ISSNI

:

zo88-8

86+

Proceeding

ZO11

lnternatfonal

Conference and

Exhibition

Sustainable Energy

and

Advanced

Material

SUSTAINABLE

ENERGY

SUPPORTED

BY

ADVANCED

MATERIAL

TECH

NOLOGI

ES

F]:kt'"

#'ffi

t. 't,,..

Surakarta,

Octob

er

3-4'n,

zott

Chairman

Dr.

techn. Suyitno

Universitas Sebelas Maret, lndonesia

Organizing

Committee

Dody

Ariawan

t-.lniversitas Sebelas Maret, lndonesia

Didik Dioko

S.Universitas Sebelas Maret, lndonesia

Safarudin

Ghazali

Herawan

Universiti Teknikal Malaysia Melaka,

Malaysia

Mohd"

Azlibin

Salim

Universiti Teknikal Malaysia Melaka, Malaysia

DR. Bagas

Wardono

Jubail University College, KSA

Secretary

Ubaidillah

Universitas Sebelas Maret, lndonesia

Wahyu

Purwo

Raharjo

Universitas Sebelas Maret, lndonesia

Thesaurus

Wibawa

Endra

Juwana

Universitas Sebelas Maret, lndonesia

Dharmanto

Universitas Sebelas Maret, lndonesia

Advisory

Board

South

East Asia Region

Prof.

Dr.

Kuncoro

Dihardio

LJniversitas Sebelas Maret, lndonesia

Prof.

Dr.

Neng

Sri

Suharty

Universitas Sebelas Maret, lndonesia

Prof. Dr.-lng.

Harwin

Saptoadi

Universitas 6ajah Mada, lndonesia

Prof.

Dato'

Dr.

Ahmad

Yusoff

Universiti Teknikal Malaysia Melaka,

Malaysia

Prof.

Dr.

Md

Razalibin

Ayob

Universiti Teknikal Malaysia Melaka, Malaysia

Prof.

Dr.

Md. Radzaibin

Said

Universiti Teknikal Malaysia Melaka,

Malaysia

Prof. Madya Abd

Salam

bin Md.

I

anrr

Universiti Teknikal Malaysia Melaka,

Malaysia

Prof. Madya

Juharibin

Ab

Razak

Universiti Teknikal Malaysia Melaka,

Malaysia

Prof. Madya

Ahmad

Rivai

Universiti Teknikal Malaysia Melaka,

Malaysia

Dr. Eng.

YuliSetyo

lnstitut Teknoio:

3--

:-rrq

Dr.

lr.

Rahman

Setirau*mnlnstitut

Teknolos: 3:-:

--9,

Dr.

Dipl.lng.

Berkah

FaflnrUniversitas Diponegor:

Dr.

techn.

Rahm i Andanfinfrlnstitut

Teknologi Sepu--lndonesia

America

Region

Dr.

techn.

Zainal

Abidin

Southwest Research

lnstit;::

-r'S$'Europe

Region

Dr.

techn.

Peter

Haselbactrs

TU Craz, Austria

Middle

East Region

DR. Bagas

Wardono

Prof. Madya

Dr. lr.

Abd Talib

bin

Jubail University College,Kingcc-Din

SaudiArabiaUniversiti Teknikal Malaysia Melaka,

Malaysia

Dr"

Khisbullah

Hudha

Universiti Teknikal Malaysia Melaka,

Malaysia

Dr.

techn. Suyitno

Universitas Sebelas Maret, lndonesia

lr.

Ari

Handono Ramelan,

PhD.

Universitas Sebelas Maret, lndonesia

Dr.

rer. nat.

Atmanto

Heru W.

Universitas Sebelas Maret, lndonesia

Dr. Eng.

Agus

Purwanto

Universitas Sebelas Maret, lndonesia

Dr.Mont. Mohammad

Zaki

Mubarok

TABI.E GF EONTE&IT

ADVISORY BOARD

TOPICS COVERAGB

PREFACE

TABLEOF

CONTENT KEYNOTEPAPERI

ii

iii

iv

viii

cFD

Analysis of Eubble Distribution in Non*Catalytic Reactor for Production of Biodiesel FuelDyah Wulandani, Tomaki Miura, Annansyah

H.

Tambunan,Hiroshi Nabetani and Shoii HagiwaraReal-time Electrical Power Monitoring Designed by using Microcontrolier ATMega-5l Muhammad Nizam, B ambang Kusha$ anta'

Muh'

Thayibvartical

Axis Marine cunent Twbine Development in Indonesian Hydrodynamic Laboratory-Surabaya for Tidal Fawer PlantErwandi,

Alan

K,

F'

Sasako, Rina,B'

Wiianarko' E' Marta' D' RahunaAn Experimental study of Leakage Rate through Rubber-seal of LPG Bottle Valve Used in

Household Gas Stove Burner

I Made Kartika Dhiputra, Raka Cahya Pratama'

I

Nym Guni RidhantaStudy Optimization

of

Jafopha Fruit Coat H1'drolysis Phase*---'

iraptiningsih,

G. Adinurani, Tony Liwang, salafudin, Leopold, o. Nelwan, YoiePhianus Salcri RaY, HendrokoEffect of Aluminum Surface Temperature Variations to Heat ftarrsfer Characteristics in Salt

