Fig.-3.8 Schematic diagram of the natural gas flow system 3.9 Fig.-3.9 Photograph of the nozzles in different sizes 3.10. Fig-4.2(b) Variation of overall efficiency with load 4.5 Fig-4.3(a) Variation of percentage of exhaust emission 4.8.

NOMENCLATURE

TO MY MOTHER

INTRODUCTION

Background

This study examines the use of natural gas in small spark engines used in small-scale electricity generation, with minimal possible engine modifications. Running the same engine with domestic natural gas supply as fuel, with as few engine modifications as possible.

LITERATURE REVIEW

Use of Alternative Fuel

Their results showed that the power developed in dual fuel operation was slightly lower than in 100% diesel operation. Their results showed that the horsepower of a CNG engine is less than that of a 100 percent diesel engine.

Natural Gas

The efficiency of the duel fuel engine was low compared to that of pure diesel engines and with larger quantities of diesel. Due to the higher octane number of the fuel, this is not necessarily considered a problem when driving on natural gas.

Combustion of Natural Gas in IC Engines

Natural gas can be stored in two ways: as a high-pressure gas or as a liquid. The flame speed of natural gas-air mixtures is lower than the flame speed of gasoline-air mixtures, so the NOV combustion chamber must be redesigned to avoid loss of efficiency.

The Experimental Setup

The gas meter was used to obtain the engine gas flow rate by measuring the time required for a given amount of gas to flow. For this, part of the engine's original air intake was replaced by a modified intake structure. To facilitate the measurement of the air flow rate through the engine, an air drum equipped with a parabolic intake nozzle was used in the air intake path.

The welded ends of the thermocouple were connected at certain points of the motor and the other ends were connected to the gauge. Engine sound has been found to be a good indicator of a smooth engine operation. A 4-gas emission analyzer (CRYPTON 290) was used to measure the share of different gas components in exhaust gas emissions.

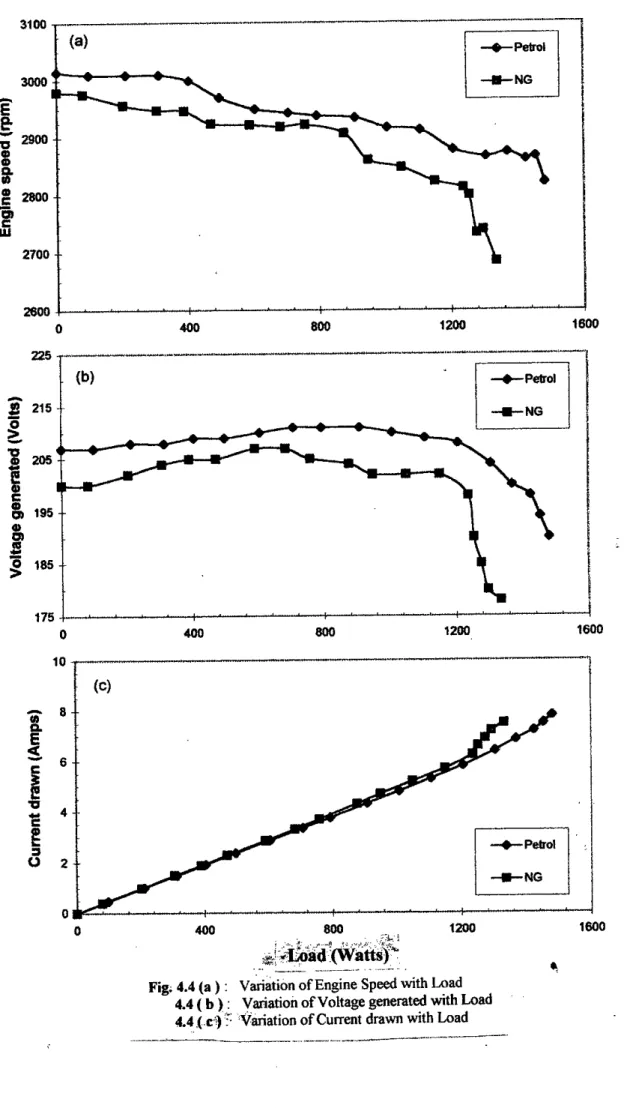

In the first phase, the performance test of the engine was carried out using petrol as fuel. The study with gasoline provides valuable baseline data indicating the designed performance of the engine-generator set. While running the engine on gasoline, the air flow rate of the engine increased almost in a linear fashion.

