UNIVERSITI TEKNIKAL MALAYSIA MELAKA

Design and Development of Safety Pedal Lock

for Manual Gear’s Car

Thesis submitted in accordance with the partial requirements of the

Universiti Teknikal Malaysia Melaka for the

Bachelor of Manufacturing Engineering (Manufacturing Process)

By

Khor Teik Lim

Faculty of Manufacturing Engineering

UTeM Library (Pind.1/2007)

Saya _____________________________________________________________________

mengaku membenarkan tesis (PSM/Sarjana/Doktor Falsafah) ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut:

1. Tesis adalah hak milik Universiti Teknikal Malaysia Melaka .

2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan untuk tujuan pengajian sahaja.

3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi.

(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

(TANDATANGAN PENULIS)

DECLARATION

I hereby, declared this thesis entitled “Design and Development

of Safety Pedal Lock for Manual Gear‟s Car” is the results of my own research except as cited in references.

Signature : ……….

Author‟s σame : ………

Date : ………

APPROVAL

This PSM submitted to the senate of UTeM and has been as partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Process).

The members of the supervisory committee are as follow:

ABSTRACT

ABSTRAK

DEDICATION

ACKNOWLEDGEMENTS

First, I would like to thank my Projek Sarjana Muda (PSM) Supervisor, Mr. Mohd. Amran Bin Md. Ali for his continuous support during my PSM program. Mr. Amran was always there to listen and give advice. He taught me how to accomplish my studies and express my ideas. He also showed me special ways to approach analysis and research problems and the need to be determined to achieve any goals.

In the meantime, I would also like to thank the other two cooperated PSM panel, Prof. Dr Md Dan and Mr. Abd. Halim Hakim for given me an opportunity to present my found. Then, I am also greatly thankful to UTeM‟s lecturers, for getting me interested in design methods, introducing me to CAD programs and concepts, and also teaching me about the entire programming skills.

TABLE OF CONTENTS

List of Abbreviations, Symbols, Specialized Nomenclature ………xiii

1. INTRODUCTION………...1

2.3 Factors of Safety and Design Codes………..13

2.4 Theory of Forces and Loading ………..14

2.4.1 Definition of Force………14

2.4.2 Loading………..15

2.4.3 Stress……….16

2.4.4 Theory of Bending………20

2.5.1 Iron………22

3.2 Description of Project Development………..39

3.3.2 Description of Data Collection……….44

3.4 3D Modeling Design Concept………...45

3.4.1 Description of Initial Design Plant Sketching………..46

3.5 3D Modeling Mechanical Drawing………...47

3.5.1 Description of Data Collection……….48

3.5.2 Description of Mechanical Drawing……….48

3.6 Product Fabrication and Assembly Development………..50

3.6.1 Description of Milling Process……….50

4.5 3D Modeling Structural Analysis………59

4.6 Product Fabrication and Assembly………62

5. DISCUSSION……….67

5.1 Introduction………67

5.2 Concept Generation and Selection……….68

5.3 Finite Element Analysis Method………...70

6. CONCLUSION……….71

APPENDICES

A Duration of PSM I Gantt-chart B Gantt-chart of PSM I

C Duration of PSM II Gantt-chart D Gantt-chart of PSM II

E Sketching 1 of Safety Pedal Lock F Sketching 2 of Safety Pedal Lock G Sketching 3 of Safety Pedal Lock H 2D Orthographic of Safety Pedal Lock

I 2D Orthographic of Safety Pedal Lock Lower Part J 2D Orthographic of Safety Pedal Lock Upper Part K 3D Modeling of Safety Pedal Lock

L 3D Modeling of Safety Pedal Lock Lower Part M 3D Modeling of Safety Pedal Lock Upper Part

LIST OF FIGURES

2.1 Steering Column Lock 4

2.2 New Lock Design 4

2.3 The Rover Sterling 800 Security Concepts Car 5

2.4 The View of Carryboy 3 Lock 6

2.5 The Main Concepts of the Carryboy 3 Lock 7

2.6 The Installation of Carryboy 3 Lock to Car Pedal 7

2.7 The view of Multiple Pedal Lock 7

2.8 The Latest Car lock System 8

2.9 The Stop-lock Steering Wheel Lock 8

2.10 The Anti-theft Steering Wheel Lock 9

2.11 Mul-T-Lock Gear Lock 10

2.12 Universal Fitting Gear Lever to Handbrake Lock 10

2.13 The Common Pedals Assembly in Car 11

2.14 The View of σissan Silvia‟s Pedals 11

2.15 The View of Toyota KE-70‟s Pedals 12

2.16 The View of Nissan Silvia 180-SX‟s Pedals 12

2.17 Toyota Corolla AE-86‟s Pedals 12

2.18 Perodua Kelisa‟s Pedals 13

2.19 Example of Forces in Equilibrium 14

2.20 Load Classified as to Location and Method of Application 15 2.21 Example of the Deformation in a Bar under Tension 17 2.22 Short Timber Post under Compression due to Load P 17 2.23 Stress Element Showing General State of 3D Stress with origin

