It is an organization of technical workers and others who are directly interested in the technical aspect of the South African sugar industry. The thirty-fifth annual conference of the South African Sugar Technologists1 Association was held at the M.O.T.H.

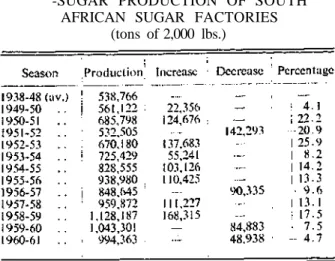

CONTROL OF PRODUCTION

These are some of the reasons why the industry abandoned the production cap scheme based on land control alone. During the 1960-61 season many presentations were made to both industry and government on the effects of the capping scheme.

THE CONTROL OF SUGAR PRODUCTION FROM A MILLER'S POINT OF VIEW

Dodds pointed out that the problems faced by the grower and the miller were not very similar. Growers could not agree that some of their numbers should be forced out of the industry and that the cream should go to the larger producers.

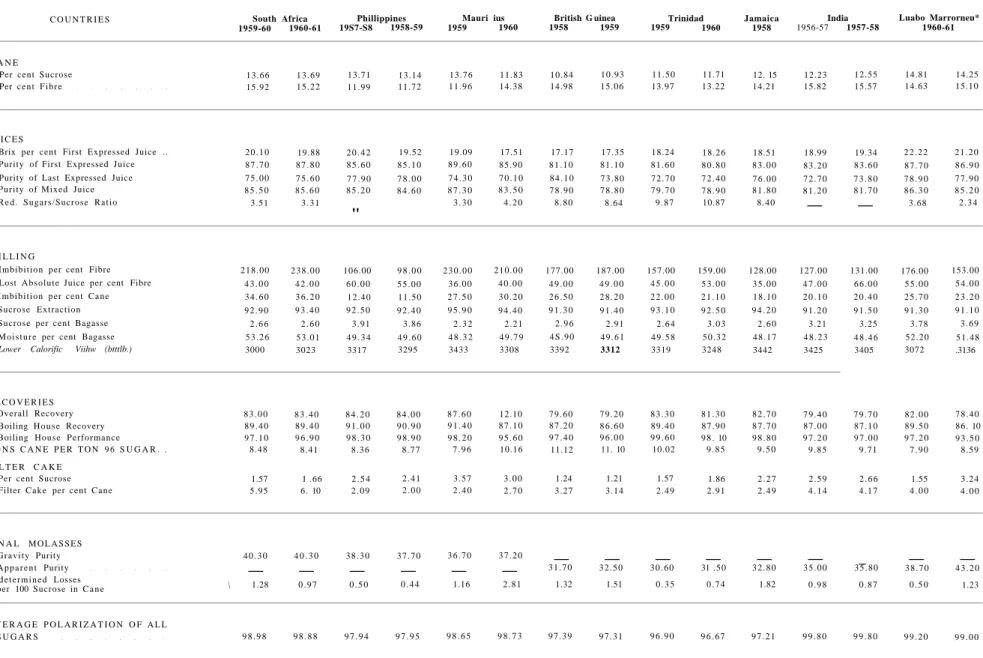

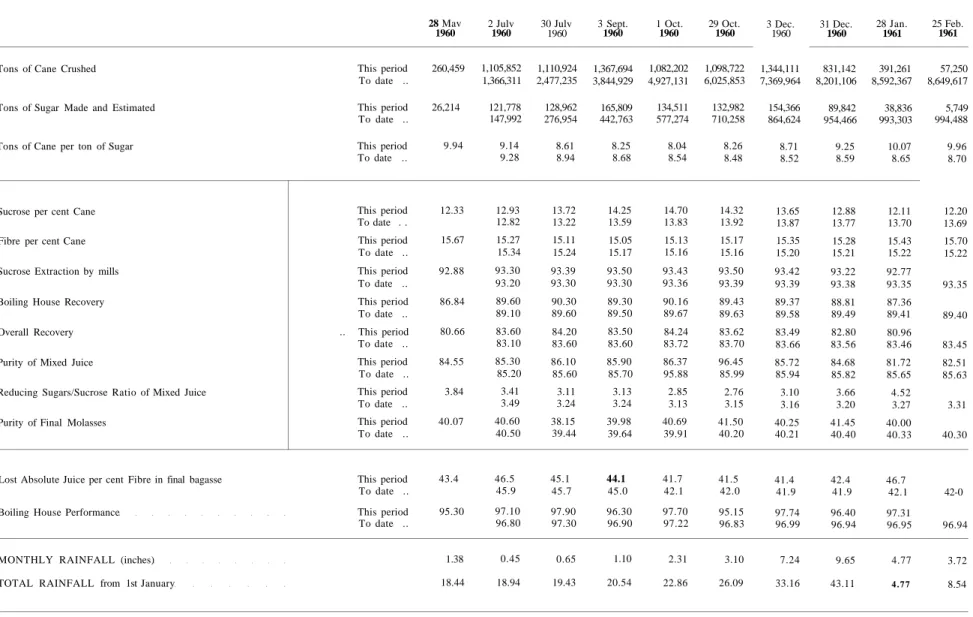

THIRTY-SIXTH ANNUAL SUMMARY OF CHEMICAL LABORATORY REPORTS OF SOUTHERN AFRICAN

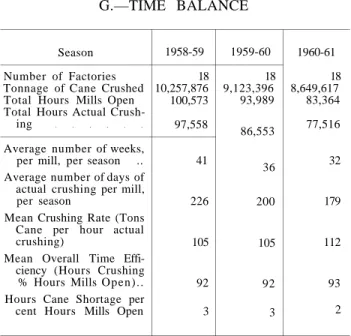

PERFORMANCE OF THE MILLING TRAINS As a yardstick for the evaluation of the performance,

The following table shows the amounts of non-sucrose in the final molasses and sugar as a percentage of the amount of non-sucrose added with the blended juice. Circulation without sucrose in the system in question results in a film of final molasses adhering to the C-sugar crystals.

LIME, SULPHUR AND PHOSPHORIC CONSUMPTIONS

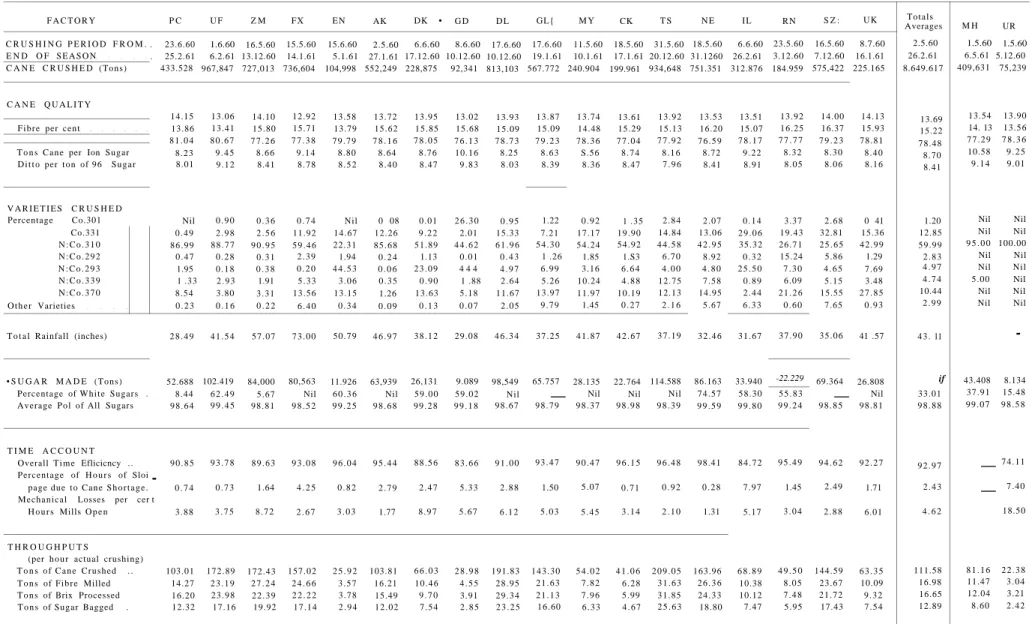

Brix percent Purity of First Expressed Liquid First Expressed Liquid Purity of Last Expressed Liquid Purity of Mixed Liquid. General Recovery Boiling House Recovery Boiling House Performance Tons Cane per ton 96 sugar FILTER cake.

