A STUDY OF AERODYNAMICS FOR F1 IN SCHOOLS

MOHD FIRDAUS BIN AB RAZAK

ii

DECLARATION

“I hereby, declared this thesis entitled

‘A STUDY OF AERODYNAMICS FOR F1 IN SCHOOLS’ is the results of my own research except as cited in the references”.

Signature : ...

Author’s Name : MOHD FIRDAUS BIN AB RAZAK

iii

iv

ACKNOWLEDGEMENT

The author would like to take this opportunity to thank to his supervisor, Mr. Mohd Afzanizam bin Mohd Rosli with his guidance and support throughout the study. Co-operation given by Mr. Razmi bin A Razak and Mr. Kamarudin bin Abu Bakar from Faculty of Mechanical Engineering technicians, and also to the UTeM’s Library, the author like thank for the co-operation and supports. Appreciation for the presentation panels with though, recommendation and encouragement.

Useful information and with raw material from F1 in Schools Sdn. Bhd. representative, Mohd Nazrin Bin Zulkifli was much appreciated. Participators from Central North and Central South, especially from KISAS team for willingness to share experience during the race day.

v

ABSTRACT

vi

ABSTRAK

vii

TABLE OF CONTENT

CHAPTER TITLE PAGE

DECLARATION ii

APPROVAL iii

DEDICATION iv

ABSTRACT v

ABSTARK vi

TABLE OF CONTENT vii

LIST OF TABLE x

LIST OF FIGURE xi

LIST OF SYMBOL xvii

LIST OF APPENDIX xviii

CHAPTER 1 INTRODUCTION

1.1 Study Backgound 1

1.2 Problem Statement 2

1.3 Objectives of Study 3

1.4 Scope of Study 3

1.5 Benefit of Study 4

CHAPTER 2 LITERATURE REVIEW

viii

CHAPTER TITLE PAGE

2.2 F1 in Schools 5

2.3 Fundamental of Aerodynamics 7

2.4 Computational Fluid Dynamics 15

2.5 Wind Tunnel Test 16

2.6 Previous Study in Aerodynamics 20

CHAPTER 3 METHODOLOGY

3.1 Introduction 23

3.2 Literature Review 24

3.3 Design Phase 25

3.4 CFD Modeling 26

3.5 Fabrication 38

3.6 Wind Tunnel Test 39

CHAPTER 4 DATA ANALYSIS AND RESULT

4.1 Introduction 42

4.2 Wind Tunnel Result 42

4.3 CFD Analysis 44

4.4 Comparison of Wind Tunnel and CFD Result

45

CHAPTER 5 DISCUSSION

5.0 Introduction 47

5.1 Source of Drag 48

5.2 CFD Validity Test 48

5.3 Secret Behind the Fastest Car 50

5.4 Modification 51

ix

CHAPTER TITLE PAGE

CHAPTER 6 CONCLUSION &

RECOMMENDATION

6.1 Conclusion 56

6.2 Recommendation for Future Studies 57 6.3 Recommendation to Faculty of

Mechanical Engineering, UTeM

58

REFERENCES 59

BIBLOGRAPHY 61

x

LIST OF TABLE

NO. TITLE PAGE

4.0 Wind tunnel result 4

4.1 CFD analysis results 6

4.2 Grid Independence Test (Drag and Lift Coefficient for 25m/s)

8

5.0 Comparison between Liou, W. W., and Son, H,. (2003) and Validity Test

9

5.1 Validity test result 10

5.2 Comparison between sleek design and blunt design

11

xi

LIST OF FIGURE

NO. TITLE PAGE

1.0 Race day of F1 in Schools (Source: By Author)

4

2.0 Blank balsa wood

(Source: Rules and Regulation 2008 Season, [10])

6

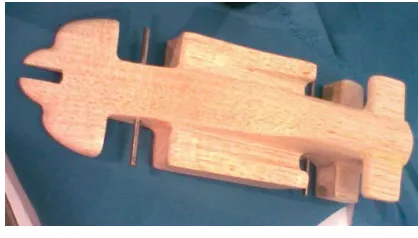

2.1 Balsa wood after machined (Source: By Author)

6

2.2 Sample of previous Formula One in Schools (Source: By Author)

7

2.3 A fluid element passing through “Point 1” in a flow field

(Source: Anderson, 2007)

8

2.4 Figure 2.2: Aerodynamic forces

(source: http://www.grc.nasa.gov/WWW/K-12/airplane/presar.html)

xii

NO. TITLE PAGE

2.5 Figure 2.3: (From left) Bernoulli’s, Newton, the innovation Aerofoil.

(Source: http://www.f1technical.net/articles/10)

