It is an organization of technical workers and others who are directly interested in the technical aspect of the South African sugar industry. The thirty-fourth annual conference of the South African Sugar Technologists' Association was held at the M.O.T.H.

THIRTY-FIFTH ANNUAL SUMMARY OF CHEMICAL LABORATORY REPORTS OF SOUTH AFRICAN

DURATION OF SEASON AND TIME EFFICIENCY

- SUCROSE AND BRIX LOSSES BASED ON CLARIFIED JUICE ANALYSIS, NON-SUCROSE

The q u a n t i t y would have been lower if the purity of C-massecuite could have been lowered. Therefore, the amount of non-sucrose in the final molasses depends on the quality of the juice and the method of purification (carbonation or defecation and sulfitation).

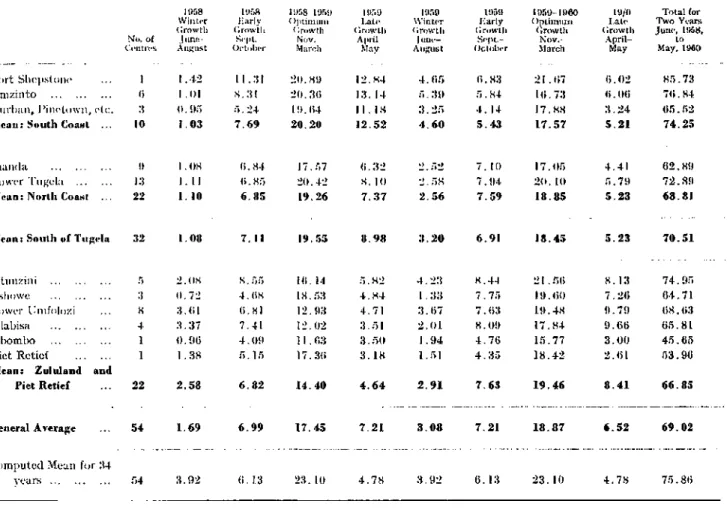

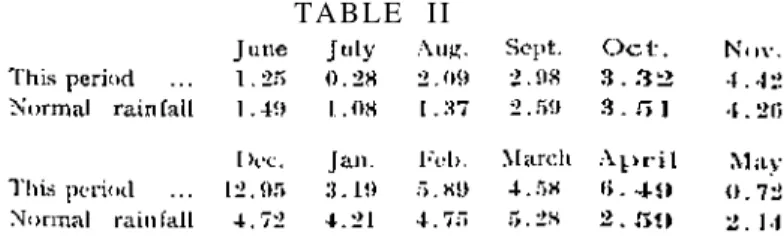

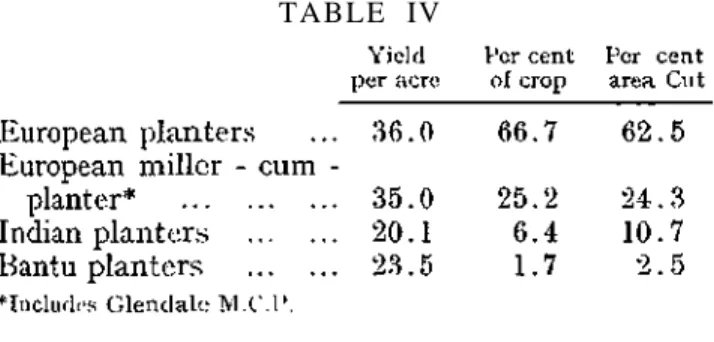

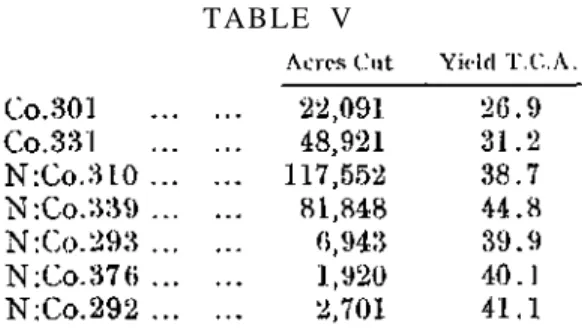

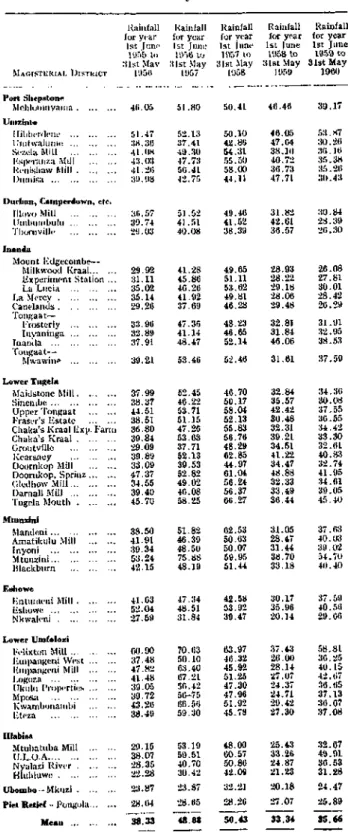

ANNUAL SUMMARY OF AGRICULTURAL DATA FOR THE SUGARCANE CROP 1957/58

This table also shows the high yields obtained from the new cultivars N:Co.376 and N:Co.339. The 1957-58 Census returns list N:Co.37G and N:Co.292 for the first time and both gave excellent yields (over 40 tons of cane per acre), but these yields, which will be mostly cane, are from such small areas that no definite conclusion can be drawn.

RIVER WATERS

34;An important factor in the growth of fungi is the water temperature. Despite the fact that increase in temperature stimulates growth, it is often found that the length of a mushroom belt in a river below the discharge point of a polluting liquid is longer in winter than in summer.

MILLING AND OVERALL PERFORMANCES

This could be quite misleading to t h e l a y m a n if he had to relate the output of the mill to the amount of cane fiber and the recovery of the boiling house to t h e p u r i t y of the juice. The percentage of c a n e fiber was something that was eliminated to a c o u n t in such a formula.

A DESCRIPTION OF THE CONVEYOR BELT INSTALLATION AT UMFOLOZI MILL

It was unfortunate that the loading of bagasse on the conveyor belt in front of the boilers was never used. Ashe said it looked like the edge of the mud conveyor had rubbed off the tire.

