i

DECLARATION

I hereby, declared this Bachelor‟s Project entitled “Use DFMA Methodology to Analyze

on Car Wiper System” is the result of my own research except as cited in references.

Signature :

Author‟s Name : Noorazmie Afzam b. Muhamad Zaki

ii

APPROVAL

This Bachelor‟s Project submitted to the senate of UTeM and has been accepted as

fulfillment of the requirement for the Degree of Bachelor of Manufacturing Engineering (Design) with Honours. The member of the supervisory committee is as follow:

………

En. Tajul Ariffin b. Abdullah Project Supervisor

iii

ABSTRACT

iv

ABSTRAK

v

DEDICATION

For my beloved family:

Muhamad Zaki bin Saleh

Ruhani binti Zakaria

Noorazrin Azafri bin Muhamad Zaki

Noorazlie Syazrin bin Muhamad Zaki

Nizartul Athirah binti Muhamad Zaki

Nur Farahana binti Muhama Zaki

To my lovely fiancé

Noor Juliana binti Jaa’far

vi

ACKNOWLEDGEMENTS

Alhamdulillah and Thank to Allah S.W.T. with all His Gracious and His Merciful for giving me strength and ability to accomplish this project research successfully. I would like to take the utmost opportunity to express my sincere and gratitude to my supervisor, En Tajul Ariffin bin Abdullah who is always giving me supports and guidance in completing this Final Year Project 1 & 2 until up to this stage in victory.

Also with the greatest thanks to my beloved parents En Muhamad Zaki Bin Saleh and Ruhani Binti Zakaria and family who always pray and give the encouragement while pursuing my research and project. Their sacrifices are never being forgotten and will be remembered forever.

Besides, thanks a lot to Dr. Mohd Rizal Bin Salleh, Dean of Manufacturing Engineering, Malaysia Technical University of Malacca and also to all lecturers of Faculty of Manufacturing Engineering.

I also would like to convey my appreciation to all the staff in Wiper car manufacture for supporting me in accomplishes my Final Year Project without hesitation. All knowledge and experience I gained would not be forgotten.

vii

2.2 Traditional Design Methods 7

2.2.1 Differences DFMA with Traditional Methods 10

2.3 Design for Manufacture (DFM) 12

2.3.1 DFM Principle 14

viii

2.5 Design For Manufacture And Assembly (DFMA) 20

2.5.1 DFMA with Concurrent Engineering 20

2.5.1 DFMA is Combination With Two Methods DFA & DFM 21 2.5.3 Design For Manufacture And Assembly Process 23

2.5.4 Benefit Design Manufacture And Assembly 24

3.0 CHAPTER 3: CAR WIPER

3.7.2 The amount of spring tension on the wiper arm 37 3.7.3 The number of pressure points or claws holding the blade 37

3.7.4 The material used in the blade itself 38

3,8 Wiper Control 38

ix

4.0 CHAPTER 4: RESEARCH METHODOLOGY

4.1 Introduction 42

4.2 Methodology 42

4.3 Questionnaire Outline / Survey Instrument. 43

4.4 The Advantages and limitations of Questionnaire Survey 44

4.5 Analysis of the Survey Data. 44

5.0 CHAPTER 5: RESULT FROM SURVEY AND DFMA ANALYSIS

5.1 Introduction 46

5.2 Data from Questionnaire 68

6.3 Analysis from DFMA 72

x

9.0 REFERENCES 79

xi

LIST OF FIGURE

2.1 Sequential Design Approach 8

2.2 Traditional Manufacturing Process 9

2.3 Model of generic process or productive system 11 2.4 Typical DFM flowchart (Martin O‟Driscoll, 2001). 14

2.5 Type for Considered About DFA 17

2.6 Typical stages in a DFMA procedure 24

3.1 Windshield wiper car 29

3.2 Picture Inventor Mary Anderson 30

3.3 Tandem System 33

3.4 Some of the different wiper blade schemes used by various cars 34

4.1 Framework of an Implementation Model for Research 45

5.1 Show Pie Chart List of Part. 48

5.2 Show Pie Chart for a Weakness for Wiper Blade 49

5.3 Pie Chart for Time Change Their Wiper Blade. 50

xii

5.5 Concept design process flowchart 53

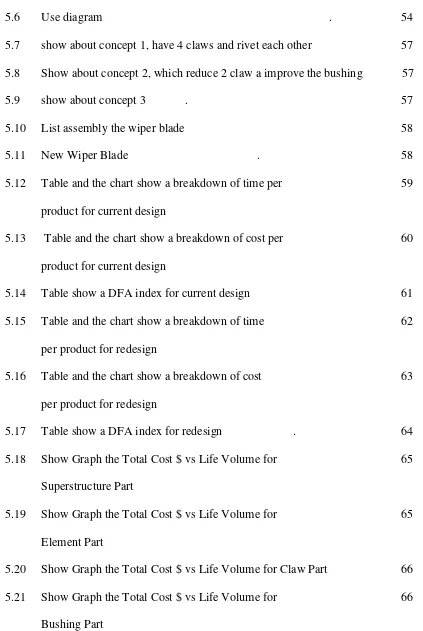

5.6 Use diagram . 54

5.7 show about concept 1, have 4 claws and rivet each other 57 5.8 Show about concept 2, which reduce 2 claw a improve the bushing 57