Water DroPlet Collision DYnamics

Slamet Wahyudi, PwtuHadi Setyarini' Surya Calcrawiiaya

Optimizing the Selection of Potential Species of Oil-Producing Microalgae

to-suppott"f"onomic Feasibility of Fiodiesei.Froduction

"Muiizat

Kawaroe, Ayi Rachmat, and Abdul Days

Mitigation of Green House Gases Emission in cassava

Mill:

case study in Lampung,Indonesia

Udin Hasanudin, Agus Haryanto, Erdi Suroso

The Effeot of Palm Oil Methyl Esthers Blends on the Combustion and Emission of Direct Injeotion Diesel Engine

Bagus Anang Nugroho, Bambang Sugiarto' and Prawoto

A Mathematical Model for Predicting the Performance of a Horizontal Axis River current Turbine with Consideration of Blade Parameters

Ridway Balaka, Aditya Rachtnan, Jenny Delly

Harvesting Energy from Flood Mitigation Ponds Using Water Wheel.

AbitutTalibDin,Mohd.Yaztdothman,Mohd.YuhazriYaakob

Passive Cooling SystemofaBuilding: ANew

ApproachMd. Hassn.ali, Mohornmad frashud, Md. Mahasin Ali, H M Mehedi Rafique Emission Testing of Diesel Engine Fueling with oxidized Biodiesel

Berknh

Faiar

T.K,DidikAriwibowo

using Infrared Radiation based Fuzzy Logic for Rice Grain Dryer Ti{ne

contol

Muhammad Nizam, Agus fuIujianto, Bambang Kusharianta' Trt

Irianto

Usage Solar Thennal Technology

ofl{ybridWood

Drying on the Integrated System HP/TColiector to Supply Energy in Rural Furnihre Industry

Budi Kristiawan, iuyilno, Danang Apriyanta' A' Fahrny Rezayona

24

61

66

74

100

T

EvllerSEAtvl

2011"

lt5

123

t28

134

143

151

160 166

174

183

189 199

2t4

22t

233

t

!,

l

t

Using Bionaass Briquette of

Arilicial

Log Waste as Kerosene Substitute in SterilizationProcess of Auricularia sp. Substrate

Budi Kristiawan, Eko prasetya Budiana

Uagrade Biogas Purification in Packed Column with Chemical Absorptior of CO2 For

Energy Altemative Of Small Industry

pKM-Tahu)

Muhammad Ki.smurtono

Design of

low

speed Permanent Magnet Generator forwind

Energy in IndonesiaHasyim Asy' ari 1, Aris Budinan, Nurmuntaha Agung

The Effect of Feed Seawaxer and

Air

Temperatures on Performance of a Desalination Unitof

Heat Pump with Humidification and Dehrrrnidification

Tri Istanta, wibawa Endra Juwana,

Indri

yaningsih, Dedet HerrnawanA Feasibility study on

wind

Energy potential in peninsular MalaysiaMuhammad Hafeez Mohaned

Hariri,

Norizah Mohamad, syafrudinMasri

CFD Analysis on Cost-effective Pico-hydro Turbine: A Case Study for Low Head and

Low

Flow Rate Condition

Masjuri Musa, ,Iuhari ab. Razak , Md Razali Ayob, Mohd Afzanbam Rosli,

safattdin

Ghazali Herawan, Kamantzzaman SopianDesign of a Stand-alone Solar photovoltaic powered Bus Stop

MohdAf-zanizamM. R., Mohd ZaidA., Muhd Ridzuan-M., Sivaraa S

Condensation Heat Transfer and Presslre Drop of Steam in a Horizontal pipe Heat Exchanger

Sulramta, Indarto, Purnomo, Tri Agung Rohnat

The Investigation on the Effect of the Blade Numbers on the Performance of a Horizontal Axis Wind Turbine

Utilizie

a Parametric Study of the Blade Element Momentumrn"orv

Ridway Balaka, Aditya Rachman, Jenny

Delly

Fabrication of Zinc

oxide

(Zno) Nanoparticle using Flame Assisted spray pyrolysis Bobie suhendra, Arfida Berliana, Dina Ratnasari, Ranopuji,

tiri^

inoinran,

Suyitno, Agus P ur-ntan to

Fuzzy Logic

Contol

for Spark Advance of Otto EngineAgus Sujono

Methane steam Reforming to produce High Ratio of Hydrogen to carbon Monoxide

by

Using CFD

Tlpharudin,

Arif

Setyo Nugroho, Suyitno, HeruAtmanto WibowoTlre Effect of Current Rate and Elecfolyte Temperature Wahyu Purwo Rahago, Eka SuroJo

The Effects

ofPANI

Addition to Characteristics of Carbon Composite Bipolarplatefor

PEMFC

Y.Sadeli,

J.

Wahyuadi, B, prihandolo, and S. HarjantoDesign of an FRP Conoposite C-BEAM

Djoko Setyanto, Jarnasri, Bambang Suhendro , AIva Edy Tontowi

The Influence of Steel Surface Temperature Against the Heat Transfer Characteristics

in

Water Droplet Collision Dlmamics

Puu

Hadi Setyarini, IndravanDwi

prasantyo, Slamet Wahyudi Effect of Erbium Dopedlper!,e-n8tn

to the Amplification on Erbium Doped FiberAmplifier

Lita Rahmasaril, Yusaf Munajat

l-S-T9v q,nuhtionship

between Process Variables and rffeld Penefation for Gas MetalArc

Welding

(GMAW)

s.

