UNIVERSITI TEKNIKAL MALAYSIA MELAKA

A Comparison of Hand Phone Primary

Packaging By Using Pugh Method (Case Study)

Thesis submitted in accordance with the partial requirements of the

Universiti Teknikal Malaysia Melaka for the

Bachelor of Manufacturing Engineering (Manufacturing Design)

By

Nuranisha Binti Mat Ghani

UTeM Library (Pind.l/2007)

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS TESIS *

JUDUL: A COMPARISON OF HAND PHONE PRIMARY PACKAGING BY USING PUGH METHOD(CASESTUDY)

SESI PENGAJIAN: 2/2006-2007

Say a NURANISHA BT MAT GHANI

mengaku membenarkan tesis (PSM/Sarjana/Doktor Falsafah) ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut:

1. Tesis adalah hak milik Universiti Teknikal Malaysia Melaka.

2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan untuk tujuan pengajian sahaja.

3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi.

4. **Sila tandakan (..../)

D

SULITD

TERHAD[i]

TIDAK TERHAD(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

Disahkan oleh:

Htaセ@

PENULIS)Alamat Tetap:

No 47, Rumah Keretapi, Jalan Stesen,

16200, Tumpat, Kelantan.

Tarikh: 14 MEl 2007

Cop Rasmi:

SURIATI BINTI AKMAL Pensyolfah

F akulti KeJuruteraan Pembuatan Universitt Tekmkal Malaysta Melaka

Karung lerkunci 1200. Ayer Keroh 7f1450 Melaka

Tarikh: ;) I

* Tesis dimaksudkan sebagai tesis bagi ljazah Doktor Falsafah dan Sarjana secara penyelidikan, atau disertasi bagi pengajian secara kerja kursus dan penyelidikan, atau laporan Projek Sarjana Muda (PSM) ** Jika tesis ini SULIT atau TERHAD, sila lampirkan surat daripada pihak berkuasa/organisasi berkenaan

APPROVAL

This thesis submitted to the senate ofUTeM and has been accepted as partial

fulfillment of the requirement for the degree of Bachelor of Manufacturing Engineering

(Manufacturing Design). The members of the supervisory committee are as follows:

Faculty of Manufacturing Engineering

DECLARATION

I hereby, declare this thesis entitled "A Comparison of Hand Phone Primary Packaging

by Using Pugh Method (Case Study)" is the result of my own research

Signature

Author's Name

Date

except as cited in the references.

:NU

: 14th MAY 2007

ABSTRACT

In the market today, there are various method used by hand phone manufacturer to package their

hand phone product. This paperwork contains the report of a comparison of hand phone primary

packaging by using Pugh Method. The main purpose of this project is to propose a guideline of

hand phone primary packaging. In order to achieve the objective of this project, there are a

systematic methodology procedure has been presented in this report. At beginning of the project,

the problems, objectives and scopes have been identified to lead the researcher to achieve the

target efficiently. The project started by performing a market study. Then questionnaires were

distributed to the respondent to make a survey in order to gather information's. The existing

product in the market will study on their design of the product and material used based on the

survey result. A benchmarking on the six different types of the hand phone packaging box was

made. Then a Pugh method concept used to compare the products in order to choose the best

product based on the elements that have been studied. The result from the Pugh method was

used as a guide to develop a guideline for hand phone primary packaging. The best product will

be discussed from their strength elements. From this evaluation, the guideline ofthe hand phone

primary packaging was developed. And finally, the conclusion and future work was presented to

conclude the study that was done.

ABSTRAK

Dalam pasaran hari ini, terdapat berbagai-bagai cara yang digunakan oleh pengeluar untuk

pembungkusan produk telefon bimbit mereka. Kertas kerja ini mengandungi laporan

perbandingan teknik pembungkusan telefon bimbit dengan menggunakan kaedah Pugh. Tujuan

utama projek ini adalah untuk mencadangkan garis panduan untuk pembungkusan telefon

bimbit. Untuk mencapai objektif projek ini, satu langkah sistematik telah dibentangkan didalam

laporan ini. Di awal permulaan projek, permasalahan, objektif dan skop telah dikenalpasti

terlebih dahulu sebagai panduan kepada penyelidik untuk mencapai target dengan lebih efisien.