MILLING CONTROL DATA WITH REFERENCE TO A MORE INTENSIVE METHOD OF SAMPLING AND ANALYSIS

COMPARISON OF RESULTS OF NEW AND OLD SAMPLING METHODS for the month of November, 1959. Usually the bag was imbibed as close as possible to the discharge opening with the idea of improving the mixing of the imbibing liquid with the remaining juice. came in the luggage.

MINIMISATION OF THE HUMAN ELEMENT IN MILLING

The method of operation of the control is simple and is mainly an "on-off" control, in the reed-knife motor circuit there is a. This relay is arranged so that in the event of the reed motor current reaching a certain high value, the Martenair valve will energize and open, venting the manifold to atmosphere and reducing the pressure on the Hagan control to less than 3 p.s.i. He said he had to abandon the use of the float and adjust to a pure overriding control.

A RECORDING ROLLER LIFT INDICATOR

Ultimately, he thought that this type of instrument could be used to control the speed of the next grinder in the tooth. He would therefore like to know the variation in the moisture content of different parts of the bagasse when it turned out that the roller was not level. It had been applied in the last factory in Illovo and it was found that the fiber content of the final bagasse did not reach the expected value.

DRAWING A STRAIGHT LINE THROUGH POINTS ON A GRAPH

A similar examination of the figures for cane sugar and extraction in the table of Perk1 leads to the regression equation: We must therefore conclude that in the data examined there is no significant relationship between the percentage of sucrose and its extraction, even though the line is sloping . After eliminating the effect of fiber, he was confident that no correlation would be found between the percentage of sugar cane and its extraction.

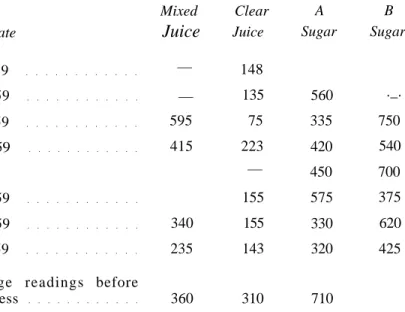

MIXED JUICE SCREENING AT DOORNKOP

The inlet to the screen was through a weir covering the entire width of the screen. With this type of screen, the capacity of the screen improved to 2½ to 3 tons of juice per square meter. As mentioned in the paper, most of the bags were removed at the first stage of the sieve.

