UNIVERSITI TEKNIKAL MALAYSIA MELAKA

EFFECTS OF WORKPIECE AND TOOL RIGIDITY ON

MACHINING PERFORMANCES

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Manufacturing process) (Hons.)

by

MOHD ZAID BIN AWANG

B 050910295

880217-11-5537

________________

NAMA PENYELIA Pensyarah,

Fakulti Kejuruteraan Pembuatan

NOTA: BORANG INI HANYA DIISI JIKA DIKLASIFIKASIKAN SEBAGAI SULIT DAN

TERHAD. JIKA LAPORAN DIKELASKAN SEBAGAI TIDAK TERHAD, MAKA

BORANG INI TIDAK PERLU DISERTAKAN DALAM LAPORAN PSM.

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS LAPORAN PROJEK SARJANA MUDA

TAJUK: EFFECTS TO WORKPIECE AND TOOL RIGIDITY ON MACHINING PERFORMANCES

SESI PENGAJIAN: 2012/13 Semester 2 Saya MOHD ZAID BIN AWANG

mengaku membenarkan Laporan PSM ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut: 1. Laporan PSM adalah hak milik Universiti Teknikal Malaysia Melaka dan penulis. 2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan

untuk tujuan pengajian sahaja dengan izin penulis.

3. Perpustakaan dibenarkan membuat salinan laporan PSM ini sebagai bahan pertukaran antara institusi pengajian tinggi.

4. **Sila tandakan (√)

SULIT

TERHAD

TIDAK TERHAD

(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysiasebagaimana yang termaktub dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

Alamat Tetap:

NO. 37, LORONG SENTOSA 2 KG TENGAH (F) NERAM SATU 24060 KEMAMAN, TERENGGANU

Tarikh: 3.JUNE. 2013

Disahkan oleh:

Cop Rasmi:

Tarikh: 3.JUNE. 2013

DECLARATION

I hereby declare that this report entitled “Effects of Workpiece and Tool Rigidity on Machining Performances” is the result of my own research except as cited in the references.

Signature : ……….

Author’s Name : Mohd Zaid Bin Awang

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Process) (Hons.). The member of the supervisory is as follow:

………

i

ABSTRAK

ii

ABSTRACT

iii

DEDICATION

iv

ACKNOWLEDGEMENT

v

TABLE OF CONTENT

Abstrak i

Abstract ii

Dedication iii

Acknowledgement iv

Table of Content v

List of Tables viii

List of Figures x

List Abbreviations, Symbols and Nomenclatures xiii

CHAPTER 1: INTRODUCTION 1

1.1 Background 1

1.2 Problem statement 3

1.3 Objectives 3

1.4 Scope of the research 3

CHAPTER 2: LITERATURE REVIEW 4

2.1 CNC Milling 5 axis operation 4

2.1.1 Type of CNC Milling 5 Axis two general groups 4

2.2 Half Sphere Milling 5

2.3 Strategy in Half Sphere Milling – Zig zag 7 2.4 Consideration Material in Machining 8

2.4.1 Aluminium 8

2.4.2 Tool Steel 9

2.5 Machining Performance 11

2.5.1 Surface Roughness 11

2.5.2 Vibration Assisted machining 13

vi

CHAPTER 3: METHADOLOGY 16

3.1 Introduction 16

3.2 Flow chart process 17

3.3 Process Planning 18

3.3.1 CATIA – Design Modelling 18

3.3.2 Create of half Sphere using CATIA Software 19

3.3.3 Detail Drawing and Dimension 20

3.4 Machining Process (CAM) 21

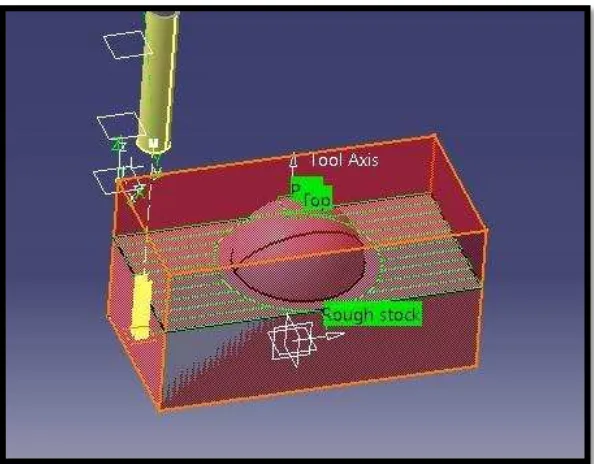

3.4.1 Drawing stock 21

3.4.2 Describes Milling Machine – CNC Milling 5 axis 22

3.4.3 Describes Axis 23

3.4.4 Describes cutting tool 23

3.4.5 Describes tool path 24

3.4.6 Determine generate NC code 25

3.4.7 Setup on CNC Milling Machine 26

3.4.8 Strategy Milling Technique 27

3.5 Performance Measurement 29

3.5.1 Surface roughness 30

3.5.2 Vibration amplitude machining 31

3.5.3 Tool wear 32

3.6 Machining Parameters 33

3.7 Analysis 34

vii

CHAPTER 4: RESULT AND ANALYSIS 35

4.1 Surface Roughness 36

4.1.1 Result 36

4.1.2 Discussion 39

4.2 Vibration Amplitude Machining 41

4.2.1 Result 42

4.2.2 Discussion 45

4.3 Tool wear 49

4.3.1 Result 49

4.3.2 Discussion 51

4.4 Statistical of Analysis data on Aluminium 53 4.4.1 Objective of Optimization 53

4.4.2 Validation 55

4.5 Statistical of Analysis data on Tool Steel 56 4.5.1 Objective of Optimization 57

4.5.2 Validation 58

CHAPTER 5: CONCLUSION AND FUTURE WORK 60

5.1 Conclusion 60

5.2 Future work 61

REFERENCES 62

APPENDICES

viii

This general characteristic of Aluminium alloy Tool Steel of Mechanical properties

This is machining parameters in machining process

Average reading a surface roughness by Aluminium on normal technique

Average reading a surface roughness by Tool Steel on normal technique

Average reading a surface roughness by Aluminium on tool damping technique

Average reading a surface roughness by Tool Steel on tool damping technique

Average reading a surface roughness by Aluminium on workpiece damping technique

Average reading a surface roughness by Tool Steel on workpiece damping technique

Average reading a surface roughness by three technique on Aluminium

Average reading a surface roughness by three technique on Tool Steel

The result of average to vibration amplitude machining by aluminium

The result of average to vibration amplitude machining by Tool Steel

The average of measurement value to tool wear by Aluminium on three technique

ix 4.13

4.14

4.15 4.16

Design actual of response by Aluminium on the three technique The result of response evaluation by using Design Expert on Aluminium

Design actual of response by Tool Steel on the three technique The result of response evaluation by using Design Expert on Tool Steel

53

55 56

x

LIST OF FIGURES

1.1 The half sphere modelling to produce 3 diamond mirror surface profile

2

2.1 DMG DMU 50 Mono Block model of 5 Axis Milling operations 5 2.2 The expected of half sphere modelling on development 6 2.3

The CAD/CAM system used creates the 5 axis CNC part

programs, with the tool axis perpendicular to the surface Selection of tool path is zig –zag way

Aluminium Tool Steel

The schedule of evaluation measurement surface roughness The Accelerometer system to detect of amplitude machining performance.

Optical Microscopy structure on the tool wear The type of tool failure mechanism

6

3.3 Half sphere of dimension drawing on the actual modelling 20 3.4

Describe of the CNC milling 5 Axis

Illustration motion of CNC milling 5 Axis Machine Describe of define Axis reference

Define of tool selection using in machining programming Describe of tool path way

Define of data input ,output and NC coding

xi

Setup machining datum Normal technique machining Tool damping machining

Workpiece damping technique machining

Surface test device and testing measurement of surface roughness The scrip resulting after surface roughness measuring

Accelerometer device and located a probe by area position The plot of diagram showing evaluation measuring of vibration amplitude

This is optical microscopy system to determine of tool wear structure a condition

The specimen sample for evaluation of structure on tool wear

Actual Visual a modelling of half sphere after machining process Actual Visual of Surface roughness by an Aluminum and Tool Steel at normal technique

Actual visual of surface roughness by an Aluminum and Tool Steel at Tool damping technique

Actual Visual of surface roughness by an Aluminum and Tool Steel at workpiece damping technique

The graph of average surface roughness by Aluminum The graph of average surface roughness by Tool Steel The Vibration amplitude machining of measurement performance system

The plot diagram of vibration amplitude machining by Aluminum on normal technique

The plot diagram of vibration amplitude machining by Tool Steel on normal technique

The plot diagram of vibration amplitude machining by Aluminum on tool damping technique

xii

The plot diagram of vibration amplitude machining by Tool Steel on tool damping technique

The plot diagram of vibration amplitude machining by Aluminium on workpiece damping technique

The plot diagram of vibration amplitude machining by Tool Steel on workpiece damping technique

The Graph of average vibration amplitude machining on aluminium to the comparison by three technique machining process

The Graph of average vibration amplitude machining on aluminium to the comparison by three technique machining process

Actual visual for tool wear by normal technique Actual visual for tool wear by tool damping technique

Actual visual for tool wear by workpiece damping technique The graph of average tool wear by aluminium

The graph of average tool wear by Tool Steel

The graph of one factor by surface roughness vs. Level technique on aluminium

The graph of one factor by vibration amplitude machining vs. Level technique on aluminium

The graph of one factor by tool wear vs. Level technique on aluminium

The graph of one factor by surface roughness vs. Level technique on Tool Steel

The graph of one factor by Vibration amplitude machining vs. Level technique on Tool Steel

xiii

LIST OF ABBREVIATIONS, SYMBOLS AND

NOMENCLATURE

Al - Aluminium

AISI D2 - Tool Steel

ANOVA - Analysis of Variance

APT - Automatically programmed tool

C - Carbon

CATIA - Computer Aided Three dimensional interactive application CAD - Computer Aided Design

PCBN - Polycrystalline cubic boron nitride

1

This report described a project of “Effects of workpiece and tool rigidity on

machining performance”. This chapter explains the background, problem statement, objective and scope of the project.