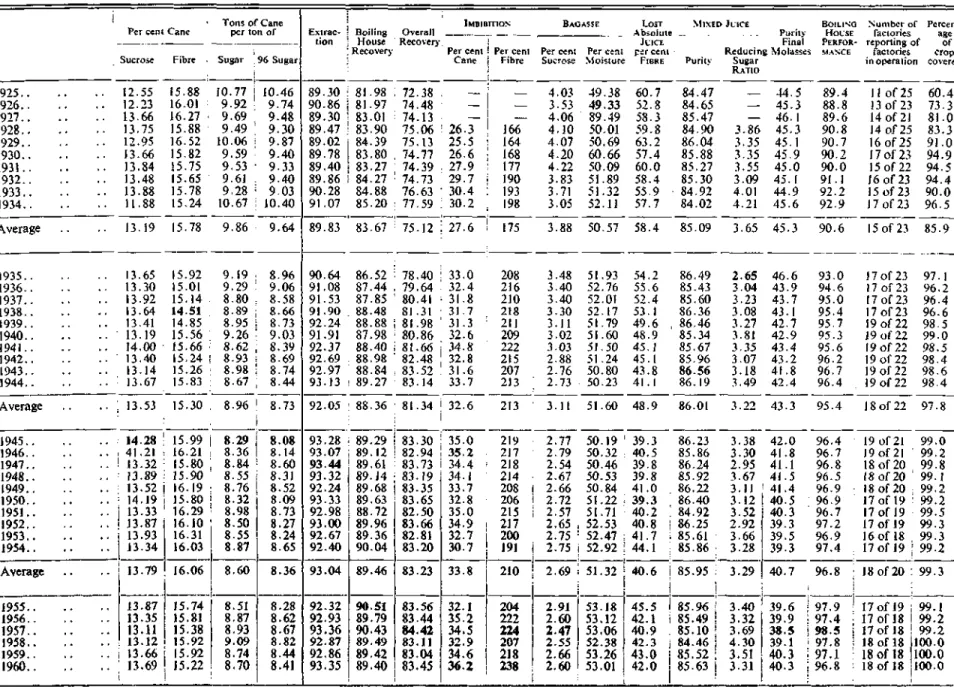

RESULTS FOR S.A

SUGAR

FACTORIES

The number of hours of sunshine for the year under investigation was 101.3 percent of the average over the 33 years. However, it is possible that the sucrose percentage of sugar cane is relatively low.

The following table gives the yields of the more popular and newer varieties. A comparison of the area under cane in April 1958 with April 1959 shows that N:Co.376 has increased at the expense of all other varieties.

SUGGESTED IMPROVEMENTS TO CLAR1F1ER DESIGNS

48 Proceedings of the Association of Sugar Technologists of South Africa—April 1961 in one installation, a main ring was placed inside. He thought that pumping mud at the top of the clarifier was wrong and that the pumps should be at the bottom. He could not see that it would make any difference to discharge the clear liquid from the outside or from the center of the clarifier.

Gunn said that if the hot juice is lowered to a point three-quarters of the way down.

THE DOUBLE MAGMA BOILING SYSTEM AT UMZ1MKULU

The system has noticeably increased grain size and we should do everything possible to improve grain quality. The quality of the sugar, however, was the biggest consideration in the change, even if an additional device had to be installed. He was warned that in a refinery "B" sugar, even if washed twice, could cause problems in the production of good refined sugar due to occluded impurities.

Rabe replied that a small amount of steam was used at the discretion of the pan.

EXPERIENCES WITH A DENSITY METER

Phipson thought that one of its main advantages was that it was independent of varying currents. Douwes Dekker said it was clear that the quality of the zinc was most important. In each case, we record the cycle times and the number of crystallizers being cured at the time of observation.

There was always a slight difference between Bach and Dorr, and usually in favor of Dorr.