A NEW ION EXCHANGE PROCESS FOR REMOVING COLOUR BODIES AND COLLOIDAL IMPURITIES FROM

CANE SUGAR

With regard to poisoning of the resins, he could not easily see how poisoning could take place. He had encountered nothing in his experience that could be called poisoning of the resins. Grant replied that it would depend on the volume of effluent and the size of the resin bed and also on the amount of color in the material to be treated.

SOME OBSERVATIONS MADE ON THE REHEATING OF MASSECUITE IN A CRYSTALLIZER

It can be safely said that the actual brix of the final molasses must have been around 96°. A mixer above the centrifugal with a small heating element to maintain the temperature of the mass spawns. He did not think this was solely due to the low crystal content of the mass roe.

DROP IN PURITY BETWEEN MASSECUITE AND MOLASSES

He had studied the performance from the point of view of evaporation at different levels in the pan. However, he pointed out to us that the steam coil that was originally in the pan Mr. Turner was talking about said the pan in question was quite new, designed to cook 1,000 cu.

STARCH IN THE MANUFACTURE OF RAW SUGAR

It was then a simple matter to use the starch figures in Table I I I to calculate the amount of starch in the juice. At the same time, the starch content of the raw sugar dropped from about 417 to 240 ppm, i.e. with 42 percent. Here it was found that in two periods of one week that when the factory was operating "normally and 55.3 percent respectively of the starch in mixed juice was removed during clarification, while in the week that the juice was kept at 70-75T .the removal was 65 percent.

THE REFINING PROCESS AT ILLOVO

It is also estimated that enough steam will be produced from sugarcane alone to operate the process in 1960. The author wishes to thank the management of Illovo Sugar Estates for permission to publish the article, especially Mr.

SOME NOTES ON THE NEW MELT CLARIFICATION AT HULETT'S S.A. REFINERIES

The increase in organic acids from the washed raw sugar to the carbonation supply is also apparently due to the organic acids in the fresh Johnson water. Organic acids appear to be the major anion after carbonation and even after carbonation the organic acid content is still almost twice that of the original washed raw sugar. The mechanism of formation of organic acids during carbonation and first charring is unknown.

A SHORT DESCRIPTION OF GLEDHOW REFINERY

From then until the return of the empty tank, the entire process is automatic and the sealing of the furnace throat is so effective that there is no noticeable drop in the CO2 content of the gas. There is a counter and a recorder for recording the number of skips, and a rotameter takes care of the density of the milk of lime. The proportion of coke in limestone for the past season was 9 percent, and CO2 is usually between 36 and 40 percent.

NOTES REGARDING THE SULPH1TATION-REFINING PROCESS AND PLANT AT UMFOLOZI

Part of the raw melt thus made circulates back to the mixer into which the raw sugar is introduced. Vegetable carbon must be added to the liquid to improve its color, and thus the color of the sugar made from this liquid. This also caused sublimation and it was found that some channeling of the liquid sulfur occurred.

THE JUICE CARBONATATION PROCESS AND

REPERCUSSIONS OF ECONOMICS ON TECHNOLOGY

This is determined by the nature of the raw juice, and especially by the pH reaction during the lime addition in the first CO2 phase. Thumann said the quality of the drink was such that there was very little deposits on the pan tubes. The level of the massecuite in the pan was only approximately above the tube sheet.

SYSTEMATIC PLANNING AND SCIENTIFIC CONTROL OF FIELD OPERATIONS

In general, the method described in the paper could be applied to small-scale cane growers. On the estate mentioned in the paper, weeding accounted for the largest share of the labor force. He said the final productivity results for 1959 exceeded the budget figures shown in the paper.

