UNIVERSITI TEKNIKAL MALAYSIA MELAKA

ERGONOMIC DESIGN OF COMPUTER NUMERICAL

CONTROL LATHE MACHINE WORKSTATION

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Manufacturing Management) (Hons.)

by

NUR HASRIN BINTI SABRI B051110342

900308-14-5382

DECLARATION

I hereby, declared this report entitled “Ergonomics Design of Computer Numerical Control Lathe Machine workstation” is the results of my own research except as

cited in references.

Signature :

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Manufacturing Management) (Hons.). The member of the supervisory is as follow:

DEDICATION

Special dedication to my parents, lecturers, siblings and friends for giving me knowledge and moral support to complete the project and reports

ABSTRACT

In manufacturing industry, the CNC lathe machine is widely used to improve productivity, repeatability and precision in machining process. However, the existing workstation of CNC lathe machine has contributed to unsafe working practices such as awkward postures, prolonged standing, repetitive movements and handling heavy loads which can lead to the muscle fatigue. In recognition the importance of these issues, the aim of this study is to improve the workstation design of CNC lathe machine. This can be achieved by redesigning the workstation according to ergonomics features required by the machinists. The ergonomics features were obtained through a questionnaire survey among 30 machinists. The machinists’ requirements were transferred into technical specifications by using House of Quality (HoQ). Then, the morphological chart was used to generate three conceptual designs of new workstation of CNC lathe machine. The final design of the workstation was drawn using CATIA software. The Rapid Upper Limb Assessment (RULA) was applied to analyze the working postures of machinists at the existing workstation and the redesigned workstation of CNC lathe machine. Based on the RULA analysis, the redesigned workstation of CNC lathe machine has improved the working postures of machinists. Hence, this study concluded that considering ergonomics features in the workstation design of CNC lathe machine contribute to safe working posture for the machinists.

ABSTRAK

Di dalam industri pembuatan, penggunaan teknologi mesin larik berkomputer (CNC lathe machine) telah digunakan secara meluas untuk meningkatkan ketepatan, kejituan dan produktiviti di dalam proses memesin. Walaubagaimanapun, penggunaan mesin larik berkomputer ini mewujudkan suasana kerja yang tidak selamat seperti postur kekok, berdiri untuk tempoh masa yang lama, pergerakan yang berulang-ulang serta mengangkat beban melebihi kemampuan jurumesin yang akan membawa kepada kelesuan otot kepada jurumesin. Setelah mengenalpasti isu ini, kajian ini dijalankan untuk melakukan penambahbaikan semula kawasan kerja mesin larik berkomputer. Ini boleh dicapai dengan merekabentuk semula kawasan kerja mengikut ciri-ciri ergonomik yang diperlukan oleh jurumesin. Ciri-ciri ergonomik yang diperlukan jurumesin diperolehi melalui kaji selidik daripada 30 orang jurumesin. Keperluan jurumesin akan diterjemahkan ke dalam spesifikasi teknikal dengan menggunakan ‘House of Quality’ (HoQ). Selepas itu, carta morfologikal digunakan untuk menghasilkan tiga konsep rekabentuk yang baharu untuk ruang kerja mesin larik berkomputer. Konsep terakhir dilukis dengan menggunakan perisian ‘CATIA’. Analisa ‘RULA’ akan dilakukan untuk mengkaji postur kerja jurumesin di mesin larik berkomputer yang sedia ada dan di mesin larik berkomputer yang diperbaharui. Berdasarkan analisis RULA tersebut, rekabentuk semula kawasan kerja mesin larik berkomputer (CNC lathe machine) dapat memperbaiki postur kerja jurumesin. Oleh itu, kajian ini membuat bahawa kawasan kerja mesin larik berkomputer yang diperbaharui dengan mengambil kira ciri-ciri ergonomik dapat menghasilkan postur kerja yang selamat kepada jurumesin.

ACKNOWLEDGEMENT

In the name of Allah S.W.T, The most Merciful and The most passionate, I am thankful to Allah for enabling me to complete this final year project and report.

First and foremost, I would like to thank my supervisor Dr. Isa bin Halim, lecturer of Faculty Manufacturing Engineering and my co-supervisor Miss Lee Mei Ph’ng, lecturer of Pusat Bahasa dan Pusat Insaniah (PBPI) for giving me a full cooperation and supervision during the making of this final year project report. Not to be forgotten, I would like to thank my family, sibling and my friends for contributing their ideas and give me a moral support in completing this project.

