-I

PROCEEDINGS OF TIlE

nnd

ASIA PACIFIC SYMPOSIUJ\1

ON

POSTHARVEST RESEARCH, EDUCATION

AND EXTENSION

Convener

H.K. Purwadaria

Yogyakarta, Indonesia

Septembcr 18-20, 2012

ISHS Commission Education, Research Training and Consultancy ISHS Commission Quality and Postharvest H0I1icllltllre

ISHS Commission Economics and Management

Acta Horticulturac1011

ISSN 0567-7572

ISBN 978 90 6605 706 7, Acta Horticulturae n° 101 I

Price for non-members of ISHS:€ 11

1,-Published by ISHS, November 2013

Executive Director ofISHS: 1. Van Assche Technical Processing: S. Franssens

ISHS Secretariat, PO Box 500, 3001 Leuven 1, Belgium

Printed by Drukkerij Geers, Eekhoutdriesstraat 67,B-904I Gent (Oostakker), Belgium

°20]3 by the International Society for Horticultural Science (lSHS).Allrights reserved. No part of this book

may be reproduced and/or published in any form or by any means, electronic or mechanical, including photocopying, microfilm and recording, or by any infol1llation storage and retrieval system, without \\Titten pe1ll1ission from the publishers.

Photographs on the front cover:

セ

R3 4

5 6

I. Salak Pondoh plants and fruits (by courtesy ofG. Szrednicki).

2. Salak Pondoh fruits (by courtesy of\\I. Maneerat).

3. Mangosteen maturity index 3 for export (by courtesy ofH.K. Purwadaria). 4. Ready to eat mangosteen (by courtesy ofH.K. Purwadaria).

5. Demonstration facility for multipurpose plant factory, Osaka Prefecture University, Japan (by courtesy ofB. Murase).

6. Demonstration facility for high efficiency energy conservation plant factory,_Os:lka PJefecture

Editors

H.K. Purwadaria

/Jogor Agricultural University, Swiss German University, lndonC'sia

G. Srzednicki

The University

0/

New South Wales, Sydney, Australia S KanlayanaratKing Mongk/lt's University o/Technology Thonburi, Bangkok, Thailand

Editorial Board

E.W. Hewett

Masse)' University, Auckland, New Zealand

C. Wongs-Aree

King Mongkllt 's University o/Technology Thonburi, /Jangkok, Thailand

LIST OF CONTENTS

Foreword Keynote Speech Preface

List of Contents List of Authors List of Participants

Keynote Papers

Postharvest HOI-ticulture Education andtイセャゥョゥョァ Opportunities in the

Asia-Pacific Region D.E Aldous

Postharvest Research Education and Extension in Thailand: Capacity Building in Postharvest Technology at the University Level

S. Kanlayanarat andC. If/ongs-Aree

Improving the Effectiveness of Small-Holder Farm Postharvest Practices in Fiji

SJR Underhill

Influence of Postharvest Cooling on Product Quality D.R. Heldman

Optimisation of Distillation ofYolatile Compounds from Citrus Using Mexican Lime Oil as a Model

Z G. Shahidi, G.Srzednicki and J.D. Craske

Improved Postharvest Technologies and Management for Reducing Postharvest Losses in Rice

M. Gummert

Recent Postharvest Technology Invention to Improve Product Quality

Favorable Transpoliation Conditions Preventing Quality Loss of 'Jiro' Persimmon for Exports

K. Fahmy andK. Nakano

Sugar Components and Invertase Activity in Different Maturity Stages of 'Rongrien' Rambutan

S Tonglao, V Srilaong, S Kanlayanarat, S Noichinda, K. Bodhipadll1a

andS Khumjareon

Applications of Electric Nose to Determine the Maturity of Sapodilla Using Pattern Recognition System

.J.Nugroho, S Rahayoe and A.A. Oka

Production of High Quality Pineapple Juice Powder for Using in Instant Jelly Powder Product

V Chan/adul, S Thianpassakorn, S.Bannakulpipat

andC.Borompichaichartkul

5 6 7

9

J5 17

25

35

41

49

55

63

73

81

87

Application ofScllli-Cutting ;1I1d Waxing in Low Temperatmc Slorage or

Mangostccn 101

U.Ahmad, E Darmmvoti and F.E Aifllnonda

Effect ofCarnauba Coating and Plastics Wrapping on the Physico-Chemical

and Sensory Characteristics or Ralllbootan J11

R. Paramawati, D.A. Naslltion, A. Nurhosonoh andIV Su/islyosari

The Effect of Temperature on the Quality ofJapancsc Bunching Onion

(AlliumfistulosumL 'Kujyo') 119

V Sri/aong, A. Soon 10rl11vat, S lamia-or and N. rOIll{/llchi

Design and Development of Potato Grading Machine 125

T.W /Yidodo, J Pitoyo, D. Anggit and E. Rahmoreslio

Safety and Quality Assurance of Tomato UsingAloe veraEdible Coaling 133

F Santoso and VA. Rahmat

Seed Potato Production Using Aeroponics System with Zone Cooling in

Wct Tropical Lowlands 141

E Sumarni, H Su/wrdiyanto, KB. Senlinar and SK Saptol1lo

Fruit Fly Disinfestations ofSl3r Fruit(A\'errhoa carambolaL)Using Vapor

Heat Treatment (VHT) 147

R. Hasbullah, E. Rohaeti and R. Syarief

Improving Productionッヲpオイゥヲセ・、 Konjac Glucolllannan from

Al17orphophallus muelleriby Multistage Drying

R. 1mpaprasert,'G. Srzednicki. C. Borompichaicharlkul,J. Zhao alld L. Yu

155 ... <

Process Modification of Potential Thai Economical Tuber Crop to Be Used in Microencapsulation for Nutraceutical Products

