UNIVERSITI TEKNIKAL MALAYSIA MELAKA

FABRICATION AND CHARACTERIZATIONS OF

HYDROXYAPATITE (HA) / CHITOSAN (CTS) COMPOSITE

LAYER ONTO TITANIUM ALLOY (Ti-6Al-4V) SUBSTRATE

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Engineering Material)(Hons.)

by

MD AFINDI BIN MUHAMMAD

B051010245

890605035423

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS LAPORAN PROJEK SARJANA MUDA

TAJUK: FABRICATION ANDCHARACTERIZATION OF HYDROXYAPATITE

(HA)/ CHITOSAN (CTS) COMPOSITE LAYER ONTO TITANIUM ALLOY (TI-6AL-4V) SUBSTRATE

SESI PENGAJIAN: 2012/ 13 Semest er 2

Saya MD AFINDI BIN MUHAMMAD

mengaku membenarkan Laporan PSM ini disimpan di Perpust akaan Universit i Teknikal Malaysia Melaka (UTeM) dengan syarat -syarat kegunaan sepert i berikut :

1. Laporan PSM adalah hak milik Universit i Teknikal Malaysia Melaka dan penulis. 2. Perpust akaan Universit i Teknikal Malaysia Melaka dibenarkan membuat salinan

unt uk t uj uan pengaj ian sahaj a dengan izin penulis.

3. Perpust akaan dibenarkan membuat salinan laporan PSM ini sebagai bahan pert ukaran ant ara inst it usi pengaj ian t inggi.

4. **Sila t andakan (√)

SULIT

TERHAD

TIDAK TERHAD

(Mengandungi maklumat yang berdarj ah keselamat an at au kepent ingan Malaysia yang t ermakt ub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang t elah dit ent ukan oleh organisasi/ badan di mana penyelidikan dij alankan)

Alamat Tetap:

DECLARATION

I hereby, declared this report entitled “ Fabrication and Characterization of Hydroxyapatite (HA)/Chitosan (CTS) composite layer onto Titanium Alloy (Ti-6Al-4V) substrate” is the results of my own research except as cited in references.

Signature : ……….

Author’s Name : MD AFINDI BIN MUHAMMAD.

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Engineering Materials) (Hons.). The member of the supervisory committee is as follow:

………...

(Official Stamp of Principal Supervisor)

ABSTRAK

Ti-6Al-4V dipilih sebagai bahan dalam pembuatan implan kerana bahan ini mempunyai ketumpatan dan modulus yang rendah serta sifat kekakuan yang tinggi. Malangnya, ia mempunyai ciri bioaktiviti yang lemah dan gagal apabila disambungkan dengan tulang. Saduran HA tulen pada Ti-6Al-4V mampu meningkatkan sifat bioaktiviti permukaan, tetapi penguraian kedua-dua bahan ini sering berlaku disebabkan kelemahan ikatan antaramuka HA/Ti-6Al-4V. Salah satu cara untuk meningkatkan kekuatan saduran HA tulen pada Ti-6Al-4V adalah dengan membentuk lapisan komposit HA/CTS sebagai bahan penyaduran pada Ti-6Al-4V. CTS yang wujud dalam lapisan komposit HA/CTS akan bertindak sebagai tetulang yang mengukuhkan elemen HA. Dalam kajian ini, komposit HA/CTS akan dihasilkan dengan komposisi CTS adalah (30 wt.% CTS) melalui kaedah metalurgi serbuk. Penyelidikan ini bertujuan untuk mengkaji kesan pengaruh suhu dalam membentuk lapisan komposit HA/CTS diatas substrat Ti-6Al-4V. Substrat akan dipanaskan dibawah pengaliran suhu relau yang tinggi didalam gas Argon pada empat suhu yang berbeza iaitu 750 °C, 800 °C, 850 °C dan 900 °C. Kesan suhu yang berbeza ke lapisan komposit telah meningkatkan sifat-sifat kekerasan dan dicirikan oleh Vickers Microhardness. Sementara itu, pengesahan komposisi fasa dan analisis kimia telah dijalankan oleh XRD, SEM dan EDX. Tambahan itu, salutan oleh HA akan bertambah baik dengan gabungan CTS kedalam lapisan komposit. Pada 900 oC dipilih sebagai suhu terbaik berdasarkan keputusan analisis yang baik diperolehi dari XRD, SEM dan EDX dan ujian mekanikal seperti Vickers Microhardness.