Last but not least, I would like to thank you for those who are directly or indirectly involved during this project and completion of this report. All of your kindnesses are very much appreciated.

LIST OF FIGURES

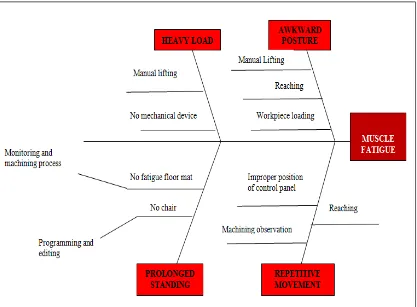

1.1 Relationship between the main effect and causation through 3 Ishikawa Diagram

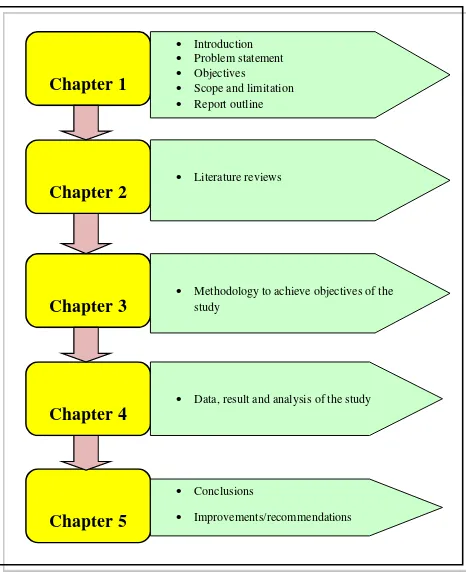

1.2 The report outline 7

2.1 VTL CNC lathe machine (left) and horizontal CNC lathe 9 machine (right) (Amtechmachine, 2008)

2.2 Matrix section of House of Quality (HoQ) 17 2.3 Customers’ satisfaction in Kano model 19

2.4 The Morphological tables 20

2.5 3D model of human body 24

2.6 RULA analysis final score 26

2.7 Working postures using RULA analysis 26

3.1 Process of developing questionnaire 33 3.2 Data from functional and dysfunctional question 35

3.3 Kano evaluation table 35

3.4 Result of Kano model 36

3.5 Customer satisfaction and customer dissatisfaction 37

3.6 The roof top of the HoQ 40

3.7 The structure of HoQ 41

3.8 Process flow in developing in HoQ 42 3.9 Rough sketch of the CNC lathe machine workstation 43 3.10 Rough sketch of the control panel 43 3.11 The morphological chart of the CNC lathe machine in 44

terms of ergonomics features

3.12 Scoring and screening method 45

3.13 Technical drawing of CNC lathe machine body 46

3.14 Process to obtain the actual conceptual modeling 47 3.15 The manikin name, gender, percentile and population 48 3.16 Standardize percentile for Malaysian 49

3.17 Manikin build in Human Builder 49

3.18 Flow charts in developing the manikin 50 3.19 RULA analysis obtained from the machinists while 51

operating the CNC lathe machine workstation

3.20 RULA score obtained from the machinists working postures 51

3.21 RULA analysis process 52

3.22 Summarized process to achieved the objective 53

4.1 Processes that contribute to the muscle fatigue 58 4.2 Level of the machinists’ physical fatigue 60 4.3 Level of requirements to the ergonomics features requirements 64 4.4 Customer satisfaction-dissatisfaction graph 66

4.5 Correlation trade-offs 70

4.6 The House of Quality (HoQ) 71

4.7 Isometric view of CNC lathe machine workstation 77 4.8 Front view of CNC lathe machine workstation 78 4.9 Machinists lifting the workpiece 81 4.10 RULA analysis for lifting the workpiece for the left sides and right sides 82 4.11 The machinists is hold a 10kg mass of workpiece 83 4.12 RULA score for the machinists while holding the workpiece 84

for the right and the left side

4.13 The machinists loading a workpiece into a chuck 85 4.14 RULA analysis score for loading workpiece for right side and left side 86 4.15 The machinists change a tool bit in a tool holder 87 4.16 RULA analysis for changing tool bit for the left side and right side 88 4.17 The machinists installing the program 89 4.18 RULA analysis for installing the program for left side and right side 90 4.19 Machinists handling the adjustable table with a roller conveyor system 91

4.20 RULA score for machinists working postures in handling 92 the adjustable table with a roller conveyor system

4.21 Machinists uses the control button that attached on the 93 adjustable table with a roller conveyor system

4.22 RULA score for the left and right sides of the machinists’ working 94 postures in operating the control button at the adjustable table

