Nazmul Hossain (BME) Showrav Chandra Saha (BME) for partial fulfillment of the requirement of bachelor of science degree in mechanical engineering from Sonargaon University. We solemnly declare that the project report on “Design and Construction of a Low Cost Operating LPG Refrigeration System " is submitted to Sonargaon University (SU) for partial fulfillment of the requirement of B.Sc Degree. Further, we undertake to indemnify the university for any loss or damage arising out of breach of the above obligation.

Mostofa Hossain, Head of Mechanical Engineering Department, and kind cooperation in carrying out this project. Finally, we would like to express our best wishes and express our sincere thanks to all our group members and friends who have been a constant source of encouragement for the successful completion of the project. Uninterrupted power supply is still not available in several areas of the country and the world.

LPG is cheaper and environmentally friendly in nature, with no Ozone Depletion Potential (ODP) and no Global Warming Potential (GDP). Even from the experiment, which was carried out in atmospheric conditions, we can predict the optimal value of the cooling effect with the appropriate operating conditions of the control valve and the capillary tube of the system. When this high-pressure LPG passes through a capillary tube of small internal diameter, the LPG pressure drops due to expansion and a phase change of LPG occurs in an isoenthalpic process.

After expansion, the phase of LPG is changed and converted from liquid to gas and then it passes through the evaporator where it absorbs the heat and produces the cooling effect.

OBJECTIVES

LITERATURE REVIEW

Theory

- DENSITY

- VAPOURPRESSURE

- COMBUSTION

- COLOUR

- ODOUR

- TOXICITY

LPG at atmospheric pressure and temperature is a gas that is 1.5 to 2.0 times heavier than air. As LPG vapor is heavier than air, it will normally settle at ground level/low-lying places and accumulate in depressions. The vapor pressure depends on the temperature as well as the mixing ratio.

This gives an indication of the danger of LPG vapor in low-lying areas in the. Entrapped air in the vapor is dangerous in an uncleaned container/cylinder during pumping/filling operation. In light of this, it is not advisable to use air pressure to unload LPG loads or tankers.

In addition to heat development, the combustion reaction of LPG also increases the volume of the products. It is therefore essential that adequate ventilation is provided when LPG is burned in enclosed spaces, otherwise asphyxiation due to lack of oxygen may occur, in addition to the formation of carbon dioxide. During leakage, the evaporation of liquid cools the atmosphere and the water vapor contained in it condenses, creating a whitish mist that makes it possible to see the escape of LPG.

LPG only has a very faint smell, and as a result it is necessary to add some odorant so that any escaping gas can be easily detected. LPG, although slightly toxic, is not toxic in vapor phase, but can suffocate in large concentrations due to the fact that it displaces oxygen.

CHAPTER - 2

Working principle

Working Elements

1. Evaporator

- Copper pipe 3. Capillary tube

- Pressure gauge meter 5. Burner

- Gas cylinder

- Temperature meter 8. Dryer strainer

- Regulator 10. Evaporator box

After passing through the evaporator, low pressure and temperature vapors absorb heat from the chamber system. When the cooling effects occur during the drying cycle, the evaporators in the cooling system produce the cooling effect. The evaporators are units that exchange the heat from the cooling material and thus take the heat from the medium.

After passing through the capillary tube at low pressure and temperature, the refrigerant reaches the evaporators. The refrigerant from the evaporator is even lower than the evaporator used by cooling water systems. The capillary tube is a sturdy device, such as a long, tight tube, that connects the condenser directly to the evaporator.

Due to the following two friction parameters, the pressure flow through the capillary tube results in the flashing of the liquid refrigerant in the vapor, resulting in a decreasing friction pressure and an acceleration. For cooling applications, the inside diameter of the capillary tube varies between 0.5 mm and 2.5 mm. The diameter is smaller and the capillary is further away than the pressure drop of the coolant as it flows through the capillary tube.

The side of the tube is fixed and the other end can move freely in or out. The indicator shows the pressure of the indicator (the difference between fluid and ambient pressure). After the cooling effect, LPG gas enters the burner under low pressure where it burns.

As we know, when the liquid flows through the narrow tube, there is a pressure drop. A filter is used to remove any particles, such as dirt, metal or chips, from entering the coolant flow control. The LPG is converted into low pressure vapor and processes to the evaporator which absorbs heat in the chamber, making it comfortable and cooling the refrigerant.

The simple idea behind the LPG cooler is to use LPG for heat absorption. Whenever the gas control tank is unlocked, the LPG is placed under high pressure in the LPG cylinder where the LPG passes through the high pressure pipe.

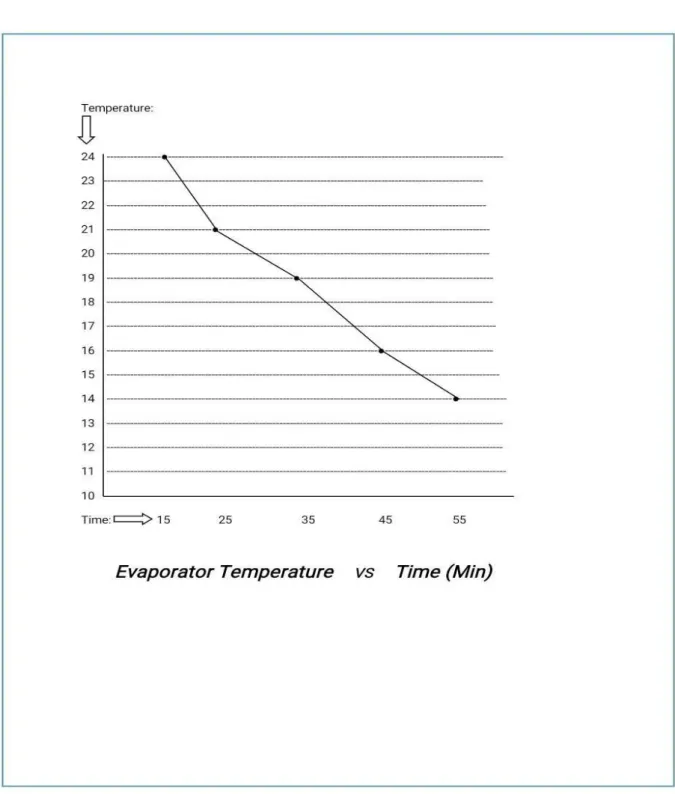

Temperature Graph

ADVANTAGES AND DISADVANTAGES

Advantages –

Disadvantages-

Future Scope

APPLICATION

Discussion

CHAPTER-4