ELECTRONIC WEIGHING IN THE SUGAR INDUSTRY

A steel beam was welded along the perimeter of the tank and mounting platforms were welded to the top of the load cell supports. In this way, possible errors due to the expansion of the tank and the temperature supports are minimized. Please note that the load bar output can also be used to control the speed of the belt.

The ratio of tare weight to total weight can be improved by measuring the load over a specific length of belt.

SOME ASPECTS OF AUTOMATION IN THE BRITISH AND SWEDISH SUGAR INDUSTRIES

The intake rate of beet slices into the continuous diffuser is generally influenced by the speed and sharpness of the knives or blades of the beet slicers. Step two is to control the brix of the raw juice from the diffuser, which is done by controlling the amount of water used by the diffuser (called draft). Here again, since the brix is constant and the amount only varies due to differences in sucrose or dissolved solids from the beet slices, controlling the temperature is reasonably simple.

78 Proceedings of the Association of Sugar Technologists of South Africa1—April 1961 The belt is weighed to show the open blades on it.

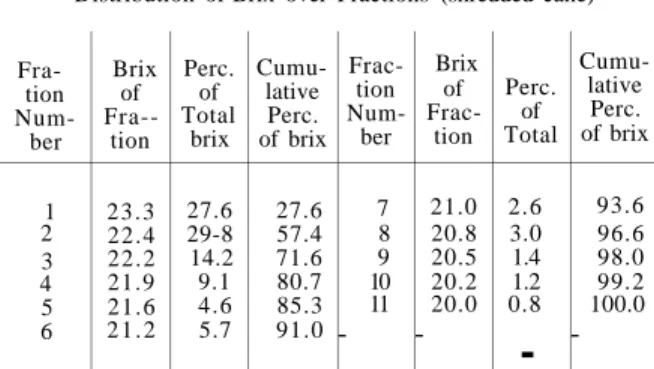

THE BRIX OF THE JUICE EXPRESSED FROM CANE BY STATIC PRESSURE

The fiber content of the cane was required to calculate the undiluted Juice percent cane. The total volume of juice expressed at the maximum pressure (734 p.s.i.) is approx. 78 percent of the juice originally present in the cane. 1 to 8 represent the brix values of the successive fractions of the juice expressed in these experiments.

At least 53.6 percent of the Brix originally present in the chips was obtained at a very high concentration.

A GUIDE TO THE MUTUAL MILLING CONTROL PROJECT

Note.— The fiber, Fbj, should be calculated as accurately as possible by obtaining a weekly "weighted average," which will take account of the fact that the daily brixes involved apply to different weights of juice. Note.—The above formula applies only to integrators fitted with 40-watt indicating spheres, each illuminated 0.05 inch. The operation of the elevator integrator is extremely simple and has been fully described in the S.M.R.I. However, the following should be carefully considered:.

An average weekly pressure (Og, Up) of the hydraulics on both sides of the first and last three roller units must be noted.

SUGAR MILLING RESEARCH INSTITUTE

MUTUAL MILLING CONTROL PROJECT DATA SHEET

Noel Deer and the improvement in extraction in some factories after using the system was astounding. An outline of the various ecological habitats in which commercial sugar production is now carried out, the type of cultivar required and the diseases recorded are given. The activities of the latter in penetrating the interior are most likely connected with the spread of the plant in Pojezerje, where some of the first European explorers found it more than a century ago.

At Elephant Marsh in Nyasaland, some young stools of cane, somewhat resembling Chinese cane, were seen, while in other cases some of the old "noble."