S. Wattanaprasert. G.Srzednicki, C. BOI'OI17]Jichaichartku/, andP. Vaithanol17sal

Hydrodynamics Modeling of Com Drying in a Triangular Spouted Bed Dryer

W.B. Bie, G. Srzednicki and D.F. Fletcher

Design and Development of the Real-Time Paddy Quality Identification 。ョセ

Separation Based on the Acoustic Vibration Response and Vibration Resonance

&marno

163

169

if

.']

179

Evaluation of Postharvest Qual ity of Three Southem Highbush Blueberry

(Vaccinium corymbosumHybrid) Cultivars Subjected to Heat Pre-Treatment

1. Zhao, R. 1mpaprasert, L. Yu, J.Li andG.Srzednicki 187

Effects of a Surfactant on Development of Senescence inGrevillea'Sylvia'

1nflorescences 197

Setyadjit,DE Irving, D.C.Joyce and D. Simons

The Optimization of Anthocyanin Pigment Extraction from Buttcrny Pea

(eli/oria lerna/eoL.)Petal Using Response Surface Methodology 205

A.M. lvfarpolll1g, N. Andarwulan alld E Prangdill1uni

Vanilla Cultivation and Curing in Thailand 213

T. Wongsheree, C. H'ongs-Aree, V. Sri/aong andP. Jilareeral

Chilling Injury in Green Mature 'Gedong Gincu' Mango Fruits Based on the

Changes in Ion Leakage 219

YA Purwanlo, H Okvilasmi,S. Mard;an, U Ahmad, Y Makino, S Oshila,

S. Kuroki and Y Kawagoe

Apple Crispness Estimation from Optical Parameters 227

S. Walllyo, A. Shuaib, G Yao and J Tan

Just in Time Potatoes 235

N.K Veerapa, s.P. Singaraju andS. Muthaly

Quality Changes of Exotic Tropical Fruits during Storage in Semi-Passive

Modified Atmosphere 243

D. SapUlra andF. Prafama

Optimizing Formula of Composite Flour-Based Snack Bar for Emergency

Food Product (EFP) 251

S Darniadi, R.S Adiandri, N. Hidayah and SlIisl1Iono

Application ofI-Mcrto Delay Ripening of 'Mas Kirana' Banana

E. SlIkasih, Setyad;·it and A W. Permana

259

Separation Process of 5-Aminolevulinic Acid fromRhodobacter spaeroides

for Increasing Value of Agricultural Product by Jon Exchange

Chromatography 265

P. Tripetch, G. Srzednicki andC.Borompichaichartkul

Hydrolysis and Delignification of Rice Straw: Effects of Various Pressures,

Duration of Process and Acidities 273

B. Dwi Argo, I. Rokhmah Hand1.Kllrniawati

Postharvest Quality Enhancement of' Mekongga' Rice as a Responseto

Liquid Organic Fertilizer Application 279

S. WlIryani, o.S Padmini, R.R.R. Brotodjojo and D.A. Puspitaningrum

The Effect ofFJooding on Rice Characteristics of'Cilamaya MlIncu]'OJ]

Various Days after Planting during the Last Reproductive and Maturation

Phase 285

Marsetio, M Djali, S Nurhasanah, E. Lembong and R. Rahmat

Microwave Treatment for Killing the Silo Insect PestSitophilus zeamais

Motsch in Maize 293

E. Hartu/istiyoso

Application ofNear-]nfraredReflectance Spectroscopy for Detem1ination of

GambirCUncaria gambirRoxb.) Moisture and Catechin Content 299

SheII'Life and Chm,lcteristics of Strawberry(Fragaria nilgcrcnsisL.)

Coatcd byAloe vera-Glyccrol and Packed with Perforakd Plastic Film 307

HR Anlin, IS Seliasih and./S Hamdani

Environmcntal Factors Affect Postharvcst Quality ofGneilim gnell70nL.

Leaves 313

K Bunya-aliehurl and S Kanglang

Ginger and Turmeric Extracts: Their Effects onThielaviopsis parodoxa

Infection of Sabk Pondoh during Storage 319

o.s.

