*

LlPIセ@

RISTI:K

ASEAN GOSAT 2014

The Proceeding of ASEAN Conference on Science and Technology 2014

-9'" ASEAN Science and Technolog y Week (ASTW-9)

Innovation for better ASEAN Community:

Science andTeohnology Innovation in Food , Energy,

Organ ized by Sponsored by Supported by

セI@

RIST[OI(

PROCEEDING

1l1is proceeding and the individual contributions contained in it are protected under copyright by LIPI Press (on behalf ofindoncsian Institute of Sciences) and the following terms and condition apply to their use:

PHOTOCOPYING

A single photocopy of a single article may be made for personal use as allowed by copyright laws. Permission of the Publisher and payment of a fee is required for all other photocopying. including multiple or systematic copying, copying for advertising or promotional purposes, resale and all forms of document delivery. Special rates are available for educadonal ilmimdons that wish to make photocopies for non-profit educational classroom use.

DERIVATIVE WORKS

Subscribers may reproduce tables of contems or prepare lists of ardcles including abstracts for internal circulation with their permissions. Permission of the Publisher is required for resale or distribution omside the institution. Perm ission of the Publisher is required for all other derivative works, including compilations and translations.

ELECTRONIC STORAGE OR USAGE

Permission of the PubJisher is required to store or use electronically any material cOlltained in this journal. including any article or parr of an article.

Except as oudined above, no parr of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior written permission of the Publisher.

NOTICE

No responsibility is assumed by the Publisher for any injury and/or damage to persons or property as a matter of products liability. negligence or otherwise. or f.·om any use or operaeion of any methods, produces, instructions or ideas contained in the material herein. Because of rapid advances in the medical sciences, in particular, independent verification of diagnoses and drug dosages should be made.

PROCEEDING

ASEAN COSAT 2014

THE PROCEEDING OF

ASEAN CONFERENCE ON SCIENCE AND TECHNOLOGY 2014

- 9

THASEAN SCIENCE AND TECHNOLOGYWEEK (ASTW-9)

Innovation for better ASEAN Community:

Science and Technology Innovation in Food, Energy,

Water and Related Topics for ASEAN Developnlent.

Editor in Chief Prof. Dr. Estiko Rijanto

© 20 14 Indonesian In stitute of Sciences (L1P I)

Cataloging in Publ ic:ll ion Data

Proceeding of ASEAN Conference on Scicncc :mJ Tech nology 20 1'IIEsliko Rijanto (Ed.).-/abrl a: L1P I Prcss, 20 1-1.

pp. xvi + pp. 562; 17,6 x 25 cm ISBN 978·979·799·812·7

I. ASEIIN CaSA r

COPYl'diIOr : Sri Suratm ini Nugroho Ann isa wセ ャィ。 イ ケ オ、ゥ ウエ ゥ@

Proofre<tder : J\'iarl illus I-I el miaw:ln l.ayoutcr : Ari:ld ni

Sili Qomariyah Cover Designer : Jtlnaedi Mulaw:lrd:ln:l

Fi rst Ed ition : Decem ber 201·1

AbSlracts ;wailablc on line al pencrbil. lipi.go.id

Published by:

UP I Press. member of Ikapi

2. Science and Technology

Jln. Gondangdia Lama 39, Men teng, Jabrta 10350

LlPI

セI@

RISrl::1<

IV

Phone: (021 ) 3 1" 0228, 314 69·12

F<LX., (021) 314 4591

E·lllai l: [email protected] ipLgo.id

CONTENTS

Editorial Fore"'ord ... xi

The Remarks by the Indonesia National ASEAN COST Chair ... xiii

Preface by Minister of Research, Technology and Higher Education, the Repllblic of Indonesia ......

xv

SUB-COMMITTEE ON BIOTECHNOLOGY-SCB

(14)GAMMA RADIATION INDUCED CHANGES OF MOLECULAR AND

PHYTOCHEMICAL PROFILES ON MUTANTS OF ANDROGRAPHIS PANICULATA

(BURM.F.) WALLICH EX NESS

(). I. Royani, et al.) ... 3

THE CHEMICAL CONSTITUENT AND ANTIOXIDANT ACTIVITY OF

THE (-)-EPICATHECIN FROM ANENDOPHYTIC FUNGUS MYCOLEPTODISCUS INDICUS

(P. C. Mawarda, "[ Ernaw.ui and Y. Srikandace) ... 19 POTENCY OF HIBISCUS (HIBISCUS ROSA-SINr..NSIS L.) AS ANTIOXIDANT TO REDUCE CARBON TETRA CHLORIDE COMPOUNDS IN RED BLOOD CELLS

(D. Priadi and Kllsmiati) ... 29

PURIFICATION OF BIOACnVE PEPTIDE WITH PROTEASES INHIBITORY ACTIVITIES FROM STREPTOMYCES MISIONENSIS

O.

M. Yllsoff: K. Silnaran and Z. Alias} ... 37ISOLATION, IDENTIFICATION, AND SCREENING OF LOCALLY ISOLATED

XANTHOMONAS siセ@ .