Thiru chitrambalam, Tan wee Ming,Imran

syakir Moharnmad and shafaal bin'

Mat

A study of Melt Flow Analysis of polycarbonate

(pc)

in Fused Deposition Modelling207

237

vIICESEAM

2011

r

291

Process

Ismet P. Ilyas

Characierization of Hydroxyapatite Based Photo Bio:connposites Material As Bone Substitute

Materiai

Joko Triyano, Alva Edy Tcrttowi, Widowati, Rochrnadi

Weldi"g

Current Effect on Mechanical Properties of Spot Welded Dissimilar lvletals between Stainless Steel J4 and Low Carbon SteelAgustinus Eko Eudi Nusantara, Triyono, Kuncoro

Diharia

Failure mode of Resistance Spot Welded Stiffened Thin Plate StructureTriyono, Yustiasih Purwaningrum, Ilonal Chamid

PaperHoneycomb Sandwiches Panels under Static 3-Point Bending Md Radzai Said, Mohd

Khairir

Ismail, Syed Ammar bin Syed PutraMeohanisms of C'"r/PVA/GOD Materials on Different Glucose Concentations and PH Variations

C. A. Dhannawan, Hariane, Qari, A. Supriyanta

Effect of Ternperature Sintering on Density, Bending Sfength and Water Absorption

of

Composite Organic Wastes-Hdpe Material

Heru Sukanto, Wiiang Wisnu Rahario

Effects of Load Secondary Voltage on Resistanee Spot Weldability of Dissimilar Metals Joint

between SUS3I6L and J4

Martinus Heru P, Triyono, Wiiang Wisnu R, Eko Prasetya Budiana

The Mechanical Properties of Green Polyblend Based on Waste Pollpropylene Filled

in

Variation Particle Size Natural Fiber and Initiator Concenfation Neng Sri Suharty, tsasuki Wiriosentono, Maulidan Firdaus 146{sling of Surface Hardening l-ayer on Transmission Gear

J. Jamari, R. Ismail, and

M.

TauviqirrahmanInfluence of Mechanical

Milling

Rate and Holding Time Sintering on Intennetallic PhaseFormation

ofMetal

Matix

Composite (MMC)Mg'Al-TiO2

H. Purwaningsih, D. Susanti, R. Rachiem, Firman S, Mangasa

Identification of Tool Damage in Turning Process by Analyzing the Correlation of Actual

Cutting and Feeding Forces Susilo

Adi

WidyantoNumerical Simulation on the Tooth Movement due to Orthodontic WAe Application

Firman A Kirana and Rachman Setiowan

Comparison of the Extended Reynolds Equation with Slip Length Model and

Two'Slip

Model: an Investigation of Load Support Improvement in Lubricated MEMS

M.

Tauviqirrahman, R. Isrnail, Jamari, D.J. SchippeThe Elastic Vibration Behaviour of Steel Spring for Mechanism of Antilock Brake System

(ABS) onVehicle

Wibowo

Dbsign Optimization Study of Food Extruder Machine for Small and Middle Industry Halomoan P, Siregar, Yose R. Kumiautsn, Andi Taqfan, Satya A' Putra

Pressure Distribution Analysis of Slip Surface and Sinusoidal Texture On Parallel Gap Slider Bearing

M. D. Surindra,

M.

Tauviqircahmcn, Jamari, Berkah F.T.K.Prediction of the Running-in Phase on Rolling-sliding Contact

R. Ismai!,

M.

Tauvi4inahman, J. Jamari andDirkJan

SchipperInitial Bacteria Contamination and Metals Content on Beef Sausage

H

ars oj o, June Mell rwati

An Analysis of EDM Die Sinking Parameters ON

Ti-6Al4V

299

304

312

317

323

354

348

-villCEStAM

201-L

Bagas Wardano, Mohd Faizal Bin Ismail, Liew Pay Jun

An Assessment on Graphite

[,tilling

CharaoteristicsBagas Wwdono, Yoon Xue Fang, Mohanad bin h{inhat

Electrical Properties of Sb Based Compound Semiconductor for Thermophotovoltaic Applications

Ari

Handono Ramelan, Ewa Goldys374

382

lntematiana! Canfcrence and Exhibition on

sustcinable Energ; *nd Advanceti Materiars (ICE fiEAM

20ir)

Solo-Indgnesis. Oetober 3-4, 20I

I.

cFD

Analysis

of

Bubble

Bistribution

in

Non-catalytic

Reactor

for

Production

of Biodiescl

Fuel

Dyah

wulandani

t )' 2)*,TomoE.VIi*u'),

Annansyah

FI"Tambunanl).