Dharmapulra, R., Hasbullah and R. KusmiadiDetermination ()f fl'ying Constant for Vacuum Fried Pineapple at Three

Levels of feeding Capacity 325

A. Laslriyanlo, S Soepannan, R. Soenoko and HS. Sumardi

Prediction of Chemical Contents ofJalropha ('ureasL. Seeds 11'-31' by Near

Infrared Reflectance Method 3J5

Lc.E.Clz. Lengkey, D.P. Sari, I. W. Budiaslra, KB. Seminar and B.S. Funvoko

Ripening Delay and Reduction of Free Fatty Acids of Oil Palm Fruit in

Response to I-IVlethylcyclopropene 343

N. Nualwifil, 1. Lerslenvong and W. lmsabai

Characterization of l-MCP Gas11-0111Synthesis of Various Ratios of

Lithium Diisoprupylamide (LDA) and 3-Chloro-2-Methylpropene (CMP) 35I

A. /;V Fennema, Selyadjit andW.Broto

Chilling Injury Alleviation in 'Golden Bell' Sweet Pepper Caused by UV-C

Treatment 357

S.Promyou and S Supapvanich

The Effect of Packaging and Storage Temperatures on the Shelf-Life of

Minimally Processed Cauliflowers 363

I.S. Setiasih, R Kaslaman andD. Jllusaddad

The Utilization of Rare Sugars as a Functional Food 369

M. Hadipernala. S.Hayakawa and R. Rachmat

Supply and Value Chain lVlanagement System for Agricultural ])'"oc!ucts

Development of Postharvest Handling Model for Mangosteen Fruit

(Garcinia 117angnstallaL.)along the Export Supply Chain

l.J\1. Edris, S. Mi7rdjan andE. Darmawati

Supply Chain Management of Rambutan Fruit for Exporting in Chanthaburi Province

S. Tongtao, V. Srilaong,P. Boonyaritthongchai, S.Kanlayanarat

and T. Wasusri

Model ofIntegr'lted Rice Milling and Value Chain Development

R. Rachmat, R. J)"ahjohutomo, S.Nugraha and Suismono

]2

377

385

Effective Postharvest Management of Tangerine Citrus(Cilms rei'lulula 'Siam Banjar') to Reduce Losses, Maintain Quality and Protect S:!lcty Zll Hassan, S Lesmayati, R. Qomariah and A. HasbiolllO

Trials for Application of Handling Technology in Mango Export

N. Selyowan,1. Mulyawanti, D.A. SeFyabudi and R Raehmal

Postharvest Research, Education and Extension Development

]<)<)

405

Postharvest Horticulture Education, Research and Consultancy: FUiUre

Challenges in the Asi3-Pacific Region 415

DE Aldous

An Overview of Postharvest Research, Extension and Education C:tpacity in

the Pacific with a Focus on Western Samoa, Tonga and The Fiji Isl:lnds 425

SJR. Underhill

Opening Hours of the Melbourne Wholesale Market and Their JmpJct on

the SustainabiJity of the Market 433

D.K. Veerapa, NK. Veerapa, L. Gorajek and S A1agazin

Novel TechnologyinPostharvest System

lon-Destructive Analysis of Internal and External Qualities of Mango Fruits during Storage by Hyperspectrallmaging

Y Makino, A. lsami, T Suhara, S. Oshita, Y. Kawagoe, M Tl'ukoda,

R. [sh/)Iamo, M. Serizawa, YA. Purwanto, U Ahmad,

S.Mardjan andS. Kuroki

443

Organ Specific Spatio-Temporal Patterns of Circadian Clock in Lettuce 451

K. Ukai, H. Murase and H. Fukuda

Characterization of Circadian Rhythms through a Bioluminescence Reporter

Assay in Laetuea sativaL. 459

1. Higashi, H. Murase and H. Fukuda

Intelligent Micro-Precision Irrigation System for Cultured Moss Mat

Production in Plant Factory 465

Y Hendrawan and H. Murase

Analysis of the Transpiration Properties in Sunagoke Moss 473

N Kawakami, H i'vlurase andH Fukuda

Pilot Model of Production System for Moss Greening Material in

Yogyakarta 479

M Ushada and H Murase

Controlling the Circadian Rhythm with Dark Pulses Leads to Improved

Quality of Production in the Plant Factory 487

S. Nishikawa, H. Murase and H. Fukuda

Optimization and Evaluation of Plant Growth Using Laser Light Source and

Air Flow Simulation in Plant Factory 493

M Akakabe, T Nishikawa, R. Masuishi, H. Narimo, H Fukuda

'Application of Semi-Cutting and Waxing

InLow Temperature Storage

of lVlangosteen

U Ahmadi E. Dannawatil and F.E. Munanda"

Jd・ー。イエュ・セエ of Mechanical and Biosystell1 Engineering

2postharvest Engllleenng Study Progr31l1

Faculty of Agricultural Engineering and Technology Bogor Agricultural University

Kampus IPB Darmaga Bogor 16680, West Java Indonesia

Keywords: mangosteen, semi-cutting, waxing, peel hardening

Abstract

Peel hHdening of mangostcen fruit is one of the problemsin low tcmperature

storage and it makes it difficult to open them before consumption, Onc atteIllpt to solve this problem is the application of semi-cutting treatmcnt before storage of the fruits. Semi-cutting application requires a combination with waxing and cold storage

to prevent faster quality deterioration beca use itprovides a way for microorgan isms

to enter the fruits, and increases the respiration as well. Waxing helps to cover the pores, and especially in this case, the cut opening, of mangosteen fruit and cold storage helps to slow down the respiration and metabolism. The purpose of this research is to study the effect of semi-cutting t,'eatment ill combinations \rith waxing treatment to increase shelf life, and provides easier opening of the fruits at the end of

long storage. Treatment of semi-cutting was conducted on two rlepths,3 and 5 nHn

whereas waxing treatment was conducted with 2 concentrations, 6 and 10%.