11

2.6 Shape of a body causing difference in pressure drag and skin friction magnitude

(Source: Anderson, 2007)

12

2.7 Type of region in fluid flow around cylinder (Source: Nishino, T. et al, 2007 [17])

13

2.8 Three type of fluid flow inside boundary layer (Source:http://www.auf.asn.au/groundschool/umo dule4.html)

14

2.9 UTeM’s Subsonic Wind Tunnel

(Source:http://www.essom.com/UserFiles/MP130 D.jpg)

17

2.10 Axial Fan speed controller 18

2.11 Force indicator 18

2.12 Load Cell

(Source:http://www.essom.com/UserFiles/MP130 D.jpg)

xiii

NO. TITLE PAGE

2.13 Incline manometer 18

2.14 (1) Nozzle, (2) filament and (3) platform

(Source:http://en.wikipedia.org/wiki/File:FDM_by _Zureks.png)

19

3.0 Flow chart for this project 24

3.1 Gambit Startup window 26

3.2 Gambit window 27

3.3 Solver selection 27

3.4 CAD import 28

3.5 Import IGES File window 28

3.6 Imported IGES file 29

3.7 Move/Copy window 30

3.8 Successfully rotated 30

3.9 Face created 31

3.10 Selected surface for face mesh 31

xiv

NO. TITLE PAGE

3.12 Translated brick 32

3.13 Split the edge to create vortices 33

3.14 Edge created 33

3.15 Symmetry plane component, face A 34

3.16 Symmetry plane component, face B 34

3.17 Connected edges were meshed as edge mesh 35

3.18 Volume selected for mesh 35

3.19 Volume mesh was inspected 36

3.20 Boundary type was set 36

3.21 Export Mesh File window 37

3.22 FDM Machine (Source: By Author)

38

3.23 Produced car 38

xv

NO. TITLE PAGE

3.25 Diagram of wind tunnel load cell, Factual = [D, L],

Findicated = [Do, Lo]

(Source: Subsonic Wind Tunnel Manual Instruction)

39

3.26 Model setup and direction of the load cell (Source: By Author)

41

4.0 Coefficient of Drag for Car Model 45

4.1 Coefficient of Lift for Car Model 46

5.0 Aerofoil grid 49

5.1 Velocity contour for 0 degree angle of attack 49

5.2 Pressure contour for 0 degree angle of attack 49

5.3 Velocity contour for 3 degree of angle of attack 50

5.4 Pressure contour for 3 degree of angle of attack 50

5.5 FUGA 51

5.6 Modification 1 52

5.7 Modification 2 52

xvi

NO. TITLE PAGE

5.9 Modification 4 53

5.10 PULSE, the 2008 International F1 in Schools Champion and Fastest Car

(Sourse: http://www.pulsef1.co.uk)

54

xvii

LIST OF SYMBOL

A = Projected Area

Cd = Drag coefficient

Cl = Coefficient of lift

D = Drag force

Do = Indicated Drag Force

l = Length

L = Lift force

Lo = Indicated Lift Force

= Density

Re = Reynolds number

ij = Stress tensor

= Dynamic viscosity

v = Kinematic viscosity

V = Velocity of fluid

x = Distance/length

xviii

LIST OF APPENDIX

NO. TITLE PAGE

A Rules and Regulation for Formula One in Schools Car Development

63

B Car Model for Wind Tunnel 68

C Wind Tunnel Experiment 70

D Modification 1 72

E Modification 2 74

F Modification 3 75

G Modification 4 76

H Final Design 77

1

CHAPTER 1

INTRODUCTION

1.0 Study Background

When the F1 in Schools’ cars were launched, the speed was build up rapidly due to thrust which was caused by CO2 pressurized cartridge. This is similar to a

bullet fired from a rifle. The speed was believed to be exceeding 70km/h or 19.44m/s at the early stage of the launching. Due to aerodynamic effect, the car tends to slow down at the end of the finish line which gives different time record [5].

It is obvious that the car with better aerodynamic shape is faster than a car with blunt shape. These because of air resistance occur while the car is moving along the track. The external flow of air around the cars can be determine by wind tunnel experiment, calculation and computerized solving which is known as Computational Fluid Dynamics (CFD) [6].

From the usage of CFD, the car can be design effectively in order to achieve better aerodynamic properties like low drag and low downforce. The CAD model can be tested without the physical model or prototype. The model has to be meshed before it can proceed to CFD analysis. However, CFD analysis has quantized error due to numerical iteration and the choices of turbulence model. The CFD analysis can be verified with wind tunnel experiment and calculation [16] [21].

2

had to be prepared by using Rapid Prototyping machine. The 3D model used in CFD may also used for Rapid Prototyping process.