(N. I. S. Bokhari, K. Simarani and M. S. M. Annuar) ... 43

ULTRAVIOl.ET IRRADIATION EFFECT OF PENIClLLlUAl GI1RYSOGENUJv! ON PENICILLIN PRODUCTION

(D. Hardianro, et al.) ... 49

ISOLATION AND CLONING OF PARTIAL HER-2 GENE FROM INDONESIAN BREAST CANCER PATIENTS FOR DNA VACCINE DEVELOPMENT

(Desriani and L. Triratna) ... 57

HETEROLOGOUS EXPRESSION OF RECOMBINANT PLANTARICIN WS34 IN

ESCHER/C,r1IA COLI

(A. S. Purri, er al.) ... 65

EVALUATION OF LOW TEMPERATURE INDUCED MUTANT OF SOYBEAN MOSAIC VIRUS FOR CROSS PROTECTION IN SOYBEAN

CiX!.

R. Andayanic and P. G. Adinurani.) ... 73 PROCESS DESIGN OF PEPTONE PRODUCTION FROM PEANUT MEAL ASBY-PRODUCT OF PEANUT OIL INDUSTRY USING CRUDE PAPAIN

POTENCY OF IJlA HORMON E PROD UCED BY ENDO PHYlTS BACTERIA ISOLATED FRO M SHORElI SELIINICA O N SU PPORT IN G T HE GRO\Xrn-1 O F PIIRIiSERIN THES

FIl LCII 'Ii'IRIA

Cr.

\Xlido\vali , ct al. ) ... ... . .. .. ... ... ... .. 93PROD UCTIO N AND C HARACTERJZATI ON OFTH E 1l10SU RFACT ANT IlYTHE FORMATION OF l ;LYCO UPID ISO LATED m O M I'SEUDOZYMA 1·IUIlE/ENSIS

Y lOnS025

(M. S:lri, F. Afi:l{ i :mJ \Y,( Kush;lryow) .... ... ... ... ... 103

APP U CAT ION OF j'vl AI\KER ASS ISTED SELECT ION AND SENSORY TEST FOR SELECTI NG AROMA ON 1'2 PROGENY OF I( IC E DER I VED FROM CROSS ING

BE'I'WEEN C1H ERANG X BASjvlATJ

(5. S:tri. cr ;11.) ... ... ... ... ... .... ... ... ... ... .... . . . ... I II D EVELOPMEN T O F RICE LINES RESISTA NT T O 13RO\\:lN I>L.I\NTH O PPER \\:1 1TH ARO MATI C' ITu \ IT S: SELECTIO N BA SED O N ivl 0LECU LAR MARKER

(A. P. Asri , N . Ca rSOIlO ;lnd S. Amien) ... ... .. ... . . ... . 122

SUB-COMMITTEE ON SUSTAJNABLE ENERGY

RESEARCH-SCSER (12)

ASS ESS i\iI ENT O F E-\'\lASTE RECOVERY FAC I LI T IES I N SE LANGOR AN D KUALA

I.W .. 'I PU R. M /\ LAYSIA

(N . A. M. Nordin and P Agamurhu) .. . ... ... . . . . . . . iセ@

PU BLI C PERCEPTION ON CU RREN T WAST E MANAGEMENT SYST Eivl: A !VIALAYSI,\ N CASE ST UDY

(5. 1-1. Eltlziah and S. F. Scr) ... ... ... .. .... ... ... ... .. . ... ... 135

BIOivl ASS Fl.OW AND CARBON SEQU ESTRATI ON IN r\ N ORGANIC FAR/vi

(L. 1-1 . Yeng anJ i セ@ Agamllthu) ... .. ... ... ... ... ... ... ... 147 BIO MASS GAS I FICt\T ION FOR POW ER GENE IV\TI O N USI NG D UAL C H AlvlB ER C I RC U I .I\TI NG FLUID IZED BED REACTOR

(H. W:1hYll, Cl aL) ... ... .

. ... ... I"

ROOF M O UN1'ED J-. l ICRO-WI N DT U RB1 NE F01{ POW ER (;ENE RATI ON IN COr\ STA L H OUS I NG IN S£ivIARA NG, INDONESIA

(D. i セ@ S:1. ri) ... ... .... .. ... ... .. ... ... .. ... .... ... ... . 16 1

PER FO RM A NC E OF A RAD IA L TUR UI NE I:OR Sr-. IAI.I. ORC,AN IC RAN KI N E CYCLE IJO\,' I::R GEN ERATION SYSTEM

(N! . Ari fin. B. \'(I:1.hono :md A. D. P.lsek) ... ... .... ... .. .... ... ... .. ... . 169

EFI :Ec r O F REI\ CTI ON Tl f..,IE AND CELLULASE LOAD I NG ON D ILUTE ALKA LI PRFTREATt ... I EN T Or SU GARCANE BAGASS E T O PRO D UC E PERA IEN TABLE SUGA RS FOR 1l10ETHANOL PROD UCTIO N

(T Fajriul:1mi dan Ri'l.ky RisS;1 lk lb) ... ... .. .... ... ... ..