Projek dimulakan dengan kajian pasaran. Kemudian soal selidik telah diedarkan untuk

menjalankan survey bertujuan untuk mendapatkan maklumat. Berdasarkan dari kaji selidik,

kajian terperinci dijalankan keatas produk sedia ada dalam pasaran untuk mengenalpasti

rekabentuk dan bahan produk. Dari ini, 6 produk penanda berlainan telah dikenalpasti dan

kemudian dengan menggunakan teknik Pugh, perbandingan dilakukan untuk mengenalpasti

produk terbaik berdasarkan elemen kajian. Keputusan dari perbandingan akan digunakan untuk

menyediakan garis panduan untuk pembungkusan utama bagi telefon bimbit. Produk terbaik itu

akan dibincangkan berdasarkan elemen kekuatannya. Akhir sekali kesimpulan dan kajian masa

hadapan turut dimuatkan di dalam projek ini sebagai penutup kepada kajian yang telah

dijalankan.

DEDICATION

To my beloved parents;

Mat Ghani bin Abd. Rahman

Ruhani binti Harun

For your love and demonstration the values of education since I'm still a little kid.

To my siblings;

Hilman bin Mat Ghani

Hilmi bin Mat Ghani

Nurasma binti Mat Ghani

Hisyam bin Mat Ghani

For your love, encouragement, and support on this project was absolutely invaluable.

To my special person;

Shahridzuwal B. Md Jabarulla

For your patience whose always tested during writing this project. Your support and

understanding are vital part of this research.

ACKNOWLEDGEMENT

セ@ )I セ@ )I A..lll

F.

In the name of Allah, Most Gracious, Most Merciful.

All praises to the Almighty Allah, for giving me the strength, patience and guidance

throughout the process of completing this research study. I am grateful to have the

support and motivation from many people throughout completing this study and I would

love to take this opportunity to thank those who are either directly or indirectly involved

during the process of this study is conducted.

Most immediately, a special gratitude goes to my respective advisor, Miss Suriati Binti

Akmal for her precious advice, time, contribution, comments and guidance in every

stage of this study. And also my deep appreciation for my second examiner, Mr. Tauftk.

My utmost gratitude also goes out to all lecturers from the Faculty of Manufacturing

Engineering for being a very nice and effective lecturer to me and thus, making this

study easier to be completed.

My token of appreciation also goes to my beloved family members who never failed to

be there for their love, support and prayers. Last but not least, I would like to thank all

my friends, especially my classmates for their never ending supports. May ALLAH

bless to all of you. Thank you very much.