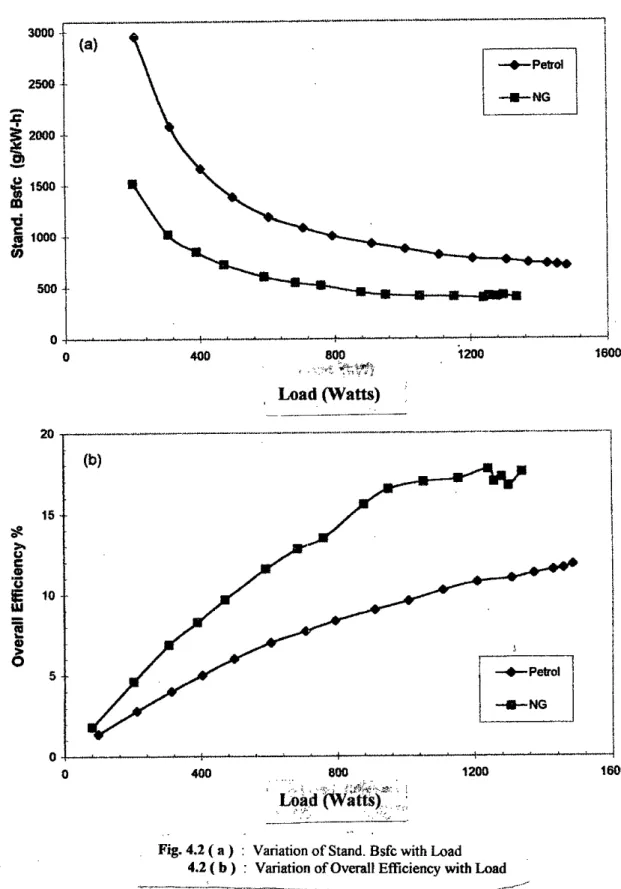

Fuel Flow Rate: Changes in fuel flow rate with increasing load for both fuels are shown in Figure 4.I(b). Variations in air-fuel ratios with different loads were also found to be limited, especially with gasoline (10-12 for gasoline and 15-20 for natural gas.

