In: Bisnrrrth: Characteristics, Production

andApplications

ISBN: 978-l-61470-640'3 Editors: K. P. Ghatak and S. Bhattacharya, pp. 145-156 @ 2012 Nova Science Publishers, Inc.Chapter 5

SyNTTTESIS

AI'{D PNOPNRTIES

OF

ND-DOPNN

Br4Tr3Orz

flstnc

rHE

Sorr

CoprsusrloN

TncnxIeuE

A.

(Imar

Al-Amani,

S.

Sreekuntan,

M,

N.

Ahmad

Fuuzi

and K.

A.

Ruzak-School of Materials and Mineral Resottrces Engineering, Universiti Sains Malaysia, 14300 Nibong Tebal, Penang, Malaysia

AssrRAcr

Nd-doped Bi+Ti:Orz ceramics, Bi4-Nd*Ti3O12 (BNT, x

-

0, 0.25, 0'50, 0'75 and l),*"r"

p."put"d using a soft combustion technique and their phase, structure, thermal behavior, grain morphology, dielectric and fenoelectric properties were investigated. The single phase of BIT was successfully obtained at different synthesis temperature, justafter combustion took place

at 450'C.

The thermal analysis confirmed the phase formation with corresponAing temperature. The single phase of BIT was also obtainedwith different Nd doping. It was also shown that Nd doping had a significance change in Raman and Fourier'ir.ansform Infrared spectroscopy (FTIR) spectra. Further increase the sintering ternperature at 900'C did not show the presence of secondary phase in X-ray diffraction

tXnp)

pattem. The average grain length and width decreasedwith

Ndcontent.

The

Curie temperatureof

BNT

also reducedto

434oC.The

remanent polarization, 2P. and coercive field, 2E" of BNT were higher than BIT, whereby the BNT075 ceramics exhibited the rnaximum 2P, and 28" valuei of aboutl8.4 pClcmz and 100.6 kV/cm, respectively.

Keyrvords : Bisrnuth titanate; Doping; Soft contbustion; Lanthanide.

146 A. Umar Al-Amani, S. Sreekantan, M. N. Ahmad Fauzi, et' al

INrnonucrIoN

Ion doping technique

is

a preferable wayto

enhance the electrical propertiesof

many ceramic materials to date. For instance, bismuth titanate (Bi+Ti:Orz or BIT) has been reportedto

exhibit low remanent polarizafion (2P,<

10 pC/crn';, high leakagecurent, low

fatigue resistant, high dielectric loss and high electrical conductivity whichlimit

its application in anon-volatile ferroelectric random access memory technology (NvFRAM)

ll-3].

In

order tosolve these issues, many researchem suggested that ferroelectric properties

of BIT

can be improved by tuning its composition using ion doping technique. Park et al. [4] found that La3*ion successfully doped in

BIT

film

which thefilm

had enhanced P, (16^- 20 pC/cm2), lowleakage

rurr*ni

110:7 A/cmz at 5V) and good fatigue resistant (3x

l0t0

switching.cycles)'Kojima et al. [5] reported that the P, up to

25

pClcm2 with fatigue free after 2x

1010 cycles could be achieved when Nd was partially doped in BIT thin fihn. Chon et al. [5] reported that the Bi: rsSm6 s5Ti3O12 thinfilm

has high P, and good fatigue endurance to reach about 29.5 pClcm2 and4.5x

1010 switching cycles. However, the increase in these values was stronglydependent

on

several things such asthe

annealing temperature andtype

of

annealing, substrate type, bottorn electrode, grain orientation, film thickness etc.Lanthanide doped BIT has been prepared using the conventional solid-state reaction [7-141, sol-gel rnethod [15-25], hydrolysis method [26,277, polymeric precursor method 128,

291, chemical solution deposition (CSD) [30-33], metal organic solution decomposition

(MOD)