Placed in Center of Element

18

2.24 The Stress Element Showing 2D State of Stress 19

2.25 Stresses Acting on Octahedral Planes 19

2.26 Bending of a Beam due to Concentrated Load P 20

2.27 Example of Bending of a Simply Supported Beam Showing Compression and Tension of the Outer Surfaces

2.28 Example of the Deflection in a Wood 2 x 4 beam Turned Flatwise and Edgewise

21

2.29 Schematic of the SRV Test Configuration 29

2.30 Schematic Diagram Showing the Relationship among the Temperature, Phase Transformation and Mechanical Response

29

2.31 The Major Components of Wet-coating 32

2.32 Typical Spray-gun and theirs Spray Techniques 34 2.33 The View of Horizontal and Vertical Milling Machine 37

2.34 The TIG Welding Circuit 38

2.35 Parts of the TIG Torch 38

3.1a Project Development Flow-chart 40

3.1b Project Development Flow-chart (continue) 41

3.1c Project Development Flow-chart (continue) 42

3.2 Flow-chart of Study and Preparation 45

3.3 Sketching View of Manual Car‟s Pedal 46

3.4 Flow-chart of Designing Concept 47

3.5 Flow-chart of Mechanical Drawing 49

3.6 Flow-chart of Fabrication and Assembly Development 51

3.7 Flow-chart of Analyses Development 53

4.1 The Application of Pedal Lock on Perodua Kelisa‟s Pedals 54 4.2 The View of Safety Pedal Lock on Relevant Pedals 55

4.3 The View of Pedals of Perodua Kelisa 55

4.4 The Upper-part Sketching 56

4.5 The Lower-part Sketching 56

4.6 The Prototype Front and Top View 57

4.7 The Product Functional 57

4.8 The Detail of Product 58

4.9 The Isometric View of Upper and Lower Parts 58

4.10 Isometric View of 3D Modeling Assembly 59

4.12 The Load Apply on 3D Modeling 60

4.13 Result of Displacement Analysis 60

4.14 Result of Stress Analysis 61

4.15 Result of Factor of Safety Analysis 61

4.16 The View of Product before Assembly 62

4.17 The View of Product after Assembly 62

4.18 The View of Product with Lock Holder 63

4.19 The View of Complete Product without coating Process 63

4.20 The Detail of Assembly Part 64

4.21 The Detail of Bottom-part Lock-up Area 64

4.22 The Detail of Upper-part Lock-up Position 64

4.23 The Detail of Pedal Holder Position 64

4.24 Safety Pedal with Under-painting 65

4.25 Product View after Fine Painting 65

4.26 Front-view of Finish Safety Pedal Lock 66

4.27 Top and Bottom View of Finish Safety Pedal lock 66

5.1 Iteration Cycle in the Product Development 67

5.2 Concept Generation Development Phase 68

LIST OF TABLES

2.1 Factor Used to determine a Safety Factor for Ductile Materials 13 2.2 The Percentage of Carbon Alloyed with Iron Defines the Final

Material

22

2.3 Constitution of Various Cast Irons 23

2.4 General Rules to Classify Steel Based on its Carbon Content 25

2.5 Theoretical Coverage for a gallon of Paint 31

2.6 Functional of Pigment 33

2.7 Common Solvents used in the Formulation and Thinning of Protective Coatings

LIST OF ABBREVIATIONS, SYMBOLS, SPECIALIZED

FMVSS - Federal Motor Vehicle Safety Standards GMAW - Gas Metal Arc Welding

LPB - Low Plasticity Burnishing LSP - Laser Shock Processing

NHTSA - National Highway Traffic Safety Administration NRMA - σational Roads and Motorists‟ Association PIAM - General Insurance Association of Malaysia PVD - Physical vapour Deposition

SAW - Submerged Arc Welding SMAW - Shielded Metal Arc Welding

Ti - Titanium

TIG - Tungsten Inert Gas

TiN - Titanium Nitride

W - Tungsten

CHAPTER 1

INTRODUCTION

1.1 Background

This project focuses on designing and developing of safety pedal lock for manual gear car. The Solidworks software was used to design the safety pedal lock because the Solidworks software is easily to sketch and design however it can be used to do analysis processed besides sketching. Furthermore, there was fabrication and assembly work; thus the relevant machining processes such as millings, drillings, and welding were involved. Meanwhile, there was some analysis by Solidworks software which to improve the productivity of product. This safety pedal lock is an additional lock for manual gear car besides gear‟s locks and steering locks.