PERFO RMA NC E OF i"vllCROBES c HI n soiセt Q um@ O N S IN(;I .F.- Cl-/MvlB FR

M IC ROB I AL H ) EL CEI.LAS ELECTR ICI T Y ceャG|i セ rat{ on@

. ... 177

(D. R:l ha),tlilillgwuhn , D . Pcrnuna dan H. E. 1\111":1) ... ... ... . . ... ... IR7

iii セ |t@ RELEASE ANALYS IS OF A T WO CYLIN DERS IN DIES El. ENG I NE FUEI.LED WITH ET H ANOL-DIESEL BLENDS

(Y. Purra.s.1.ri. er a1.) ... ... ... 199

AN EVALU1\TION FOR ENZY,\rlATI C SACCHARIFI CAT ION OF FA5T·CRO\X'ING TREE SPECIES froセi@ SECON DARY FOREST IN WEST KA LI MANTAN

(I .. Risanlo. (;( :1 1. ) ... .... ... ... .. ... .... ... ... .. ... ... ... .... ... ... 209

A NOVEL M ICROWAVE- BIO LOG ICAL PRETREATMENT EFF ECT ON CELLULOSE AND LIG N IN CHANGES OF BETUNG BAMBOO WENDROCALAMUS ASPER)

(\'\1. F:llriasa ri , (;1 .11. ) ... .. ... ... ... ... ... 21 9

THE EMERGENC E 01' I\I OGAS TECH NOLOG Y FOR RED UCING RUI\i\L I'OVER IY

EMI'IRI C/\L ST UD ] ES IN JAVA ISLAND

(L.l\riana) ... ... ... .. ... 23 1

SUB-COMM ITTEE ON METEOROLOGY AND

GEOPHYSICS-SCMG (9)

ASSESS r-.·I ENT OF EROS ION POT ENT IALS ON VA RI OUS CROPP ING lW1TERNS USI NG US LE, CASE OF SUBANG REG ION, WEST JAVA

(R. I. Sholi hah. 1.:[ :11.) ... ... ... .... ... ... ... ... ... ... .. 243

NEW STAGE OF I N TERNATIONAl . CO LLABORATION ON C1 .1 t-.IATOLOGI CAI. OI3SERVATI ON

(lvl . D . Y.lnl:lIl:lka) ... ... 253 SIr-..I UIJ'ANEOU5 CO RRELATION ANALYS IS OF AU5TRI\UAN SUMl'vlER rl.'ION500N INDEX (AUSr-. 11) t\ GAI NST RAINFALL IN B;\U REGION

(5. Muji:ls ih :llld I. G. t\. Purbawa) .. ... 26 1

DEVELO PI NG ST RATEGY FOR MONITORI NC AND DECIS ION SUP PORT SYSTEM

FOR SwlOKE HA ZE TI\i\NS-BOUNDARY PRO IlLEM W IT HI N ASEAN REG ION

(S . D. j\ . Kusum:lI1 ingl)'as) .... ... ... ... ... ... ... ... .. . 275

THE POTENTIA l. I 1\11 PACT OF CARBON MONOX ID E E)\IlI SS ION TO T H E COMMUNIT Y H EAC I'I-I I N 'I'HE V ICIN ITY OF BAR/\NANGS IANG 'r OLL G/\'r ES

(Y. V. P.u-amitaJcl.'i.l\. S. Y1I\\,0 110, :md M. \'(Iidy:mi) ... ... 289 THE MECHAN ISM

or

DRY MID -ATM OSP H ERE IN TH E WESTE RN MAR IT IMECONT INENT DUR ING RA INY SEASON [N 20 14

(5ulxl ri, 1.:1 :11.) .... ... ... ... .. ... .. 299

DES IC,N Or AUTO;\I ,\TIC ;\IEASUREt--IENT INSTR Ut-.IE NT FOR \,\/ATER DISC HARCE ON DRAINAGE MON ITOR IN(; SYST H.!

(It

rr

\'\I:th)'uni) ... ... ... 31 1ACEHSEIS, A LOCAL se i sセ G iic@ EXPERIMENT IN BENE!< セier i ah@ AND CENTRAL

AeEI-!

(r-. I. )\Iuzl i, Ct .11.) ... ... ... 319

SELECTION OF GLOBAL GMPES MODELS FOR SEISMIC HAZARDS ASSESSMENTS IN INDONESIA (CASE STUDY SUMATRA-JAVA AREA)

(A. Rudyanto. et al.) ... 329

SUB-COMMITTEE ON MICROELECTRONICS AND

INFORMATION TECHNOLOGY-SCMIT

(7)LED-BASED SPECI'ROMETER FOR ADVANCED CHEMISTRY LABORATORY EXPERIMENTS

(M. A. Alagao, et al.) ... 343

INTRODUCTION INVESTIGATION: EXECUTIVE INFORMATION SYSTEM FOR UNIVERSITY

(5. Warnars. Sasmoko and N. Susianna) ... 353 DESIGN OF IMPLEMENTATION DELAY TOLERANT AT WIRELESS MESH

NETWORKS USING IBR-DTN AND BATMAN-ADV

(H. Yuliandoko, 5. Sukaridhoro and M. U. H. A. Rasyid) ... 365

DEVELOPMENT OF A PROGRAMMABLE MULTIPURPOSE FORCED CONVECTION TYPE DRYER

(E. C. Guevarra) ... 377

A STUDY OF NETWORK SPEECH RECOGNITION USING TCP

(A. Jarin, K Ramli and Suryadi) ... 389

AURAL AND PHOTONIC SPECTRUM BASED DIGITAL PEST CONTROLLER FOR ORYZA SATIVA (RICE)

