Informasi Dokumen

- Penulis:

- Aris Adhi Permana

- Mad Yamin

- Pengajar:

- Ir. Mad Yamin, MT

- Sekolah: Bogor Agricultural University

- Mata Pelajaran: Agricultural Engineering

- Topik: Mechanical Vibration and Noise Measurement on Thermal Fogger Machine Type TS-35A (E)

- Tipe: thesis

- Tahun: 2012

- Kota: Bogor

Ringkasan Dokumen

I. INTRODUCTION

The introduction outlines the importance of studying mechanical vibrations and noise levels produced by the Thermal Fogger Machine Type TS-35A(E) in agricultural settings. It emphasizes how the health and comfort of operators can be affected by these factors, necessitating thorough research. The section also sets the stage for the objectives of the study, which include analyzing vibration and noise levels and determining optimal usage times for operators.

1.1 BACKGROUND

This subsection provides context regarding the extensive agricultural land in Indonesia and the increasing use of pest control machinery, which leads to potential health risks due to mechanical vibrations and noise. It establishes the need for research into the effects of these factors on operator comfort and safety, highlighting the significance of this study in advancing agricultural practices.

1.2 OBJECTIVES

The objectives of the research are clearly defined, focusing on analyzing the mechanical vibrations and noise levels experienced by operators during the operation of the Thermal Fogger machine. Additionally, it aims to establish the optimal daily usage duration for operators to ensure safety and comfort, thereby contributing to better occupational health standards.

II. LITERATURE REVIEW

This section reviews existing literature on various relevant topics such as pesticides, historical development of spraying equipment, pest control technologies, and ergonomics. It provides a theoretical framework that supports the analysis of mechanical vibrations and noise in agricultural machinery, emphasizing the importance of understanding these concepts for improving operator safety and machine efficiency.

2.1 PESTICIDES

This subsection defines pesticides and discusses their role in agriculture, outlining their impact on pest control. It emphasizes the need for effective application methods to minimize health risks associated with pesticide use, linking this to the importance of studying the operational environment of pest control machinery.

2.2 HISTORY OF SPRAYING EQUIPMENT

The historical development of spraying equipment is traced, highlighting innovations over the years. This context is crucial for understanding the evolution of pest control technology and the relevance of current machinery, such as the Thermal Fogger, in modern agricultural practices.

2.3 HAND SPRAYERS

This subsection discusses the different types of hand-operated sprayers, their mechanisms, and applications. Understanding these devices provides insights into the ergonomic challenges faced by operators and the importance of minimizing vibrations and noise during their operation.

2.4 POWER SPRAYERS

An exploration of motorized sprayers and their operational dynamics is presented. This section emphasizes the technological advancements that have led to more efficient pest control methods, while also addressing the associated risks of noise and vibration.

2.5 PEST CONTROL

The importance of effective pest control methods is discussed, along with the implications of improper pesticide usage. This highlights the necessity for research into the safety and ergonomic aspects of pest control machinery, such as the Thermal Fogger.

2.6 APPLICATION TECHNOLOGY

This subsection focuses on the technology behind pest control applications, including aerosol methods. The relevance of technological advancements in reducing operator exposure to harmful effects is emphasized, supporting the study's objectives.

2.7 ERGONOMICS

The principles of ergonomics are discussed, emphasizing the need to design machinery that minimizes operator discomfort and health risks. This theoretical foundation is vital for understanding the implications of vibrations and noise on operator health.

2.8 VIBRATIONS

This subsection defines mechanical vibrations and their potential health impacts on operators. Understanding vibration mechanics is crucial for assessing the risks associated with prolonged use of agricultural machinery, such as the Thermal Fogger.

2.9 NOISE

The characteristics of noise and its classification are explored. This section discusses the health implications of noise exposure in agricultural settings, reinforcing the importance of the study's focus on measuring and analyzing noise levels produced by the Thermal Fogger.

III. RESEARCH METHODOLOGY

This section outlines the research design, including the location, tools, and methods used for data collection. It details how measurements of vibrations and noise were conducted, ensuring a systematic approach to data analysis that aligns with the study's objectives.

3.1 TIME AND LOCATION

The research was conducted over six months in a designated laboratory setting, detailing the conditions under which data was collected. This timeframe is significant for capturing variations in operational dynamics and environmental factors affecting vibration and noise levels.

3.2 TOOLS AND MATERIALS

The specific tools used for measuring vibrations and noise, including the Thermal Fogger and measurement devices, are described. This subsection emphasizes the importance of accurate measurement tools in obtaining reliable data for analysis.

3.3 PRELIMINARY RESEARCH

Preliminary observations were conducted to assess the operational conditions of the Thermal Fogger. This initial phase was crucial for identifying key variables that would influence the research outcomes.

