UNIVERSITI TEKNIKAL MALAYSIA MELAKA

Development of Standard Time Utilizing Work

Method and Time Measurement

In QC Department

At A Textiles Manufacturing Company

Thesis submitted in accordance with the requirements of the

Universiti Teknikal Malaysia Melaka for the Degree of

Bachelor of Manufacturing Engineering (Design)

By

Nor Izati Binti Md Salleh

Faculty of Manufacturing Engineering

JUDUL: DEVELOPMENT OF STANDARD TIME UTILIZING WORK METHOD AND TIME MEASUREMENT IN QC DEPARTMENT AT A TEXTILES MANUFACTURING COMPANY

SESI PENGAJIAN: 2/ 2006-2007

Saya NOR IZATI BINTI MD SALLEH

mengaku membenarkan t esis (PSM/ Sarj ana/ Dokt or Falsaf ah) ini disimpan di Perpust akaan Universit i Teknikal Malaysia Melaka (UTeM) dengan syarat -syarat kegunaan sepert i berikut :

1. Tesis adalah hak milik Universit i Teknikal Malaysia.

2. Perpust akaan Universit i Teknikal Malaysia dibenarkan membuat salinan unt uk t uj uan pengaj ian sahaj a.

3. Perpust akaan dibenarkan membuat salinan t esis ini sebagai bahan pert ukaran ant ara inst it usi pengaj ian t inggi.

(Mengandungi maklumat yang berdarj ah keselamat an at au kepent ingan Malaysia yang t ermakt ub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang t elah dit ent ukan oleh organisasi/ badan di mana penyelidikan dij alankan)

Disahkan oleh:

(TANDATANGAN PENYELIA) Cop Rasmi:

Tarikh: _______________________

* Tesis dimaksudkan sebagai t esis bagi Ij azah Dokt or Falsaf ah dan Sarj ana secara penyelidikan, at au disert asi bagi pengaj ian secara kerj a kursus dan penyelidikan, at au Laporan Proj ek Sarj ana Muda (PSM). ** Jika t esis ini SULIT at au TERHAD, sila lampirkan surat daripada pihak berkuasa/ organisasi berkenaan dengan menyat akan sekali sebab dan t empoh t esis ini perlu dikelaskan sebagai SULIT at au TERHAD.

BORANG PENGESAHAN STATUS TESIS*

SUNGAI BAKAP, PULAU PINANG.

FAKULTI KEJURUTERAAN PEMBUATAN

Rujukan Kami (Our Ref) : 11 May 2007

Rujukan Tuan (Your Ref):

Pust akawan

Perpust akawan Universit i Teknikal Malaysia Melaka UTeM, Ayer Keroh

MELAKA. Saudara,

PENGKELASAN TESIS SEBAGAI SULIT/ TERHAD

- TESIS SARJANA MUDA KEJURUTERAAN PEMBUATAN (REKABENTUK): NOR IZATI MD SALLEH

TAJUK: DEVELOPMENT OF STANDARD TIME UTILIZING WORK METHOD AND TIME MEASUREMENT IN QC DEPARTMENT AT A TEXTILES MANUFACTURING COMPANY

Sukacit a dimaklumkan bahawa t esis yang t ersebut di at as bert aj uk “Development Of Standard Time Utilizing Work Method And Time Measurement In QC Department At A Textiles Manufacturing Company” mohon dikelaskan sebagai t erhad unt uk t empoh lima (5) t ahun dari t arikh surat ini memandangkan ia mempunyai nilai dan pot ensi unt uk dikomersialkan di masa hadapan.

Sekian dimaklumkan. Terima kasih.

“ BERKHIDMAT UNTUK NEGARA KERANA ALLAH”

Yang benar,

PUAN ROHANA BINTI ABDULLAH,

Pensyar ah,

Fakul t i Kej ur ut er aan Pembuat an (Penyel i a)

+6062332548

UNIVERSITI TEKNIKAL MALAYSIA MELAKA Karung Berkunci 1200, Ayer Keroh, 75450 Melaka

APPROVAL

This thesis submitted to the senate of UTeM and has been accepted as partial fulfilment of the requirements for the degree of Bachelor of Manufacturing Engineering.(Design).

The members of the supervisory committee are as follows:

……… Main Supervisor

(Official Stamp & Date)

……… Co-Supervisor

DECLARATION

I hereby declare this thesis entitled “Development of Standard Time Utilizing Work Method and Time Measurement In QC Department At A Textiles Manufacturing

Company” is the result of my own research except as cited in the references.