Hiroshi

Nabetani2)3) and

Shoji

Hagiwari)

ttdechali$11{Bigsvstem

lpineerine

Department, Bogor Agricultural Universiry, lndonesia,, ^..f'?ol TSlneTing

"' Division, National Food Research institute, NARO, Japan(iraduate school of

*

Agrieultural andLife

Science, The university of Tokyo, Japancorresponding

"Hff"j*1iffiffi:f3:.,.:il'

lil

ih

eZi;;;;,

"*^'

Abstract

Biodiesel fuel is a biodegradable of diesel fuel that is produced tbrough trans-esterification between vegetable

oil

and methanol' The non-catalytic biodiesel

fuel

productioo*"thod?led

superheat"J

-.trr*ol

vaporin

the bubble column reactor which is usedin

this research has advantage; no requiring purification before and afterreaction, due

to

the not-e-xistingof

catalyst, so bothinitial

andtio"i"g

costs areto

be redused. However thereaction rate of biodiesel fuel production is

still

lower than othermetnoaicatarvtic;rh"dift

previous studiesnoted that the contact surface between the methanol bubble and the

oil

*t"

urtn" h*itiolg

a"to,

ro, enhancing the reaction rate. The contact surface area is influenced by the bubble sizedistributi;r,;;ril;

tum affected by

the reactor design. Therefore, this study

is

devotedto

t[e

analysisor

tne bubbteoi.ul"tio"

in

non catalyticreactor to increase the reaction rate of biodiesel fuel production using the Computationairirria oyoumics

(cFD)

method'

cFD

can minimize the experimental design cost and timeby-simuhft;;;;

"**}*""t

conditionsto show a real phenomenon,

witl

a reasonable ac-curacy andprecision.-BasedL th"

ptope;

cFD

modeling we obtained at the previous work, ten scenarios of treatment and designof

obstacle installed in the column reactorwere simulated

to find

the highest contact surface area. ThecFi

modeling represeotedweil to

describe thebubble behavior.

A

significant conclusion both of.simulatioo uoaerp"iim"ntu]

r..utt,

*"

tl"i iv,tilizing

of the obstacle in the reactor, contact surface between oit and methanol

uuio, io"r"ur"

*rri"rrl.

id;"

to the reactionrate of biodiesel fuel production about 2.g times over than without obstacle.

Keywords: CFD, Bubble column, Non-catalytic reactor, Biodiesel fuel.

1.

Introduction

Biodiesel fuel is a biodegradable of diesel_oil that is produced through ftans-esterification processing from vegetable

oil,

such as soybean oil, rape-seed oil, palmoil,

sunflower seed1il,p"h

;ii,

ff;;a

oil, etc.

Trans-esterification is the reaction betweenoil

and methanol to obtain biodieselC"tty

""ia

-J.trrvi'ester (FAME)) andglycerol'

FAMB

could be..producedby

catalytic methodor

non catalyticmethod.

Til';;

of

non catalyticP:1h"9

for produci"g biodieset is the superheut"a*tn*ol

vapor u"uuie column method.-iauE

is producedby'both

of

transesteri{ication reaction beiween methanol vapoi and triglycerideand also esterification reaction between methanol vapol and free fatty acid at the same time under atnaosphere pressure and high temperature

(290"c)'

This method does notrequiri

deacidification processpri"it"

tL

iraction becaus" oot ooty triglyceride

but also &ee fattv acid can be convlrted into

FAME.

And this methodd;;;il;;"tj;;

process after the reaction because no catalystis used.

Therefore, bothinitial

and runningcosts are

th;Ght;"

be reducedby

appllnC

the method.However, reaction rate

is still

lower than thatof

conventional alkaline catalyticmethod.

The previous

studies noted that the contact surface between the methanol bubble and the

oil

actsu, tir"

ii*itirrg

factorfor

enhancing the reaction rate (.Akita

et

al,,1974).

The contact surface areais

influenced

by

the bubble size distribution,which in

tum-affectedby

the reactordesign.

Therefore, analyzingof

the contact surface areabetween methanol and

riglyceride in

the reactoris imfortant to

know the parameters influence reaction ra0e. The computational Fluid Dynamics(cFD)

method is usea to*utv""

tn" contact surface area during the processin the reactor' The best modeling of cFD-found in previous

*o*ir

u."a

to analyze bubble size distributionaird contact surface area between methanol vapors in

thi

oil

(wulandani et al., 2010).rru"tiii"uli*

of the obstacle in the reactor is predicted to infiuencetni

uuuute size dishibution and thecontact,urf";";;;.

Therefore, the]niei'vzaiicil&l Canference and Exhibition on Sustainable

il*ergy

*nd Arivr;nced Materiais (ICE SEAM20Il)

Solo-Indonesia. Octaher

3'4'

201I.

objectives

of

the paper ere {o obtain ihetyp* of

llre oi:stacle u'iri,:h rc"qilit t}re highest contact surface area a:td here in after to vieta#e

ugnest reaction raGof'FAe{g

irr i.*

bubbic ,:o!umn reactor tr-v usingfFD

analysis'2.

iV[etRrodclogY

CFD nrcdeling

The modei af br:bble coiumn reaetor w"as implemented into

cFD

oode ANSYS FL{JENT {vsrsion 6'3'26'version l2"1.2l,and

version 13.0"0) ar:d the gearxetry and rnesh*f

reactor was constructed usingGAMBIT

2.4.6. The vol.rnne

"r

a.-*ii*" ivoF)

model uJo:n-t*ir"t€n{

ilcn

equilibririm

wail

function cF'D modeling has been f,oundi"

**

pr*.noo,,"*rL*,u*

uppliedt*

ropresent rnethanol anei triglyoeride systern in the bubble:"lyT"

reacror" The gas ano

uiJi

pi-p-"ir-

i*sutted thetifference initial heigtrt of liquid is tabulated in the Table I 'Table

i.

Properties ef me*.hanoi and triglyceride at tliree conditions of temperatureNo.

hdaterial Densi Visccsity {Pa.s) Surface tension Height of liquidN/m

-

0'695 i.8738-052.