Mangosteen fruit which has been semi-cut and waxed was stored at 8 alld27°C for

60 days. It was observed that application of semi-cutting 5 mm and waxing 6% in

mangosteen fruit stored at goC provided easy opening until 33 days of storage while

maintaining fruit quality, which is the best result compared with other treatments, because the treatment was able to reduce the peel hardening.

INTRODUCTION

Mangosteen (Garcinia mangos/anaL.) is one of many exotic fi'uits from tropical

areas including Indonesia. Demand for mangosteens in Indonesia continues to be high

every year, both from local and export market. Quality of harvested mangosteen should be maintained, or even improved, whenever possible, through the application of postharvest handling. Low temperature storage is olle of the technologies that is widely used in postharvest handling of fresh products. Low temperature is able to pi'olong shelf life of fresh products by decreasing physiological activity. of the product such as

respiration, transpiration, and ethylene production as well as inhibiting mould

development during storage. However, some problems associated with low temperature storage of mangosteen such as green colour on stem and calyx turning them into brown, and peel hardening that makes it difficult to open the fruit for consumption after long-teml storage (Sjaifullah et a!., 1998). According to Qanytah (2004), peel hardening happens during low temperature storage and is a serious problem for mangosteens because their thick peel can be very hard to open if it loses water through transpiration process. In some cases, the stored fruits are impossible to open without any tool at the end of storage.

One attempt to overcome this problem is through the application of semi-cutting,

which is done by half-cutting mangos teen peel along its equator line to facilitate easy

opening even after the peel gets dry and hard. However, peel cutting, even only a part or maximum half of its depth, causes injury that creates a path for microorganisms to enter the fruit and start deterioration processes. To minimize the effect of semi-cutting, fruit

Proc. Second Asia Pacific Symp. on Postharvest Research, Education and Extension

Eds.: H.K. Purwadaria et al.

II'ill be coaled using a natural wax. Waxing is very il11pOl"lant J0r fruits and ver::etabL espccially when small injuries are present nn the surface ur'the pmducls. Waxing f.1re ver huits and vegetables from excessive water loss through respiration and e\'aporati, happening during storage. The aim oflhis research was to lind out hoI\' well semi-culLi'

facilitates opening of mangos teen fruits after long storage period nnJ how effective

II'axing pre\'ents quality detcrioration processes hy microorganislns.

MATERIALS ANDMETHODS

Mangosteen Ji'uits used in the expel'iment were those harvested in the second sta maturity level. Second stage IJ1JlUrilY level in milngosteell can be recognized through p( surface that started to change its color from yellow to red. The frnits II' Te harvested frc a farmer's orchard in Karacak village, Leuwiliang sub-district, Bogar District, West Jal Other materials used in the experiment were bee wax cl11lilsion, distilled water and otl: chemicals used in laboratory analysis. The equipment used were a cold store, a compLlI

controlled electronic universal testing machine, a constant tempcratul'e oven,

ehromameter, a hand refractometer, an analytic balance. and other utensils.

The preliminary experiment was conducted to determine how deep t

mangosteens need to be cut for facilitating easy opening \\"hen the peel gets dry and hal

By measuring peel thickness frol11 about 40 fruits, tbe minimum, maximum, and avera

peel depth were obtained. These data then were used to detennine the optimum depth semi-cutting, not too shallow because it will have no effect to opening force, and not t deep because it will cause breakage to the fruits during handlinn and storage.

In the main experiment, 1200 picces of second stage maturity mangosteen fru were selected and used. The fruits were selected from the same harvest time to be fr from defects, injuries, and diseases contamination, with the size ranges from 5.5 to 6.0 ( in diameter and from 80 to 100 g in weight. Thc fruits were divided into tbree groups, be semi-cut with 3 111m depth, semi-cut with 5 mm depth, and without semi-cutting. T

samples then were soaked into natural bee wax. Each group was soaked into 6 and JC

bec wax emulsion concentration for 60 s. Each different treatmcnt \\'as then divided ir two groups, one group to be stored at 8°C and the other at room.. temperature (27°( Observations were conducted for eight weeks with the observation schedule was start on day-O and then continued to day-6, 12, 18,23,28,33,37,41, 45, 48, 51, 54, 56, : and day-60 during the storage period. In the observation, 96 [mits were observed for ea treatment. Sample weight loss, peel hardness, peel moisture content, totll sol uble sol and fruit flesh colour were measured.

RESULTS AND DISCUSSION

From the preliminary experiment, the minllJmm and maximum thickness

l1lLlIlgosteen peel were 3.86 and 8.10 mm with an average thickness 01'5.91ml11. Based

this observation, semi-cutting was then determined as a treatment in two different dept to observe tbe effect, 3 and 5 mm depth from the peel surface. During the 60-day peri of storage, some quality attributes of fresh mangosteen were observed, and the results c discussed below.

