In this work we used three different types of fibers to produce four different types of composite. Banana fibers offer important advantages such as low density, appropriate stiffness and mechanical properties and high disposability and renewability, just like jute fibers, and it is also environmentally friendly. Third, we use fiber optic. This is a material consisting of countless extremely fine glass fibers.

Glass fibers have roughly comparable mechanical properties to other fibers such as polymers and carbon fibers. Although not as stiff as carbon fiber, it is much cheaper and significantly less brittle when used in composites. It is an unsaturated synthetic resin produced by the reaction of dibasic organic acids and polyhydric alcohols.

Fabrication of composite material using finely cut pieces of jute, banana and glass fiber. It is widely used to reinforce other types of composite material to make the material more reliable and strong.

![Figure 1: Composite Materials (Carbon fiber based) [4]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10776894.0/5.918.112.762.391.830/figure-1-composite-materials-carbon-fiber-based-4.webp)

Polymer Matrix Composite

Traditionally, thermoplastics were mainly reinforced with discontinuous fibers, but recent development of high temperature resins such as polyetherketone, polysulphur and polyamide have also made thermoplastics competitive with thermoplastics in the field of high performance continuous fiber composites. However, the full list of applicable thermoplastic matrices is more comprehensive and includes acrylonitrile-butadiene-styrenes, acetals, acrylic fluoropolymers, polyamides, polyamide-imides, polyarylsulfones, polycarbonates, thermoplastic polyesters, polyetherketone, polyethersulfones, polyethylenes, polyamides. polypropylene, polystyrenes, polysulfones, poly (vinyl chloride) and styrene-acrylonitriles.

![Figure 8: Polymer Matrix Composite [11]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10776894.0/12.918.217.665.510.806/figure-8-polymer-matrix-composite-11.webp)

FIBER

Natural Fiber

MATERIALS USED IN PRESENT STUDY

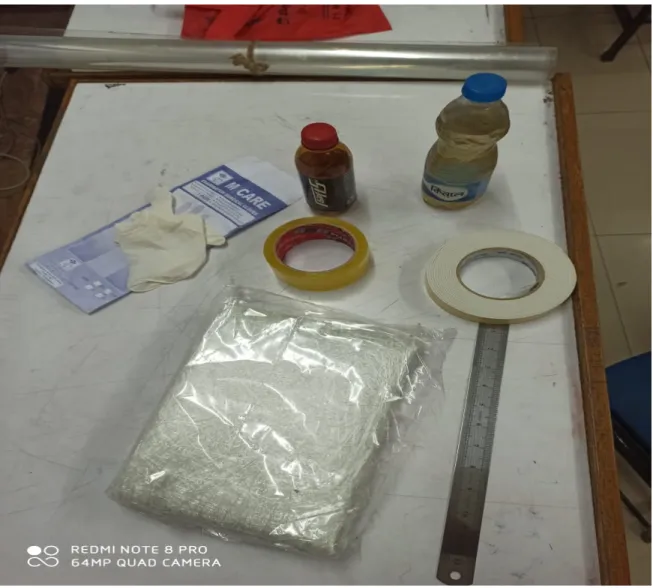

Resin

HARDENER

Jute fiber

Unlike most textile fibers which are mainly composed of cellulose, jute fibers are part cellulose, part lignin. Cellulose is a major component of plant fibers while lignin is a major component of wood fiber; Jute is therefore part textile fiber and part wood.

Characteristics of Jute fiber

Properties of Jute Fibers

Banana Fiber

Banana plant is available throughout Thailand and Southeast Asia, India, Bangladesh, Indonesia, Malaysia, Philippines, Hawaii and some Pacific Islands.

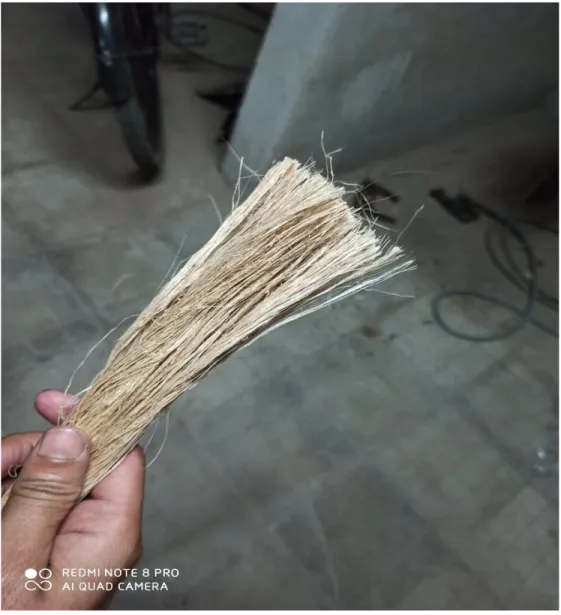

Characteristics of Banana fiber

It is biodegradable and has no negative effect on the environment and can therefore be categorized as an eco-friendly fiber. It can be spun by almost all spinning methods, including ring spinning, open-end spinning, bast fiber spinning and semi-worsted spinning.