Vll

Nuranisha Mat Ghani

UTeMMelaka

TABLE OF CONTENTS

Borang Pengesahan Status Tesis ... .. ... .i

Approval ... .ii

Declaration ... . ... .. ... ... .. ... ... iii

Abstract .... ... . ... . ... .iv

Dedication ... vi

Acknowledgement. ... vii

Table of Contents ... .... .... viii

List of Figures ... xi

List ofTable ... . ... xiii

List of Abbreviations ... . ... ... ... ... ... xiv

1.0 INTRODUCTION ... l

1.1 Overview ... .. ... .. ... . .... 11.2 Problem statement ... .. ... . ... 2

1.3 Objective of project ... ... 2

1.4 Scopes of project ... .. ... 2

2.0 LITERATURES REVIEW ... 3

2.1 Definition of packaging ... . ... .. .3

2.2 History of packaging ... 3

2.3 Purpose of packaging ... 4

2.4 Categories of Packaging ... 5

2.5 Packaging Material. ... . ... 7

2.5.1 Plastics ... ... .... .. ... 9

2.5.2 Paperboard ... . ... . ... 10

2.6 Primary Packaging Box ... 12

2.6.1 External packaging ... 12

2.6.2 Internal packaging ... 14

2.6.2.1 Bubble wrap ... 15

2.6.2.2 Foam ... 16

2.6.2.3 Molded pulp tray ... 19

2.6.2.4 Plastics ... 20

2. 7 Material Characteristic for Electronics Product. ... 21

2.8 Guideline for Design for Ease of Packaging ... 22

2.9 Pugh Method Concepts ... . ... 23

3.0 METHODOLOGY ... 26

3.1 Introduction ... 26

3.2 Defme Objective and Scope ... 26

3.3 Literature review ... 26

3.4 Market study ... 28

3.5 Benchmarking ... 28

3.6 Evaluate using Pugh Method ... 28

3. 7 Propose Guideline and Improvement ... 29

4.0 MARKET STUDY ... 30

4.1 Introduction ... 30

4.2 Market Study Method ... 30

4.3 Benchmarking of Product ... 32

4.3.1 Product 1 ... 32

4.3.2 Product 2 ... 34

4.3.3 Product 3 ... 37

4.3.4 Product 4 ... 40

4.3.5 Product 5 ... 43

4.3.6 Product 6 ... 45

5.0 RESULT AND DISCUSSION ... 48

5.1 Introduction ... 48

5.2 Pugh Method Result ... ... ... . .... ... ... . ... .. ... 48

5.3 Hand Phone Primary Packaging Guideline ... 54

6.0 CONCLUSION AND RECOMMENDATION ... 59

rejヲセreセcセs@

... 60

APPENDICES

A Project Schedule (Gantt Chart) for PSM 1

B Project Schedule (Gantt Chart) for PSM 2

c

Hand Phone Packaging Box SurveyD

Properties of PolyethyleneE

Properties of PolystyreneF Folding Carton Price

G Polyethylene Antistatic Bag Price

H Ziplock PE Antistatic Bag Price

I Antistatic Bubble Wrap Price

J Foam Price

LIST OF FIGURES

2.1 Primary packaging (Sweet dispenser) 5

2.2 Secondary packaging (shrink wrapped water bottles) 6

2.3 Tertiary packaging 6

2.4 Weight of packaging material pie chart 8

2.5 Percentage of package goods 8

2.6 Single-faced board 11

2.7 Single-wall or double-faced board 11

2.8 Double-wall board 11

2.9 Triple-wall board 11

2.10 Folding carton dimensions 13

2.11 Types of folding carton 13

2.12 Bubble wrap 15

2.13 Polyurethane foam 17

2.14a Cell-Aire Foam 17

2.14b Cell-Aire Antistatic Foam 17

2.14c Corro-foam 18

2.15 Polystyrene foam 18

2.16 Molded pulp tray 19

2.17 Plastic packaging material 20

2.18 Surface resistivity rate 22

3.1 Steps of methodology 27

4.1 Transparency plastic view 32

4.2 Visi Grip packaging method 33

4.3 Polyethylene antistatic bag 33

4.4 Folding carton box for Nokia E65 hand phone 34

4.5 Bottom layer of foam tray 35

4.6 Top layer of foam tray 35

4.7 Schematic diagram stacks 36

4.8 Ziplock polyethylene antistatic bag 36

4.9 Molded foam tray pulp 37

4.10 Folding carton box 02 XDA hand phone 38

4.11 First folding box 38

4.12 Battery charger inside first folding box 39

4.13 Second and third folding box 39

4.14 Schematic diagram stacks 39

4.15 Folding carton box for Treo 700w hand phone 40

4.16 Treo 700w packaging method 41

4.17 Schematic diagram stacks 41

4.18 Plastic tray 42

4.19 Antistatic bubble wrap 42

4.20 Folding carton box White Helio Drift hand phone 43

4.21 White Helio Drift Packaging method 43

4.22 Schematic diagram stacks 44

4.23 Folding carton box for Newgen n720 hand phone 45

4.24 Newgen n720 packaging method 45

4.25 Schematic diagram stacks 46

4.26 Packaging material 46

5.1 Rigid folding carton 54

5.2 Schematic drawing of the cushioning material condition 55

5.3 Separated compartment for hand phone packaging 55

5.4 Wrapped item schematic drawing 56

5.5 Antistatic bubble wrap 56

5.6 Safe comer for packaging 57

LIST OF TABLES

2.1

Types of plastics 92.2

Pugh method concept screening matrix25

2.3

Pugh method concept screening matrix25

2.4

Rating reference table25

4.1

Summarization of survey results31

4.2

Properties of Polystyrene47

5.1

Pugh method concept result50

5.2

Strength of products53

LIST OF ABBREVIATIONS

PE Polyethylene

PET Polyethylene terephthalate

pp Polypropylene

PVC Polyvinyl chloride

PS Polystyrene

HDPE High density polyethylene

LDPB Low density polyethylene

RTE Reverse-Tuck-End

STE Straight-Tuck-End

ESD Electrostatics Discharge

SD Static dissipative

PSM Projek Srujana Muda

1.1 Overview

CHAPTER ONE

INTRODUCTION

Hand phone can be described as a radio transmitter and receiver. It is designed and