SUGARCANE IN CENTRAL AND EAST AFRICA

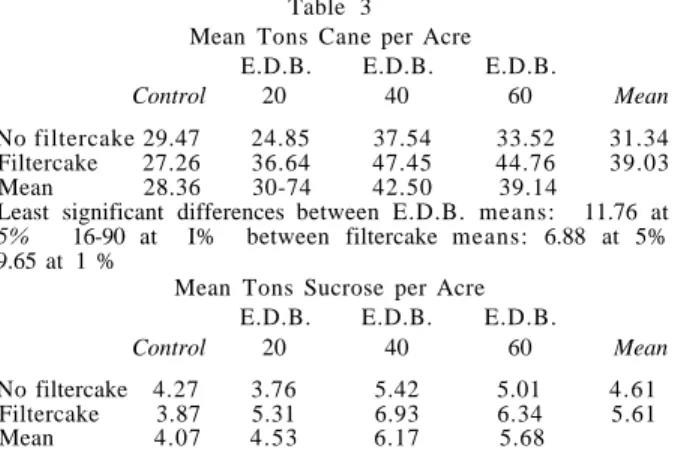

However, it is interesting to note that one of the varieties showing extreme vigor in small plots is N :Co.79 - in fact on the shores of Lake Victoria it is outstanding. In this secondary growth of the "forest fall", an accumulation of minerals begins again in the vegetation, which can be returned to the soil for another short period. An interaction between nitrogen and phosphate is commonly experienced, in that no reaction to one is obtained in the absence of the other.

The regeneration of the forest floor with the help of "bush litter" has been mentioned and it is important to note that he is one of the first pioneers.

EELWORMS AND SUGARCANE

These results showed that furrow treatment alone was not as effective as complete fumigation. At this rate, the cost of the fumigant alone would be £21 (R42) per hectare and the estimated cost of application would be around £3 (R6). Amounts above a ton per hectare were found to be phytotoxic and inhibit the development of tomatoes planted four weeks after tillage.

Dick replied that a high organic content of the soil would promote the fungi that attack the eelworms.

SOME PRACTICAL AIDS IN TRACTOR MAINTENANCE

It is encouraging to note that a number of tractor distributors are now recommending one type of oil in all the different compartments of the tractor. It was desirable that it required a minimum of the farmer's time and that the system was easily understood by non-European workers, who in some cases might be illiterate. It was desirable that it required a minimum of the farmer's time and that the system was easily understood by non-European workers, who in some cases might be illiterate.

Colin Mattinson, a sugar cane farmer in the Empangeni area and member of the Zululand Regional.

CORRESPONDING

INDING GRADE TABLE FOR TRACTOR LUBRICANTS

BRICANTS

The only difference in the system for different makes and models of tractors is the details on the lubrication charts. Thus, after each day's work, the operator inserts a peg with a number corresponding to the tractor's hours counter into the hole on the board. This means that all operations required every 10 hours will be displayed in the line marked "A".

The color cards he had mentioned were used in the tractor schools currently being held.

PRESENT VARIETIES IN PRE-RELEASE TRIALS

Only two faeces of dirt and a rare faeces with chlorotic streaks have been found in this variety. On the very poor coastal sand, this variety came second, giving a better yield than Co.331, but which itself was clearly surpassed by N:Co.376. In the pre-release trials, it appears that Saccharine is currently one of the best grown varieties on the North Coast and in terms of appearance is preferable to Salvo.

The broad bracts, present on both sides of the leaf sheath but particularly well developed on one side, provide a useful guide to identification.

A COMPARISON OF THE RESULTS OBTAINED WITH

AINED WITH VARIETIES AT PRESENT IN THE PRE-RELEASE TRIALS

On soils derived from dwyka conglomerate, this variety outperformed N:Co.376 in the plant cane crop but fell away in ratoons. Here, Saraband N:Co.376 was inferior in the cane crop, but outperformed it in the first ratoon crop. Here this variety gave N:Co.376 in the plant cane crop, falling somewhat in the first ratoons but picking up again in the second ratoons.

Fair returns were also given on coastal sand, where it yielded N:Co.376 in the ratoon crop.