Properties of Banana Fibers

Glass fiber

Glass wool, which today is a product called "fiberglass", was invented in 1932–1933 by Russell Games Slayter of Owens-Corning as a material to be used as thermal building insulation. Fiberglass when used as a thermal insulation material is specially manufactured with a binder to trap very small air cells, resulting in the characteristic air-filled low-density "glass wool" family of products. Glass fibers are therefore used as a reinforcing agent for many polymer products; to form a very strong and relatively lightweight fiber-reinforced polymer (FRP) composite material called glass-reinforced plastic (GRP), also commonly known as.

This material contains little or no air or gas, is denser and is a much poorer thermal insulator than glass wool.

Classification & Properties of Glass fiber

CHAPTER3: FABRICATION PROCESS

Selection of lamina

Among them, three types are layer oriented, and other types are made of a mixture of very small pieces of all fibrous materials.

Possible orientation of fibers in the lamina

MATERIALS PREPERATION

- Matrix material collection

- Jute fibers

- Banana fibers

- Glass fibers

Usually jute fibers are very long, we selected the fresh jute fibers and then cut them to the desired length. The banana tree is the most common tree in our country, wherever we look, we see a banana tree everywhere. After collection, banana trees are treated as waste, but there is a huge opportunity to utilize this tree by extracting the banana fibers.

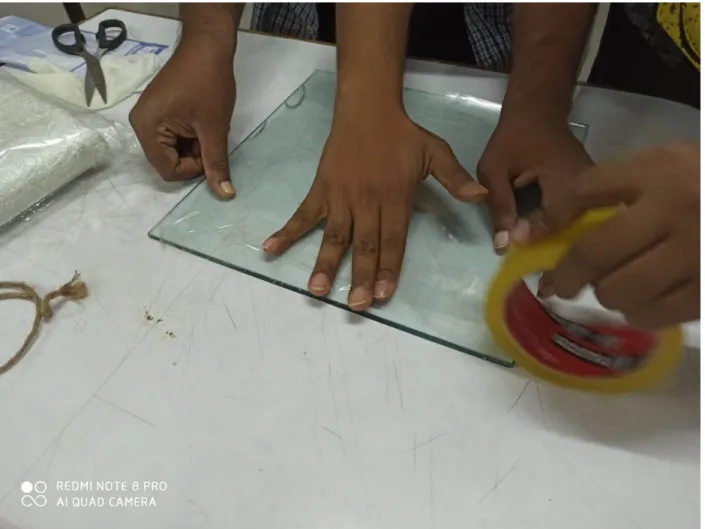

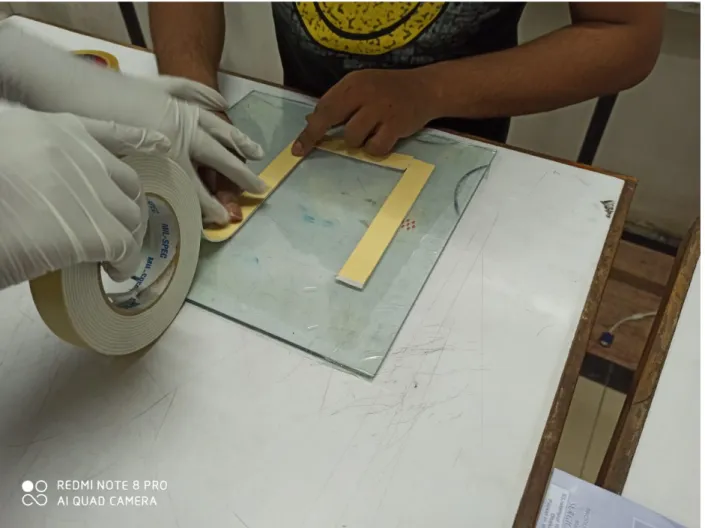

FABBRICATION OF COMPOSITIE

Scissors 5. Brush

- Fabrication process

- Some steps of Fabrication process are described in below with photos

For this paper the plane of the composites will be smooth and we can remove the core material from the surface/mold. After preparing all the fibers and other materials we started to make the composites, in the first step we poured the resin-hardener mixture on the pilot paper and carefully removed all the braids. We have always used fiberglass as the first layer, we place it carefully and press it with something to remove the rags.