(I. A. P. Banlawe) ... 40 I

DEVELOPMENT OF PROGRAMMABLE LOGIC CONTROLLER (PLC)-BASED COF-FEE PULPER FOR WET PROCESS

(M. R. Perena) ... : ... 413

SUB-COMMITTEE ON MATERIALS SCIENCE AND

TECHNOLOGY-SCMST

(13)EFFECT OF SINTERING TEMPERATURE RATE ON PHYSICAL PROPERTIES OF POROUS TRICALCIUM PHOSPHATE (TCP) CERAMICS

(A. Fadli. A. Rasyid and R. Firmansyah) ... 427

STUDY OF KINETICS AND THERMODYNAMICS AS WELL AS THE EFFECT OF

THE PRESENCE OF CO-IONS IN INFLUENCING ADSORPTION CU2• ION BY COAL

FLY ASH ADSORBENT

(A. Zakaria, ec al.) ... 433

ORGANOPHOSPHORUS (OPS) IN THE ENVIRONMENT: EFFECTS OF REPEATED APPLICATION OF CHLORPYRIFOS ON AGRICULTURAL SOIL

(C.:. Carol and S. H. Fall'liah) ... 443

RONDED PRFEB MAGNET: FABRICATION AND CHARACTERIZATION

(D. Aryanro, et al.) ... 449

::Viii:'

EFFECT OF SINTERlNG TEMPERATURE ON DIELECTRIC CONSTANT OF SILICA PREPARED FROM RICE HUSK ASH

(Qudratun, et al.) ... 457 SYNTHESIS AND CHARACTERIZATION OF AL·DOPED LITHIUM TITANATE Ll4TIsO,2AS ANODE MATERIAL FOR LHON BATTERY

(S. Priyono, et al.) ... 463

CELLULOSE FIBERS FROM OIL PALM FRONDS REINFORCED POLYLACTIC ACIDB COMPOSITE

(F. A. Syamani, Y. D. Kurniawan and L. Suryanegara) ... 473 ISOLATION AND CHARACTERIZATION OF LIGNIN FROM ALKALINE

PRETREATMENT BLACK LIQUOR OF OIL PALM EMPTY FRUIT BUNCH AND SUGARCANE BAGASSE

(M. A. R. Lubis. et a!.) ... 483 CHANGES IN THE CELLULOSE CRYSTALLINITY DURING DIFFERENT PHASES OF DISTILLED VETIVER ROOT CELLULOSE FIBERS DEVELOPMENT

(F. A. Syamalli. ct al.) ... 493 BIOETHANOL PRODUCTION USING SACCHAROMYCES C'EREVISIAE

IMMOBlLISED ON FRESH AND MODIFIED SUGARCANE BAGASSE

(S. H. Anita, ee al.) ... 503 EFFECT OF PH ON EXTRACTION EFFICIENCY AND DISTRIBUTION IN NICKEL ION SEPARATION USING SOLVENT EXTRACnON

(A. Maimulyanej and A. R. PrihadO ... 515 ETHOXYLATED GLYCEROL MONOOLEATE: PALM OIL BASED NONIONIC

SURFACTANT FOR OIL-IN-WATER EMULSION SYSTEMS

(I. B. Adilina, ct al.) ... 523 CONVERSION OF CITRONELLA OIL AND ITS DERIVATIVES TO MENTHOL OVER BIFUNCTIONAL NICKEL ZEOLITE CATALYSTS

(I. B. Adilina, et al) ... 531

APPENDIX

PROCESS DESIGN OF PEPTONEPRODUCTION FROM

PEANUT MEAL AS BYPRODUCT OF PEANUT OIL

INDUSTRY USING CRUDE PAPAIN

¥u1yorini Rahayuningsih* and Ninuk Gilang Wiranti

Departement of Agroinduscrial Technology, Faculcy of Agriculmral Technology, Bogor Agricultural Universicy

)1. Puspa, Kampus IPB Darmaga, Bogor, Indonesia Contact author: +628128534505

Email: [email protected]

Abstract

Peptone is an impormnt component in the microbial growth media which has function as the source of amino acids. Up until now, Indonesia still importS peptone which reaches $17.84 milion per year in the last five years. That fact is the reason to develnp the research in peptone production by using protein source material chae is available in Indonesia, such as peanut meal that can be obtained as by produce of peanut oil industry. 'Ihe objectives of ehis research was to design the production process of peanm peptone using enzymatic hydrolysis by crude papain. Design process was performed by determination of the best condition (time of hydrolysis, crude papain concentration and temperature of hydrolysis. Peanut peptone produced was characterized on its amino acids content and applied to be used as microbial grO\vch media and compared with a commercial product. Crude papain powder was obtained from the sap of papaya fruit, through drying and milling proct:ss. TIle acrivicy of ccude papain used in this experiment was 5057.47 U/g min. Hydrolysis process was conducted on peanut meal that have been diluted in water with ratio of 1 :2. TIll! rt:search showed thac tht: best hydrolysis condition of peanut peprone was obtained by using 0.4% of crude papain for 4 h at エ・ュー・イセャcオイ・@ of 55 "C. "[he peptone product has appearance of brownish yellow color in liquid form. lhe yield peptone produced was 40.8%. The analysis of amino acids coment showed that peanut peprone produced had high glutamic acid aspartic acid and arginine. TIlOse 3 amino acids are very imporran[ for microbial growth. The result of growth test of Escherichia coli and Staphylococcus aurcus by determining optical densicy (OD620nm) and Toral Plate Count showed that peanuc peptone produced has similar performance with commercial peptone.

Key words: Enzymatic hydrolysis, Peanut metl!, Ci-ude papain, Peanut peptone

I. INTRODUCTION

Peptone is a protein hydrolisate product which is common to be used as nitrogen source in growth media of microorganisms. Up until now, Indonesia still imports peptone [0 fulfill irs demand due [0 rhere is no peprone indusrry available in

86

Procmlmg ASEAN COStIT 2014'----iョ、ッョ ・ウ ゥ セN@ Impo rred pepwm: within the lasr tWO ye;1rs incrcase by 3,296 [QH Il CS

with (h e v:l lue of US $ 12, 1 5 million in 2012 :l nd become 5, 102 ronnes wirh the value of US $20 ,76 million in 20 13[1

J.