4.23 The machinists’ new working postures of changing the tools bits 95 4.24 RULA score for machinists’ new working postures in changing the tool 96

bits

4.25 The new working posture of machinists when operating 97 the adjustable control panel

4.26 RULA score for the left sides and right sides of the 98 machinists’ working posture

LIST OF TABLES

2.1 The examples of the proactive and reactive approach 12 2.2 The examples of engineering control and administrative control 14 2.3 Examples of three categories of attributes 18 2.4 Explanation about the four tools used in CATIA 23 2.5 Final scores range from 1-7 developed by McAtamney and 25

Corlett (1993)

2.6 Differences between previous study and current studies 27

3.1 Machinist requirements based on relative important 38 3.2 Voice of customer translated into Voice of engineer 39

4.1 Age categories 55

4.2 Heights of the machinist 55

4.3 Experiences in handling the CNC machine 55 4.4 Tasks that contribute to the difficulties experienced by the 56

machinists before handling the machine

4.5 Tasks that contributed to the difficulties experienced by the 57 machinists during operating the machine

4.6 Task that contributed to the difficulties experienced by the machinists 58 after operating the machine

4.7 The relative importance of the ergonomics features 63

4.8 Kano table 67

4.9 Voice of Customer 68

4.10 Relative importance of VoE 69

4.11 Morphological charts of the CNC lathe machine design 72 4.12 Conceptual designs of CNC lathe machine workstation 74

4.13 Screening procedure for each conceptual design of 76 workstation of CNC lathe machine

4.14 Comparison of the newly designed CNC lathe machine workstation 99 with the existing CNC lathe machine workstation

TABLE OF CONTENT

List Abbreviations, Symbols and Nomenclatures xi

CHAPTER 1: INTRODUCTION 1

CHAPTER 2 : LITERATURE REVIEW 8

2.1 Ergonomics Features Requirement of the CNC Lathe Machine 8 2.1.1 Workstation Design of CNC Lathe Machine 8 2.1.2 Ergonomics Features in CNC Lathe Machine 10 2.1.3 Methods to Determine the Ergonomics Features 11 2.1.4 Survey by using Questionnaire 12 2.2 Redesigning the CNC Lathe Machine 13 2.2.1 Administrative Control and Engineering Control 13

2.2.2 Pilot Study 14

2.2.3 Quality Function Development (QFD) 14

2.2.4 Kano Model 17

2.2.5 Morphological Chart 20

2.3 Validation of Working Posture CNC Lathe Machine 21

2.3.1 CATIA Software 21

2.3.2 RULA analysis 24

2.4 Difference between Previous Studies and the Current Study 27

CHAPTER 3: METHODOLOGY 30

3.1 Ergonomics Features Requirement in CNC Lathe Machine 30 3.1.1 Questionnaire Development 30

3.1.2 Pilot Study 30

3.1.3 Alpha Cronbach 30

3.1.4 Respondents 33

3.1.5 Survey Period 33

3.1.6 Survey Method 34

3.2 Redesign the CNC Lathe Machine 34

3.2.1 Kano Model Analysis 34

3.2.2 House of Quality (HoQ) 37

3.2.3 Sketching 42

3.2.4 Morphological Chart 44

3.2.5 Scoring and Screening 45

3.2.6 CAD/CATIA Software 42

3.3 Validation of working posture at CNC Lathe Machine 47 3.3.1 Manikin development in body posture analysis 47 3.3.2 RULA analysis by using CATIA Software 50

CHAPTER 4: RESULT AND DISCUSSION

4.1 Ergonomics Features Required by the Machinist to Improve 54 the Workstation Design of CNC Lathe Machine

4.1.1 Background Information 54

4.1.2 Difficulties Experienced in Handling the 56

4.1.3 Parts of the bodies that experienced physical fatigue 59 by the machinists

4.1.4 Ergonomics Features Requirements

4.2 Redesign the existing CNC lathe machine 65

4.2.1 Kano Method Analysis 65

4.2.2 House of Quality (HoQ) 67

4.2.3 Morphological Chart 72

4.2.4 Final design 77

4.3 Validation of working postures analysis at existing 80 CNC lathe machine

4.3.1 Working postures analysis at the existing CNC lathe machine 80 4.3.1.1 Working posture while lifting the work piece 80 4.3.1.2 Working postures while hold the workpiece 83 4.3.1.3 Working posture while loading a workpiece 85 4.3.1.4 Working posture while changing the tool bit 86 4.3.1.5 Working Posture while Installing the Program 89 4.3.1.6 Working postures analysis at the redesigned 91

CNC lathe machine workstation

CHAPTER 5: CONCLUSION AND FUTURE WORK 100

5.1 Ergonomics Features to Improve Existing Workstation 100 Design of CNC Lathe Machine

5.2 Redesign the Existing Workstation of CNC Lathe Machine 100 5.3 Validation of Working Posture at Redesigned CNC Lathe Workstation 101

This chapter contains of background of study, the problem statement, objectives of study, and scope and limitation of study.

