemical conditioning and it's ready to go back to the boiler. Obvious are condensing turbines, first effects evaporators, steam cells, juice heaters, pans — the latter process equipment is often fed by direct exhaust gas. But we have to remove the heat from the condensate using a mixed juice heat exchanger as the coolant.

Ammonia and carbon dioxide are removed to a low constant value before the condensate is fed to the conduction cell.

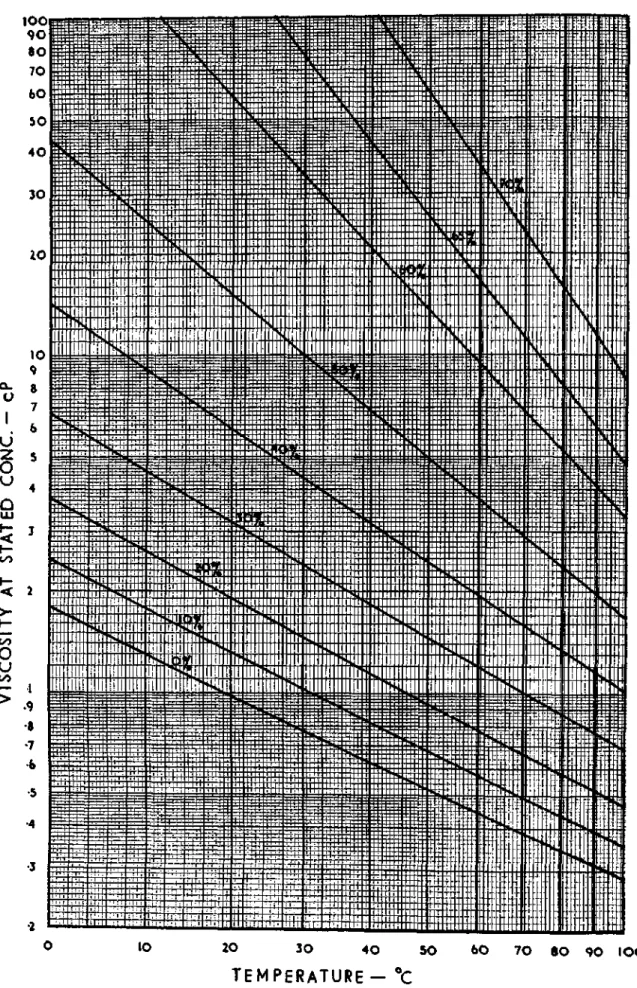

RESIDUAL FUEL OIL AS A SUPPLEMENTARY FUEL

As it is a viscous product, the ambient temperature plays an important role in handling fuel oil. In the case of boilers of the considered type and size, the distribution of fuel oil into the boiler with the help of a ring line is preferred. Proceedings of The South African Sugar Technologists' Association—March 1966 can provide the maximum amount of fuel oil at.

They must be aware of fuel oil temperature requirements, system layout and mode of operation.

STEAM ECONOMIES AT DARNALL

Proceedings of the South African Association of Sugar Technologists — March 1966 143 thermocompressors could be used. Jones: What was the percentage of exhaust steam from the primary engines and was it sufficient to allow for the flow differences and prevent blowout. Jones: So when you started the new boiler, you again had a lack of main drive exhaust.

Hulett: It helps equalize the load on the boiler but I can't say it helps balance the steam.

HOW TO MEASURE AND EXPRESS SUGAR MILLS EFFICIENCIES

However, the same ratio of non-sucrose to sucrose cannot be expected in the molasses for the simple reason that about 18% of non-sucrose is eliminated during the clarification process. Excessive destruction of the reducing sugars during clarification at too high a pH will also lead to poor boiling house performance. It indicates the amount of crystallizable sucrose recovered in the form of commercial sugar as a percentage of the crystallizable sucrose available in sugar cane.

For example, you could say that if one part non-sucrose holds 0.460 part sucrose, then the expected purity of the final product is the same.

ALTERATIONS AND IMPROVEMENTS TO MOUNT EDGECOMBE MILLING TANDEM

Cush-Cush

Proceedings of the South African Sugar Technologists'1 Association — that our feeding problems throughout the mill train were due to:. To ensure the best possible use of the installed chain, P.C.D. This chute has been designed and equipped with the added option of automatic mill speed control.

Hulett: At Darnall, the bottom feed roll setup ratio is under 3 to 1 across the plant.

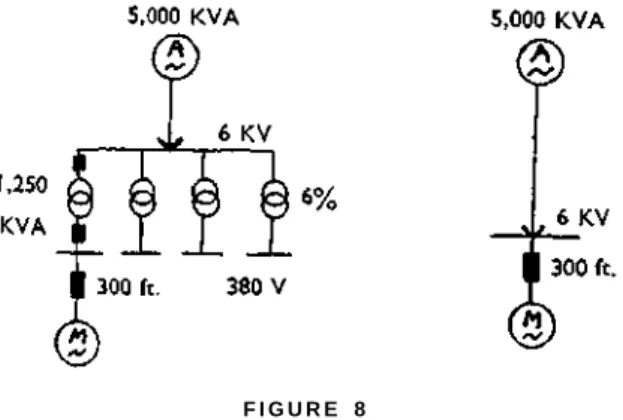

THE ELECTRICAL SUPPLY SYSTEM OF SUGAR FACTORIES

It should be understood that the peak value of the short-circuit current is responsible for the dynamic load of the electrical equipment. For rough calculations, it is sufficient to use only the reactances of the components included in the short circuit. Another observation is that the placement of the electrical equipment before the main LT distributor has a considerable influence on the resulting short-circuit current.