Triglyceride (At T-

250"C) .i.64e-05[3]3.

Triglyceride (At T = 2?0"C) ?.4?e-05i31i.

iffiiffi;;

io'

t

-

zsq:-q)

Eqr'ql'r

,

i'3?e-qil"

Note:

1. Teske et al. {2006) 2. CouPlaad at al. (1997) 3. F"abelo at at. i?000i4. ChumPitaz et al. {1999)

The meihanol vapor

inlet velocity

was 5.32 m,/s rn'kich equalwith

msthanolflow

ra-teof

4

g/min

attomperature

of 290'c..

l-

t*"-

stopof

ti.o-oco:-. was usedin

the sinnulationtill

the solution reach thequasi-periodic stste, at Z **noiAu.

firu

qouiit'

of*"uh

ionu"nces the requiringof

computationaltime'

The valueof

worst quality of meshfo,

ufi ofCfn

*oAuf1og;;under

0'85'

Typicat grid rvere used depend on the modelof

obstacle settling rn lhe reactor coiumn" The combinatioa of Hexagonal-cooper and Tetra-hybrid fior mesh type at

1'

2

and3

mm

of

nesh

dimensions*.,"

o**d

in

thc sirnulation' Tlre

computational demand increasessignificantly with grid refinement'

Scenarias of CFD simulation

cFD

sinrulations are carried outin

ten conditions as showin

the Table2'

scenarioss-1'

S-2 and S wereperforrned to describe the effect of temperature which indicated by difference of thermal physicai properties as

shown

ia

Table1

scsnsriosDo-?,

DO-10,bg-u,

DO-8ab and'Do-8ba wefe carried on at differeut typeof

perfiorate plate of obsta,rc.

-ou,*"lais

a perforated plate iastalled in the cylirrder as shown in Figure 1.

Table 2. The geometrical configuration used in the

cFD

modeling and experiment for methanol and triglyceridesYst€m.

Scenario Description

CFD

Biodiesel

Simulation

reaction923"5i21

815.3t?l

0.018?4i41

0.01?51141 0.01628t41

109.i

110"4 111.6

exoeriment

-

, ==.==

-

7

I

-S'-1--

Witho*

obstacie at T:

250'Cs-2

without;;;i;

itr:zts'c

'/

x

S

WitU"ot oUrtu"i" u'f

:

ZSO"C

'/

DO-TDoubleobstacle(Tmmpitch,24holes'4nncodiameter)'T:290oC{'/

Do.10Doubleobstacle(10mmpitch,riuoio,+nrmdiameter),T:290oC

O-Sa

Single obstacle {8 mm pitch, ?itoi;';

;tn

diameter)'T:

290"C

'/

'/

D0-8abDoubieperforateplateoftoo*plrcU'4rnm-diametor(Tholes'/'/

perfbratJplate

at Lelow and 12 holes at above)' T:

290"CDO-gba

Double perforate plateof

I ;-;;;;,

+

mm_a;ameter(12

hoies "/

'/

perforatJdplateattelow

and 7 holes at above)'T:

?90"Cp-t

porous;i"il;

iU"

*"tft*ol

inlet

(porosity-of 0.4 and dianneter1

/

X

mm),

T:

290'CDO Porous

plate at

the heightof

5mm from the battom

of

reactoritv of 0.4 and diameter 1 T = 290oC

X

:

not Performeci2llcrs{s.hl

?*31

Obstacle could be setting

in

the columnreactor.

Seven typesof

perforated plate were usedin

the CFD simulation and 5 types of them were tested by experimental biodiisel fuel production using by ttre bench scaleof

biodiesel reactor. The scenarios of model of CFD simulation are described in Table 3.

International Conference snd Exhibition on

Sustsinal)le Energt and Advanced Msterials (ICE SEAM 20I

I)

[image:9.595.57.528.65.325.2]Solo-Indonesia. October 3-4, 20I L

Figure 1. The obstacle and types ofperforate plate used in experiment Material

for

experimentMaterials used for this research are methanol and canola

oil

for biodiesel fuel reaction. Hexane,dietil

eterand acetic acid are used as developer solvent and Squalane (C:olloz) as standard

for TLC/FID (Thin

layer chromatography/Flame ionization detector) analysis. Acetonitrile and distillated water as a solventfor UpLC

(High performance liquid chromatography) analysis.

Experimental set up, pracedure and analysis

The experiments

of

biodiesel production are implementedto verify

the best resultof

CFD modeling byimplementing apparatus

of

Superheated Methanol Vapor Bubble Column. The apparatus consistsof

methanoltanlq pump

of

methanolliquid,

temperature conftollern heaterof

methanolto

pioduce superheated methanol vapor, reactor vessel (whereoil

and methanol are reacted under temperature 290oC and atmosphere pressure), heaterofreactor,

condenser to condense biodiesel(in

the vapor phase) obtained from the reaction ofmethanoland oil, and tank ofp;oduct (to collect biodiesel).

Methanol

liquid

was pumped at constantflow

rateof

4

g/mininto

ttretin

bathfor vaporization.

Then methanol vapor was heated gradually (75"C, 180"C ,240oC and 290"C) and the reaction is started by blowing the superheated methanol vapor intooil in

the reactor vessel. Temperaturecontoller

kept the reaction temperitureat29AoC. Biodiesel fuel was produce from the reaction

in

the gas phase. Furtherrnoie biodiesel and wr--reactedmethanol vapor were oondensed and were collected

in

the tankof product.