[34-39], pulsed laser deposition(PLD) [40],

and metalorganic chemical vapordeposition (MOCVD) [41]. Each method has own merits and drawbacks. Conventionally prepared powder often uses high calcination temperature with repeated grinding in its process

which then produces hard powder and high agglomeration. As an alternative, wet chemical synthesis is beneficial to reduce the calcination temperature and improve the reactivity and

homogeneity

of

the

composition.For

deposition processof

thin

films, the PVD,

CVD, MOCVD andrf

sputtering are costly and the parameter settings are also complex. Sol-gelmethod

is

the simplest methodto

producethin

films. Sol-gel method also offers several advantages including pre- and post-depositionat

low

temperature, easier compositional control and better unifonnity of the films, economical compared to CVD and PVD techniques 13l.To the best of authors' knowledge, very least works on soft combustion technique have been reported. Previously, this technique has been used extensively to prepare a large number

of

technologically useful oxide materials such as refractories, magnetic, semiconductors,dielectric, catalyst, sensors, phosphors, etc. and none oxide materials such as carbides,

nitrides, borides

and

silicidesf42,

43]. This

approachis

convenient, requires simple experimental set up and save time as well as requires low energy consumption [44]. This is because this technique is characterized by self-sustaining solution combustion synthesis in which the exothermicity of the redox chemical reaction is used to produce the useful materials[45]. Recently, our group used glycine to produce praseodymium-doped bismuth potassium titanate and praseodymium-doped bismuth sodium titanate 146, 47). There also a study on praseodymium-doped bismuth titanate, however,

the fuel

agentwas

not

introduced insynthesis process [a8]. In the present study, Nd was partially doped in

BIT

using a noveltySynthesis and Propertis of No-Doped BiaTi3O12. ...

were investigated in terms of phase formation, thermal behavior, structnre, grain morphology, dielectric and ferroelectric properties.

ExpnnrprENTAL

Pnocnnune

Nd-doped

BIT

(Bi4-Nd*Ti3O12) were prepared according to the Nd contentx:

0, 0.25, 0.50, 0.75 and 1, the samples are denoted as BIT, BNT025, BNT050, BNT075 and BNTIO0, respectively. Firstly, bismuth nitrate(Bi

(NO3)3.5H2O, Sigma-Aldrich, 98 %) was dissolved at 40oC in distilled water. Separately, neodymium nitrate (Nd (Nq)3.6H2O, Sigma-Aldrich, 99.9 %) was dissolved in distilled water and citric acid (CoHsOz, Sigma'Aldrich,99.5 %) was used as a fuel agent. The neodymium solution together with citric aqueous were added into the bismuth solutionwith

continuousstining.

The titanium solution was prepared from titanium isopropoxide(Ti

IOCH (CHr)z]+,Aldrich

Chemistry, 97%)

which was initially dissolvedin

2-methaoxyethanol (Sigma-Aldrich, >99). Finally, the titanium solution wasslowly added into the bisrnuth neodymium solution

to

obtain the precursor solution. This solution was adjusted to pH7 with NH+OH (29 % solution). The prepared solution was stirred at 60oC for additional24hlo

obtain a homogeneous solution. After that, the temperature was increased to 80"C to form a dried precipitates. The precipitates were gently crushed using anagate mortar pestle.

The

crushed powderwas

heatedon

a

hot

plate

attached with thermocouple for the soft combustion process to take place, and the temperature was recorded-450"C. The reaction lasted less than 5 min and produced yellowish and greenish powders for BIT and BNT powders, respectively.

Thermal behavior

of

the

dried

powderwas

investigated using Themogravirnetry-Differential Therrnal Analysis, TG-DTA (Linesis). Phase identification was investigated by X-Ray Diffractionwith

Cu-Ku radiation, X-ray diffraction (XRD) (Bruker D8 Advanced). Raman spectrometer (Horiba Jobin-Yvon HRS00UV) and FTIR spectrophotometer (Perkin Elmer) were usedto

investigate the phonon mode and adsorption band, respectively. Themicrostructure

of

the

prepared samples was examined usinga

field

emission scanning electron microscopy, FESEM [Zeiss Supra 55VP PGT/HKL]. To investigate the dielectric and ferroelectric properties, the sintered pellet was coated with silver conductive paint andfired

at

700"Cfor

15 rnin.The

capacitance and loss tangent were measured using an Impedance analyzer (Hewlett Packard 4192A LF). The ferroelectric P-E hysteresis loop was investigated using Sawyer-Tower circuit.Rnsur-r