From the wind tunnel result, CFD setting shall be adjusted to gain similar result from the wind tunnel. Further study of aerodynamics can be proceeding as suitable setting obtained. The aerodynamic characteristic can be determine and can gives better understanding of the design consideration of a Formula Student in Schools car.

1.2 Problem Statement

The aerodynamics study about the F1 in Schools is quite interesting because slight changes and differences may cause the performance of the car same as real F1 cars. Many of the contestants from the school within Malaysia did not have proper data and analysis to investigate the effect of the aerodynamics. Past two year, Malaysia team from SMK Convent Bukit Nanas had awarded third place, afterward, no other Malaysian team can go further [5]. These may because of improper analysis for the building of the cars.

• Mostly the student designed the cars with ecstatic element rather than aerodynamic efficiency.

3

1.3 Objectives of Study

From the problem statement, the solution has been planned and the objectives for this study were set. The objectives of this project are:

• To study the effect of aerodynamics in “F1 in School” cars. • To provide a systematic research about the aerodynamic.

• To compare the designed “F1 in School” car with the fastest car as a benchmark which was recorded in 2007 International Finals.

• To fabricate the designed car. • To perform the wind tunnel test.

• To run CFD simulation for modeled Formula One in Schools cars.

1.4 Scope of Study

The main objectives of this research are to make analysis about the aerodynamic effect on “F1 in School” cars and then to fabricate them. This project will covers from:

• Designing: design consideration about feature in real F1 cars, specification studies given by the organizer, manufacturing considerations are taken into account, design concept and 3-dimension modeling. 3-dimension modeling of previous world record holder shall be made. The software used for 3-dimension modeling is CATIA V5R10

• CFD Analysis: Aerodynamics analysis will be the main analysis for this research. The aerodynamics analysis may cover entire part of the cars including bodywork and wheels. This project may use CFD software for aerodynamics simulation and detailed analysis. The software used for CFD analysis is Fluent 6.2.

4

• Wind Tunnel Testing: After fabrication has completed, wind tunnel analysis will proceed. Wind tunnel used for this study is UTeM’s subsonic wind tunnel.

Element that may not be covered in this project are:

• Material analysis such as stress analysis shall not be covered.

• Surface finish may not be cover in this study because of expensive materials. • Ecstatic element will not be included in this research.

1.5 Benefits of Study

The CFD and wind tunnel analysis may able to clarify and gives better understanding for the student about the importance of aerodynamic effect. It also gives the reader an idea to overcome the drag force and also low in negative lift force.

[image:22.612.199.454.467.656.2]From this report, hopefully this project may give them (participating school) a guide line for design consideration and better analysis the main element in “F1 in School”.

5

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

In this chapter, all terms in this study shall be defined and some explanations of the term may take place. This chapter may discuss about the “F1 in Schools”, the definition of aerodynamic, the CFD usage and application, fabrication and wind tunnel test.

2.2 F1 in Schools

“F1 in Schools” was founded in 1999 by Andrew Denford. “F1 in Schools” first established only at United Kingdom during year 1999 until 2003. In 2004, the “F1 in Schools” was introduced to many countries across the globe and accepted widely. The “F1 in Schools” competition is about 3 years old in Malaysia. During the first year in 2006, Malaysian team managed to get the “Fastest Car” award and break the record which was 1.083 second [5].

6

less density of hard wood. The main driver of the “F1 in School” is compact compressed reclaimed CO2 power plant. The six elements for “F1 in School” are;

business plan for acquiring sponsors, designing using CAD, analysis using CFD, fabricating using CNC machine, wind tunnel testing, and race [5].

Figure 2.0: Blank balsa wood (Source: Rules and Regulation 2008

[image:24.612.310.519.163.282.2]Season, [10])

Figure 2.1: Balsa wood after machined (Source: By Author)

Competitors came from all over the world has to compete in national stage before selected to represent for their country. All of them using same rule and regulations and the criteria for marking such as specifications, design portfolio, team design for F1 cars, used of CAD and ICT, and quality of manufacturing [5].

The interesting is, the main factor which can make the car be a fastest car is the aerodynamic of the car. The car which can cut the air smoothly through the straight line about 20 meters (m) can become the fastest car. In the “F1 in School” track record hold by Team Fuga from Northern Ireland in 2007 at Melbourne Australia venue. The time recorded is 1.020 second (s) [5]. The velocity of the car is 19.608 m/s which equal to 70.589 km/h.

Basically, the car was placed onto the track and a string will be attached to the screw pin underneath the car for guidance. The acceleration builds up from the force generated from CO2 cartridge until the pressure depleted. The cars keep on