This is to certify that the work presented in this thesis is the outcome of the investigation and research carried out by the following students under the guidance of Major Md. Our goal was to understand the automated mechanism of a throwing robot that delivers an efficient throw. Using a sonar sensor and a servo motor it determines the angular and radial distance of the destination from the sensor.

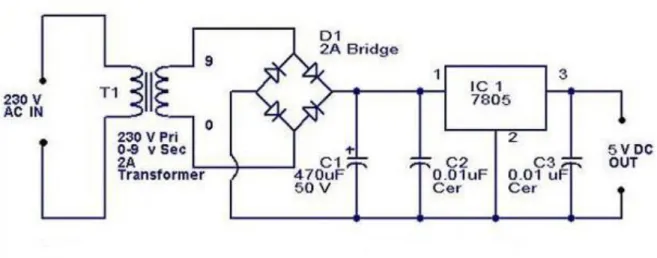

To achieve such a result we had to develop some geometric relationships and also inspect experimental behavior of the robot. 56 Figure 16: Circuit diagram of the power supply unit 57 Figure 17: Actual power supply unit of the robot 58.

Introduction

Background

For scientists, the challenge is to get the robot to throw an object at a precise location. A throwing robot must be able to automatically throw an object at any target. Let's say that for a robot to play basketball, it is necessary to determine the position of a constantly moving object and, while moving, also throw the ball to the goal or to the basket.

Sometimes it is difficult for people to go into a harmful environment and work effectively there. In the case of flood areas, it is risky for a man to spread the relief among the people.

Objectives

Applications

Literature review

Robot and robotics

- Definition of robot

- Different parameters of robot

- Robotics

- Laws of robotics

Three more axes (yaw, tilt and rotation) are required to fully control the orientation of the end of the hand (i.e. the wrist). This can be defined in terms of the angular or linear velocity of each axis or as a composite velocity ie. when the absolute position of the robot is measured and compared to the commanded position, the error is a measure of accuracy.

How well the robot will return to a programmed position is called the robot's repeatability. But if this position is taught into the controller's memory and every time it is sent there it returns to within 0.1mm of the taught position, then the repeatability will be within 0.1mm. Accuracy and repeatability are different goals.

Historical development of robots

- Early history of robots

- History of Humanoid robot

A robot must obey the orders given to it by humans, except where such orders would conflict with the First Law. A robot must protect its own existence as long as such protection does not conflict with the First or Second Law.[4] [5]. The first humanoid robot was a soldier with a trumpet, made in 1810 by Friedrich Kauffman in Dresden, Germany.

Simon pioneered the fledgling field of artificial intelligence with The Logical Theory Machine (1956) and The General. John McCarthy also created LISP in the summer of 1958, a programming language still important in artificial intelligence research.

The revolution of robotics

The Motoman L10 was introduced in 1978: Vicarm, Unimation creates the PUMA robot (Programmable Universal Machine for Assembly) with support from General Motors. It is the first to install motors directly into the joints of the arm. 1988: The Motoman ERC control system was introduced with the ability to control up to 12 axes, more than any other controller at the time.

GM Fanuc Robotics Corporation was restructured into FANUC's wholly-owned holding company, FANUC Robotics Corporation, along with its subsidiaries, FANUC Robotics North America, Inc. 1994: The Motoman MRC control system was introduced with the ability to control up to 21 axes.

Electrical equipment

- Transformer

- Diodes

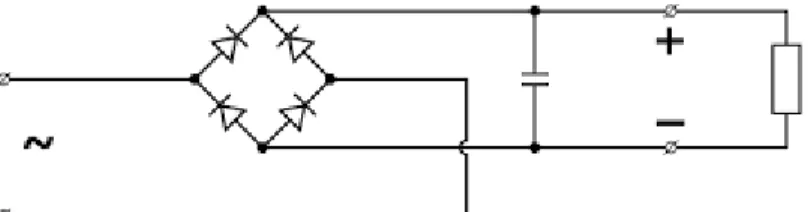

- Bridge rectifier

- Capacitor

- Servo motor

- DC motor

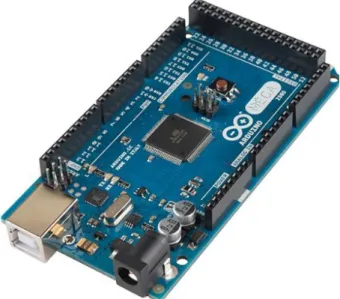

- Arduino

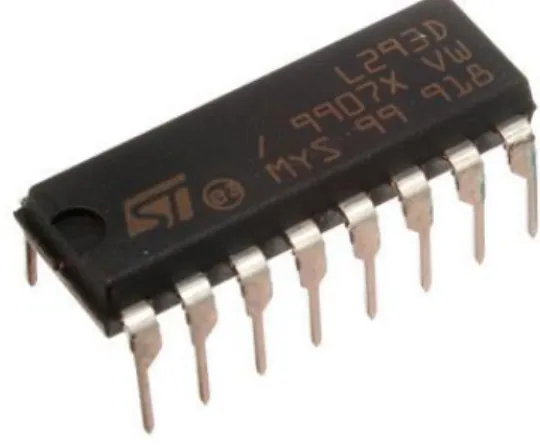

- Motor Driving IC ( L293D)