According to the General Insurance Association of Malaysia (PIAM) analysis, the vehicle theft was a serious problem in society today. Based on the latest statistics from the General Insurance Association of Malaysia (PIAM) had shown that Proton has had the highest number of cars reported stolen for the first half of the year. Theft of Proton cars accounts for about 51 per cent of the total 2,436 private cars reported stolen to insurers during the period [22]. This means, on average, about 7 Protons are reported stolen every day. However, the theft prevention studied of United State showed that the vehicle theft was the nation‟s number one property crime, which will be occurred every 25.3 seconds and costing over 8.4 billion dollar each year [23].

1.2 Objective

The aim of this project is to design and development of safety pedal lock for manual gear car. While the main objectives are:

1. To design and develop the safety pedal lock for manual gear car. 2. To design 3D modeling using Solidworks software.

3. To analysis 3D modeling using Solidworks software. 4. To fabricate safety pedal lock.

1.3 Scope

This safety pedal lock is helpful because it can provide an additional security to the users‟ vehicle, which can prevent the stolen in a very short period. Besides that, the product was advantage than the concurrent gear and steering lock because most of the locking system solutions were being decode, therefore the safety pedal lock can provide more security to the users.

1.4 Problem Statement

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

Nowadays, the vehicle theft was the nation‟s number one property crime; therefore there were several of safety devices such as alarms system, gear lock, steering lock and door lock that had been created to car theft.

Traditionally, car alarms were the primary resource in protected vehicle from thieves. These alarms had been developed from silent to talking alarms; meanwhile the car alarm industry has invented everything under the sun to put the car owners‟ minds at ease about the safety of motor vehicles. Unfortunately, car alarms were not enough to prevent thieves from seizing a car or truck [23]. However, in the United States a study by General Motors found that cars fitted with alarm systems as standard equipment were 20% less likely to be stolen than equivalent cars without alarms (Clarke 1987) [26].

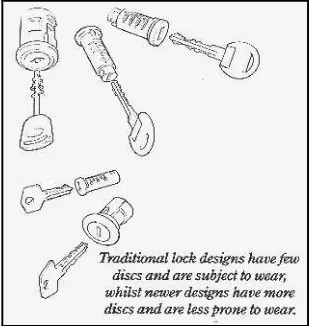

in West Germany in 1963 (Mayhew et al. 1976). Figure 2.1 and Figure 2.2 were showed the common lock for car steering and car door [12].

Figure 2.1: Steering Column Lock

Figure 2.2: New Lock Designs

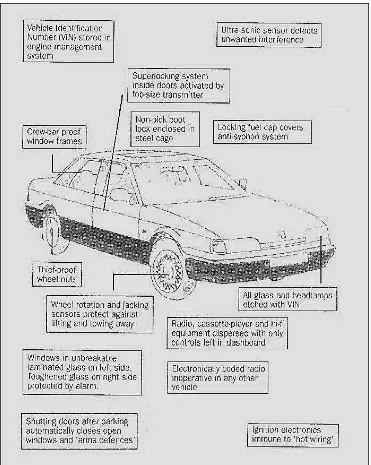

Figure 2.3: The Rover Sterling 800 Security Concepts Car

2.1.1 Pedal Lock

The first lock as shown in Figure 2.4 was 9 rings core code key system that 100% protection from any unauthorized keys. Then, second lock has had a key hole which is specially designed to spin around if drilling was attempted. It was followed by third lock that the hardened steel padlock protected from hack-sawing or damaged by jack. After that, the slide arm that used to lock by just pull the arm, then the first and second locks will be engaged simultaneously within a second. Besides that, lock body for the device was manufactured from high grade tensile steel and the lock casing fabricated by high-grade tensile steel that with firearm grade. Finally, the lock was fitted on floor to prevent the exhausted of steering column if attempts were made to force entry. However, this lock was not familiar to be used because it was very complexity and higher cost. Therefore, it was not recommended for some vehicle. Figure 2.5 shows the main structure and function of the lock while Figure 2.6 shows how the lock was being installed onto pedals‟ side [37].

In addition, Figure 2.7 shows the pedal that being used in market today. This lock had a handle of first lock, security ring of second lock, and locks for clutch and break pedal arm. Figure 2.8 was showed the summarization of common types of safety devices that were applied in automobile technology today [39].

Figure 2.5: The Main Concepts of the Carryboy 3 Lock

Figure 2.6: The Installation of Carryboy 3 Lock to Car Pedal