AND

DlscussloN

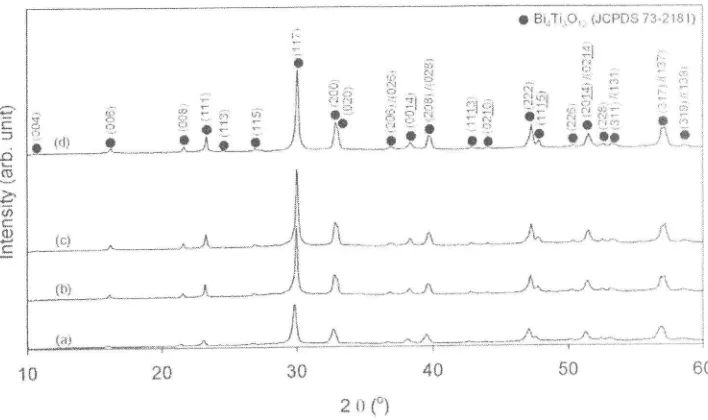

Figure

I

shows theXRD

patternsof

theBIT

powder prepared at different synthesis temperatures. The XRD pattems were compared with standard BIT data (JCPDS 73-2181).It

was found that a stable phase

BIT

with

layered perovskite structure could be obtained at temperatures between 40 and 60'C. Additionally, the stabilityof

phase formation was also achievedin

calcined powderat

500"C.This

indicates thatthe

synthesis temperature is sufficient to obtain the single phase of BIT without further calcination process.148 A. Umar Al-Amani, S. Sreekantan, M. N' Ahmad Fauzi, et. al

t

a.;l

:i!

a

;ll

t.

{'.,

.;,

:

i;

_:i

.i

t

l

I Pi,Ti,O,. {JCPr}$ ?3-?l8li-- * -**A*."---

**A*'n*'*

A

;

l.-^r-.A*^-

-.

-*

-,A-*-*-,,\*-*-A*"

i [image:4.518.94.448.68.278.2] [image:4.518.97.451.336.578.2]20f)

Figure 1. XRD patterns of BIT por,vder at differdnt synthesis temperatures: (a) 40'C, (b) 50"C. (c) 60"C and (d) calcination at 500"C for (c) samples.

,n

I

exoI

800

1000Temperature {oC}

Figure 2. TG and DTA of BIT polvder derived from 60"C.

Figure 2 shows the TG and DTA of BIT powder derived at 60oC. As shown in Figure 2,

the

TG

curve can be divided intofwo

distinct stages. Thefirst

weight loss took place at temperature rangeof

100-

355"C and second weight loss at temperature rangeof

480-505"C. Above 505oC, the reaction was completed as indicated

by

linear curve. The total weight lossof

abaut 42.4 Yo was obtainedfor

BIT

powder. TheDTA

curve showed theq

d

(g

,6

c

{l)

{fr)

s0 40

7A

1S

JU

eu5

16

c

'6

109

rcl

90 \o

;

(,-9

so-c .sl

o

B70

Synthesis and Properlis of No-Doped Bi+Ti:Orz

'..

endothermic peaks at approxirnate 60, 130 and 170"C, while exothermic peak at approxirnate

252,28A,307 and 501"C. The corresponding endotherrnic peaks could be ascribed

to

the vaporizationof

residual water and organic snbstances, which correspondto

a small weight loss. The exothermic peaks hetween 183 and 347"C could be explained by decompositionof

the nitrate and combustion/pyrolysis

of

the

Bi-Ti

organic chelating agent[49]. This

is supported by rnassive weight loss of about 39.8% on the TG curve.A

small exothermic peakat

final

weight loss couldbe

dueto

phase transitionfrom

amorphous oxidesto

BITcompound.