Sampling was taken at every 30minutes

until

300 minutes. The sample is divided in twoportions. A little

partof

sample was amlyzedto-find out the glycerol contentby

usingIIPLG analysis.

Another one was evaporated from un-reacted methanol toproduce biodiesel fuel (FAME) by using vacuum roiary evaporator at 46oC and 168

Pa.

Furthermore, biodieselwill

beanalped

by usingTLC/FID

methodto

examine thepurity

or the conteutof FAME,

diglyceride @G),monoglycerol (MG) and free fatry aeid (FFA).

The experiments were carried out at

five

scenarios as mentionedin

Table2

under several parameters asfollow in Table 3.

Table

3.

Pararneter used for experiment of biodiesel fuel productionParameter Value

Methanol vapor:

l.

Temperature('C)

2.

Flowt'ate (g/min)Canola

oil

l"

Initial mass (g)Reaction temperature (oC) Reaction pressure (MPa)

Time of reaction

(hour)

5Interval time of sampling

(hour)

0.53lrc[${AM

?0]"1

290

4

250 290

[image:9.595.59.556.581.814.2]International Conference and Exhibition on Swstainable Energt arcd Advaneed Materiqls (ICE SEAM 20I

l)

Solo-Indonesia. October 3-4, 20 I 1.3.

Results and Discussion

CFD Simulation Result

The efect af thermal physical properties

In

the CFD modelingof VOF

(volumeof

fracticn), approachof

temperature effectby

change the thermal physical properties ofgas and liquid could not explain the contact surfaco area and gashoidup.

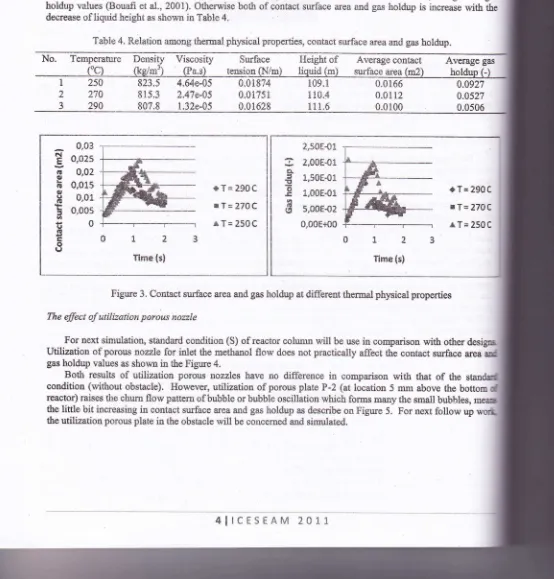

nlgure 3 shows the contact surface areaof

three models ofCFD.

Similar fiend occurs for the re lation between gas holdup andliquid temperature. In this figure, an increase of temperature is decrea.se the contact surface area and gas holdup.

The results have contrary with reality and bubble column theory.

How€ver, the result could explain the influence

of

height, and the valueof

oil

density,oil

viscosity and surface tension betweenoil

and nrethanol vapor. Both of contact surface area and gas holdup is increase with an increaseof

density, viscosity and surfacetension.

A

remarkis

supported by other investigator (Mouza et aL,2001; Wu et a1., 2001), that an inerease in liquid surface tension increase gas hold up, due to appearance of small

bubble formation

by

promoting breakage and demoting coalescence.The

smaller bubbles, the greater gasholdup val.ues @ouafi et al., 2001). Otherwise both of contact surface area and gas holdup is increase

with

the decrease of liquid height as shownir

Table 4.Table 4. Relation among thermal physical properties, contact surface area and gas holdup.

No.

Temperature Viscosity Surface Heightof

Average contact Average gas tension surface areaI

2

3

250

823.5

4.64e-A5270

815.3

2.47e-05290

807.8

1.32e-050.01874 0.01751 0.01628

109.1

I10.4

11 1.6

0.0166 0.0112 0.0r00 0.0927 0.0527 0.0506

"T*?90C

I

T:270C

lTa

250Cg T 'Et a ra It r.t ?,501-01 2,00e.01 1,50t-01 1.,009{1. 5,008-02 0,009*00

L2

Time (s)Figure 3. Contact surface area and gas holdup at different thermal physical properties

The elfect of utilization porous nozzle

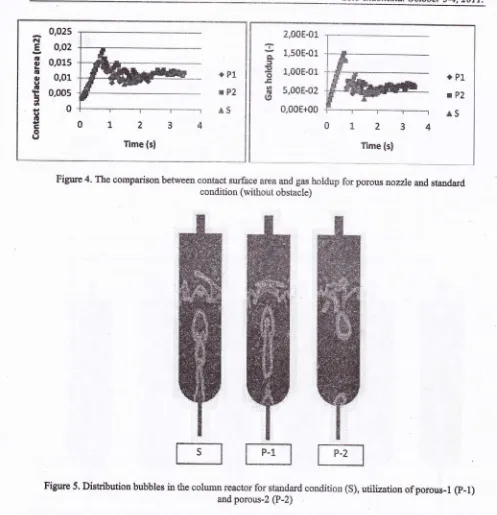

For next simulation, standard condition (S) of reactor column

will

be usein

comparison with otherUtilization of porous nozzle for inlet the methanol

flow

does not practically affect the contact sgrface area gas holdup values as shown in the Figure 4.Both

resultsof

utilization

porourr nozzles haveno

differencein

comparisonwith that

of

thecoudition (without obstacle). However, utilization of porous plate P-2 (at location 5

rrm

above the bottomreactor) raises the churn flow pattern of bubble or bubble oscillation whieh fomrs many the small bubbles, the

little bit

increasing in contact surface area and gas holdup as describe on Figure5.