This ("ct5 lead to ,he need of preliminary research of dcvdopmcm of pep wile industry ill Indo ncs b us ing raw materials which :I re セカjゥャ。「ャ 」@ such JS protein from plants.Pea n u t is one o f the protein source planrs with the porcmial to be used as

pepron e raw m:lrerial. Us u::Illy. peanur is used as m arerials fo r sl1;l ckli. pcal1m butl er ;lud peanut oil. O n rh e production of pC;lI1u r o il , pcal1m mea l will be produced as by producrs wh ich contain 45-50% crude prorein char ca n be utilized as raw m:lrerial of pcpronc. Usually, by products of peanur o il industry is lIsed for feed or lrad iliol1:11 food , stich as oncolJI whi ch ha ve low added "Jllle. By condu cting th is research, peanur l11eal is urilized as peptone raw matcrial and app li ed to substiwtc im ported pcpcon c as mi crobial g rowrh media. This research was :limed to design rhe product ion proccss of peanllf pepto llc usin g enzy mari c hydrolys is by crude papain. Design proccss was pt.:rform cd by d ercl'min:lt ion of hydro lysis ri me. enzyme cOll centrarion

and

hyd rolys is rempcrarurc and com pared rhe peptone prociucc.:d wir.h cOllllllercial pcp ro nc as grow dl media of BSc/Jl'riciJia coli and sャョーOセIGャッ」ッ」」ャャjG@ r/lln'us.II. MATER IALS AND METHODS

A. Materials

Mate ri als rhar were used wcre peanut meal , papaya sa p, Sodium mctab il sul phirc, NaCL. yeasrex rracr, BactoTII.l pepron e from BO (Bec kron Oi ckinso n). lhcroA gar (130), aquadcsr, Escherichia coli, !'J/flplJ)'lococcm rl/frflfS and Nutrient Broth (130).

B. Methods

Ellzyme Pl'epal'lllioll

Enzym e prcpara ri on was obtain ed by mi xing papaya sa p with 1.4% sod ium mctabilsulphi tc :l nd 0.3% NaC I in proporrion of 1: 1. セ ョ ャc@ mi xture was thcn genrly stirred. fi ll:crcd and dri ed in

50-55"C,

:ll1d m ill ed. Th e crude enzyme \vas characterized by al1<ll yz in g its enzy mc acr iviry using Glsein :IS subst rates. Yield ofpapai n Ct17.Yllli:: o bta i ncd was 19.894) wirh prorease act ivity of

5,057

.47Ulg

III i n.Delermillation of BセャGエャャG ッ HB ウ ゥウ@ Tim e alit! E,,;,yme COIJ(:elllmlioll

Peanm meal was added wirh aquad es r o f 1:2

(b/,,)

and papain enzy me of 0.2%;Innov,uion for Ikner ASEAN COllllllun i(y

87

4,00 0 rpm fo r 15 m in utes [0 ob ta in so lub le fm crion. Hydro lisis perfor mance \Va$ d ete rmined by analYling rat io of Tota l of Solub le N itrogen [Q N irrogen l ora l o f m ater ial us ing Kjed hal method.

Deferlllill tlfirJII ol '·')'droli",; ... Tempem tllre

After hydro lys is, rime and cllzy me cO ll cc nrr;ui on we re o btain cd :lnd rhe rescarch was com inu cd by dercn n in ing hydrolysis rcmperarure, Hyd ro lys is was carried our i 11 tcm pcra rurc of 50. 55 and

60°C.

Perfor mance of hydro lys is w:ts mcasu redby

de tcrm in ing rario of Tora l of So lubl e N irrogen ro N itroge n Tora l of material using Kjedha l mcrhod .Determination olA mi" o Add COIl/elll ill Peptone Produ cell

Th c pep to nc p roduced W3S analyzcd by

HPle

[Q determ ine the ami no acids COl1tcnr.Application of Pepton e Produced as Bacterial r,,,mvth l14et/ill

The peprone produced was :lna lyzed ro be used :15 groWdl media ofb:ICler i:1 and

compared with co mmercial peprone (Bactol t-.lpcpw nc, 130). Thc bacrer ia used werc Escherit:bin

coli

andSfflpIJJ"ocoa:lIs

tIlirellS.Liquid med ium for growin g b;'l ctcria was prepared by m ixing 0.5% J'enst

eX('}'([CI, 10/0 pepro ne, and 1 % NaCI. The using of pepron e sa mples that were

p rodu ced fro lll pean ur mea l hydrolysate was ser lip by eq ualizing the total of n itrogen sa mp les with ro t:ll of ni trogen CO I11IllCl'c i:1 I pep ron t:. M ed ium was ste rili zed :1,[ ' 2 ' OC fo r' 5 l1l in urcs. Bacteri a wen .. : inocula tcd to 10 m l of mcd ium co nta ining pepro ne p roduced and (hen incubared at

370C

fo r 24 h and theopr ical de nsity(00

620 nm) was me:1s ured as ind icato r of bacrel'ial g rowrh,Bacre ri al growth as Total Pla te CO lllH was also me:1surcd

by

pbting bacteri:1on agar plarc mcd ium us ing pepronc produced ;'Ind co m pared w ith co mlllercial pcprone. -111c co mpos irion of mcd ia W:'lS rh c sa mc as liqu id m cd ium bur it was

ad ded by 1.5% Bacra Ag;ll'. After in ocubcioll, the agar p la ces wt.: n.: incubated a(

37 °C

for 48 h. The nu mbe r o f colony was co unted by using CololI), CounterQuebec.