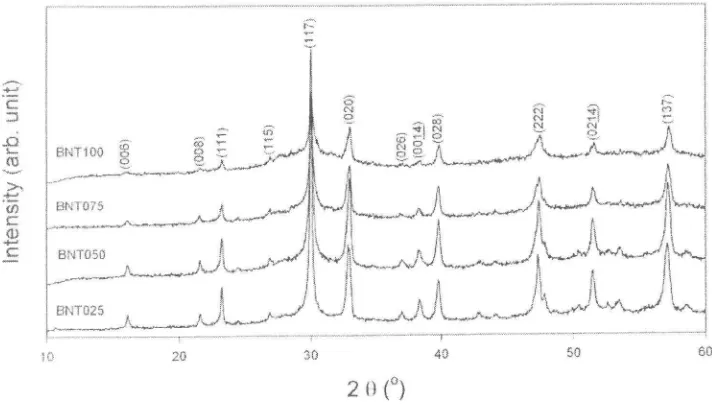

[image:5.509.68.424.191.395.2]2 {} {a) Figure 3. XRD patterns of BNT por'vders.

Figgre 3 shows the XRD patterns of BNT powders with various contents. The diffraction

peaks are inclexed using the standard data of BIT phase (JCPDS^73-2181). It was found that a

single phase was obtained for all compositions that indicates Nd3* ions were fully dissolved in the BIT solid solution. Additionally, the intensity of diffraction peaks were found to decrease ancl to have a broaden peak with Nd doping. Broadening of the peak indicates the decrease

of

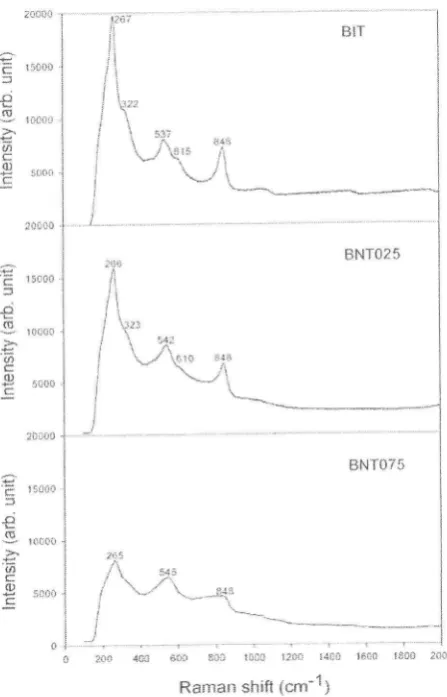

crystallite size [47].Figure 4 shows the Rarnan spectra of BIT, BNT025 and BNT075 at room temperature

from 100 to 2000 cm-1. The BIT exhibits a sharp and narrow peak with high intensity in five

Raman modes at267

,322,

537,615 and 848 cm-r.These modes characteristic changed with Nd content, which corresponded to the decrease

in intensiry and the increase in peak width. The peaks became broader and only showed three Raman modes as shown

in

BNT075. The interactionof

intemal modeof

TiOo octahedra appeared above 200 cm-1 dueto

large intragroup binding energyin

the octahedra and the mnch smaller lrass of Tia* ions [50, 5l ].In the case of BIT, the mode at 267 crn-l ascribed from the torsional bending of TiOo and those at 615 ancl 848 cm-l assigned to the stretching vibration. The mode at 322 cm-l was

from a combination

of

the stretching and bending vibrations. The modeat

537 cm-t was ascribed to the O-Ti-O stretching vibrations.149

=

J

.ciL

f0

z

qc

o

c

150 A. Umar Al-Amani, S. Sreekantan, M. N. Ahmad Fauzi, et' al

20css

'E l5*0t

-cj

I taoo,

>r

dt

c g scoo

c

eSttE

'* lsaoo

d

dl

+ t0060

>

'4 g 5oso

c

?*009

'E

''osd

€

*9 ,nooo

Et4

o

_--^=

cl-***?-

--"--t-.--o t4n ,{co 6t6 S$S 1883 t:tf l48e 1*fd l80s 200f

Raman shifl icnl'1)

Figure 4. Raman spectrum of BIT, BNT025 and BNT075 at room temperature.

G-t{

c0:

.co0Ffc-o lJ

Bi"o,

Ti-o

3r0$ 2t$0 ?006 150s

wsvenumher (cm't)

o #q a 6

I

$ C{

.aB F 1: :i: 1, t. i, ,{-::l f. :.ir*: .Sli ,{.i: .*,*

.l ;F,lt

iL: i.{, 1! ]la :g $ $ "t: $, .Yr a t; :1, i$. [image:6.516.153.377.67.416.2]'$::i:.,x,

[image:6.516.142.388.467.655.2]Synthesis and Propertis of No-Doped Bi+Ti:Orz ' '.