COVERED DRAINS

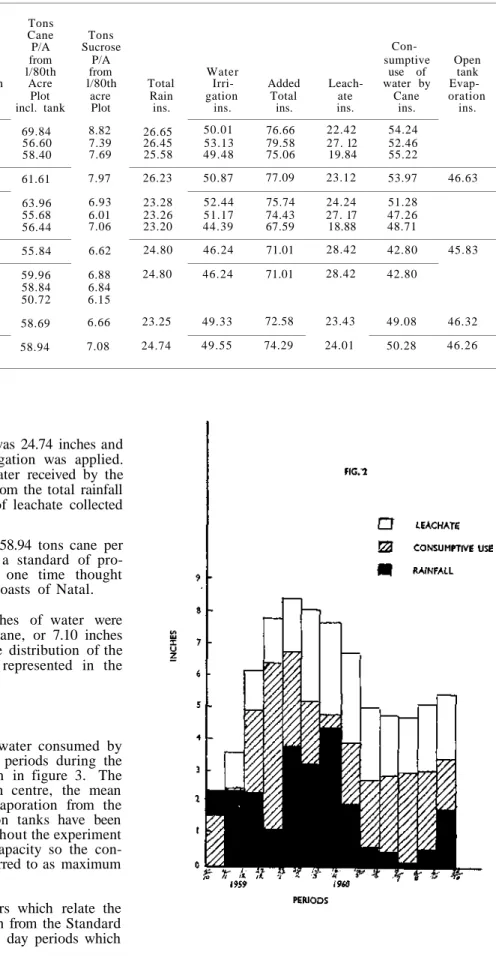

ATTEMPTS TO CONFIRM IRRIGATION CONTROL FACTORS BASED ON METEOROLOGICAL DATA IN THE CANE BELT

OF SOUTH AFRICA

The leachate was collected from sites 1 and 2 using plastic pipes leading from the bottom of the tanks to a sump or sumps so that gravity drained the tanks. The distribution of rainfall and irrigation is represented in the form of a histogram in Figure 2. At this stage, evaporation from the soil surface is a major factor in the consumptive use and transpiration an increasing factor as the young crop closes in. .

For the above results, the consumptive use for the entire plant cane crop is 109 per cent, of the evaporation from a Standard tank, and for the period from December 27 when the cane closed.

THE EXAMINATION OF THE CRITICAL PERIOD OF GROWTH OF A SPROUTING CANE SETT WHEN WEED

COMPETITION MUST BE ELIMINATED

The comparative development of the same age is first seen in photo 1 of a cane lifted 20 days after planting and to be made 60 days after planting. Weeding was carried out at this stage. Weeding took place after 20 days and again after 60 days, allowing the sugarcane plant to develop quickly in photos 5 and 14.

THE EFFECTS OF TIMING OF WEEDING OPERATIONS ON THE YIELD OF SUGARCANE AND THEIR ECONOMIC

SIGNIFICANCE

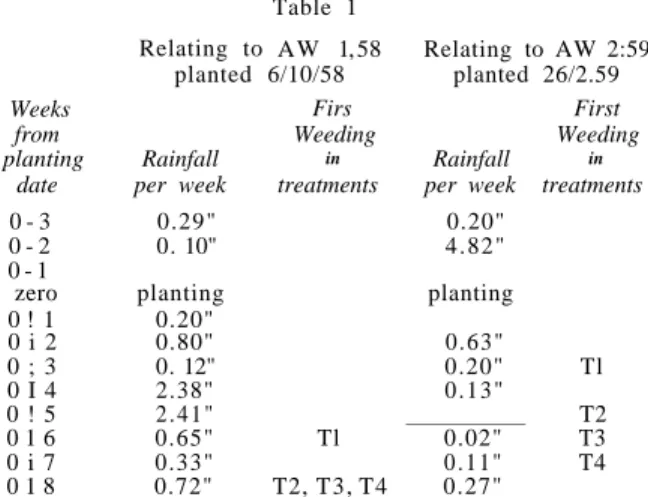

It would appear that when early weed control was applied in the line of sugarcane, better yields were obtained. T3 Only inter-row operations every 6 weeks T4 One-handed weeding in the line of cane accom-. The return journey is taken in the same way on the other side of the intermediate row.

Thus a complete eradication of weeds in the row is guaranteed with manual weeding, while with scraping the same applies to the interrow.

A WEED EXPERIMENT AT ILLOVO

The weeds on the plots that were weeded every seven days never developed to the point where they could have hindered the growth of the sugar cane in the first place. About a third of the sugar cane was planted in the period from March 15 to April 25. This meant that from one thousand hectares, thirty thousand tons of sugar cane was available for milling at the end of the following year.

Coignet said mosaic disease has increased on the South Coast in recent years and he suggested it may be due to herbicides acting on the aphid parasites that spread the disease.