manufactured not to exceed the limits for exposure to radio frequency recommended

by international guidelines. In this era of globalization, hand phone utilization is very

important as a necessity for people to support them in daily communication.

Hand phone is a very sensitive electronic product. It is a product of superior design

craftsmanship and should be treated with care. Thus, hand phone need a good

protection especially in their packaging. Packaging can be defined as a sealed box,

bag or container that is used to store or transport the product that requires a

protection from tampering. In the market today, most of the current hand phone

packaging box design are varies and complicated. In this project, a study will be

done on the hand phone primary packaging design. The existing product in the

market will study on their design of the product and material used. Then a Pugh

method concept will be use to compare the products in order to choose the best

product based on the elements that has been studied. The result from the Pugh

method will be act as a guide to propose a guideline for hand phone primary

packaging. The best product will be discussed from their strength elements. From

this evaluation, the guideline of the hand phone primary packaging will be

developed. And fmally, the conclusion and future work will be present to conclude

the study that was done.

1.2 Problem Statement

In the market today, there are some various method used by packaging department of hand phone manufacturer to package their hand phone. There are no standard or

guidelines in producing the hand phone packaging box whether in their design,

material and manufacturing process. Because of the various types and complicated

method of this packaging box, a study will be done on the hand phone primary

packaging design. A study will be done on the existing product in the market based

on the important element such as design of the product and material used. A

comparison will be done by using a Pugh method concept in order to choose the best

packaging box for hand phone thus make it as a guide to propose a guideline.

1.3 Objectives of Project

The objectives of this project have been identified and it should be achieved to

produce a successful product. The objective is to develop guidelines of hand phone

primary packaging.

1.4 Scopes of Project

In order to achieve the objective, the scopes are required to assist and set direction of

the project development. These scopes should identifY and planned appropriately.

The scopes are:

a) Literature review of the project.

b) Study of the current hand phone packaging.

c) Evaluation of the product using Pugh method.

d) Suggestion of guideline for the project.

CHAPTER TWO

LITERATURE REVIEW

2.1 Definition of Packaging

To most people 'packaging' means the carton, sachet, jar etc. which enables a

product to be handled and used. It also means the bag or box to carry goods to the

home or office. Packaging is the enclosing of a physical object, typically a product

that requires protection from tampering. Packaging can be define as a sealed box,

cardboard box, bag or container that is used to store or transport good materials.

However, to industry and retailers, the term 'packaging' also covers the whole range

packaging products used to protect, transport and distribute goods such as corrugated

cases, multi-wrap and pallets [I].

2.2 History of Packaging

The history of the packaging was begun over centuries that have undergone an

evolution. The very first people to roam the earth have sought to find the way on how

to keep the surplus food collecting after they were hunting and fishing. When

containers were needed, nature provided gourds, shells and leaves. Later, containers

were fashioned from natural materials such as hollowed logs, woven grasses, and

even animal organs. Chinese people have invented the cardboard in 1600's but the

first commercial cardboard box was produced in England in 1817. Corrugated paper

appeared in the 1850's [2].

At the beginning of the 20th Century goods were delivered in bulk and weighed out

by the shopkeeper. This led to unscrupulous suppliers to bulk out products with

other cheaper substances or short weigh quantities to make larger profits. In the later

half of the century pre-packaging became more common and was welcomed by

shopkeepers as it makes the manufacturer rather than the retailer, responsible for

quality, quantity and hygiene of the product. It also reduced the time it took to serve

customers weighing and wrapping loose goods [2].

Paper and paperboard packaging increased in popularity well into the 20th Century.