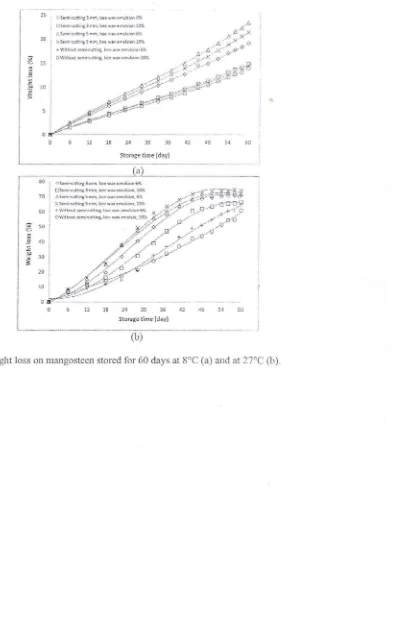

Weight loss is one of important factors that contribute to quality change horticultural products. Fruits lost their weight because of some water inside the fruits gc oul through respiration and evaporation. Water loss also happens during the ripeni process, since this process generates heat that makes the evaporation rate even higher, a this can be an indicator to physico-chemical changes that affect ftllit quality (Sihombil

20I0). Weight loss increases with storage time, and the higher the storage temperatu

the bigger is the weight loss. In the experiment conducted within the CUtTent study, at t

end of storage (day-60), the highest average weight loss was 74.05%, observed in t

fruils stored at room temperature (around 2JOC), while the lowest ayera6e was 13.89'

observed in the fruits stored at 8°C. At SoC storageエ・ュー・イセQエオイ・ as seen in Figure la, 1

range of average weight Joss for all treatments are 13.89-23.48% after 60 days storal

5 Illm depthウ・セャャゥM」オエャゥョセ and soaked in 6% bee wax emulsion. while the lowest (l3s<)n/,)

one observed from the frUits Wllhou[ semi-cutting and soaked In J0% bee wax UTIliisilL

Changc of weight loss for Illangosteen stored at room lelllpc:raturc is shown in Figure lb.

Weight loss ot Illangosteen after long period SlOr;)gc IS 。セウッ」ゥ[Iエ」、 with lhe loss "i

water through respiration that generates heal to evaporate sOl11e \\'atel, cspc:cially \\'ater QセQ

the peel which is close to the surface, and evaporation du..: to high stor:lf;c tempcratu",' "and low humidity. So, change in Illoisrure content during storage was also investiga:ed.

- From the obtained results, it ゥセ understood th;)t the hi;;hest ll10islUre content (high ill

freshness) afier 60 days storage \\'as observed from fn its stored at 8°C without

sel1:!-cuttinp. and 10% bee wax cllluision, which \vas 59,64%, The Il)west moisture content(10',\'

inヲイ・セャョ・ウウI was observed from fruits stored at room temperature with 5JDtn depth

semi-cutting and 6% bee wax emulsion, which was 1J.43%. The data show that low

temperature storage slo\\'s down water ャッセウ through cvaporation from fruits surface, whik'

semi-cutting treatment fastens the rate of water loss as It was prc:dlcted. and finally, wax coating slows down the rate of water loss and improves the sw-faee protection, TIlL' changes in moislLJre content of mangosteen peel arc shown in Figure 2a and b. It is clearlv noticed that at 8°C, moisture content decreased in slo\\Tr Idte if cOl1lpared with the rate cf those stored at room temperature.

"The results show that 5 mm depth semi-cutting caused higher rate of water loss

because the rate of evaporation increased as some part ofIi'uit surfaces was damaged, for

storage at all temperatures. Semi-cutting caused damage of epidennal layer of the mangosteen peel, which is an outer protection layer for the fruit, \vhere cuticle plays an important role in water evaporation. The cuticle was damaged a:ld caused water evaporation in that part. According to Muchtadi et a!. (2010), gas exchange, water loss, pathogenic, infiltration of chemical substances, heat resistance, mechanically injuries, evaporation of essential oi Is and other changes begin fi-om peel surface.

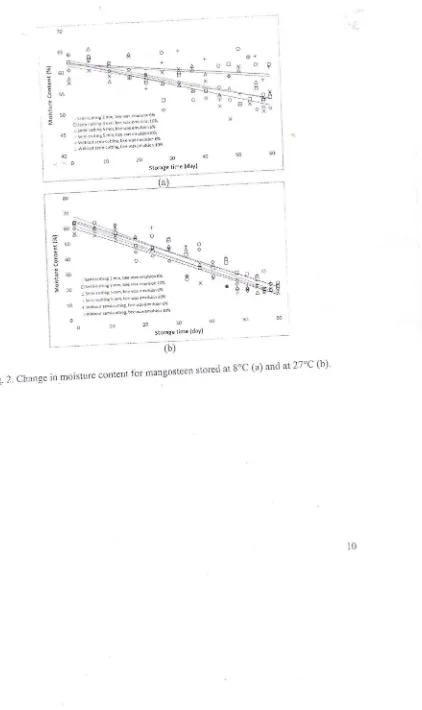

The results also show that fruits stored at 8°C in all treatments, experienced lower increase in peel hardness during the storage as compared to those stored at higher temperature, The lowest increase in peel hardness (0.562 kN) observed frOI11 mangosteen stored at 8°C with 5 mm depth semi-cutting and 6% bee wax emulsion coating. The highest increase in peel hardness (2.072 kN) was observed in fruits stored at room

temperature without semi-cutting and with J0% bee wax emulsion coating (Fig.. 3a and

b). It can also be mentioned here that, when the fruits are stored at 8°C, the increase of

peel hardness started on day-48, however the increase in hardness happened earlier (on day-33) when they were stored at room temperature.