ABSTRACT

Ti-6Al-4V is preferred as material in the production of implants because it possesses favorable properties, such as relatively low modulus, low density, and high strength. Unfortunately, it has poor bioactive properties and fails to bond to bone tissue. The pure HA coating on the Ti-6Al-4V, improves the surface bioactivity but often flakes off as a result of poor HA/Ti-6Al-4V interface bonding, which may cause the surgery to fail. One way to improve the low strength of pure HA coatings is to form a composite coating by reinforce HA coating with CTS. In this study, HA/CTS composite were produced with the composition of CTS is (30 wt.% CTS) by powder metallurgy method. The study is focusing on identifying the effect of temperatures on HA/CTS composite layer onto Titanium Alloy (Ti-6Al-4V) substrate. The substrate were sintered under flowing high temperature furnace in Argon gas atmosphere at four different temperatures for 750 °C, 800 °C, 850 °C and 900 °C. The effect of different temperatures onto composite layer has improved its hardness properties were characterized by Vickers Microhardness. Meanwhile, the verification of phase composition and chemical analysis were conducted by XRD, SEM and EDX. In addition, the biocompatibility of the alloy was remarkably improved by the HA coating and the incorporation of CTS into the coating. At 900 °C was selected as the best temperature due to the good results obtained from XRD, SEM and EDX analysis and mechanical testing such as Vickers Microhardness.

DEDICATION

Specially dedicated to my beloved family

Thanks

for all their support, motivation and caring during the course of this project

ACKNOWLEDGEMENT

First of all, in a humble way I wish to give all the Praise to Allah, the Almighty God for with His mercy has given me the strength and time to complete this report.

I am deeply indebted to Mdm Adibah Haneem Binti Mohamad Dom, my supervisor, for her patience, supervision, encouragement and thoughtful guidance towards the completion of this report.

I am particularly grateful to Department of Material Engineering, Faculty of Manufacturing Engineering, Universiti Teknikal Malaysia Melaka (UTeM) for financial support.

Lastly, I would like to acknowledge my family; whose patient love enabled me to complete this report. Thank you.

TABLE OF CONTENTS

CHAPTER 3: METHODOLOGY

3.5.3 Scanning Electron microscope (SEM) and X-ray spectroscopy (EDX) 56 3.6 Mechanical Testing 57

3.6.1 Vickers Microhardness Machine 57

CHAPTER 4 : RESULT AND DISCUSSION 4.1 Observation of Sample Preparation 60

4.2 Mechanical Properties 62

4.2.1 Microhardness 62

4.3 Surface Morphologies 64

4.3.1 Scanning Electron Microscope 64

4.4 Chemical Element Contents / Embedded Layer Characterization 66

4.4.1 Energy Dispersive X-ray 66

4.5 Phase Analysis 71

4.5.1 X-Ray Diffraction 71

CHAPTER 5 : CONCLUSION & RECOMMENDATION

5.1 Conclusion 74

5.2 Recommendation 74

REFERENCES 77

APPENDICES

LIST OF TABLES

Table 2.1 Type of Biomaterials, characteristics and applications 8 Table 2.2 Application of Metallic Biomaterial 9 Table 2.3 Application of ceramic material 10 Table 2.4 Titanium alloys for dental applications and their mechanical

properties (Mitsuo, 1998) 16

Table 2.5 Types of Calcium Phosphates with Their Respective Formula and

Acronym 21

Table 2.6 Elastic Modulus Of HA and Mineralized Tissues 22

Table 2.7 Some applications of Chitosan 34

Table 4.1 Vickers Hardness Result 62

Table 4.2 Average of primary components in the composite layer 70 Table 4.3 The average thickness of composite coating 70