After placing all the fiber one by one, we then used pilot paper again to cover the main material. For that additional resin hardener mixture will be removed, and the fibers are compressed.

TESTING

- MECHANICAL CHARACTERIZATION OF COMPOSITES .1 Flexural test

- Specimen preparation

- Test operation

- Tensile Test

- Specimen preparation

- Test operation

- Hardness Test

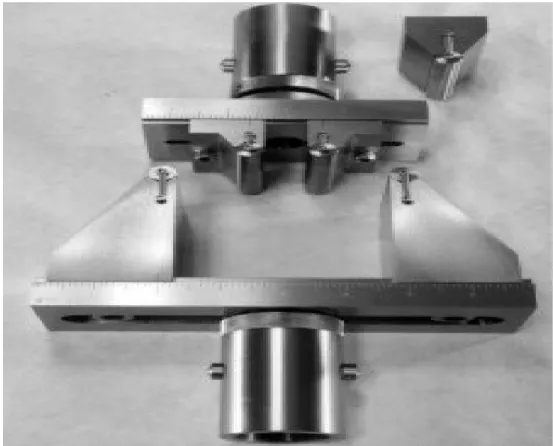

This test was conducted to determine the mechanical properties of the specimens under load and to understand the mechanisms of deformation and the mode of failure. The bend test method is designed to properly produce bend data for the control and specification of plastic materials. To conduct the test, three sets of test samples of 10 mm and 100 mm long were cut from each four main samples, as shown in the figure.

The fiber powder mixture sample is labeled as No. 3 and the horizontally oriented sample is labeled as No. 4. Testing Machine A properly calibrated testing machine capable of being operated at a constant rate of crosshead movement over the indicated range, and in which the error in the load measurement system shall not exceed ±0.1 % of the maximum load expected to be measured. Then start to create pressure on the placed sample until it reaches maximum deformation.

This test was performed to determine the mechanical properties of the specimens under tensile loading and to understand the deformation mechanisms and failure mode. Tensile test method is designed to produce correct tensile data for the control and specification of plastic materials. By grasping the ends of a thin dog-bone shaped specimen with a pair of crosshead grips and pulling at a constant speed, mechanical properties can be determined.

A total of two test specimens were cut from master specimen in the form of 2 inches in hex and 6 inches in height. After all the test samples are completed, the samples are placed on the UMT machine to perform the test. For this test we use crosshead grips on either side of the machine this particular attachment is used for tensile testing.

By grasping the ends of the thin sample with a pair of crosshead handles and pulling at a constant speed, the mechanical properties can be determined.

DATA COLLECTION, ANALYSIS AND DISCUSSION

- EXPERIMENTAL RESULTS

- Flexural test

- Mathematical analysis and Stress-Strain diagram

- Tensile test result

A HOUNSFIELD UTM 500 KN with a lower limit of 10 KN with the appropriate capacity and connections was used to perform the Flexural test. Each specimen was loaded under the moving cross of the testing machine which holds a load cell, taking care to align the long axis of the specimen and the automated testing program initialized. Great attention was paid to the specimen, noting the different stages of deformation, the load response and the displacement was measured and recorded automatically on the computer by a "load cell". which is cross-attached and connected to a CPU.

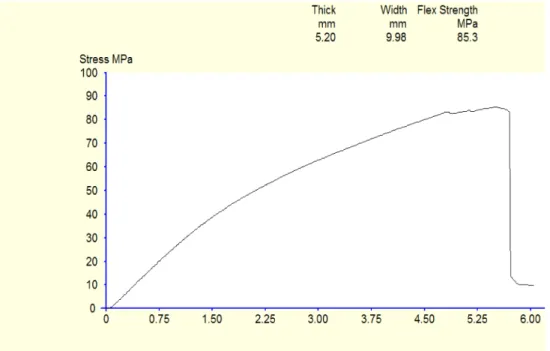

Stress and strain diagram for vertically oriented fiber composite marked No. 1 is given below. Flexural strength of sample 1A= 85.3 MPa Flexural strength of sample 1B= 89.5 MPa Flexural strength of sample 1C= 98.7 MPa. Stress and strain diagram for vertically oriented fiber composite marked No. 2 is given below.

Flexural strength of specimen 2A= 55.8 MPa Flexural strength of specimen 1B= 83.0 MPa Flexural strength of specimen 2C= 79.8 MPa. Stress and strain diagram for vertically oriented fiber assembly labeled No 3 is given below. Stress and strain diagram for vertically oriented fiber assembly marked as No 4 is given below.

