Commodity aggregation refers to the sorting and consolidation of recycled materials to prepare them for sale to markets. The Waste Transfer and Resource Recovery Facility will be an integrated facility providing a range of recycling and waste management services that reflect modern state-of-the-art facilities.

Purpose of the Report

Approval Process

Environmental Approvals

Under Part IV of the EP Act, Aurigen referred the proposal to the Environmental Protection Authority (EPA) to determine the level of assessment in July 2016. The EPA's decision under Section 39A(3) of the Environmental Protection Act 1986 (EP Act) was that the proposal would not be assessed under Part IV of the EP Act.

Planning Approvals

Construction of the facility requires a work permit from the Department of Environment Regulation (DER). As a result of the DER reform, work approvals and licenses can now be applied for simultaneously.

Site Location

Site Identification

Site Description

Site Access

Surrounding Land Uses

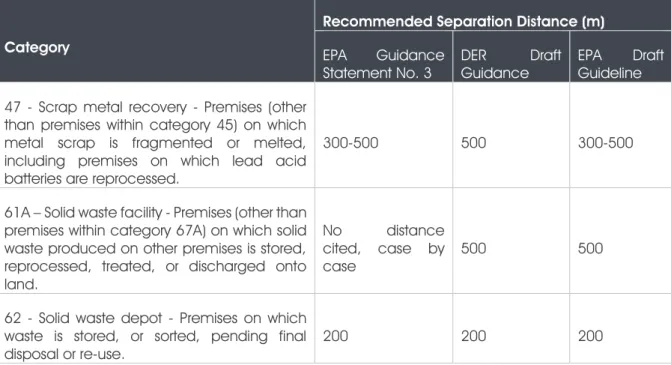

Separation Distances

EPA Guidance Draft Guidance 47 - Scrap Recycling - Facilities (other than facilities within Category 45) where scrap metal is fragmented or melted down, including facilities where lead acid batteries are recycled. 61A – Solid waste facilities – Facilities (other than facilities within category 67A) in which solid waste produced in other premises is stored, recycled, treated or discharged to land.

Zoning

As previously mentioned, the nearest residential area to the Site is approximately 570m away, at its closest point, to the north of the Site in the neighboring suburb of Bayswater. This is well beyond any of the existing or draft recommended separation distances for the activities proposed for the Site.

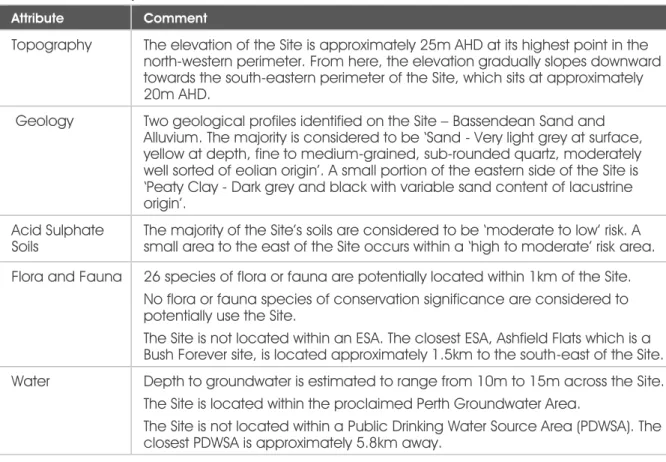

Topography

Geology

Acid Sulphate Soils

Flora and Fauna

Threatened Species

The results of a one kilometer search around the approximate 'centre' of the Site yielded a total of 26 flora and fauna species that could possibly be found in the search area. Of these there were fourteen species of plants, six species of arachnids, five species of reptiles and one species of fungus.

Environmentally Sensitive Areas

It is expected that due to the industries already established in the surrounding area, the construction and operation of the Facility will not have a significant impact on any identified species. This does not necessarily mean that the species is actually located within the search area or the Site.

Water

- Groundwater

- Groundwater Proclaimed Area

- Public Drinking Water Sourced Areas

- Surface Water Hydrology

- Wetlands

- Floodplains

- Surface Water Proclaimed Area

The closest identified wetland is a multi-use wetland (UFI 8433) located approx. 250 m north of the site. The next closest wetland is a multi-use wetland (UFI 15700) located approximately 390 m south-southwest of the site.

Cultural Heritage

Aboriginal Heritage and Native Title

A review of geospatial floodplain datasets indicated that the nearest floodplain, a mapped floodplain with 100 year ARI, is approximately 1.5 km southeast of the Site, associated with the Swan River (Figure 10). Based on a review of available mapping, the Site is located outside of any proclaimed surface water areas, with the nearest being approximately 2.2 km north-east of the Site, associated with the 'Swan River System' proclaimed area.