1.1 Background of Study

In industrial sectors and educational institutions nowadays, Computer Numerical Control (CNC) machines are commonly used to produce parts from the simplest to complex shape. There are different types of CNC machines such as lathe, milling, and grinding. The CNC lathe machine is usually use to make boring or drilling holes, cylindrical, conical and flat shape machining operation. To perform machining operation in CNC lathe machine, a machinist has to program the machine using unique software and G-code language setup. The advantages of applying CNC lathe machine in machining operation are high productivity, precision and accuracy.

Even though the CNC lathe machine can contribute to enormous profits to industry practitioners; however the machine can lead to occupational injuries due to lifting of heavy or large workpieces, accidents while starting the machine, and unclean mating surface causing the object to slip (Rey Y, Dec 2009). In addition, the machinists might be exposed to low back pain, shoulder pain, and neck pain due to improper design of control panel of CNC lathe machine (Krishnamoorthy et al., 2012). Other factors that contribute to the injuries are handling heavy workpieces, repetitive motions, and awkward working posture (Imtiaz Ali khan, 2012). A previous study reported that the

INTRODUCTION

CHAPTER 1

machinists experienced muscle fatigue in the legs due to standing in a long period of time.

There are several tools that can be utilized to improve the design of CNC lathe machine. One of the popular tools that commonly used is the Quality Function Development or known as QFD (Akao, 1990). The QFD is an approach to determine the technical and ergonomic design requirement characteristics of new or innovated product to meet the users’ requirements. This method translates the Voice of Customer (VoC) obtained from questionnaire to fulfil the customer satisfaction (Adila Md Hashim et al., 2012). To generate the result, users’ requirements will be summarized in the House of Quality (HOQ).

By realizing these needs, the aim of this study is to improve CNC lathe machine workstation by redesigning it according to the ergonomic features and customer's requirements by focusing to the common risk of factor occurred. To do so, the QFD tools are needed for this study.

1.2 Problem Statement

Based on on-site observation, the existing design of CNC lathe machine requires further improvement in terms of ergonomics as it leads to muscle fatigue that can be summarized as follow:

1. Awkward posture: The machinists adopted awkward postures associated with trunk flexion while loading the workpiece into the machine chuck. This is due to the machinists that have to bend forward to reach and manually lift the material from the buffer area. This may cause the machinists to feel pain especially in their arms, shoulder and neck (Imtiaz Ali khan, 2012).

2. Prolonged standing: The machinists are exposed to prolong standing while performing monitoring, observation, programming and editing process. This happens as a result of not having a chair and floor fatigue mat at the workstation. This process will lead to muscle fatigue to the machinists. They tend to sense this

muscle fatigue especially on their lower back, knees and legs (Isa Halim et al., 2012).

3. Repetitive movements: The machinists operations in repetitive movements were during the machining and observation. Others than that, the improper position of control panel also leads to the repetitive movements. Nowadays, there are too many designs build out there which do not fulfil the anthropometry standard for Asians. This may exposed the machinists to serious injuries and illness. They may experience musculoskeletal disorder such as neck pain, shoulder pain and back pain if there is no improvement occurred (Krishnamoorthy et al., 2012).

4. Heavy load: The machinists need to carry heavy load of the raw material manually during the workpiece loading. Until now, there is no mechanical device being provided. This may exposed the machinists to experience pain in their arms due to this activity (Imtiaz Ali Khan, 2012).

As a consequence of this ergonomic risk factor, this working condition may reduce the productivity, accuracy and efficiency of the industry. By referring to Figure 1.1, the relationship between the main effect and causation can be found through the Ishikawa Diagram.

Figure 1.1: Relationship between the main effect and causation through an Ishikawa Diagram

1.3 Objectives of Study

To provide solution for the above mentioned problems, this study is carried out to achieve the following objectives:

1. To determine ergonomics features required by the machinists to improve the existing CNC lathe machine workstation design.

2. To redesign the existing workstation design of CNC lathe machine by taking into account ergonomics features required by the CNC lathe machinists.