PWOI __ NG I

- Performance of a Prospective Commercial System

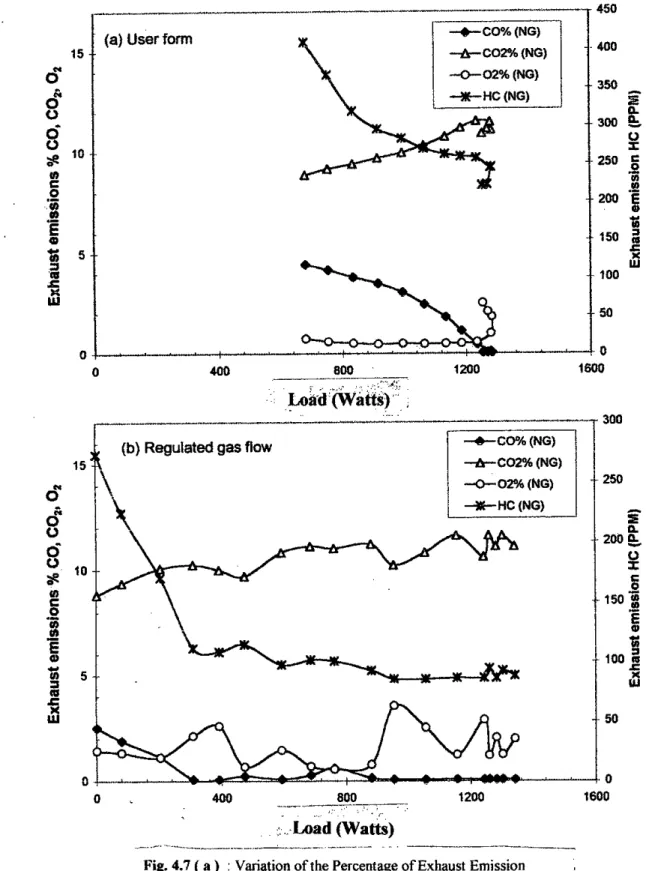

It has been found that when installed in the main gas line, the necessary amount of gas is provided through the engine when the control valve is fully opened. One was the dimension of the hole and the other was the length of the piece. The length of the piece controls the flow more than the diameter of the hole.

This is because greater length causes more friction loss, which leads to more pressure drop, which controls the flow rate, but the hole diameter directly controls the current rate. Tests using the simple, single-stage gas flow regulator demonstrate engine performance when gas flow remains the same while electrical loads are varied. The one-step flow regulator provided a suitable gas flow rate that allowed the generator to run at a load close to its rated capacity (approximately 1.3 kW at a gas flow rate of approximately 0.53 kg/h).

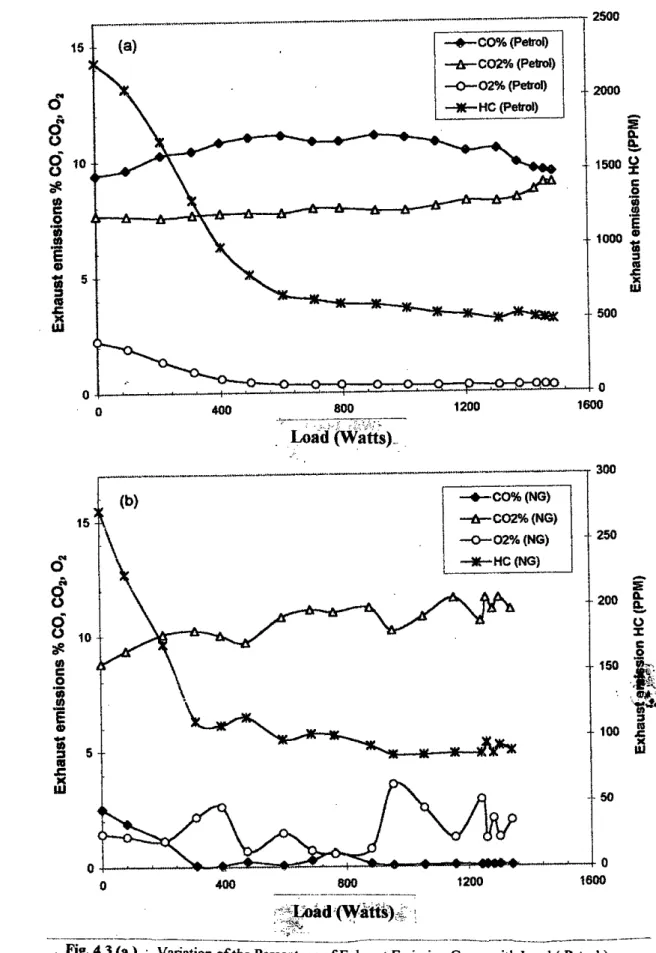

At lower loads, since the fuel flow rate remains almost unchanged, the A/F ratio was changed while the overall efficiency was gradually reduced. The variation of engine speed (which also indicates the generated voltage) within the operating load range of the generator with fixed gas flow is compared in figure - 4.6 (c) with the previously found test results. With the fixed gas flow operation near the rated capacity, the emission characteristics corresponded to the results shown in Figure - 4.3 (b).

CHAPTER-5

DISCUSSION OF RESULTS

Running the Engine on Petrol

Performance tests of a motor-generator set running on gasoline (the fuel for which it was designed) under various electrical load conditions were originally intended to generate baseline data against which to compare performance with natural gas. Brake specific fuel consumption was very high at part load and still around 690 glkWh close to rated capacity. This relatively poor combustion and high fuel consumption rate was evident from the A/F ratio curve and emission characteristics.