For next follow upthe utilization porous plate in the obstacle

will

be concerned and sinmrlated.N E lll (, (} o t"l t! i't, (t

c

o

U 0,03 0,025 0,02 0,015 0,01 0.005 0tT*290C

rTr270C

rTo

250C12

Iime

ts) [image:10.595.28.582.248.827.2]International Conference and Exhibition on

Swstainable Energt and Advanced Materials QCE SEAM

201I)

Solo-Indonesia. October 3-4, 201 L

0.02s

it

g

sqz

g

0,015fi

o,o1€

o.oo5I

Yo

C'6 Eo

(,

+pt

llFZ

*S

L2

Iime

(s)I

tt

!t

e

v,

|!

(t

2,008-01 1,508-01 1.,00E-oL 5,008-02 0,008+00

rPl

tP2

eS

01234

[image:11.595.51.548.43.558.2]rime

{s}Figiue 4. The comparison between contact surface area and gas holdup for porous nozzleand standard condition (without obstacle)

Figure 5. Distribution bubbles in the column reactor for standard condition (S), utilization of porous-l

(p-l)

and porous-2 @-2)

Tly

influence of the utilization perforatedplate

installedin

obstacle inside the column reactor and distributionof bubble

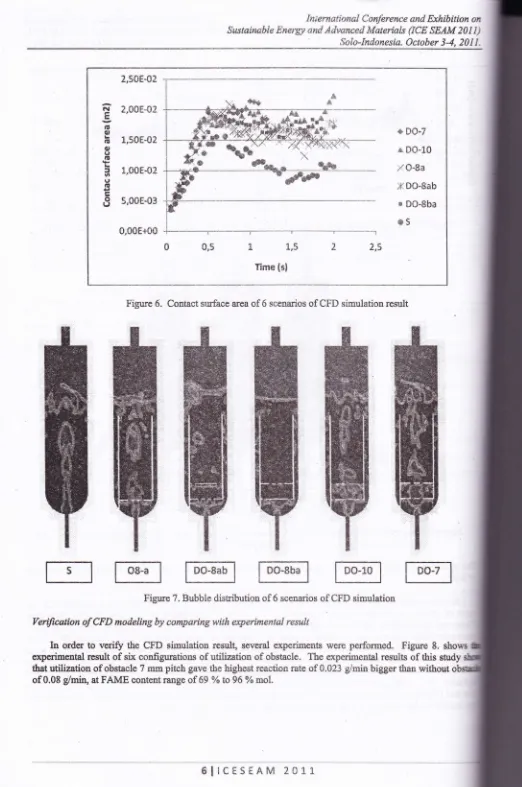

Five scenarios of CFD modeling have been simulated to describe the effect of utilization obstacle with

five

tlpes of

obstacle as shoqmin

Figure 6. Generally, utilization of perforaied plate increase oontacts'rface

area.There are

no

significant difference result among O-8a, Do-8ab-andDO-Bba.

Utilization of

obstacle DO-7shows the highest contact surface

area.

In

caseof

utilizationof

obstacle, bubbles sfte1 dstaehing the surface nozzle at the bottom of reactor are retained by obstacle. Breakage occurs aiter the bubblep*.'tf,toign

the holesof

obstacleinto

small bubbles, as shownin

Figrue7. Utilization

double perforatedifutr

1pO--Z) increase turbulence which isidentifiedby

liquid and small bubbles bacldlow from the outside ofrviioao

to the insideof

cylindc.

This condition enables increase the surface contact area and gas holdup. Especially for scenarios DO-8ab and DO-8ba, bubblesllow

thrgugh the edge ofreactor more than through the reactor.rorrr.

Consequently, the surface contact area and gas holdup are lower than that ofDo-10

andoo-2.

Intet nctional Conference and Exhibitian on Sustainable Energt end A,dvcnced Materials (ICE SE,AM 2011)

Sola-Indonesia. October 3-4, 20 I

I.

N

o

6l

o o

LI

(! I$

|J

l! g tJ

2,50E-0?

?,00r"o?

1,50H-02 1,008-02

5,00[-03

0,008+00

e D0-7

a

00-10

/A4*

XD0-8ab

r

D0-8ba [image:12.595.45.567.6.793.2]*s

Figure

6.

Contact surface area of 5 scenarios of CFD simuiation resultl-s

I

I

08{

t

?""*l

F"*:l

tl'*,1

t'"1

Figure 7. Bubble distribution of 6 scenarios of CFD simulation

Verifr,cation af CFD modeling by comparingwith experimental result

In

orderto verifu

the CFD simulationresult

several experiments wereperfomred.