A comparison of the left rear columns of each group shows that the short-circuit current on the main busbars decreases from Case 1 to Case 4.

PHOSPHORIC ACID AS AN AID TO CLARIFICATION, AND OBSERVATIONS ON LIMING TECHNIQUES AND

MUD VOLUMES

174 Proceedings of the Association of Sugar Technologists of South Africa—March 1966. Phosphoric Acid treatment was started by adding 100 ppm. of acid in the heated liquor before secondary heating. The results are given below in Tables IX and X. Analysis of mixed liquid during Test Part 2. Proceedings of The South African Sugar Technologists' Association—March 1966 175. being the final clay volume percentage of the original volume.

I don't see why this would affect the clarity of the juice in any way, but it will certainly save on inversion losses.

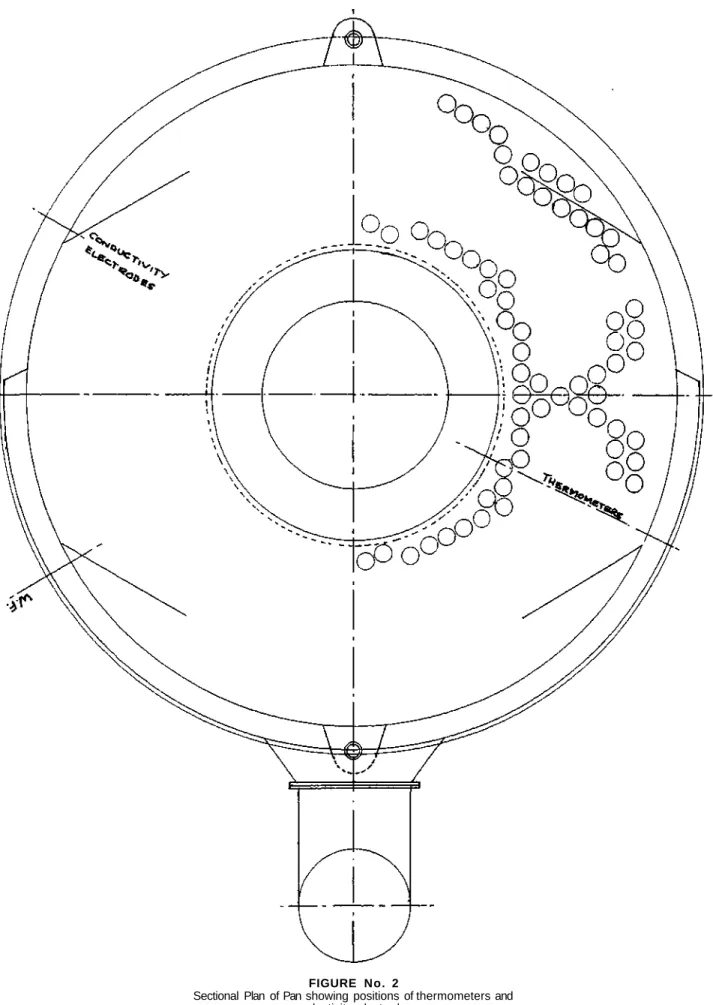

182 Proceedings of The South African Sugar Technologists' Association — March 1966 As previously stated the survey was. The ratio of heating surface to volume of the pan was 1.83, and the total heating surface was 2,380 sq. 2 is another recording of the absolute pressure, again recorded during normal boiling of the pan.

Asfee: The temperature rise recorded under the calandria appears to be right at the end of the boil.

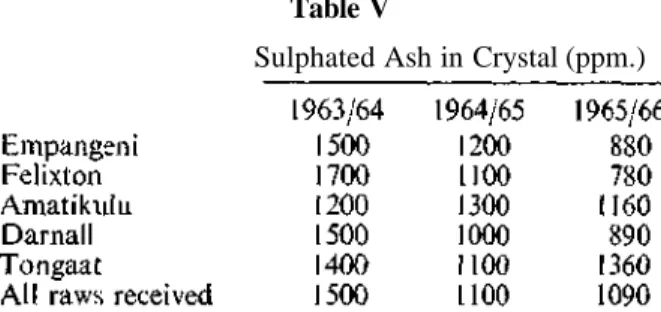

IMPROVEMENTS IN RAW SUGAR QUALITY

The improvement in specific grain size of raw sugars obtained over the past three seasons may not appear as dramatic as the increase in filterability. Another major impurity, the gums, has been determined in the crystal since December 1964, too late to permit a meaningful trend analysis. An assessment of variations in the concentration of other impurities such as reducing sugars, silica, phosphate and wax was not attempted.

The reduction in the concentration of impurities in the crystal over three seasons has been the most striking.