European Heritage

The 100-year flood plain distance ARI together with the elevation range of the area from 20m AHD to 25m AHD would indicate that the area is at a low risk of flooding. Under the Water and Irrigation Rights Act 1914, designated surface water areas in Western Australia are areas in which licenses are required to take water from a surface watercourse.

Local Government Heritage

Contaminated Site Information

Contaminated Sites Database Search

Summary of Environmental and Social Attributes

The following section provides a conceptual description of Aurigen's proposed site development under the following headings:.

Current Site layout

Proposed Site layout

A series of unloading quays will be built along the southern wing of the new building. The scrap metals are processed in the metal baler or shredder and prepared for sale on commodity markets.

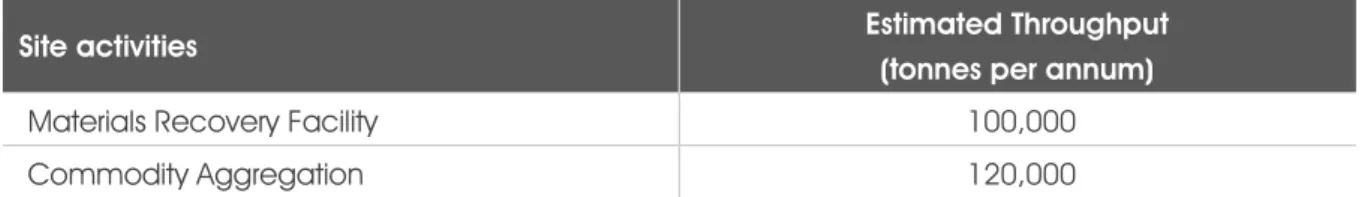

Material volumes

An extension to the existing metal recycling facility shed will be built to house a metal baler or shredder. The parking facilities on site will be expanded with facilities for at least 40 parking spaces, as shown in the Conceptual Floor Plan (Drawing G-001).

Waste Acceptance

Materials accepted will generally consist of mixed recycled materials from local authorities and commercial and industrial generators. The waste flow station will have a design capacity of 100,000 tonnes per annum and will generally accept municipal solid waste collected from local authorities and commercial and industrial waste from private waste management service providers.

Materials Recovery Facility

Equipment and Machinery

Materials Handling

Materials Transport

Commodity Aggregation

Equipment and Machinery

Materials Handling

Once baled, these materials will be temporarily stored in the closed bale shed until they can be loaded into a sea container for onward transport to port for export. Once the materials have been processed in the metal baler/grinder, the materials will be transported by a short conveyor into a storage bin that will be emptied periodically via an access door on the northwest side of the building and moved into the metal recycling facility for storage until it can loaded into a sea container.

Materials Transport

When unloading the materials, the personnel inspects the quality of the materials and ensures that they meet the acceptance criteria. Metal goods would be unloaded under appropriate supervision into the covered unloading area and then loaded into the baler/shredder using an excavator.

Putrescible Waste Transfer Station

- Putrescible Waste Bunkers

- Equipment and Machinery

- Materials Handling

- Materials Transport

In particular, all decaying waste handling operations will be confined within the designated waste transfer station within the building. The equipment that will be used within the waste transfer station is a front loader and a compaction system.