The FTIR spectra of BIT, BNT025 and BNT0?5 are shown in Figr.rre 5. Three adsolption bands appeared at 815, 587 and 418 cm-r were ascribed the perovskite-layered structure

of

BIT. The band at 815 and 587 crn-r belong to the Ti-O stretching vibrations while the peakaround

418

cm-r correspondedto

the

Ti-O

bending vibration.The

broad peak above 3000 cm-r and a small peak at 1645 cm-r were attributed to the stretching vibrationof

O-H groups and the bending vibrationsof

absorbed molecular water and 2-methaoxyethanol, respectively. The weak peak at 2365 crn-t belonged to the stretching vibrations of CO2, whilethe stretching vibration for carboxylic group (-COOH) was indicated by the presence of band at 1385

"*-t,

Th" bending vibrations of C-O were detected at 1052 cm-I, indicating that a few [image:7.508.82.420.291.482.2]organic groups were absorbed on the surface ofthe powders.

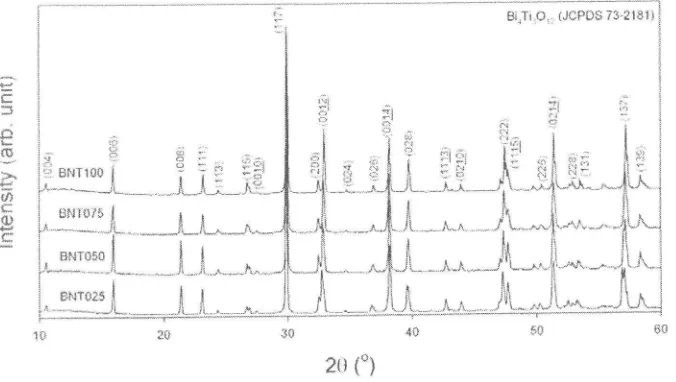

Figure 6 shows the XRD patterns of

BIT

and BNT ceramics sintered at 900oC for 3 h. Regardlessof

the Nd contents, all the ceramic samples were pure phase with no secondary phase.This

indicates thatthe

stabilityof BIT

phasewith

Nd

dopingat high

sintering temperature. Additionally, the intensityof

diffraction peaks was foundto

decrease with increasingNd

content.It

also suggested thatNd

doping hasa

significance effect on the crystallite size and lattice parameter of BIT.Bi,Ti.*,, (JcPos 73^:lsll

20 {o)

Figure 6. XRD pattems of BNT ceramics sintered at 900oC for 3 h.

Table 1. Average grain length and width of

BIT

and BNT ceramicsCompositions Average length (pm) Average width (pm)

BIT 10.66 t.5'7

BNTO25 8. l4 r.33

BNTO5O 6.88

l.l0

BNTO75 6.37 0.90

BNTlOO 5.

l9

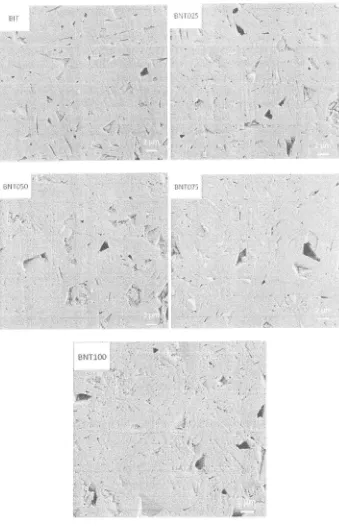

0.78Figure 7 shows the SEM micrographs of

BIT

and BNT ceramics.All

the ceramics withdifferent Nd content exhibited rod-like grains. The grain size of BIT was larger than that

of

151

=

c

-;

L

{B

's

f,

0)

$

, gNftO0 t

t

Bri l{i 5 I

*.-

*--lL,

I

afiroso I

**. " _. ^it*.. .

I

8r.rr025

il

'.r.i

[image:7.508.62.449.552.636.2]t52 A. Umar Al-Arnani, S. Sreekantan, M. N. Ahmad Fauzi, et. al

BNT, both in terms of grain length and width. Additionally, the grain size of BNT ceramics decreased

with

increasing Nd content. The calculated average grain length and thickness is presented in Tablel.