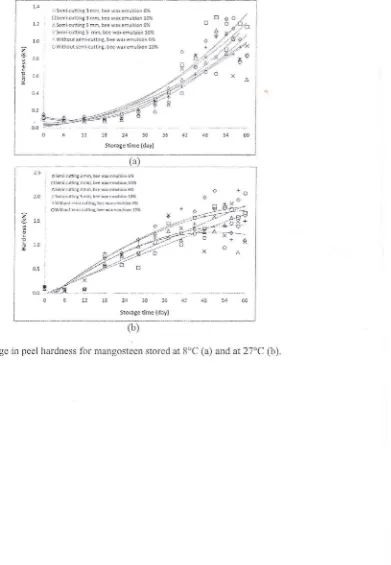

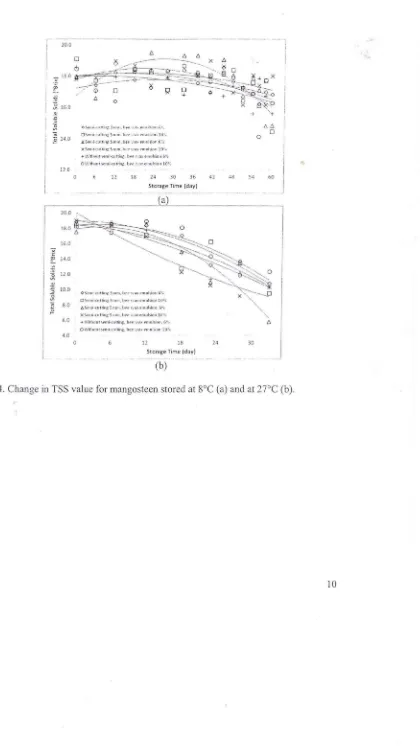

Another quality attribute that was affected by chemical changes in the fruit during storage period is total soluble solid (TSS) which contributes to taste of mangostcen, a

specific combinatiOll of sweet and sour (Muchtadi et aI., 20I0). From a measurement on

day-O, TSS of the fruits was found to be around 17.5-19 .00Brix for all treatments. During

the storage period, TSS ィ。カセ gradually decreased with time, and samples that were stored

at goC showed smaller、・」イセ。ウ・ in TSS compared to these stored at room temperature, as

shown in Figure 4. Among the treatments, the highest TTS value after 60 days storage

(lowest rate of quality deterioration in TSS content) was observed in samples stored at goC with 5 111m depth semi-cutting and 10% wax emulsion coating, with final TSS value of 18.000Brix, while the lowest TSS value (lowest rate or quality deterioration in TSS

content) was observed in samples stored at 8°C with 3 mm depth semi-cutting and 10%

wax emulsion coating, with final TSS value of 14.44°Brix. In general, TSS values were gradually decreased during storage period as shown in Figme 4a and b.

Determining if the flesh is damaged due to improper storage Cill1 be done by

pressing mangosteen peel. The damaged flesh'tends to be harder than the normal one so we can know it when we press it by our fingers, and \"hen we open the fruit, the flesh has transparent colour instead of while in nOllJlal fiesh, and its lexture changed from soft into

hard like an ice flake (Suyanti and Setyadjit, 2007). According to Suyanti ami Setyadjit

(2007), change in fruit flesh is reflected by change of peel cJli1ractcristics, in this case Il1crease of peel hardness, Bright white colour flesh at beginning of storage period turned

into dull lI'hilC colour セエ the end of ウエッイセァ・N Dur r:.: ;, - :.: セ =(' for 60 、セャysL tl

\igh\ness (L*) |B。|オセ orfn.\i\ fksh tendsto、エ」イ」N。ウセN \\I\i\-: "\1"0\\1<.\|ᄋH||iNIHZセNウ «\* and 1/')tel

to increase, indicating there was a chemiC<ll rC:3cliwl ·\ilhin the flesh. 1be hi;;he

lightness value was observed from mangosreen stOred:lt C,:) mill depth semi-cullin

and 10% bee "'ax emulsion. However, the same treatnL..'t also g2ve highest valuer.

green to red colour change(a*) and blue toyellow colo; ,'hangc (b"). During storage

room telllper<llllre. the change in lightness and chroma lo,'" place evenヲ。ウエセイL and most I

fruits stored at room temperature experienced severe .lctcrio!·atiOJl so they Wl:re n suitable for eating. For tbis reason, the data for the sarll,1,c:S storc:d at room tcmperatu were recorded only until day-IS.

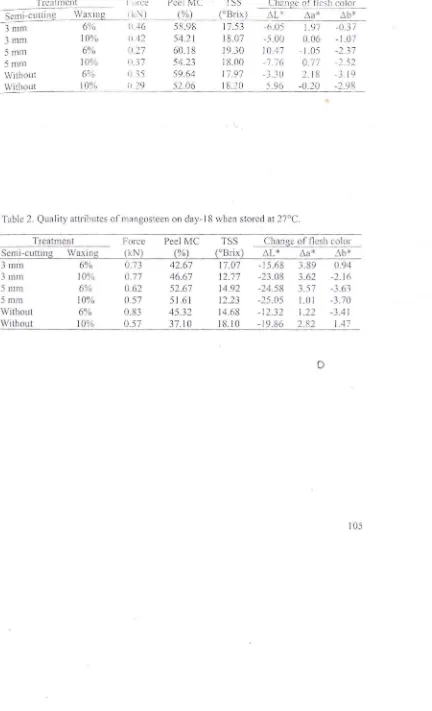

As can be seen in Tables 1 and 2, semi-cutting tends to prevent reel fro

becoming very hare! so it can facilitates easy opening ai"lcr long period storage al 10

temperature. This phenomenon was measured using a uili\ crsal testin

s

machine to recOItbe force that was needed to open the fruits.