3.4 RESEARCH METHODS

The methodologies employed for data collection and analysis are outlined. This includes the specific procedures for measuring vibrations and noise at various points, ensuring a comprehensive understanding of the operational environment of the Thermal Fogger.

IV. RESULTS AND DISCUSSION

This section presents the findings from the measurements of vibrations and noise, along with a detailed analysis of the data. The results are discussed in relation to the established safety standards and the implications for operator health and comfort.

4.1 VIBRATION MEASUREMENTS

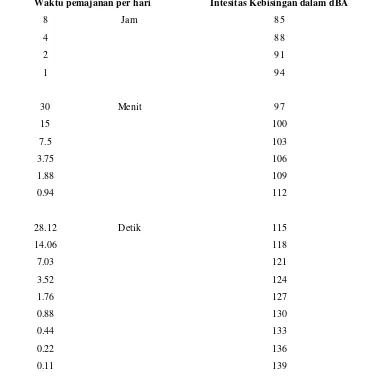

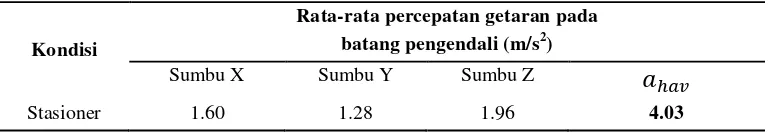

The results of vibration measurements taken during the operation of the Thermal Fogger are presented. The data highlights the levels of vibration experienced by operators and the potential health risks associated with prolonged exposure.

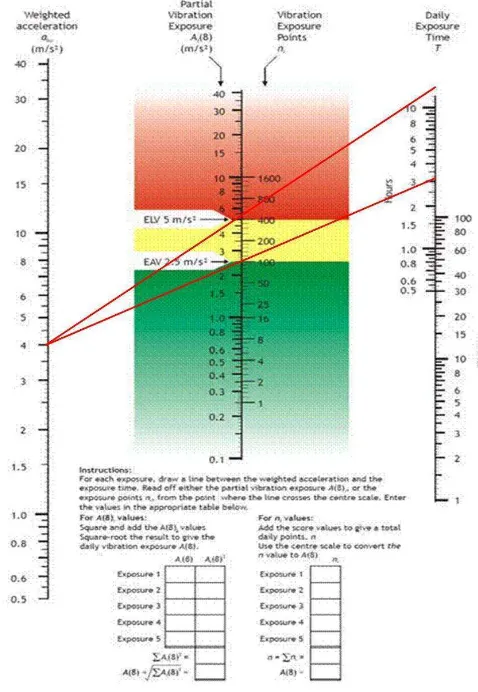

4.2 VIBRATION ANALYSIS

This subsection analyzes the vibration data in relation to established safety standards. It discusses the implications of the findings for operator health, emphasizing the need for interventions to mitigate risks.

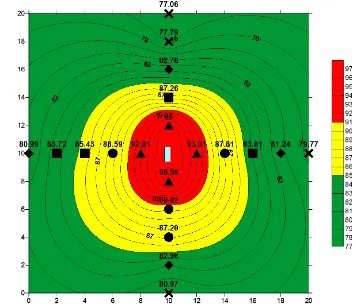

4.3 NOISE MEASUREMENTS

The findings from noise level measurements are presented, detailing the sound levels produced by the Thermal Fogger. This data is critical for understanding the auditory environment faced by operators during machine operation.

4.4 NOISE ANALYSIS

An analysis of the noise data is conducted, comparing it to regulatory standards. This discussion addresses the health implications of noise exposure for operators and the need for protective measures.

4.5 OPTIMAL USAGE TIME ANALYSIS

This subsection determines the optimal daily usage time for operators based on vibration and noise levels. It provides practical recommendations for safe operation, contributing to enhanced occupational health practices.

4.6 OPERATOR SUBJECTIVITY STUDY

A study on the subjective experiences of operators regarding vibrations and noise is presented. This qualitative data adds depth to the understanding of the impact of the Thermal Fogger on operator comfort and safety.

V. CONCLUSIONS AND RECOMMENDATIONS

The final section summarizes the key findings of the research and offers recommendations for improving the safety and comfort of operators using the Thermal Fogger. It emphasizes the importance of ongoing research and development in agricultural machinery to enhance operator health outcomes.

5.1 CONCLUSIONS

This subsection summarizes the main conclusions drawn from the research, highlighting the significant findings related to vibration and noise levels and their implications for operator health.

5.2 RECOMMENDATIONS

Practical recommendations for mitigating the risks associated with vibrations and noise are provided. This includes suggestions for protective equipment and modifications to machine design to enhance operator safety.