Figure 3.13 Vickers Microhardness Machine 58

Figure 4.1 Result and Discussion chart 60 Figure 4.2 Titanium Alloy (Ti-6Al-4V) (a) before sintering and (b) after

sintering process 61

Figure 4.3 Average of hardness before and after coating at four different

temperatures 63

Figure 4.4 SEM surface morphologies of 70 wt.% HA, 30 wt.% CTS composite layer onto Ti-6Al-4V substrate at various temperatures (a) 750 oC, (b) 800 oC (c) 850 oC and (d) 900 oC 65 Figure 4.5 Cross-sectional observation of HA-30 wt.% CTS composite embedded

layer onto Ti-6Al-4V substrate 67

Figure 4.6. Cross-sectional thickness observations and EDX spectra on 70 wt.% HA, 30 wt.% CTS on Ti-6Al-4V substrate ;

(a and b) 750 oC, and (c and d ) 800 oC. 68 Figure 4.7. Cross-sectional thickness observations and EDX spectra on

70 wt.% HA, 30 wt.% CTS on Ti-6Al-4V substrate ; (e and f) 850 oC

and (g and h) 900 oC. 69

Figure 4.8 XRD pattern of HA/CTS composites (a) before (b) after sintering

process 73

LIST OF ABBREVIATIONS, SYMBOLS AND

VM - Vickers Microherdness

nm - Nanometer

N - Newton

Wt.% - Weight Percent

kgf - Kilogramforce

g/cm3 - Gram per cube centimeter N/mm2 - Newton per square millimeter m/s - meter per second

% - percentage

kW - kilo watt

min - minute

kg - kilogram

mm - millimeter

s - second

CHAPTER 1

INTRODUCTION

This section basically provides research background, problem statements, objectives and scope of this research.

1.1 Research Background

There are tremendous materials such as ceramic, glasses, metallic and polymeric biomaterials are used for medical purposes. The metallic substrate such as Ti-6Al-4V usually used in medical implants due to its excellent biocompatibility properties, excellent corrosion resistance in body fluid and strength to weight ratio advantage. For hard tissue replacements, Ti-6Al-4V is the most excellent biomaterials because of the ideal recipe for implanted alloy included low elastic modulus, low stress shielding, good wear resistance, high mechanical strength and fatique resistance (Thirugnanam, 2009).

Further studies showed that the release of both vanadium and aluminum ions from the alloys may cause long-term health problems, such as peripheral neuropathy, osteomalacia, and Alzheimer diseases (S. Rao et al., 1996 ). However, the effect of metal release and corrosion in vivo due to titanium accumulation in tissues adjacent to the implant. In addition, these metal implants may lose and even separate from the surrounding tissues during implantation (Aziz et al., 2001). Titanium material is bioinert which have slower abilities to bond to bone and to guide bone growth as compared to the other biomaterials with bioactive properties such as Hydroxyapatite (HA) or

Chitosan (CTS). Titanium does not have surface properties similar to the bone tissue. This weakness should be improved by producing bioceramic coating on the surface (Dudek, 2009).

Hydroxyapatite (HA) is the most popular bioactive ceramic materials used in medical. It is a ceramic material that possesses exceptional biocompatibility and bioactivity properties with respect to bone cells and tissues, due to its similarity with the hard tissues of the body (Ferrazz et al., 2004). HA has been widely used as a bulk implant material in non-load bearing areas of the body (Curran et al., 2011). Although HA has excellent biocompatibility properties, it is limited in use due to its low strength and brittle nature (Prokopiew et al., 2006). The main reason of this loss in mechanical properties of HA is decomposition of HA into some calcium phosphate phases such as tricalcium phosphate (TCP) and even tetra-calcium phosphate (TTCP) (Mobasherpour et al., 2009). Calcium phosphate phases are brittle and have weaker strength. Hence, HA can be used only for applications in which an insignificant magnitude of stress needs to be borne (Thomas et al., 1980). Attempts to overcome these disadvantages have been made by using HA as a surface coating on bioinert metallic substrates such as titanium, Ti-6Al-4V, and stainless steel 3I6L (Yip et al., 1997). Nonetheless, most of the reports demonstrated that bonding strength between HA surface coating and titanium substrate was not high enough for the requirement of clinical application. The main difficulty encountered is the sintering of the HA coating. As high temperatures result in degradation of the metal substrate and the thermal decomposition of HA, sintering temperatures ideally should be below 1000 °C under which HA is difficult to be fully densified (Wei et al., 2005).