Signature : ………

Author’s Name : ………

ABSTRACT

ABSTRAK

ii

DEDICATION

To my beloved mum, Rohani Ahmad for all that you have given me.

iii

ACKNOWLEDGEMENTS

In The Name of Allah Almighty and The Most Merciful and Blessings

Be Upon His Messenger Prophet Muhammad S.A.W and His Companions.

I acknowledge the contributions of all those who helped bring the idea of this research to fruition. It has been a long road and it could not have been done without the constant support of so many people.

I am thankful to Allah S.W.T. for bless me along the way that I have been through, for enabling me to undertake the Bachelor of Manufacturing Engineering and for granting me the strength and wisdom to face and overcome challenges and obstacles during accomplish this research.

I appreciate all those around me who had to put up with temporary neglect while I focused on the demands of accomplishing this research. I thank my supervisor, Madame Rohana Abdullah for continuing to be sources of inspiration for my intellectual pursuits. Several individuals participated directly in putting together this work. I could not have done it without cooperation and support of Madame Noor Suriati Amat, Quality Assurance Supervisor and especially to Mr. Ridzuan Abu Chek who’s worked tirelessly to make all this happen.

iv

1.2 Objective of the research……….2

1.3 Scope of the research………..……….2

1.4 Problem statement………...……….3

2.5 Introduction to Work Method and Time Study….………….………....15

2.6 Work Method……….………...….19

2.7 Process Flow Charts…...19

2.8 Work Measurements………...21

2.9 Techniques of Work Measurement………...……….23

2.10 Element Breakdown ………..…..…23

v

2.11.1 Systems of Rating ………...24

2.12 Allowances……….28

2.13 Standard Time….……….………...31

2.14 Estimating the number of observations to make……….32

2.15 Principles of motion economy………34

2.15.1 Use of the human body………...34

2.15.2 Workplace arrangement………..39

2.15.3 Design of tools and equipment………...42

3. METHODOLOGY………...45

3.1 Introduction………...45

3.2 Project Methodology …….………...46

3.3 Problem Statement Identification……….47

3.4 Company Selection and Problem Identification………..47

3.5 Data Gathering………..…...48

3.6 Data Analysis………...49

3.9 Process flow chart for textiles division………....49

3.10 Conclusion………...…………..51

6. ANALYSIS OF THE RESULT………...……....62

vi

6.2 Data Collection………....62

6.3 Time Study…………..………...63

6.4 Standard Time………..63

6.5 Rating Factor and Allowances……….65

6.6 Process Flow Charts……….………66

7. CONCLUSION………...…..67

7.1 Conclusion………..……..67

REFERENCES...………...………68

APPENDICES

A Gantt Chart

B Time Study for QC Jobs in Textiles Manufacturing Company C Table of ILO Personal and Fatigue Allowances

D Performance Rating for Quality Control in Textiles Manufacturing Company E Calculation of Performance rating for Quality Control

vii 3.1 Project Methodology Flow Chart 46 3.2 Flow Charts of the steps involved in establishing standard time 48 3.3 Textiles Division Process Flow Chart 50

4.1 Prym Consumer Malaysia 52

viii

LIST OF TABLES

1. The symbols that may be found in Process Flow Charts 21

2. Performance Rating Table 26

3. Number of Time Study Readings N’ required for ±5 % Precision and 95 32 % Confidence Level

ix

LIST OF ABBREVIATIONS, SYMBOLS, SPECIALIZED

NOMENCALTURE

x

LIST OF APPENDICES

APPENDIX A - Gantt Chart

APPENDIX B - Time Study for QC Jobs in Textiles Manufacturing Company

APPENDIX C - Table of ILO Personal and Fatigue Allowances APPENDIX D - Performance Rating for Quality Control in Textiles Manufacturing Company

1

CHAPTER 1

INTRODUCTION

1.1 Introduction of the Research

In this study, is clearly shown that work methods and time measurement can be implemented in manufacturing processes for increasing company productivity. Traditionally, the manufacturing process has been concern with how people perform their jobs. Two areas have been received considerable attention. The first is determining the best way to perform a job. This determination is commonly called methods analysis. The second is measuring the time required for a job to be completed using the best method. This measurement has most often been concerned with time measurement.

This research involves the performance of worker based on the jobs and how work methods relate to productivity improvement. By using the process charts, series of actions need to be identified that those activities should or could be improved. Every time an element of a job can be eliminated, combined or shortened, the worker will be able to produce more in the same time period. This improvement will make the work easier to perform. This type of improvement translates to an increase in productivity.

2

and fully trained in the specified method that will need to perform the job if the worker works at a normal or standard time. In addition to determining current productivity levels, time measurement is also used to build wage incentive plans, estimate cost, schedule production jobs and for other planning and control purposes.