This indicates that Nd could act as grain growth inhibitor.gli I0t5

:r:

,l

[image:8.514.94.433.114.643.2]Synthesis and Propefiis of No-Doped Bi+Ti:Orz ...

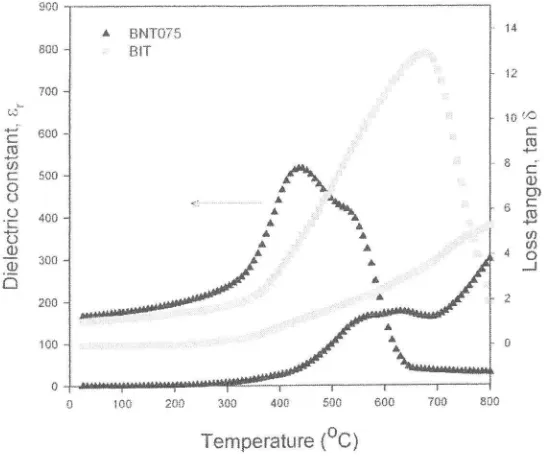

Figure

8

shows the temperature dependenceof

the

dielectric propeftiesof BIT

andBNT075 ceramics, measured at

I

MHz. With increasing temperature, the dielectric constant increases and has a maximum peak at the Curie temperature T.. The T" ofBIT

is 675"C. On the other hand, BNT075 has lorver T" valueof

434"C. This indicates that theT.

decreasedwith

Nd

doping. Additionally, the dielectric peak broadens with Nd doping, indicating thediffusing

of

the ferro-paraelectric phase transition. The paftial substitutionof

Ndfor

Bi

in BNT significantly reduced the loss tangent as shown in Figure 8.Temperature {oC)

Figure 8. Dielectric properties of BIT and BNT075 as a function of temperature.

153

ft,a

c

(osc

(u o) ac -nt a .A 4O J 2d

600($

a c 500

o o .g L 400

()

(l)

E

300(]

i1u 15, ttl I li: s (l ., "it fl;-5 I

:

l

l{

-1i i

{a) ilij

*

,il

*

.t

- i ...1

'.

.I..-1'-a'.

*

.'ir

t

e{t b

3

is uJ

*'

'|'i

Eir BtlrCzS FilrtlFC SNT0?$ tsri11{i0

{js*rps:r'!Jon

;i .50 .25 0 2$ 53 j5 103 F {kviint

154 A. Umar Al-Amani, S. Sreekantan, M' N' Ahmad Fauzi, et. al

The ferroelectric hysteresis loops of BIT and BNT ceramic measured at the applied field of 75 kVlcm are illustrated in Figure 9(a). The remanent polarization, 2P, and coercive field, 2E. were plotted

in

Figure 9(b).As

shownin

both figures, the 2P, and 2E" are strongly dependent on Nd content. The 2P, and 2E. increase from 0 to 0.75 and decrease beyond-that. Then, the BNT075 ceramics shows the maximum 2P, and 2E, valuesof

18.4pClcnz

and 100.6 kV/cm, respectively. These values are higher than that of BIT ceramicof

10.9 pC/cm2 and 50.6 kV/cm. This indicates that Nd doping improved ferroelectricity'CoNcr.usron

The single phase of

BIT

was obtained at different synthesis temperatures using the soft combustion technique. Nd-doped Bi+Ti:Orz was successfully investigated in tennsof

phase formation, structure,thermal

behavior,grain

morphology,dielectric

and

ferroelectric properties. Thermal analysis showed the reaction was highly exothermic and completed at 500"C. The influence of Nd doping on Raman mode and FTIR spectra was clearly observedin both analysis. Additionally, the grain size both the length and width exhibited in small size at higher Nd content. The maximum dielectric peak was found

to

be broaden and to have a reduced Curie temperature,T"

with

Nd

doping.The

ferroelectric properties was also improved with Nd content.ACXNOWLEDGMENT

The authors appreciate the technical support provided by School of Materials and Mineral

Resources Engineering, Universiti Sains Malaysia, Prof. Uematsu Keizo and Assoc' Prof. Tanaka Satoshi of Nagaoka University of Technology, Japan. This research was supported by

USM-RU grant 1001/PBahan/8042018 and l00liPBahan/81 1069.