One way to improve the low strength of pure HA coatings is to form a composite coating by reinforcing HA coating with a strong secondary phase such as (CTS) (Xiu Feng Xiao et al., 2005). It is expected that the incorporation of CTS particles as reinforcement within the coating will improve the bonding strength between the coating and the substrate. An alternative solution is to develop a composite composed of CTS

powder and HA. The coating has been applied extensively for metallic prostheses with the aim of improving bone apposition (Kaya et al., 2008) and implant obsession, well as reducing curative time (Sun et al., 2001).

Numerous methods of surface coating techniques have been established to deposit HA/CTS based coatings on to Ti-6Al-4V. These methods range from the conventional press-and sinter method to more elegant approaches such as sputtering (Yoshinari et al., 1997), electrophoretic deposition (Kaya etal., 2008), and plasma spraying (Cheng et al., 1997). However, further investigation revealed that HA coatings are rather more soluble than expected in vivo or in vitro (simulated physiological conditions), that may result in loose or even failure of the implant after long time of implantation. It has been reported that although the early fixation is good for HA coated implants, but the high dissolution rate of HA coating in biological environment does show detrimental effect and eventually leads to the failure of the implant (Gineste et al., 1999). In this study, HA/CTS composite powder was mechanically mixed with ball milled for 4 hours. Designed clamp was used for support the deposition of HA/CTS powder onto Ti-6Al-4V substrate in a tube furnace. The HA/CTS composite layer on Ti-6Al-4V substrate were characterized physically and mechanically behavior using X-Ray Diffraction (XRD), Scanning Electron Microscopy (SEM), Energy-dispersive X-ray (EDX) and Vickers Microhardness.

1.2 Problem Statement

The biocompatibility of titanium is inferior to that of calcium phosphates, such as Hydroxyapatite (HA) due to it falls into a group of bioinert materials (Zavgorodniy et al., 2010). However, HA have low toughness and poor bonding strength between substrate. Thus, a modification of the surface of a Ti-6Al-4V implant is really essential to defend any detrimental effects on cell and bone tissues. Throughout this research, such systems will combine the mechanical properties of the metallic substrate and the

biological advantages of the HA surface to bone. Consequently, this research aim at preparing (70 wt% HA, 30 wt% CTS) composite layer onto Ti-6Al-4V substrate using clamp at various temperatures to enhance the bonding strength by forming a composite coating. The characterizations techniques such as X-Ray Diffraction (XRD), Scanning Electron Microscopy (SEM), Energy-dispersive X-ray (EDX) to analyzed the surface-interface structure , chemical elements and phase present. Surface hardness of HA/CTS composite coating were analyzed by Vickers Microhardness, respectively, and the residual stress and bonding strength were measured.

1.3 Objectives of Project

The objectives of this research are :

i. To produce (70 wt% HA, 30 wt% CTS) composite layer onto Titanium Alloy (Ti-6Al-4V) substrate.

ii. To study the effect of temperatures on (70 wt% HA, 30 wt% CTS) composite layer onto Titanium Alloy (Ti-6Al-4V) substrate using Scanning Electron Microscopy (SEM), Energy-dispersive X-ray (EDX), Vickers Microhardnes and X-Ray Diffraction (XRD).

iii. To study the effect of temperatures on the mechanical properties and material properties.