- Sonar sensor (Ultrasonic Transducer)

32 The varying current in the primary winding of the transformer creates a varying magnetic flux in the transformer core and a varying magnetic field affecting the secondary winding of the transformer. This changing magnetic field on the secondary winding induces a changing electromotive force (EMF) or voltage in the secondary winding due to electromagnetic induction. 33 resistance to current flow in one direction and high (ideally infinite) resistance in the other.

According to the conventional model of current flow (originally established by Benjamin Franklin and still followed by most engineers [24]), current is defined as positive when it flows through electrical conductors from the positive to the negative terminal. In reality, free electrons in a conductor almost always flow from the negative to the positive terminal, but in the vast majority of applications the actual direction of the current is irrelevant.

When the input connected to the left corner is negative and the input connected to the right corner is positive, current flows from the lower power terminal to the right along the red (positive) path to the output and returns to the upper power terminal via the blue (negative) path. The measured position of the output is compared with the command position, the external input to the controller. If the output position deviates from the required one, an error signal is generated which then causes the motor to rotate in either direction depending on what is required to bring the output shaft into the correct position.

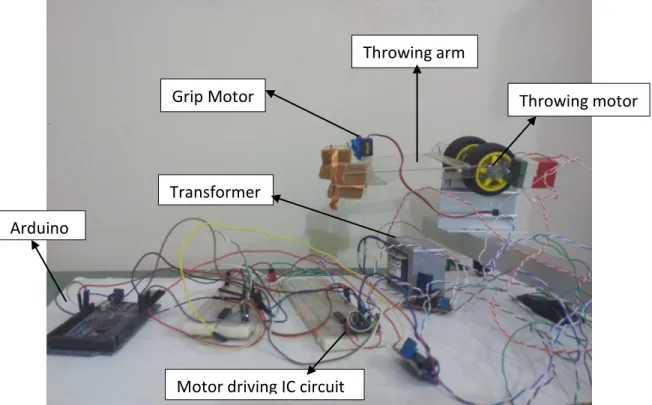

Being a high torque motor (30 kg/cm), it is used in the forearm to hold and move the throwing mechanism. Dual H-bridge Motor Driver integrated circuit (IC). The l293d can also power small and quite large engines. An electrical square wave powers the transducer and creates sound in the solvent strong enough to cause cavitation.

Structure and mechanism

- Basement

- Position detecting mechanism

- Throwing mechanism

- Arm rotating mechanism

- Electronic architecture

The distance to the position where the robot has to throw is measured by the distance measuring mechanism. The microcontroller always checks the position of the motor, where it rotates with an angular velocity. As soon as it finds signs of object detection, it detects the position of the servo motor.

Two DC motors mounted at the lower end of the arm cause the arm to move at an angle. These directions are determined and calculated by the controller using a servo motor of the distance measuring mechanism. This vibration may be responsible for the failure of the joints of the throwing arm and the lower rotating arm.

This allows the arm to support the load of the throwing mechanism and also causes a smooth and frictionless movement of the arm throughout its range of motion. The robot's power supply unit consists of a transformer (2amps, -12 volts to +12 volts), a bridge rectifier containing diode, two capacitors, voltage regulating IC. The current rating of the transformer depends on the current required for the load to be driven.

The signal pin of the sensor is also connected to a digital I/O pin of the Arduino. The servo motor used to determine the angle of the throwing position from the sensor is connected to the Arduino. Here the Arduino pins act as output pins and activate the input pin of the motor driving IC.

- Initial manual control and experimentation

- Geometrical analysis of throwing position

- Algorithm

- Coding and automation

But to perform this action, the robot must be aware of the angle at which it will rotate its arm. When the controller is given any signal by the sonar sensor, it stores the angle of the servo motor and records the distance of the object from the signal of the sonar sensor. Therefore, to throw in different positions, the line of throw must be the tangent line of the circle in which the forearm moves.