E.\1Jer i lllel1lf11 f) esig lJ

Experimcma l dcsign used in thi s resea rch was R3ndol11 i7.ed F3 clo ria l Des ign which pt.: rfo rTm.:d in two steps namely Randomizt:d Facrorial Design rwo f.lcrors to d e- tenn ine hydro lys is rime an d enzy me conccl1 rradon; and Rando m ized Facto rial Des ign olle f.1cro r ro dete rmin e rhe effect of hyd ro lys is rcmperature. The res u lts rh:lt showed signi nc'lI1 t d if'lerenr va lut.: was ;'lI1:'11yzed fu nher lls ing Du nca n rt:sr.

88

Pmcl'tllillg ASEiIN COSII ·' · 201 4'----III. RESULTS AND D ISCUSSION

Hydro lysis Time and E nzyme Concentration

111c

best hydro lys is condition was determin ed based on ratio ofToral of Soluble N irrogc ll (Nn -) lO N irrogcll Tora l of Material (NT B). Hi gher Rario of NTTINTB meant that hydrol ys is process W ;l S op d mall y occurred [2] .

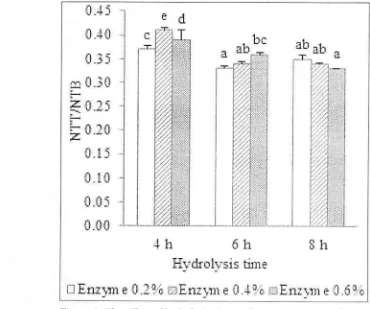

Fi gure I showed th e eff-tcr of hydro lys is time and enzyme cO llcemrarion 0 11 ratio ofNTI/NTB. Based on srati stical analys is, it was d etcnnin ed that hydrolys is rime and cnzyme 」ッョ」・ョイ イ セ ャN{ゥッョ@ significa ntly affected rario of NTf/NTI3 (p <

0.05). 1l1C highes t ratio ッヲntiセOntb@ was obta ined at 4 h of hydrolys is time with

enzym c conce ntra tion of 0.4 % . Dun GIIl test result showed that 4 h hydro lYS is time was significa ntl y different with 6 h and 8 h of hydrol ys is rime. En zyme conccJl(ration ofO.4(Yo was significan tly di fferent with ellzyme concemr:uion of 0. 2% but nor significa ntl y different with enzy me con centration of 0.6% .

I-I yd rolisis tim e is one facror char affects the enzyme stability, \vhi ch rends to dec rease along with hydrolYSiS tim e [31. 1n add ition to that,

[41

stared rh:u hydrolysis rate and nitrogen recovery wi ll in crease alon g with rhe ゥョ」イ ・セャウ ゥョ ァ@ of enzy me concentratio n. Rati o ofNTT/NTI3 which rdarively low wirh in creasing0.45

e

d

0 .4 0

0.35

co

0.30

E--;;;:: {) 25

'

-1-

0

セo@

;Z Nセ@

0 .15

0.10

0.05

0.00

-ih

6h

S h

Hydrolysis time

o

Enz,m e 0.2%

-

o

Enz,lll

-

e

0 .4 %

OEnz \lll

-

e

0.6%

[image:14.588.75.445.402.711.2][nI10v:niOIl ro r Bc([cr j\ SEAN Community

89

セM

hydrolys is tim e ca ll be affected by d ecreasing enzym e stab ility. Bes ides fhar ,

i5]

stared rhar enzymat ic hydrolys is rare dec rease and reaches starionary phase when th ere is no more hyd ro lys is process occured. So luble protein hydrolysate will be obtain ed in ca rly stage of hydrolysis, but although,m

amo unt of enzy me is add ed on stat ionary srage oF hydro lysis pro cess, there will be no in crease of hydro lysa re yield. On thar condi tion, produc r inh ibi tion will be occu rred. More over, rh e d ec reast: of enzyma tic rt:action mtc GlIl be occurredby

d ecreas ing spec ifi c pt: prideha nd , enzy me in3cr ivat ion :lI1d competit io n belweell substrates with pept ide obta ined from hydro lys is process

[6].

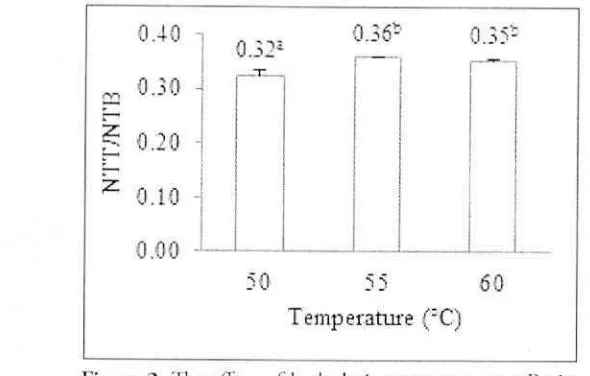

Hyd.rolys is Temp erature

Figure 2 showcd rh:H hydrolysis tc m pc ram re affectcd rario o f Nl·T/N'fB . The h ighest ratio of

NTT /NTB

was obta in ed on hyd ro lys is re mperam re of55

OC. Starisrica l analyzes fo ll owed by D un ca n rcsr showed char hydrolys is rC l11 peram re of55°C

W:1S signifi ca ntly diffcrcnc with hydrolys is t"unperaturc of50 "C

andwas not セゥァョゥヲゥ」。ョ イャ ケ@ d ifferent with hydrolysis temperature of

60 °C.