RgrnRENcrs

t1]

Sedlar, M., Sayer, M., Ceramics International,22,3,1996.t2)

Yamaguchi,M.,

Kawanabe,K.,

Nagatomo,T.,

Omoto, O., Mrtlerials Science and Engineering B, 41,l,

1996.t3]

Madeswaran, S., Giridharan, N. V., Jayavel, R., Materials Chemistry and Physi$, $$,1,2003.

t4]

Park, B. H., Kang,B.

S., Bu, S. D., Noh,T. W',

Lee, J., Jo, W', Nature, 401,6754,

1999.

15]

Kojima,T.,

Sakai,T.,

Watanabe,T.,

Funakubo,H.,

Saito,K.,

Osada,M.,

AppliedPhysics Letters,80, 15, 2002.

t6l

Chon, U., Kim, K. 8., Jang, H. M.,Yi,

G. C', Applied Physics Letters, 79,2001'Synthesis and Propertis of No-Doped Bi+TirOrz

...

155t8]

Kim,

J. S., Lee, S.Y.,

Lee, H. J., Ahn, C. W.,Kim,

I.

W., Jang,M.

S., Journalof

Electroceramics, 21, 1-4 SPEC. ISS., 2008.

19]

Chen, M., Liu, Z. L., Wang, Y., Wang, C. C., Yang,X.

S., Yao, K. L., Physica StatusSolidi (A) Applied Reseqrch, 2A0, 2, 2A03.

[10]

Chen,M.,

Litt,Z.

L.,

Wang,Y.,

Wang,C.C.,

Yang,X.

S., Yao,K.L.,

Physica B: Condensecl Matter, 352, l -4, 2004.[11]

Mao, X. Y., Mao, F. W., Chen,X.8.,

Integrqted Ferroelectrics,79,1,2006.Uzl

Tang,Q. Y.,

Kan,

Y.

M.,

Li, Y.

G.,

Zhang,G.

J.,

Wang,P.

L.,

Solid

StateC ommun icati on s, 1 42, 1 -2, 2007 .

[3]

Wang, W., Zhu, J., Mao, X. Y., Chen,X.8.,

Journal of Physics D: Applied Physics,39, 2,2006.114]

Pineda-Flores, J. L., Chavira, E., Reyes-Gasga, 1.,Gonzai

lez, A. M., Huanosta-Tera,A,

Jow'nal of the European Ceraffiic Society, 23 , 6, 2003 .[15]

Chen, X. Q., Qi, H. Y., Qi, Y. J., Lu, C. J., Physics Letters, SectionA:

General, Atomic qnd Solid State Physics,346, l-3,2005.[16]

Cui, L.,Hu, Y. J., Physica B: Condensed Matter, 444,1,2009.[17]

Fan, S., Zhang, F., Wang, P., Ren, Y.,Journal of Rure Earths,26,4,2008.t18]

Kim, J., Kim, J. K., Heo, S., Lee, H.S.,Thin Solid Films,503,l-2,2Q06.[19]

Ke,H.,

Wang,W.,

Chen,L.,

Xu, J.,

Jia,D., Lu,

Z.,Zhou,Y'

Journalof

Sol-Gel Science and Technology, 53,l,

l20l

Cuo, D. Y., Li, M. Y., Liu, J., Fu, L., Wang, J., Yu, B. F., Yang, 8., Materials Science nnd Engineering B: Solid-State Materialsfor

Advanced Technology, 142,2'3,2007.l2l)

Bae, J. C., Kim, S. S., Choi, E. K., Song, T. K., Kim, W. J., Lee, Y .1., Thin Solid Filns,472.l-2,20A5,

1221

Tajiri, T.,

Sumitani,K.,

Haruki, R., Kohno,A.,

IEEE Transactionson

Ultrasonics, Ferroelectrics, and Frequency Control, 54, 12, 2007.l23l

Lu, C. J., Qiao, Y., Qi, Y. J., Chen, X. Q.,Zhu,I.S.,Applied

Physics Letters,87,22, 2005.l24l

Tomar, M. S., Melgarejo, R. E., Singh, 5.P., Microelectronics Journal,36,3-6,20A5.I25l

Bae, J. C.,Kim,

S. S., Park,M.

H., Jang,K.