With the boom in packaging came huge advertising campaigns which sold the

products before customers even stepped into the store. The image of the product

itselfbecame familiar and was easily recognized on the top shelf or back of the

store. Then, the first packaged branded product was launched in 1746 when Dr

Robert James sold his 'Fever Powder' in a box. A few years later, Yardley of London

began selling its famous lavender water in glass bottles, and Crosse & Blackwell

began selling olive oil and mustard in jars. A. F. Pears, also in England, launched

what was to become one of the most consistently prosperous industries in the world

when he established the first packaged Soap Company [2].

2.3

Purpose of PackagingPackaging method has such a purpose. This function of packaging can bring a lot of

benefit to us either as a product manufacturer, retailer or consumer. First, packaging

can be as a physical protection of the products. The product that enclosed in the

package can be protected from damage that caused by physical force, rain, heat,

sunlight, cold, pressure, airborne contamination and automated handling devices.

Secondly, an agglomeration can be done with a packaging. Small objects are

typically grouped together in one package for reasons of efficiency. For example, a

single box of 1000 pencils requires less physical handling than 1000 single pencils.

Alternatively, bulk commodities such as salt can be divided into packages that are a

more suitable size for individual households. Thirdly, packaging can give us an

information transmission.

The information on how to use, transport, or dispose of the product is often contained

on the package or label. An example is pharmaceutical products, where some types

of information are required by governments. Next, packaging is used for marketing

purpose. The packaging and labels can be used by marketers to encourage potential

buyers to purchase the product. Finally, packaging can reduce theft. It is important to

product manufacturer and retailer to save their product from that. So some packages

are made larger than they need to be so as to make theft more difficult. An example

is software packages that typically contain only a single disc even though they are

large enough to contain dozens of discs.

2.4

Categories of Packaging

There are three categories of packaging such as primary packaging, secondary

packaging and tertiary packaging. Primary packaging is referring to sales packaging.

This involves all packaging that is in direct contact with the product. Hence primary

packaging could be soft drink bottles or sweet wrappers. Primary packaging can also

be described as part of the product. For example if sweets come with a sweet

dispenser that pops the sweets into the hand, that sweet dispenser would be known as

primary packaging. On the other hand it can be describing products that will be

[image:20.578.199.420.477.611.2]received by customer [3]. The Figure 2.1 shows the example of primary packaging.

Figure 2.1: Primary packaging (Sweet dispenser) (Source: http://www .sustainpack.com/aap _packaging.html)

While a group packaging is in secondary types of packaging. This is designed to

[image:21.578.110.510.76.387.2]collate primary packaging so that it can be handled manually. Hence a box, containing many soft drinks, or shrink wrap would be secondary packaging. Secondary packaging is used so that goods can be transported more easily, saving energy and costs [3]. The Figure 2.2 shows the example of secondary packaging.

Figure 2.2: Secondary packaging (shrink wrapped water bottles) (Source: http://www .sustainpack.com/aap _packaging.html)

The tertiary packaging is referring to transport packaging. It has been designed to prevent damage during the handling and transportation of products. This is used to transport products in large numbers [3]. Hence a crate or pallet containing many

small shrink wraps is tertiary packaging. The Figure 2.3 shows the tertiary packaging.

Shrink-wrap

and pallet '

Figure 2.3: Tertiary packaging

(Source: http://www .sustainpack.com/aap _packaging.html)

[image:21.578.100.511.97.758.2]2.5

Packaging MaterialMaterial for packaging has a wide variety in the manufacturing world. Generally the

selection of material for packaging commonly selected due to manufacturing cost.

An essential function of the product package is to protect the product as it makes its

hazardous journey from the production line-with transfers and layovers at storage

points-to the customer's premises. A package that affords too little protection

invariably leads to unacceptably high losses, and one that is overprotective, to high

purchase, transportation, and storage costs. Once it leaves its place of origin, the

typical product is exposed to multiple hazards:

i) damage from shocks and vibrations during normal handling, storage and

transportation.

ii) deterioration or contamination from foreign matter such as fungi , insects,

bacteria, dirt, chemicals, water, and corrosive gases.

iii) losses from pilferage or unauthorized package openings.

iv) contamination from unanticipated chemical interactions between

packaging materials and product ingredients.

v) damage from environmental factors such as high temperature, freezing,

high-altitude, excessive humidity, and sunlight.

vi) creation of surface imperfections such as mars, dents, scratches, finish

discoloration, and loss of gloss or shine.