1.1 Background

In the manufacturing engineering sector is very challenging especially for produce a

product into the automotive factory. It’s very needed to higher quality according to a

specification standard on guideline of requirement. The stamping mould and dies are used to produce high precision metal components which are identical in shape and size. The mould and die fabrication normal accomplished by milling machining operation where the operation assisted by CADCAM technology software to provide design and machining automation. All general, there are three main necessary stages of mould die machining, namely, a rough machining stage where the work piece material is removed as quickly as possible, semi finishing machining stage where machining is carried out to ensure consistent material removal rate and finish machining stage where the emphasis is on work piece dimensional accuracy and quality finish.

INTRODUCTION

2

The mould and die is further polished manually in order to get diamond finishing. The multi-activities from rough to finish the product of mould and die based on material requires a significant portion of the lead-time and substantially increased the overall operational cost. Fine surface finish is essential not only to provide accurate and stringent tolerance for complex stamping product but also provide optimum heat transfer during quenching process. This multi-method process sequence consumed numbers of cutting tools, facilities, highly skill manpower and long working hours to achieve the desired product quality. In the research, to determine to optimum condition the surface profile in mould dies to produce a smooth surface or smooth integrity the mould die. Finally, the results from a research will provide useful information to obtain fine optimum surface finish during machining mould and die based material without further requirement of polishing activities. The information obtained also will be useful as reference materials for machining in planning their machining in requirement to produce maximize surface integrity, reduce process and hence minimize operation costs in manufacture industries.

3

1.2 Problem Statement

Thus, this study, it’s will known that machining stability have a direct effect on

machining performance. Thus , critical on the machining stability need to be understand. The will investigate effects of workpiece and tool rigidity on machining performance and stability.

1.3 Objective

(a) To investigate the effects of workpiece and tool rigidity on machining performance( surface roughness, vibration amplitude and tool wear).

(b) To evaluate the effects of workpiece material characteristic on machining stability.

1.4 Scope of the research

4

This chapter explains a systematic method for identifying evaluating and interpreting the work done by researchers, survey scholarly articles, journal, handbook and other sources such as patent, journal and others. This chapter covering the literature review of the topic specified.

2.1 CNC Milling 5 Axis Operation

In the most production to higher productive by using a CNC milling 5 axis machining is designing as a highly sophisticated component that cannot operate by CNC Milling 3 axis machining. The probability of performance very high accuracy of the work when carry out of complex design. It is combined with the increasing generate system software and offline CNC multi axis program has been in regularized to 5 axis for improvement in productivity and output configurations.

2.1.1 Type of CNC Milling 5 Axis two general groups

The positioning of the work piece in several planes or a variety of angles to the spindle, which then executes a 3-axis machining cycle. Five sections of a prismatic part, plus any combination of compound angles can be machined in one setup.

The continuous 5-axis cutting motion of sculptured surfaces, pockets or other 3-dimensional features, also in a single setup.

LITERATURE REVIEW

5

Figure 2.1: DMG DMU 50 Mono Block model of 5 Axis Milling operations

2.2 Half Sphere Milling

6

In the roughing cuts, a large amount of material is removed to sphere the general shape of a surface, as quickly as possible without bring the tool in contact with the description surface. Next method, this is finishing cuts are used to remove the remaining material. Typically a single point on a Ball Mill is used to generate the desired surface profile. ( A. Warkentin, S. Bedi and F. Ismail, 1995)

Figure 2.2: The expected of half Sphere on development

7

2.3 Tool Path Strategy in half sphere Milling – Zig-zag

The strategy to made half sphere is used of zig –zag tool path. This is zig- zag pattern is cut first (Shown in heavy dotted lines). Then the outer tool path (light solid line) is cut. Regardless of design of half sphere or number of islands, only one starter cut is required at the beginning of the zig –zag. The cutting tool may or may not be withdrawn and moved between completing the zig-zag and starting the outer tool path. Based on the review research, the selection of tool path has the best method of the machining operation. In the case of the zig-zag tool paths it is desired that the tool moves in a straight line in the feed-forward direction. Planning tool motion on the design surface guarantees straight line motion of the tool contact point, but the tool center may not move in a straight line. On the other hand, tool path planning on the offset surface ensures straight line motion of the tool center. Hence, in the current approach, CL points have been directly planned on the offset surface generated through the ITO. ( Debananda Misra, V. Sundararajan and Paul K. Wright, 2002)