TI1c[efore, hydro lys is temperature of 55 OC \vas dec ided as th e hest temperature for peanut m eal pepron e p rod ucri on llsin g crud e papa in conct.: nrrar io l1 o f 0.4% for 4 h.Th e in crease of temp erature a ffec rs che mi cal reacr io n rate du e ro rhe in crease of kineti c energy berwcen rc;\cranr. This phenomenon also occ urred in enz.y mat ic reactio n wh ich in volves sl! bsrr:1tcsa nci enzym es. H owever, because an enzyme is protein, rh e increase of enzymatic rcacti o n will be perform ed on ceHa in tem perarure. I fhy d rolys is rempcrarure is roo high, protein enzym e ca n be d enatura rcci, tenia ry erlzymc strucrure can be dis nl pred and rhe enzym e Cl ralyri c :lcrivity will d ec rease

[7J .

OAO

O. 36t>o

セNLN@1

o ;)';

.. セIN@

, '-

r -"

0.30

'"

.

;z:

0.10

-"

;

;z:

0.10

I

0.00

50

55

601 , rnperature ('C)

Figlll"c 2 . ' [he cftecr ()r hyd rolysis H・イョイ ・ イNャエャャイセᄋ@ 011 R:nio

of N·JT/ N·' ·B. Differen t sl Lperscript indiGltl!d significant

[image:15.588.134.429.519.707.2]Proem/illg ASEAN COSAT2014

Amino Acid Content in Pepton e Produced

rill e co ncent rat ion of amino acids in pepto ne prod uced was diffcrcI1l with com mercial peprone (Bac[QTlo.l peprone). Pea nm pep m ne co ntained

duee

highest am ino :1Cids, namely1.63%

glu ta mi c aci d ,0.87%

3spa rtic :1cid :1 nd0.78%

argilli nc wh il c the lowest ami llo acid was methionin e (0.06%). CO llllllcrcial pepto ne co n tained the hi ghest a mino aci d namely glyci nc amoulHcci

2.03%.

The differe nt o f amino :lCid conrent is C:llIsed by rh e d ifFe rence of raw materi <ll used in peptollc produ cti o ll . 18] s(;1(ed th:u b。 」イッイセャ ー ・ーャo ャャ 」@ was prod uced by lI sing of an imal prote in as raw materia l and hydrolyzed by pancrea ci c enzyme.

App lication of Peptone Produced as Baclerial Growth Media

£:Jiclterichia (·oli

l esting resul t of pepro ne prod uced on formulat ion of li quid med ia showed (ha t pca nut peptone produ ced had thc hi gher ability (o r growin g of E. coli (h all IhcroT'\l pepco nc. Th is ca n be showed by [he resu lts of rurb idi ty dererminacion

of the culmre (OD620 11m) '.vhi ch rela rivel y hi ghe r than co mm ercial peprone (Figure 3a).

Sra ci!irical ana lysis showed rhar 00620 !lm of cu lrure brorh using pean ut pepro nc produced was sign i fi C:l llri y d i (feren t with co mm ercia] pepron e. Diffe rent widl liq uid med ia, appli cat ion of pcallu t pcpronc produced in soli d med ia showed [har the growth ab ility W:1S nor signi ficantly d ifferenr widl co mm crcial pepton e (Figure 3b) .

Acco rdi ng ro [9], :I rn i no :lcid !icri ne, :1spartic ::tcid, an d glur:11llic :1C id arc セ ュゥョ ッ@

ac ids whi ch arc very impo rranr For ba cteria l growrh. Pea nut pepronc produ ced conta ined high er glm<1 l1lic acid J nd aspa r{ ic acid {han co mmercial peptone, so rhose cou ld suppo rt bencr cel ls growth ofbacrcria.

SIf1phyloco("('U,f,· {fllreus

Figure 4a showcd n.:sring resul{ of pca ll u[ peptonc prod uced fo r growing of

Sftlph)'/OfOCCUS flurellS. セ i@ he res ul t showed rh:u peptone produced had higher abi lity

to Sll P POr( growth of

S.

fiuems [han cOlll mercial pcp rone. Statisrical ana lys isshowed [hat [he growth res ponse of pC.HIUC peptone produced was signi fican rl y d ifFe rent \virh cO lllm ercial peprol1 c.

The same with irs respon se [Q

E.

coli, app li ca tio n of peanut peptone in sol id med ia for grow ing sエョーOセス、ッ」occQヲs@ fiUrl'1IS showed rh at th ey were not signi fican rlydiA:Crcnt (Fi gure 4 0). By h,:s lin g the Pl.": Ull1l pCpLO ll e produced for growing of

Innovation for llener ASEAN C ommuniry 91

,..;...._

...

'"

2.00 1.64b'" 10

1

8.24'Nセ@ 1.5 1b QNUP セ@ セ@ 8 ·

0

I,SO

j

;:>"

1.021 U 6N セ@ 1.00

n

'"

"-

.3

"

0 セ@

0,50 - u 2

セ@

0.00 - - - - 0

S.:! II 8. 17' S.2·' ·

550 SSS 560 C SSO 555 S60 C

L _ _ _ _ __ _ -'S:e:''",,"',p"',,' -_ _ _ --' Sample

'PeptOllc on hydrolysis temperature: 50uC (550); 55°C (555): 60°C (S60): and co mmercial per rone (C)

(,) (b)

Figu l'c 3. G rowth fo r EJdJI'ridJin ('vIi in (:I) liqu id media and (b) solid med ia. dゥaセイ 」 ュ@ superscript inclic:ncd significanr di fference (p < 0.05).