1.4 Scope of Research

This research is focusing on the effect of temperatures on (70 wt% HA, 30 wt% CTS) composite layer onto Titanium Alloy (Ti-6Al-4V) substrate. HA (Merck, US) and Chitosan (CTS) powder were used in this study as the embedment agent. The fabrication powder of composite material were prepared with HA matrix reinforcing by CTS powder contains. The HA and CTS powder was mechanically mixed using planetary ball mill for 4 hours. The purpose of the milling were to mix the two different powders homogeneously as much as possible and to reduce the initial particle size of CTS. Special designed clamp was used for the deposition of HA and CTS powder onto Ti-6Al-4V substrate. The substrate was heated under flowing high temperatures furnace in Argon gas atmosphere at 750 °C, 800 °C and 850 °C and 900 °C for 4 hour with heating rates of 10 °C min-1.

The HA/CTS composite layer on Ti-6Al-4V substrate was characterized using XRD, SEM, EDX and Vickers microhardness. XRD was used to characterize the phases composition of HA/CTS before and after the sintering. The hardness and compressive strength of HA/CTS was determined by Vickers Microhardness due to the importance of mechanical properties for a coating material. SEM was used to characterize topography of solid samples after sintering process. Chemical characterization or element composition analysis volume of the sample was characterized by SEM, XRD and EDX techniques.

CHAPTER 2

LITERATURE REVIEW

This section provides literature review related to the project development. It reviews on basic alloy materials used and its properties as an implant in medical application.

2.1 Biomaterial

Biomaterials is a term used to indicate materials that constitute parts of medical implants, extracorporeal devices, and disposables that have been utilized in medicine, surgery, dentistry, and veterinary medicine as well as in every aspect of patient health care. Artificial biomaterials is a biocompatible and biodegradable materials and suitable to develop and characterize artificial material for use in the human body to improve physical function and quality of life. The National Institutes of Health Consensus Development Conference defined a biomaterial as ‘‘any substance (other than a drug) or combination of substances, synthetic or natural in origin, which can be used for any period of time, as a whole or as a part of a system which treats, augments, or replaces any tissue, organ, or function of the body’’ (Boretos et al., 1984). Biocompatible is a synthetic or natural material used in intimate contact with living tissue (it can be implanted, partially implanted or totally external). Figure 2.1 shows application of biodegradable material for medical application.

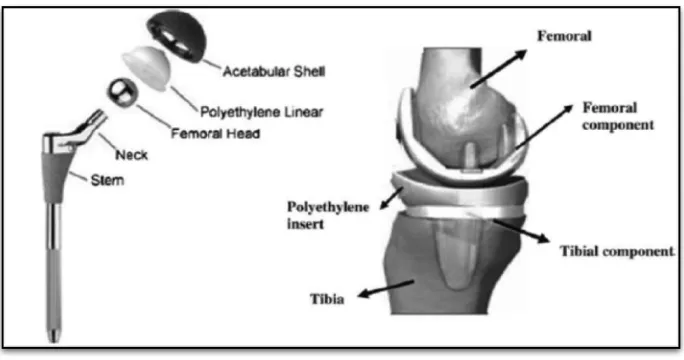

Figure 2.1. Total hip and knee implants replacements (Geetha, 2009)

According to the surgical uses, biomaterials with a variety of properties are needed. Table 2.1 contains a wide-ranging list of biomaterials, their advantages and disadvantages, and examples of their applications. Comparing all materials in this mould, polymers are used when complex forms or high flexibility are needed, metals when the implant will suffer high mechanical loads, while composites are used to improve the interaction with the tissues. The importance of ceramics is growing due to their biocompatibility, resistance to corrosion and mainly because an important part of bones themselves are mineral phases. Therefore, ceramics are used as bone substitute or to promote bone regeneration. Natural materials are preferred due to their availability and because the problem of rejection is eliminated, particularly when they come from the same patient (Alejandro et al., 1999).