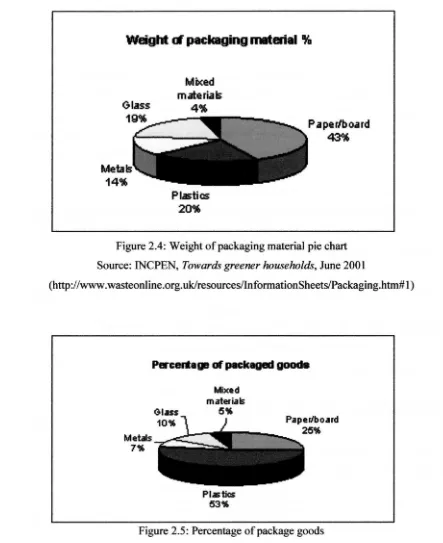

The Figure 2.4 shows the weight of packaging material pie chart and Figure 2.5

shows the percentage of package goods. The most common types of material used

for packaging such as:

i) Plastics

ii) Paperboard

iii) Bottle or cans (aluminium)

iv) Wood

v) Glass

Weight

m

packaging mlterial

%

Mixed materials

4%

Plastics 20%

[image:23.576.79.522.41.584.2]Paper/board 43%

Figure 2.4: Weight of packaging material pie chart

Source: INCPEN, Towards greener households, June 2001

(http://www .wasteonline.org.uk/resourcesllnformationSheets/Packaging.htm# 1)

Mixed materials

Uセ@

Plastics

USセ@

Paper/board

RUセ@

Figure 2.5: Percentage of package goods

Source: INCPEN, Towards greener households, June 2001

(http://www. wasteonline.org. uk/resourcesllnformationSheets/Packaging.htm# 1)

2.5.1 Plastics

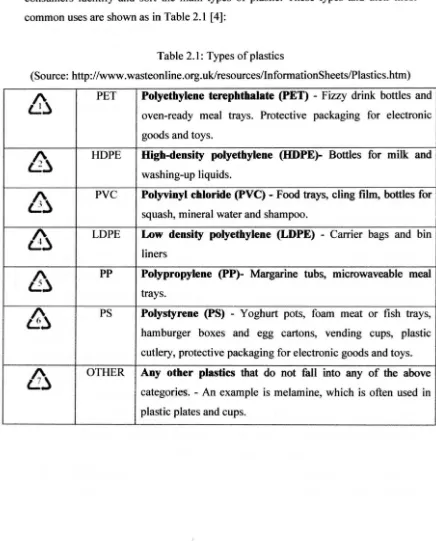

There are about 50 different groups of plastics, with hundreds of different varieties.

All types of plastic are recyclable. To make sorting and thus recycling easier, the

American Society of Plastics Industry developed a standard marking code to help

consumers identify and sort the main types of plastic. These types and their most

[image:24.578.86.522.178.719.2]common uses are shown as in Table 2.1 [ 4]:

Table 2.1: Types of plastics

(Source: http://www. wasteonl ine.org. uk/resources/InformationSheets/Plastics.htm)

Xセ@

PET Polyethylene terephthalate (PET) - Fizzy drink bottles and oven-ready meal trays. Protective packaging for electronicgoods and toys.

8::,

HDPE High-density polyethylene (HDPE)- Bottles for milk and washing-up liquids."'::,

PVC Polyvinyl chloride (PVC)- Food trays, cling film, bottles forL;

squash, mineral water and shampoo.

8::,

LDPE Low density polyethylene (LDPE) - Carrier bags and bin liners8::,

pp Polypropylene (PP)- Margarine tubs, microwaveable meal trays.8::,

PS Polystyrene (PS) - Yoghurt pots, foam meat or fish trays, hamburger boxes and egg cartons, vending cups, plasticcutlery, protective packaging for electronic goods and toys.

8::,

OTHER Any other plastics that do not fall into any of the above categories. -An example is melamine, which is often used inplastic plates and cups.