The A/F ratio was found to be nearly constant throughout the power range, indicating the efficiency of the fuel control system for a constant speed engine. The variation characteristics of all the emission data were found to have a stable trend with a slight improvement in the emission results beyond 50%. Although for all three brands studied, generators with higher power ratings were found to have much improved fuel consumption.

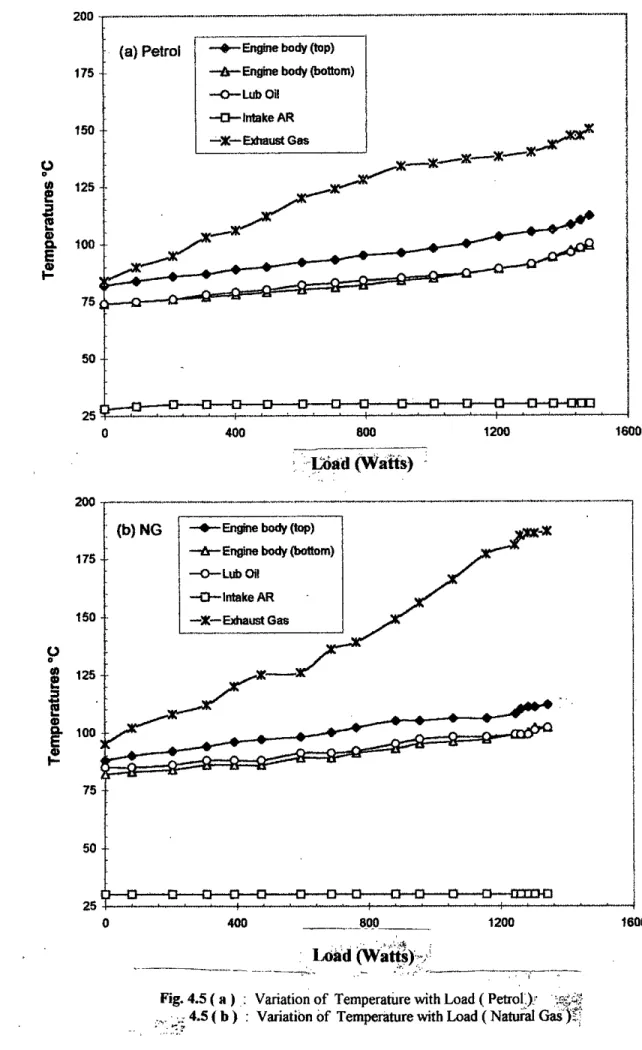

Another interesting finding was that although these generators imported into Bangladesh are supposed to be capable of producing 220V electricity, the voltage practically under load was never found to be 21OV and dropped almost by 10%, for loads above 80% of rated load. capacity. This voltage drop was found to increase once the generator's rated current capacity of 6.8 amps was exceeded. The variations in the temperature of the lubricating oil and engine body were found to be within 25°C, while the exhaust gas temperature increased by approximately 75°C over the entire power range.

Running the Engine with Closely Regulated Natural Gas Flow

Due to the higher level of environmental pollution of gasoline compared to natural gas, it is also more prone to taxation in the near future from an environmental point of view. The most important improvement in emission characteristics is the drastic reduction of CO emissions to a minimum by using natural gas. The reduction in air flow resulted in a limitation of the maximum power produced despite better combustion.

Improper spark advance associated with slower flame propagation speed for natural gas may also have contributed. The engine was found to be capable of producing nearly 85% of the rated capacity with petrol fuel. Beyond this limit, the engine performance was found to degrade in terms of bsfc and overall efficiency, voltage generated, engine speed as well as noise and vibration.

This was promising, indicating less potential for variation in engine component life expectancy when using natural gas. Noise and vibration levels were found to be very similar for both fuels in the load range where the engine ran smoothly. Although the maximum load capacity was found to be somewhat limited by the use of natural gas and the need to control the gas flow added complexity, the improvement in overall efficiency and significantly better emissions definitely justify the use of natural gas.