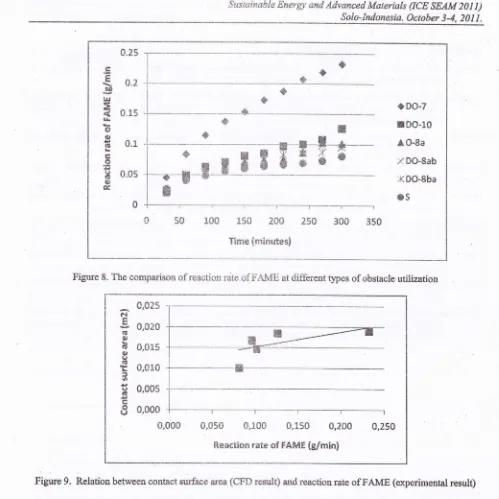

Figure8.

shorrr experimental result of six configurations of utilization of obstacle. The experimental results of this studythat utilization of obstacle 7 mm pitch gave the highost reaction rate of 0.023 g/min bigger than without

of 0.08 g/min, at FAME content range of 69 yo to 96 % mol.

Internstianql Conference and Exhibition on Susiainable Energy and

'

.dvanced Materials (ICE SEAM201t)

Solo-Indonesia. October 3-4, 201t.

0.25

'e

i

8.2 n!l*l

5

E

0.15t&

o

t 6 rJ,J.

a

H

0.0sc;

*

0

w

a

ffi

g-rffi-s---ffi

oo0-7

fi00-10

A0-8a

;a*A-&ab

XD0-8ba

e5

*ffi

w

---*- *-l---*---.--i---*--- - i---- -"----r---.---]

[image:13.595.51.550.23.522.2]1"00

r.$0

200 250 300

350 Time {mlnutor}Figure 8. The comparison of reactios rate of FAI4E at different types of obstacle utilization

l\l

I

o

{,

'I

dt LI

fit

l'

4t

al

(}

u

0,025

0,020

0,015

0,010

0,005

0,000

s,000

0,s5s

0,10s

0,150 0,200

0,250 Reartion rate 0f FAME {g/min}Figure

9.

Relation between contact surface area {CFD result) and reaotion rate of FAME (experimental result)Conkct

surface arcain

ssmparisonwith

the reaction rateof

biodiesel produotion has positive correlationtrend as shown

in

Figure9.

The result indicates that reaction rateof

biodiesel could be explainby

contactsurface contact area by using CFD method. For next work, oontact surface

will

be a key parameter to estimate the reaction rate ofbiodiesel production on pilot plant scale reactor.4"

Conclusions

The 3D

-

turbulentflow

and non-equilibriumwall

function-

CFD msdsling was successful to describe thephenomenon

of

bubble distributionin

the columnreactor.

An

increaseof

contact surface areaof

methanol bubble in theoil

increases reaction rate of biodiesei fuel production. Utilization of obstacle in the column reactorof biodiesel fuel production increases the reaction rate significantly. Utilization of obstacle DO-7 (7 mm pitch, 24 holes and 4 mm diameter) in the column reactor increases reaction rate of biodiesel fuel production

of

0.23g/min bigger than without obstacle of 0.08 g/min.

5.

Acknowledgement

We would like to

thankts

United Nations University andKirin

leading company, throughUNU-Kirin

Fellowship (2010-2011) program for a grant that made it possible to complete this research.

lnternstional C onfermce

od

Sustsinable Energt and Advanced Materials OCE$,IY

Solo-Indonesia-

fufu

34.

References

Akita,

K.

and Yoshida, F. (1974) Bubble Size, Intetfacial ,4res, and Liquid-Phase Msss TransferC$rc*na,'

Bubble Columns,Ind. Eng. Chen., Process Des. Develop.13,

84-90.Bouaifi,

M.,

Hebrard G., Bastoul,D.

and Roustan,M.

(2001)A

carnparative studyof

gasholdry,

hdlt"irB

inte{aeial area

and mass transfercofficients

in

stirred gas-liquid

reactors andkbble

Chemical Engineering Process 4A,

91-lll.

Chumpita2,

L.D.A.,

Coutinho,L" F.

and Meirelles, A.J.A. (1999) 'surface

Tensionof

Fatty

AEifuJ

Triglycerides', JAO CS, 7 6:3, 37 9 -382.

Coupland, J.

N.,

andMc

Clements.D.

J" (1997) 'Physical Fropertiesof Liquid

EdibleAIs',

JAOCS, 7,1:llt.

1559-1564.Mouza,

A.A.,

Dalakoglou, G.K., Paras,S.V. (2005)Efect af

tiquid properties on the performanceof

ffi

calumn reactors withJine pore spargers, Chemical Engineering Science 60,1465

-

1475Rabelo, J.,

E.

Batista,F.V,W.,

Cavaleri and Meirelles,A,J.A.

(2000) 'Viscosity predictionfor fatty

systri

JAOCS. 77

:12,

7255-1262Teske,

V.,

and Vogel,E,

(2006) Viscosity meqsuremeftts an Methanol vapor and their evaluation,&er-\,.

Data 51: 628-635.

Wu, Y.,

Ong,B.C.

and Al-Dahhan,M.H.

(2001) Predictionsof radial

gas holdupprofiles in

bubblecobr

reactors, Chemical Engineering Science 56, L207-t27CI.Wulandani,

D., T.

Miura,A.H.

Tambunan,H.N.

and Hagiwara, S. (2010) 'Determination on CFD Modelfu

Bubble Column Reactor

to

TmFroveBiodiesel

Fuel

Production', Proceeding

of

Internafisd

Conference on SwtaiN 20lA,December 11-12,2010, Kyoto. Japan