xiii

xiv

LIST OF TABLE

5.1 List Manufacture and Car Used. 47

5.2 List of Part. 48

5.3 List the Weakness 49

5.4 Show Time Change Their Wiper Blade 50

5.5 The Criteria from Correspondent Thinking 51

5.6 Show calculation pointer for questionnaire as use in Pugh‟s matrix 52 5.7 Pugh‟s Matrix for concept collection 55 5.8 List Part Material and Process (Champion Motor Sdn. Bhd.) 57

xv

LIST OF ABBREVIATIONS

DFA - Design for Assembly DFM - Design for Manufacture

DFMA - Design for Manufacture and assembly SPC - Statically Process Control

2

enough. This matter, if continuously will make one company pay for higher whereas stated cost can be reduced. Apart from that, part also actually could be reduced.

By year end 1970, this problem realized by a person whose named Geoffrey Boothroyd in University of Massachusetts. With the case study which is done by Geoffrey Boothroyd has made it with one method whose can solve the problem with producing his Design for Assembly and Design for Manufacture (DFA and DFM). Design for Assembly (DFA) is a method or system to facilitate a deep product installation. This matter, emphasize with some procedure that need followed and am being cared deep assembly method. It can be reduce cost bear by the company. Apart from that, can reduce part unconnected sense in the products can be chased away. With that system, installation time could be reduced hereby get increase productivity quoted company. Whereas Design for Manufacture (DFM) is a system or method that concerned to the components something easy of use in the products process and cost. Process driving at is deep machine utilization make stated product could be reduced. Hereby, designer necessary drop heavy process that have and the process that would face. Each part necessary have the process or machine that there on the company because it will reduce manufacturing cost. Through DFM and DFA, wall approach get be torn and are eliminated in a sector. Through to the DFM and DFA, to will start of something product will happen a discussion through the chief of each department. They will jointly discuss deep tackle will happen and can produce one product with good. Hence, the process dialogue is this in that process paramount is very importance. Dialogue is important to encouraged between designs and manufacturing engineers that will giving the team an attitude necessary to concurrent engineering.

3

emphasized, product one make will reduce in the use cost to make and through data are obtainable get also that person, redesign something product until producing a good product.

This motivated author, to use the method DFMA for his bachelor's for the project. A product wiper seated study deep product wiper now much difference car among one product wiper with one product another. Whereas function to wiper car is the same, namely wiping things that there were to car mirror and also help driver give the view best-of in his driving. In study weakness have the product will be identify, by using DFMA methodology, design that there were this, Get our particle suffixed to the emphatic word in sentence pores to quantify design efficiency. Apart from that, increase goodness to current design and new design and comparing them.

In conclusion is the method use this can be help a tackle will arise after this. It is the method for sense get helps the research. Our one box know, DFMA's method can help in settling minimize part that there to each product. Apart from that, through no DFMA work that postpone too long as time can be shortened.

1.2 Objective

There were 3 objectives would be made:

4

1.3 Problem Statement

In recognition process to use DFMA method, a product would be identified. Through stated product, with necessary study in the use and function product stated. Current product will be undertaken via the market that there were in passed market study material and difference design that there were in circulation in the market. Current product that there were to market have difference each design and each product different form and unequal follow the price to market. Proven each product have cost in whose bear different. Through DFMA, will approach current design with comparing all products to market and find best-of to approach current product stated become primary current product. Later, to current design stated redesign back to gain product a more favorable go comparing it to section evaluate the effectiveness software DFMA stated in tackle stated. Whether software DFMA can solve this problem and enhance product stated to best from the aspect benefit to manufacture and assembly process.

1.4 Scope

5

stated there were DFA and DFM. With this method, the extra time spent in the early design stage is much less the time that ill be spent in the repeatedly redesign. And meanwhile, the cost will be reduced. A design team was founded and the goal of the team was to finish the design with a concept that would meet the product requirement and meanwhile, improve the manufacturability of the product. They used Boothroyd – Dewhurst DFMA as the framework during the whole design process.

When the concept design finished the designer will met the supplier at this time, reviewed the part design and developed a better one. The results of this effort are that the new product is greatly simplified, the improvement of assembly and assembly cost. DFMA shorten the manufacturing time, decrease the cycle time and keep the high quality of the product, and meanwhile make the design more creative. The author was focused the efforts on the analysis material selection, assembly process and the sheet metal working of the parts. Have a five parts were redesigned from a manufacture point of view which reduce time and cost. An added bonus to those changes was a time and cost saving at the assembly stage.

6 Assembly (DFMA) technique has been utilized extensively in industry field these days. If its trace the history of DFMA its can even find it before the Second World Warford and Chryler use the DFM philosophy in their design and manufacturing process of the weapons, tanks, and other military products. Dr. Geoffrey Boothroyd and Dr. Dewhurts who founded the Boothroyd Dewhurts. Inc (BDI) in 1982 is the first persons doing the research job in this new technology in the early 1970‘s. Currently these programs are used to help the design in almost all the industrial fields including circuit boards with manual assembly, with robotic assembly and with machining. It also does a lot of work examining the economic justification of each design revision. It has been practiced in many manufacturing industry around the world, among other seek to reduce development time, lower costs, increase productivity and improve product quality.