2.50

b 2.OO 'r"

セ@ 1.50

"

-;; 1.00

••

8-0 .50 1.9.1t iNsセセ@ r"'-!.SIt -1.031• Peptone on hydrolysis temper:Hure: 50 C (S50): 55'-C

(S;'i) : 60' C (560); :lIId cOllllllerci.tl pcpton ... (C)

J' iglll'c 4:1. Growth of S/flphy/ocvcl'llS mm:w in liquid 0 .00

S55 S60 C med ia. Di ffcro.:nt supe rscript indicated signinc llII Sampl e d iffe rence (p < 0.0 5) .

550

L -_ _ _ _ _ _ _ _ セセ@ _ _ セ@

IV. CONCLUSION

Pea nm pcpwn e can be produced

by

hydro lys is o f pe:1I111C meal using crude papain enzy me. Producrion process of the pepw ne can be performed by hydro lys is co ndit io n usi ng0.40/0

o f crude papai n for 4 hat rcmpaafure of 55 "C.1111.:

yield ptprone p roduccd \Vas 40. 8%. Amino :lCids co m cnr in peanU[ pepronl.: tha r was ob cain cd had hi gh g luram ic acid, as partic acid and arginine. Generally, pe:mut pcpron c produced has simib r ab ility wirh co mm erci al peproll t: l3aclo"',\l pepro nc(or セ イッ ャvゥ ャャ ァ@ of [;.: coli :Illd Staphylororrus 1IIII'I' /i S in liqu id :lIId ... olid meJ ia.

v.

ACKNOWLEDGMENT

[image:17.593.32.514.37.614.2]92 Pmcmlillg ASEIIN

cos/! r

20 /410 Q ... --.,

, -

.

.)'''"9.38

1 9371r - r

-E

s

セ@

::J

6

..

UcD 4

0) セ@ 2 U 0-0

SSO

SiS

S60

Sample

VI. REFERENCES

9.32'

-C

' I\:prollc on hydrolysis (cm pcr:UUfC: 50 "C (55 0), 55 "C (555), 60 ·C

(560); :lnd colllll1 erci:l1 pepwne (C)

Figure 4h. Growth of Swpb;-lo{o{(lIS

rlllrt'/fS in sulid media. Different

super-script ゥ ョセャ ゥ 」Zャ{」、@ signific:mt 、ゥエエセG イ ・ョ」」@ (I' < 0.(5).

I) Rldal1 Pusa[ S[a d s[ik. (2 01 4).

'lnbel

impor mellI/rift /.:OIJlOc/ili. Rcrri evcd fromhttp://wlVlV.bps.go.icl/exilll-fi.llnc.php?/.:m=2&ic.-sllbJ•ek= 08cl .• /o I.II. =50

2) W ijayami , A.

T.

(2009).Kajial1

pCll)lflringandall lama

penyimpfwontlfI/anl

pembufilfIJI

]ish

peptone dari ikflllselar

klluing (Cara nx lepro lcpis) (M:ts rcr's rhcs is) . Bogor, Incioncsi:t: Inslirur Pcrranial1 Bogor.3)

Rose,A. H.

( 1980) . A1ico/;ifi/Enzlme

alit! BincollvenioJl (Econom ics Microbiology Vo l. 5) . New Yori<.US,

Ac,c1e lTl ic Press.4)

Benj,kul,S.

and M. l'vlorrisey.(1997).

Protei n hydro lys,tes from pasific whi t-ing so lid was[es.journal o/Agricultural ami Food

cィ・ュゥウャQjセ@ 45,3423-3430.

5) Shah idi , E , Xio-Qing, H. :1n ci

J.

Sy now iec ki. ( 1995) . Produ cr io n :1nc! char:1.crcrisr ics of prortin hydrol ysa res from c lpdin (M:1 ll orlls villosus).Foud

ChellJistry,

53,

285-293.

6)

Ncrro,E M.

andM.

A.M.

G:t IC:lZZi, ( 1998). Production :l.Ild char,lcrr.:rinrionof enzymadc hyd rolysarcs from soy prort.: in iso b rl!.

Lcbeusmilfcl- \.\'Iiss('llscbnji

&

Tec!Jllologie, 31

(8), 624-631.

7) Th ell aw ici jaja, M. ( 1984).

Pel/gallftf}"

KiJlelikfl

Euzim. Bogor, Indon es ia:I nsrirut Percanian Bogor.

8)

Becton, Dickinso n 3nd Comp,ny.(2009) .

Difcon ' & RilL'"Mmlllni of

Micro/;iologim/ Culture Ivlctiitf 2nd crl.

Sparks, M:1ryl:mcl: BO Di:1 gn osrics.9) SclvMaslI, 5., \Vei Ow, D . S., Lee, S. Y., Lee, M. M, \'(/c ng Oh, S. K., K:lr imi ,

I.

A.

and D.Y.

Lee.(2008).

Charoc terizing Escherichia co li DH5a growrhand mcraboli slll in a co m p lex m r.:ci iu lll using ァ・ ョッャャャ・M ウ」。 ャ セ@ Au x an alys is.