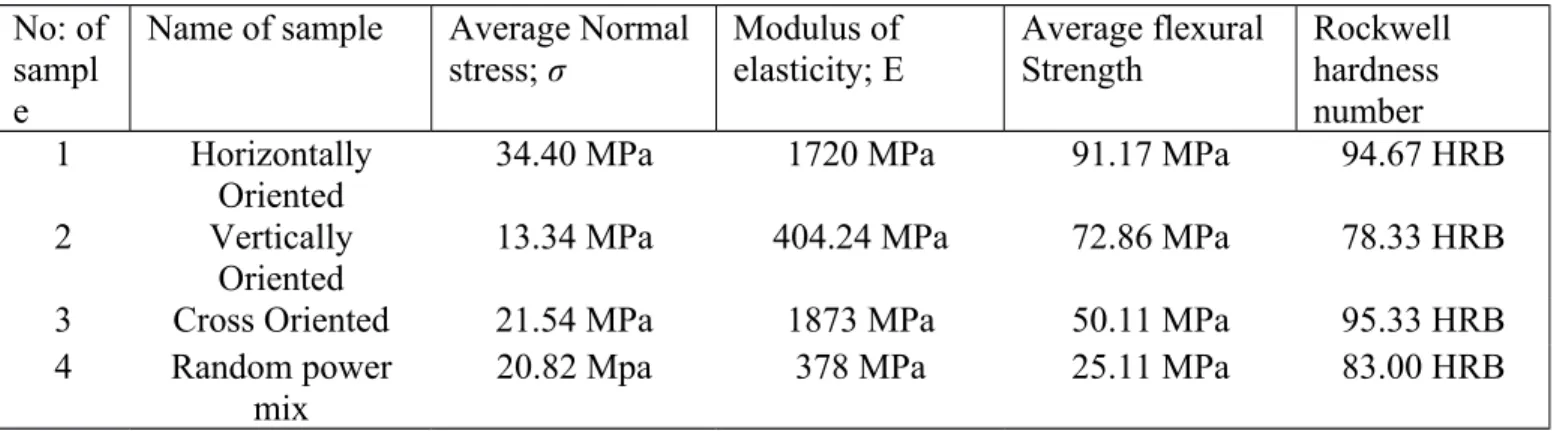

Result: We noticed that the value of Flexural strength is maximum of Sample 1, which is oriented as a horizontal layer of fiber. And the minimum value is from sample 4 which is made by mixed oriented cut fibers. A UTM with proper capacity and appropriate attachments was used to perform the tensile test.

Because it is an old model manually operated machine, all data is taken manually, no automated or computerized operation. Each sample is correctly placed between the two grips and then all necessary data is collected correctly with great care. Before then, all necessary measurements (thickness & width) of the materials are carefully measured and noted.

Mathematical analysis

Layer oriented Horizontally)

- Hardness Test Result

- Result

After showing all results, we noticed that the composition of Sample 2 has the maximum value of stress and Strain. And the lowest value of stress is from sample 3, which is vertically oriented layer of fiber. From the value of Rockwel hardness testing machine we got, Value of Sample 1 (horizontally oriented).

From all the data, we have seen that sample 3 (cross-oriented) has the highest value of hardness test.

DISCUSSION AND CONCLUSION

- SUMMARY OF THE WORK

- DISCUSSION

- CONCLUSION

- Some application of this Hybrid fiber composites

In the present study, tensile properties of jute fibers, banana fibers and fibers with synthetic resin composites were carried out by varying span length. Our goals were to produce some composites with better mechanical properties such as tensile strength, flexural strength and harness by using natural fiber and synthetic fiber hybrid composites. As natural fiber used Banana fiber and jute fiber and synthetic fiber was glass fiber.

For the layering process we made 3 types of orientation as horizontally oriented, vertically oriented and cross oriented fiber layer. The cross-oriented fiber material is the hardest material, but other mechanical properties are not as good. In conclusion it can be said that all the Composite that we had tested the most promising result that we got from the layered sample with horizontal orientation.

10]https://steemkr.com/chemical/@markettrends/global-ceramic-matrix-composites-cmc-market-2018-size-share-demand-and-analysis-2023. Comparison of filler-dependent mechanical properties of jute fiber reinforced sheet and bulk molding compound. Swell prediction of jute-banana fiber composites using ANN and regression.

![Figure 7: Ceramic Matrix Composite [10]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10776894.0/11.918.136.780.129.498/figure-7-ceramic-matrix-composite-10.webp)

![Figure 15: Resin and hardener. [20]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10776894.0/25.918.146.771.338.990/figure-15-resin-and-hardener-20.webp)