1.2 Objective of the Research

The objective of this research is to develop standard time utilizing the work method and time measurement in a real situation and discover how the work method and time measurement can be implemented in the manufacturing company for increasing company productivity. Besides, the objective also to used process flow chart to study the flow of operations as it relates to material or workers within a process and to show the flow of QC activity from the beginning to the end of the process.

1.3 Scopes of the Research

3

1.4 Problem Statement

4

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

This chapter describe about the source and history in this research which had been done by others in the work methods and time measurement and the methods use by them. It also summarized several of work methods and time measurement and the application related to this field that can be implemented in the industry.

2.2 Productivity Improvements

Poor job match, poor work ethic, absenteeism, substance abuse, employee fraud and theft, weak managers, and employee turnover are some of the factors that contribute to substandard productivity. Today’s global business leaders depend on significant productivity increases to maximize the bottom line. Consequently, employees are asked to do more each day with less, resulting in a mismatch of resources and loss of productivity.

“Productivity is being better today than yesterday, and that tomorrow will be better than today…” The concept of what is better and how to become better is changing.

5

Productivity in its broadest sense is the quantitative relationship between product that have been produce and the resources which been use. There is a clear a distinct difference between production and productivity. It is quite possible to increase the actual volume of production and yet decrease productivity. Productivity is an overall conception which is difficult to express or to measure. It is, however, possible to consider productivity in terms of various basic resources used in industry. It is sometimes expressed in term of output from labour, or from services, or from the capital invested.

Whereas traditionally, productivity is viewed mainly as an efficiency concept which is amount of outputs in relation to efforts or resources used, productivity is now viewed increasingly as an efficiency and effectiveness concept, effectiveness being how the company meets the dynamic needs and expectations of customers. Productivity is now seen to depend on the value of the products and services (utility, uniqueness, quality, convenience, availability, etc) and the efficiency with which they are produced and delivered to the customers.

2.3 Productivity Techniques

Techniques are approaches to improving productivity. Techniques must not be regarded as the providers of improved productivity but as assisting agents in the process, a part of the overall approach. There are a number of approaches and techniques which have grown out of the productivity movement which are work study, organization and methods, and operational research. Below are the seven basic quality control tools:

(i) Pareto Analysis

6

some form of partnership that is addressing productivity issues. The Pareto chart is a bar graph that ranks problems in decreasing order of frequency. The important outcome of a Pareto chart is its assessment of process problem priorities. It separates the vital few problems from the trivial many. Another plus for the Pareto chart is its elimination of recentivity, the tendency to overestimate the importance of the most recent problem.

Figure 2.1: Pareto chart (Arnold, K.L., Holler, M., 1995)

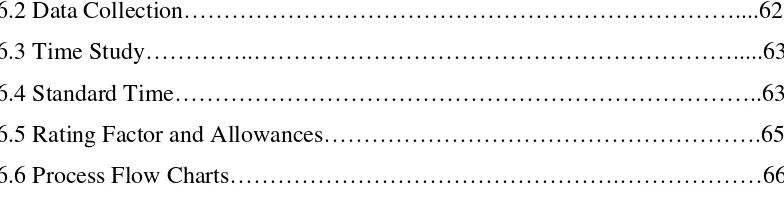

(ii) Cause and Effect Diagram

7

subdividing continues until the root cause to the problem is found. There may not always be a single root cause, but at least a few potential root causes will surface and a decision for action can be made.

Figure 2.2: The cause and effect diagram (Smith G.M, 1991)

The four M’s are generally used as the initial main categories for a cause and effect diagram. Other categories specific to the particular process may be added if the team decides they are important. Environment is one example of a possible other category. It may be considered important enough to be a main category of problem causes, or it may be a subcategory in any or all of the other categories, depending on the process being analyzed.

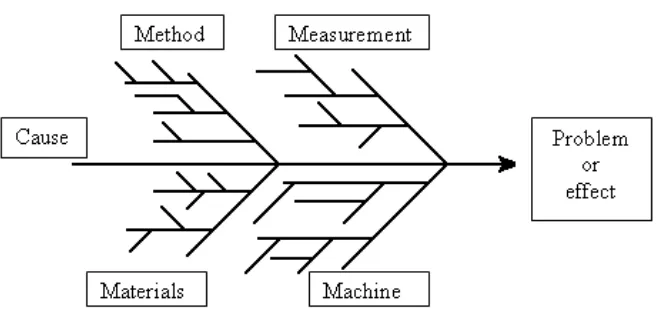

(iii) Process flow charts

8

Figure 2.3: Example of Process Flow Chart (Barnes, R.M., 1980)

(iv) Check sheets