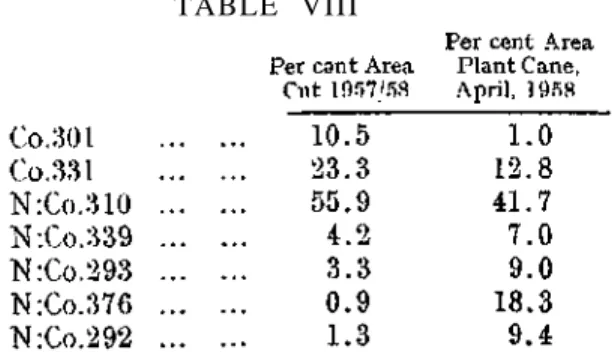

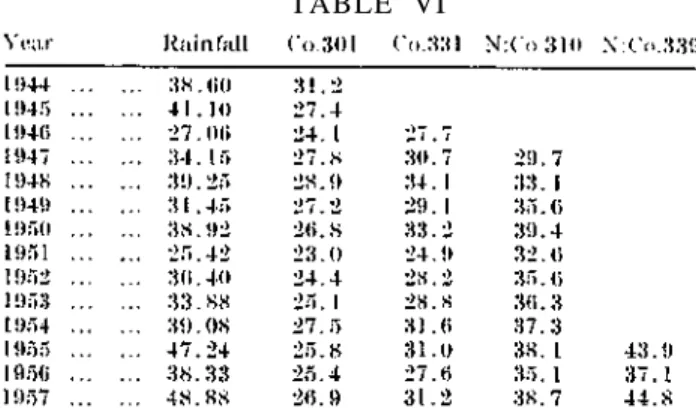

NATAL SUGARCANE VARIETIES

SOME OBSERVATIONS AND STATISTICS

Steward said that some growers maintain that N:Co.310 is in decline, when in the author's experience this has not been the case. With large amounts of N:Co.339 in the industry, there was a chance that mosaic disease would develop rapidly. If one calculated the growth per acre per month, N:Co.293 appeared to be one of the best.

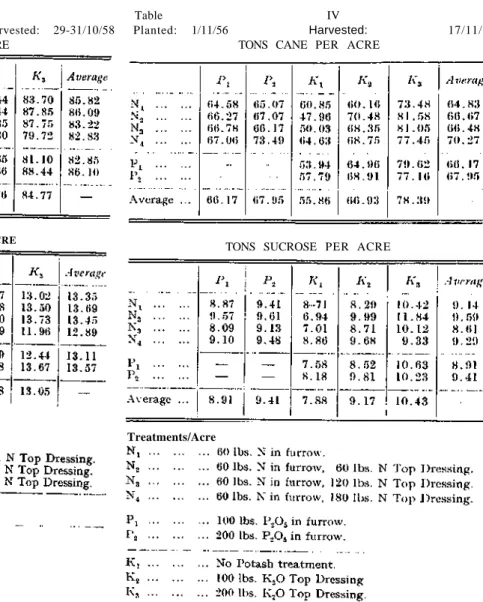

YIELD DATA FOR EXPERIMENTS, HARVESTED AT ILLOVO, 1958—1959

This would lead to the conclusion that available moisture could be the deciding factor in selecting the best row width for dry land conditions. With the narrow plantings it was noticeable that less hardening of the soil crust occurred after the application of water. This was done in the early days of the Experiment Station on acidic soils at Canelands and Eshowe, where it was found by adding lime, even to a pH of 7.0 (neutralisation), which resulted in no increase in yield.

SOIL CONSERVATION IN SUGARCANE FIELDS

He wondered if this was a possible approach on the steep hills of the South Coast which, in conjunction with strip planting, would justify the burning of the last crop and allow easier preparation of the land. His idea was to cut the cane and burn the remaining trash after rain, which got rid of the bulky portion of the trash, leaving the partially rotted trash to plow into. The Chairman (Dr. McMartin) referred to the opening paragraph of the paper where soil erosion was blamed on the arrival of the white man, while the erosion in the Native Reserves was even worse.

34;HE COMPACTION OF SUGAR-BELT SOILS AT VARIOUS MOISTURE LEVELS

Indeed, with the exception of the soil of the fog belt with its peculiar properties, maximum com- . Soil density is not the only factor to consider in the study of soil compaction. It was better in this case to express the water in the soil as a percentage rather than in relation to the amount of precipitation that it received.