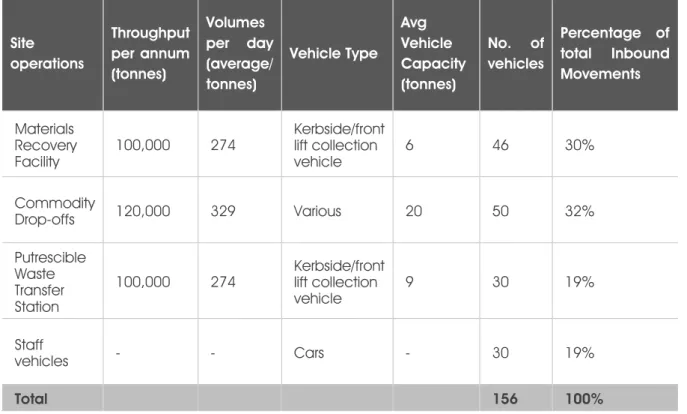

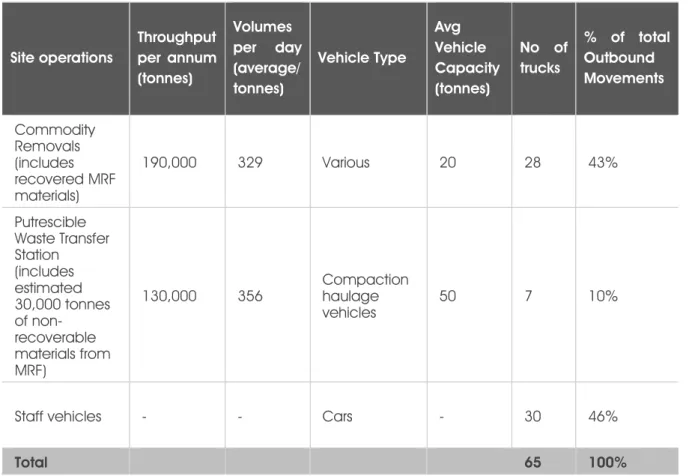

Vehicle movements

However, the modeling illustrates that the site can handle such volumes and associated traffic movements. Details of traffic movements on site are included in the Traffic and Transport Assessment (Appendix G).

Staffing

The materials processed in the MRF are included in the traffic movements associated with raw materials, as the output from the MRF will be processed on site where possible as part of the commodity aggregation operations. It is therefore expected that the traffic volumes will be significantly less than those modeled above.

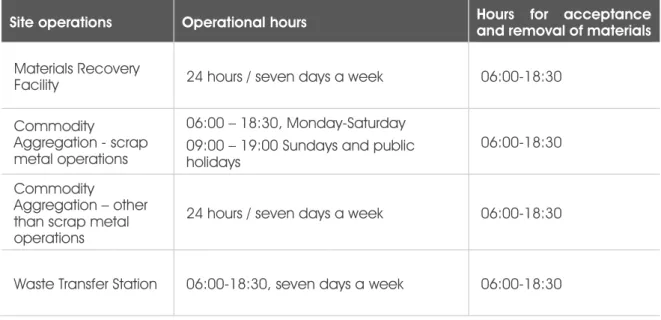

Operational Hours

Supporting Infrastructure

Waste diversion from landfill

Reduced Carbon Emissions and Costs

Local employment

Local Government Services

Community engagement and education

This section details all potential environmental impacts associated with the proposed waste transfer and resource recovery facility. The source and potential impacts associated with these aspects are described in the following sections.

Odour

The Odor Unit reported that both scenarios demonstrated a "PASS" with respect to the nearest sensitive receptor locations. Additionally, the Odor Unit report states that “the split scenario does not reflect improved odor control, rather it describes keeping the odor concentrated over the Waste Transfer Station rather than mixed throughout the building.

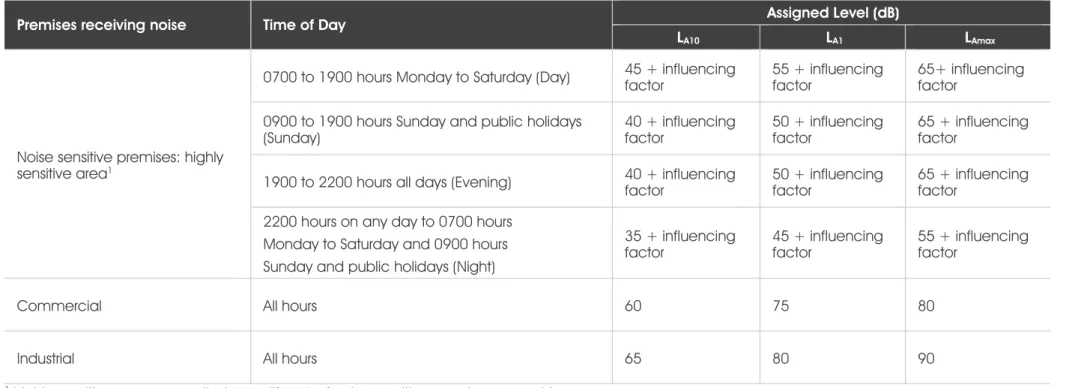

Noise

Day Operations (06:00 – 18:30)

The main source of noise was considered to be the operation of the metal chipper. The assessment found that truck noise should also be mitigated at the receiver on the east side of the Alice Street entrance.

Night Operations (18:30 – 06:00)

The noise model showed that a total noise reduction of 20 dB would be required to meet the requirements. However, based on the available information, Lloyd George suggested that noise control measures to address the noise emission from the shredder, such as the erection of a local noise barrier, were considered sufficient to remove the impulsivity characteristics and result in compliance.

Dust

The sound power levels used in the noise assessment were derived from sound pressure measurements made by others. Lloyd George recommended that final confirmation of noise levels by the manufacturer or supplier be arranged to identify targeted noise controls to mitigate the shredding noise at source.