Running the Engine with Single-Step Natural Gas ~Flow

CONCLUSIONS AND RECOMMENDATIONS

CONCLUSIONS AND RECOMMENDA nONS

Conclusions

Although the engine was found to operate more efficiently on natural gas, two limitations were also observed. The Teater's volume occupied by natural gas limited the airflow of the fixed-speed engine, especially at high loads. This limited the maximum load that could be applied during smooth engine operation to approximately 85% of the rated capacity for gasoline.

Another limitation was the need for an additional flow control system to control gas flow at different engine loads. The load-sensing throttle control governor designed for gasoline was found to be insufficient to do the same for natural gas. The performance of the engine generator set using natural gas can be further improved by modifications and proper adjustment of some engine components like - ignition timing mechanism, throttle control system and engine cooling system.

To find an effective and low-cost solution to the problem of gas flow control, a simple but carefully tailored fluid resistor (a I" long brass cylinder with a 3/32" axial bore) was insert into the gas line that works as a step flow regulator. With this regulator the engine was found to run smoothly in a range of 50% - 85% of rated gasoline capacity. Although with the single-step regulator (i.e. near-fixed gas flow) energy efficiency and emission characteristics were sacrificed to some extent, this freed the operator from the need to frequently adjust the gas flow. applied electric charge.

Recommendations

REFFERENCES

Optimizing the Emissions and Diesel Replacement on a Dual-Fuel Two-Stroke Bus Engine.". and Hill, P G., "Emissions and Fuel Economy of a Natural Gas Dual-Fuel Front Chamber Diesel Engine", SAE Paper No. W., "Operating Experience of buses with compressed natural gas in regular transport service", SAE Paper No. I.,"Emissions from heavy-duty trucks. An Overview of Combustion Process in the Duel Fuel Engine - The Gas Diesel Engine." Prob'TeSSin Energy and Combustion Science, Vol. A,". The Compression Ignition Type Dual Fuel Engine - Prospects, Problems and Solution - A Review", Transactions, Vol. and Ali, A 1., "Combustion, Knocking and Emission Characteristics of a Natural Gas Fueled Spark Ignition Engine with Special Reference to Low intake temperature conditions”, Proc.

SIAM, 1992) Sichuan Institute of Agricultural Machinery, China, “Application of Biogas to Finn Combustion Engine”.

APPENDIX- A

From a chart provided by the manufacturer of the air drum and inclined manometer, the air flow rate was found directly. Inclined Manometer Reading (Initial) =-.02 Inches of Water Column Inclined Manometer Reading (Final) =0.66 Inches of Water Column Manometric Deflection =Final Reading - Initial Reading. Inclined Manometer Reading (Initial) =0 Inches of Water Column Inclined Manometer Reading (Final) =0.48 Inches of Water Column Manometric Deflection ~ 0.48 Inches of Water Column . = )5.1 )bs./hF"(From Graph Appendix-C).

Fuel Flow Rate

Air Fuel Ratio

Air-Fuel Ratio = Intake Air Mass Flow Rate/ Gasoline Mass Flow Rate Used. Air-Fuel Ratio = Intake Air Mass Flow Rate/ Exhaust Gas Mass Flow Rate.

Speed

Load

Standard Power (kw)

Brake specific fuel consumption

APPENDIX-B

Charge Ammeter Voltmeter Inclined Inclined Manometric for (watt) read read manometer manometer deflection. ampere) (volts) reading (inch of water col.). Corresponding amount of gas Time of gas Fuel flow rate Bsfc (9m/kw-hr) Value of air flow rate (kg/hr) collect (m') collect (sec) (k9/hr).

Data For a Prospective Commercial System

Yo of C02 in % of 02 in HC ppm Value of ~actual AIF Engine Overhaul exhaust gas xhaustga Vol.

APPENDlX- C

Tahle-4