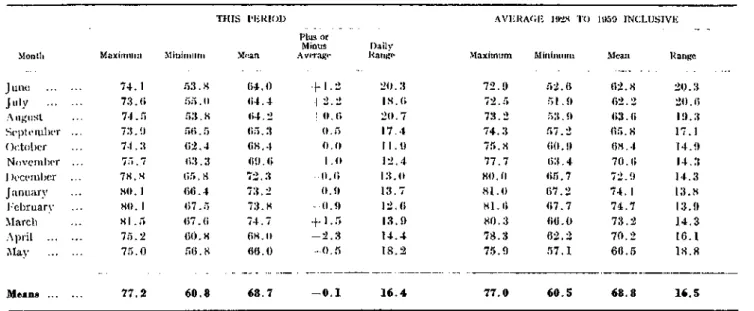

IRRIGATION CONTROL AND EXPERIMENTATION AT ILLOVO

There is a significant P-K interaction indicating that higher P reduces yield in the absence of K, but appears to increase it in the presence of K. Average cane percentage sucrose data are shown on page 166. So p r o p o r t i o n of change in percent sucrose cane treatments is shown to be due to moisture content. Both the statistical analysis of the results and the sucrose tests were performed at the Experiment Station.

IRRIGATION CONTROL

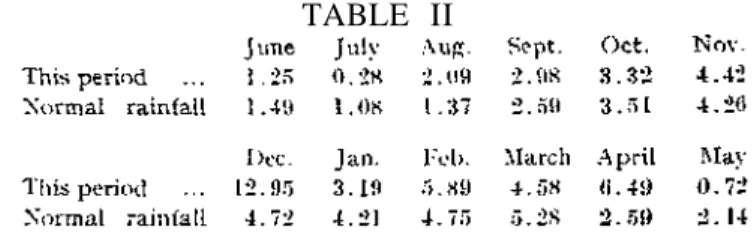

SOME NOTES ON IRRIGATION

N per acre appears to be sufficient for the plant cane crop and something in the neighborhood of 200 lbs./acre for the 1st ratoon crop. In the infiltration process, the size of the water droplets is just as important as the application rate. At Chaka's Kraal, irrigation in the early stages was only applied during the winter period and this would have possibly had a greater effect on the amount of water used per ton of cane.

VARIETY AND ENVIRONMENT

Dick said he did not have any direct evidence that N:Co.339 was more attractive to insects. He could find no significant difference in relative attractiveness, although the insect lived longer in N:Co.339. Steyn said that he had grown excellent cultures of N:Co.339 up to 5 or C ratoons where the mosaic was prevalent.

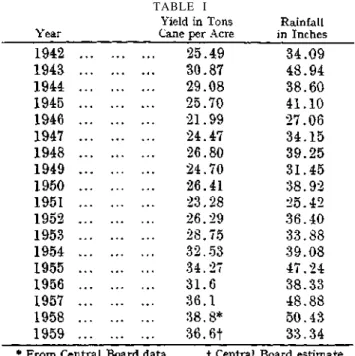

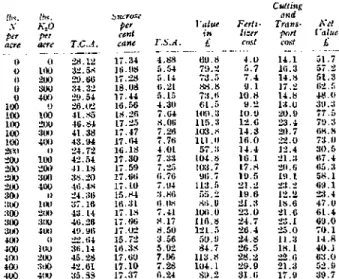

SOME ITEMS OF ECONOMIC IMPORTANCE IN SUGARCANE PRODUCTION

Our payment system also does not take into account the recyclability of sucrose in the cane. The answer will of course depend on the yield variation between the plant stock and the different ratoons, the costs associated with each crop other than cutting and transport and the value of the stock. Some of them have a direct impact on the plant box, and others affect the availability of the sugar in the factory.

THE DEVELOPMENT OF THE MECHANISATION COMMITTEE OF THE SOUTH AFRICAN SUGAR ASSOCIATION

This has been a brief description of the history and current activities of the Mechanization Committees. As a result, I think the activities of the Mechanization Committee can be divided into four main groups, viz. Considerable discussion has taken place in the past regarding the research activities of the Mechanization Committee.