Stormwater

The range in estimated noise reduction was due to the model assuming that noise emissions from the shredder are impulsive (defined as a noise source that has a momentary banging, clunking, or explosive sound) when assessed at the boundary, which adds a 10 dB penalty to the overall noise reduction . The measures to deal with stormwater that will be generated on site are outlined in Section 7.5.

Leachate

Litter

Traffic

Measures for the management of stormwater that will occur on the site are described in section 7.5. duration of each). Therefore, it is assumed that the volume of traffic will be significantly lower than the stated one.

Vermin

Further details regarding the facility's traffic and transportation are available in the traffic and transportation assessment (Appendix H). The management measures that will be taken to ensure that all impacts arising from traffic on the site are adequately managed are described in section 7.8. In order to ensure the appropriate management and mitigation of potential environmental impacts identified in this EAMP, Aurigen will implement various engineering and management measures, which are described in the following sections.

Legislative Context

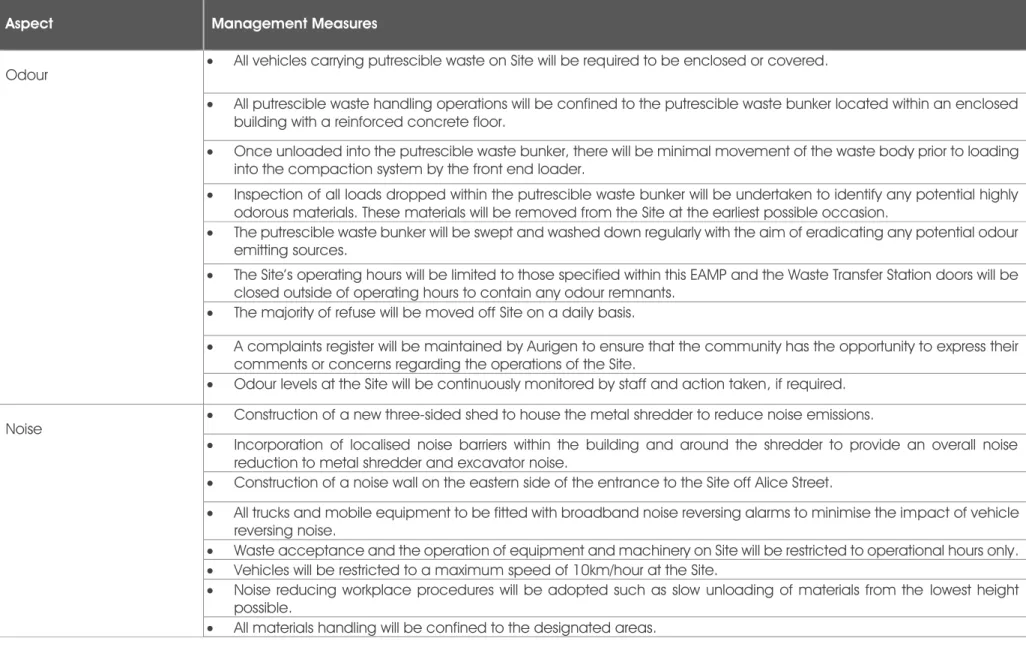

Odour Management

A complaints register will be maintained by Aurigen to ensure that the community has the opportunity to voice their comments or concerns regarding the operations of the Site; and. Odor levels at the Site will be continuously monitored by staff and action will be taken if necessary.

Noise Emission Management

The rotting waste bunker will be swept and washed regularly in order to eliminate any possible sources of odor. Site operating hours will be limited to those specified in this EAMP and the doors of the Waste Transfer Station will be closed outside of business hours to contain any odor residue;.

Dust Management

Stormwater Management

Leachate Management

Aurigen will implement good practice waste holding operations on site and limit holding time for perishable waste on site to 24 hours; and. By adopting the above management measures, it is expected that any potential impacts associated with the generation of leachate will be appropriately managed.

Litter Management

All perishable waste handling operations must be confined to the designated hard area of the waste transfer station;. Aurigen will develop a leachate collection system that will capture all leachate generated on site and either go to sewer or be emptied by a liquid waste tanker on a regular basis.

Traffic Management

By adopting these controls, all potential impacts associated with traffic movements on and around the Site will be controlled to appropriate standards. Further information on the traffic and transport of the proposed facility can be found in the Traffic and Transport Test (Appendix H).

Vermin Control

Security and fire safety

Complaints Management

The staff member will assess the nature, severity and potential consequences associated with the complaint. If similar complaints are made more than three (3) times, a toolbox meeting will be held to reevaluate control measures and determine if additional measures can be used.

Summary of Proposed Management Measures

Odor All vehicles transporting perishable waste on site must be closed or covered. All rainwater engineering features on site will be inspected regularly and maintenance works will be properly planned.