CONCLUSIONS

Semi-cutting treatment can contribute to easier npening (need smaller force'

open the fruit) after long stol'age at low temperature. how('ver semi-cm peel rrffccts

tJ-rate of deterioration of some quality parameters such as \\eigbtloss,moisture contentar

nesh colour. At SoC storage semi-cutting can slow down peel hardness developmentlInl

e!ay-37 of storage, while at room temperature it can only keep good quality fruits un1

day-IS.

A combination of5mll1 depth semi-cutting with 6'/:) bee wax cmulsion was foU!:

to best contribute to easier opening while preserving quality ;Jttributcs by reducing weigl

loss and maintaining moisture content and flesh colour. With 5 mm depth semi-cutlin

and 6% bee wax coating, mangos teen was still easy to open with 0.189 J...N force aLi

33 days storage at low temperature.

ACKNOWLEDGEMENTS

The authors wish to thank Directorate General for Higher Ecneatioll (DGHE), tl: Ministry of Education of Republic of Indonesia for funding this research throug Competitive Research Grant (Hibah Bersaing) 20] 2.

Literature Cited

Jvluchtadi, T.R., Sugiyono and Ayustaningwarno, F. 20IO. Ilmu Pengetahuan Balw

Pangan. Alfabeta Press. Bandung.

Qanytah. 2004. Kajian Perubahan Tvlutu Buah Manggis(Garcinio 111QngostolloL)deng:l

PerJakuan Precooling dan Penggunaan Giberelin Selama Pc.nyimpanan. Tesi

Fakultas Teknologi Pertanian. IPB. Bogor.

Sihombing, y. 20]0. Kajian Pengaruh Konsenlrasi Pelilinan dan SLlhu Penyimpana

Terhadap Mulu Buah Manggis (Gorcinia mangoslano L.). Tesis. Fakultas Teknoloi

Pertanian. IPB Bogor.

SjaifulJah, Setyadjit, Donny, A.B.S. and Ruse!iyanto, U. 1998. Pcnyimpanan Eua

Manggis Segar e!alam Atmosfer Tel1110difjkasi padn Berbagai Suhu Dingin. 1. Har

S(3):1191-1200. .

Suyanti and Setyae!jit. 2007. Teknologi J'enanganan Buah Manggis DuLL!

Mempertahankan Mutu Selama Penyimpanan. Ba1:Ji Besar Penelititan da

Pengembangan Paseapanen Pertanian. Buletin Teknologi Pascapallen Perlanian \' oJ. 2007.

-Table I. Quality attributes of m lIlgosteen on day-37 when stored at 8°e.

Treatment I'uree Peel MC TSS ⦅セ・ ofllcsh color

Semi-culling Waxing IJ.;N)

(%)

(OBrix) 6.L* 6.a* 6.b*3ml11 6% () -+6 53.98 17.53 -6.05 1.97 -037

3111111 10% 0.42 54.21 ] 8.07 -5.00 0.06 -107

5ml11 6% 027 60.18 19.30 )0.47 -1.05 -237

5111111 10% 0.37 54.23 J8.00 -7.76 0.77 -252

Without 6% IUS 59.64 17.97 -3.30 2.18 -319

[image:14.610.87.519.114.825.2]Without 10% 029 5206 18.20 5.96 -0.20 -2.911

Table 2 Quality attributes ofl11angosleen on day-18 when stored at

n°e.

Treatment Semi-cutting 3 111111 3 111111 5111111 5111111 Withoul Without

Waxing 6% JO%

6% 10%

6% 10%

Force

(kN)

073 077 062 0.57 0.83 0.57

Peel MC

(%)

42.67 46.67 52.67 51.6 ] 45.32 37.10

17.07 J2.77 14.92 12.23 14.68 18.10

Change of flesh color

6.L* 6a* t.b*

-J5.68 3.89 094

-23.08 3.62 -2.1{i

-24.58 3.57 -3.63

-25.05 1.0] -3.70

-12.32 1.22 -3.41

-19.86 2.82 1.47

D

figUITS

Storage time (day)

(ISemi-cutting 3 mm,be:!wa:.:em\llsion 6%

oSemi-cutting 3mm, bee ...,'C1)0;セュオャウゥッョ ャoGセ

t:.Sami-cutting 5 mm. bee\':ilXセュオャウゥッョ 6%

セ\s・ュゥG」オエエゥョF 5 mm, bee wax emubion 10%

-+WitMlIts:!mi-cuttjng,「セe WilY.emliisionG%

OWithout semi-cutting, bee wax l!mul5ionlO%

60 54 42

36 30

(a)

24 20

25

セ 15

セ 10

60 54 48 42 20

80 <)Sgmi-cutting 3 mm, bee wax emulsion 6%

OSemi'cuttine 3 mm, bee wax emulsiQn,lO% --fNNMxセNRG

70 bSemi-eutti,..,g S mm, beeW4Xemulsion, 6% ,... ...,...yZZZyセQセセᄁN

;'':Sen'li-cutting 5mm.bee wax・ュオャウゥッャセN 10% Jセ「p NNNNNッMMM・M・ャMセ

60 +Wtll'lotJts.emt·wtfing,beewa).emlllslon6% xセBZGセO セONー セaOvセNY

OV..'ithout semi-wtting, bee wax en1ulsio,ャoEOᄃセセO ..0'/-- ,...rf .,O/0

セ 50 _ セZNセ\y / 0 " / j:/-r 4 /0

セ 40

..v/

セO6'

y/Q/<J;: f " / ./

Y

y /t..O ,/77 / ' / " '/0-"

,- 3 0 / '/:f / 0 ;V/ .