3. To validate the working postures of machinists while performing jobs at the redesigned CNC lathe workstation.

1.4 Scope and Limitation of Study

This study performs ergonomics improvement on a Haas CNC lathe machine manufactured at York Country, Virginia that is available in CNC laboratory in Faculty of Manufacturing Engineering, Universiti Teknikal Malaysia Melaka (UTeM). In the design of the CNC lathe machine, the following ergonomics risk factors were critically studied: unsafe working postures adopted by the machinists while inserting the workpieces into the machine chuck, prolonged standing while the machinists monitors the machining process, and unsafe working posture while the machinists editing and programming the G codes in the control panel of machine.

As a limitation of the study, the ergonomics design applied in the CNC lathe machine focus on workpieces loading mechanism, standing platform, and control panel. These improvements were applied in the existing CNC lathe machine workstation through computer aided design, and their effectiveness was validated based on simulation study. In other words, there was no actual fabrication and assessment done for the redesigned workstation.

1.5 Report outline

In chapter one, it provides an introduction of the study, the problem statements of the study, objectives, scope and limitation of the study and also the report outlines. The main objectives of the project are: to determine ergonomic features required by the machinists to improve the workstation design of the existing CNC lathe machine; to redesign the existing workstation design of CNC lathe machine by taking into account ergonomics features required by the machinists; and to validate the working posture of machinists while performing jobs at redesigned CNC lathe workstation. The scope and limitations of the project explain the range of the project that will be done and the limits of the project itself.

In chapter two, the literature review is provided in order to support the discussion and the methodology of study. The literature review was performed by online search through journals and other reliable resources.

Chapter three discusses the method applied to redesign the CNC lathe machine workstation. The questionnaire survey was used to obtain the machinists requirements. Next, the Kano model was used to evaluate the satisfaction-dissatisfaction of the machinists. Then, the machinists’ requirements were translated from Voice of Customer (VoC) into the Voice of Engineer (VoE). Next, the conceptual design of the CNC lathe machine workstation was determined by using morphological chart, screening and scoring method. The final design of the workstation draws by using the CATIA software. Lastly, the working postures of the machinists were validated by using RULA analysis.

Chapter four presents the data and results obtained through the questionnaire survey, House of quality (HoQ), morphological chart, scoring and screening method and RULA analysis.

Last but not least, chapter five concludes the findings of study and it provides recommendations for future works. Figure 1.2 illustrates the report outline.

Figure 1.2: The report outline

Chapter 1

Chapter 2

Chapter 5

Chapter 4

Chapter 3

• Introduction • Problem statement • Objectives

• Scope and limitation • Report outline

• Conclusions

• Improvements/recommendations • Data, result and analysis of the study • Methodology to achieve objectives of the

study

• Literature reviews

While the previous chapter introduces the background of the study, this chapter continues with the literature review on the following subjects: features and ergonomic requirements regarding CNC lathe machine; and validate the working postures in terms of ergonomics features. The information and knowledge are obtained through hardbound and online journals, relevant articles and reference texts.

2.1 Ergonomics Features in CNC Lathe Machine Design

2.1.1 Workstation Design of CNC Lathe Machine

Nowadays, the CNC lathe machine is widely used in the manufacturing industry and metalworking industry because it can increase productivity and reduce downtime (Tufan and Erhanbozdag, 2006). The CNC lathe tools are usually controlled by a computer program. It is used to produce parts from the simplest to the most complex shapes either in small or large batch sizes. Generally, the CNC lathe machine can be classified into two types; vertical (VTL) and horizontal orientations as shown in Figure 2.1.

LITERATURE REVIEW

CHAPTER 2

Figure 2.1: VTL CNC lathe machine (left) and horizontal CNC lathe machine (right) (Amtechmachine, 2008)

The VTL machine consists of a spindle that can move along the z-axis. On top of that, it provides the headstock that place in the floor and the potter wheel to handle a heavy and large workpieces. Due to this element, it can complete the machining process by single setup; and at the same time, the time and cost will be saved. For the horizontal CNC lathe machine, it consists of a variety of cutters that can easily change. Generally, it performs a face cutting by using spindle and allows side, face and form machining in only one operation. Besides that, the horizontal spindle make the workpiece to spin and the cutting tools are moved across it in the z-axis and x-axis.

Basically, the CNC lathe machine has its own workstation design. Commonly, a workstation contains of one or two workers to perform a job. In the workstation, the workers need to prepare the materials and equipment to perform a job. Therefore, this workstation needs to be design according to the worker's convenience. On top of that, the workstation has to be built according to worker anthropometry to minimize the