The angle of rotation of the lower part should be such that the throwing mechanism can throw to the target tangentially from the circle of movement of the lower swing arm. To geometrically analyze the position of the sensor connected to the servo motor, the rotation circle of the lower arm and the throw destination is shown in Figure 1. SR = the reference line of the sensor servo motor for determining the angle OT = the length of the arm of bottom = r.

69 Figure 24: Determination of forearm angular rotation by geometric analysis when the throwing destination is on the left side of the robot. In the above analysis, the position where the object should be thrown is on the left side of the robot. This geometry is different from the geometry of the destination which is on the right side of the robot.

73 Figure 25: Determination of angular rotation of the lower arm by geometric analysis when the throwing target is on the left side of the robot. The controller then reads the code and performs tasks according to the code's command. It will decide on the angle of attack, the speed of throwing the object so that the object can reach the desired position.

Results and discussions

Accumulated results of the experiment

- Initial observation of the throw characteristics with varying voltage

- Initial observation of the throw characteristics with varying angle

- Observation of automatic performance

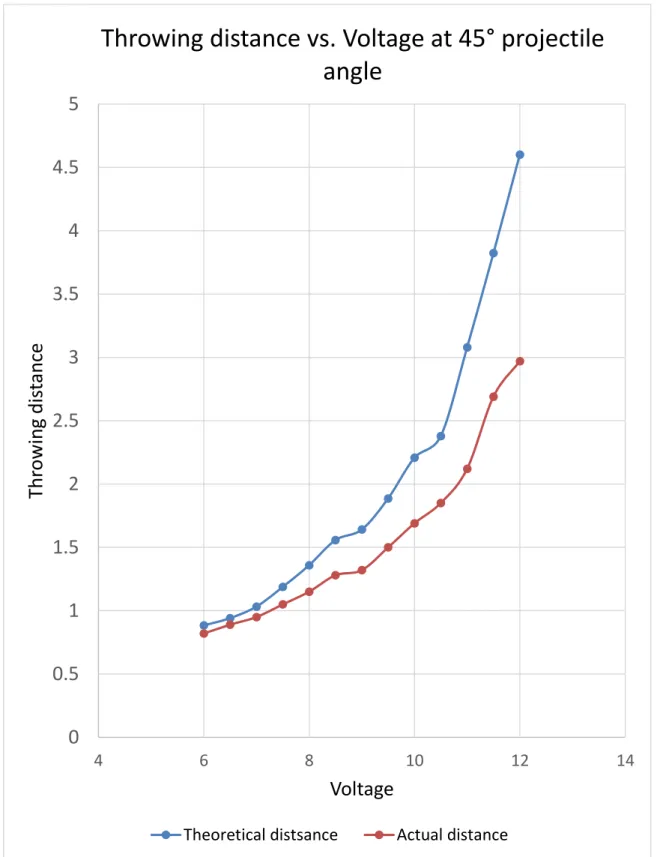

Initially, the characteristics of the meta were observed by manual control of the input parameters. In the second phase, the automated operation of the robot was observed using previous experience. The input tension of the throwing arm was varied to understand throwing performance with tension.

Then the throw arm voltage is varied in range to have reasonable throw performance. This throw angle is in the opposite direction to the rest position of the throw arm. This is due to the fact that as the voltage increases, the speed of the throwing arm increases.

This results in a reduction in throw angle due to arm inertia. The greater the distance to be covered, the greater the tension of the throwing arm must be. Thus, the values correspond to the maximum throwing distance only by changing the tension of the throwing arm.

The dump characteristics are now observed with varying dump angle and keeping the input voltage constant. This is due to the inertia of the robot's throwing arm, which moves it slightly forward of the position the arm is commanded to stop. Also the deviation of the actual throw distances increases as the angle increases.

Conclusion

Conclusion

Our goal was to try out the field of robotics with the least resources we got. The main idea was to improve an innovative approach to the throwing mechanism for further improvements. Our robot is based on a simple and accurate method to automatically detect the location of the destination and automatically deliver an object given to it to that destination.

While developing this machine, we understood the complexity of an automatic throw and tried to overcome it. This will give them a new method to apply for casting mechanism that is simple and effective.

Limitations

Recommendations

29] Remote position control system of stepper motor using DTMF technology, Sagarika pal; Niladri Tripathy, international journal of control automation, Vol 4, No :2, June 2011. 31] Wireless Hand Gesture Controlled Robot, Pankaj Singh; Amanjit Singh; Abhinav Bhatra; Aditya Gupta, International journal of advanced research in engineering technology and sciences, Vol 2, Issue: 3, March 2015. 32] Microcontroller Based Dc Motor Control, Authors: Jayshree Sahu, S.K.Sahu, Jayendra Kumar, International Journal of Engineering Research &.

APPENDIX