セ セOLO / /-:-e

セ

Oサ^セOサO. / /' /.qb?'i"

I

I 10

i

セNNMMZNOOoセ .._._._.._.__

.._._,-_._.__.._--,_._,.-o 12 18 24 30 36

Storage time (day)

L

セ⦅N__

セ__..._._.__

セ_ _..._..

._ ...__ .. "

(b)

[image:15.605.151.404.111.454.2]Fig. 2. Change in moisture content for mangosteen stored at. goC (a) and at

noc

(b).10

60 so 50

x

40 40

o

(b)

)0

Storage time (day) 30 Storage time (day)

20 20

10

⦅NMMMMセMMMMMMMMM

10

o

o

70 80 40 45 70

&5 b.

<!J_

e

セ 0 + 0'i: &0

セBGZZZセ

<> X- __ BGセBcZSZ^⦅MMMMMM + x4: + @ +0 0 X 0 Qセ b. x MMMセ・MMBGMMBMMMM " .

§

55 X b. +セBGZGMMセMM・セM

セ

0o\^セMoセセ

Mセ

50 ,,,n,_<uu,,,,3 "''''W."",,"""00." <> X <>セ

<>DS(m. (ull,nb3mfll.bte wa.. em",hlon lOt. i.:.ScmHutbnSセmm.tr.'<"wall emlllsion6')i,

.Sell\,.(utlI/1g 5 mm.tee'.'ta.'.elnlllsiGnlO%

セ WithoutセQャQゥN」ャャャAゥョF 「セ・ v.aK emulsion 6%

1,4 1.2

<·Semi·cutting 3 mm, bee wax emulsion 6%

OSemi-culting 3mOl,bee wax emulsion 10% 0 <>0 /

.6Semi-cutting5mm,bee waxemulsion6% 0 セセッ 11//9/0

XSemi-cutting 5 mOl, bee wa)! emulsion 10% セ セO

1.0 +Without semi-cutting, bee wax emulsion 6% 0 /18セ

Z OWithout semi-cutting, bee wax emulsIOn 10% +セO[ / ...

/x

セ (> I"iセ⦅OONᆪ_jイ 0

セ 08 0 GWOエOセO 5

セ X...-::::O...-:/;.P

セ

06 __セOセイ

0 X t;I 04 Pセセ[

セiゥ

02

セセヲaセMセセH

0.0 - .

-_._--_._---_._---N⦅N⦅MMセ⦅ ...

_--.---i

12 18 24 30 36 42 48 54 60

Storage time (day)

(a)

EO

54

x

43

j

r--;s

+0osemi.cutting 3 mm,セ・ ....'aXemulsion6%

Dsemi.cutlinS 3 mm, bet wax fllllJhiolllO%

ll.Semi.cuning)mn), b<'l.'wax emulsion6% <>

I

,

2 . 0 ' " semi-conine) rom. bet wax emubion 10% 0I +Withoutsemi-cutting.beeWJXemuJsion 6% セH^

I QWithoulsemi-CUlling, bee wax emulsionJO% + 0 @

I! セ (( セ A..e-B

I

セ 1.5 (> セNNZN + ---"'x+Ii::

セセZ

I

ッNッャNセ .. f!l

o 6 12 18 24 30 36 42

L_.

.

セセッイ。ァ・ セセセセセ ... . . [image:17.610.140.531.120.685.2](b)

20.0

;;; セ 14.0

12.0

O ....IlIHlIlTit\;/セュャャャ h ..i''.;.11t'lillthlOn HF,

b '>('IIIi,cullinf'... 111111, !Jet' \\',lX・ャャQャャャセゥoiャ FBセ XSt'mHlIllirl& Sl11m, Iwt" \'.'(17.エGャiャオャG^ゥGZスャャャoセMセ

+V;it!lOUI <\t'ml-{llllilll. bet'\".ll<EUlUlsioll6"'<_

o'"VithlJlIl Sl"llli-{lIllilig. ht'!' \'!;!XE'lIluhiolllO"o

o

12 18 24 30 36 42 45 60

10.0

セ

s:

11.0'" :cセ

a

8.0

6.0

4.0

Storage Time(day)

(a)

lJ. Sl'llli-{utrint S 111 Ill. bet'l'.'iHcャQQャQイセoiャN VBセ

xSemi-olllj",SlUlll, h .... W,.1)( pnluh.i('lnl0...

-+'Nicholll \t>mi-<:ltllill£. bE'E' W,1) t'lIlutsi{lll. (, ..セ OVJit1w111 $E'mi-Clllling, b" ..|Gサ[ャセ .:'lllllJsiollャoセI

11 18

Storage Time (day)

(b)

[image:18.610.111.531.52.798.2]24 30

fig. 4. Change in ISS value for mangos teen stored at goC (a) and at

noc

(b).