W., Lee,Y.

I.,

Song,l.5.,

Journalof

Cr1,s 701 Grow lh, 268, 1 -2, 2004.

[26]

Kan,Y.M.,

Zhang, G. J., Wang, P. L., Cheng,Y.B., Jottnql

of the European Ceramic Society,28, 8, 2008.t27l

Kan,Y.,

Jin,X.,

Zhang, G., Wang, P., Cheng,Y. 8.,

Yan, D., Journal af MaterialsC hem is try, I 4, 24, 2004.

l2S]

SimApres,A. 2.,

Quinelato, C., Ries,A.,

Stojanovic,B.

D., Longo, E', Varela, J. A., Materials Chemistry and Pltysics, 98, 2-3, 2006.129) SirnApes, A. 2., Stojanovic, B. D.,Zaghete, M. A., Riccardi, C. S., Ries, A., Moura, F', Longo, E., Varela, J. A,, Integrated Ferroelectrics, 60,2004.

[30]

Yang,8.,

Zhang,D.M.,

Zhou, B., Huang, L.H.,Zheng, C.D., Wu, Y. Y., Gtto, D. Y,, Yu, J., Journal of Crystal Grov,th, 310, 21, 2008.[3 I

]

Chen, Y. C., Hsinng, C. P., Chen, C. Y., Gan, J. Y., Sun, Y. M., Lin, C. P., Thin SoliclFilms,5l3,l-2,2AA6.

I32l

Chen,Y.

C., Sun,Y.M.,

Lin, C. P., Gan,J.Y.,

Journal of Crystal Growth,268,1-2, 2004.1s6 A. Umar Al-Amani, S. Sreekantan, M. N' Ahmad Fauzi, et. al

t34l

Giridharan, N.,Supriya, S.,Thin SolidFilms,5l6,

16, 2008.t35]

He, H., Huang, J., Cao, L., Wang, L., Microelectronic Engineering, 85, 3, 2008't36]

Liu,W.L.,Xia,H.R.,Han,H.,Wang,X.Q,MaterialsResearchBulletin,39,9,2A04.

t37]

Liu,

w.

L.,

Xia, H. R., Han, H., Wang,X.

Q., Journal ofcrystal

Growth,264,l-3,

2004.l3S]

Liu, W. L., Xia, H. R., Han, H., Wang, X. Q., Materials Letters,58,24,2004'[39]

Liu, W. L., Xia, H. R., Han, H., Wang, X. Q., Iournal of Solid State Chemistry, 177,9,

2004.t40]

Zhang, S. T., Zhang, X. J., Cheng, H. W., Chen,Y'

F', Liu,Z'

G', Ming'N'

B', Hu, X' B., Wang,LY

., Applied Physics Letters, 83,21,2003 't41]

Kojima,T.,

Sakai,T.,

watanabe,T.,

Funakubo,H.,

Saito,K.,

osada,M.,

AppliedPhysics Letters, 80, 2002.

t42l

Patil,K. c.,

Aruna,s.

T.,Mimani,T.,

current opinion in solid stqte and Materials Science, 6, 6,2002.l43l

Lno, s., Tang,Z.,Yao, W., Zhang,z' Microelectronic Engineering, 66, l-4,2043.t44l

Berger, D., Matei, C., Papa, F., Voicu, G., Fruth, Y., Progress in Solid State Chemistry,35,2-4 SPEC. ISS., 2007.

t45]

Patil, K.C,

Bulletin of Materials Science, 16, 6, 1993'[46]

Ng, C. Y.,Razak, K. A., Journal of Alloys and Compotrnds,509,3,I47)

Razak, K. A., Yip, C. J., Sreekantan, S., Journal of Alloys and Compounds, 509' 6,t4g]

Goh, P. Y., Razak,K.A.,

Sreekantan, s., Journal of Alloys andcompounds,475,l'2,

2009.

I4gl

Du, X., Xu, Y., Ma, H., Wang, J., Li,x.,

Journal of the American ceramic society,9A, 5,2007.t50]

Kojima, 5., Ferroelectrics, 239,