ZEOLITE-FILLED NATURAL RUBBER LATEX FOR GAMMA RAYS RADIATION SHIELDING APPLICATION

Ihda Novia Indrajati1), Indiah Ratna Dewi1), Dolly Gusrizal2), Ahmad Roisus Syifa’2)

1)Center for Leather, Rubber and Plastics, Jl. Sokonandi No. 9 Yogyakarta 55166,

Indonesia

2)Sekolah Tinggi Teknologi Nuklir, Jl. Babarsari, Sleman, DIY 55281, Indonesia

email: [email protected]

ABSTRACT

The objective of this research was evaluating the application of zeolite-filled

natural rubber latex as a gamma ray shielding material. Parameters studied were the

linear attenuation coefficient (μL), effectiveness of shielding by calculating half value

layer (HVL) and the effect of irradiation on rubber crosslink density performed by

swelling experiments. The samples were prepared either by dipping or by casting

process with various zeolite concentrations. Gamma ray radiation used 137Cs as the

source with the energy of 780 keV. The result findings showed that the linear

attenuation coefficient was dependent on zeolite concentration for the dipped

samples, while for casted samples were independent. Irradiation greatly affected the

crosslink density of casted samples, while dipped samples showed little changes or

remains unchanged.

INTRODUCTION protection can be achieved in many ways; radiation shield is one of them. Principally, a radiation shield is a kind that creates a barrier between a person and the radiation source, such that the radiation can be reduced to a lower level (Mheemeed et al. 2012; Abdel-Aziz et al. 1995). The shielding effectiveness of a given material largely depends on the type of radiation and the range of energy associated with the radiation (Nambiar & Yeow, 2012). Radiation shielding materials and its component should possess good mechanical properties, long-term reliability, good fabrication and joining properties, low density, high radiation tolerance and high energy absorption capabilities (Chen et al. 2014).

substances passed by. Zeolite containing rocks are used in wastewater purification to

remove anthropogenic radionuclides and also heavy metals (Galamboš et al. 2012).

These abilities make zeolite potentially to apply as high-Z filler of polymeric composite for gamma rays shielding. Several studies have been conducted utilizing zeolite in different media for this purpose (Akkurt et al. 2012; Kurudirek et al. 2010; Puiso et al., 2015).

Rubber composites have been used as shielding material by employing either lead or nonlead filler (Onjun et al., 2014; Mheemeed et al., 2012; Gwaily, 2002; Abdel-Aziz & Gwaily, 1997). Radiation proceeds to chemical changes of the rubber molecule chains, e.g. crosslinking (intermolecular bonds) or degradation (chain scission of bonds in the main polymer chain and inside chains). Crosslinks produced by this technique similar to those obtained by sulfur vulcanization. However, the net

effects, while similar, are not identical (Samaržija-Jovanović et al. 2014; Khalid et al.,

2010). Once exposed to a given dose of radiation, the C=C bonds in thermoset resin chain will be partially cross-linked to form a 3D stable gel. As a result, the mixture is no longer viscous liquid, but becoming viscoelastic gel (Martínez-Barrera et al. 2013). Radiation crosslinking produced carbon-carbon crosslinks that improve the

mechanical properties especially in high temperature (Samaržija-Jovanović et al.,

2014). Several studies had been successfully employed radiation to cure the rubber. Naseri & Jalali-Arani (2015) compared the effect of gamma irradiation and sulfur cure system on SBR/EPDM blends in the presence of nanoclay. (Mohamed et al. 2012) conducted a research on radiation vulcanization of NR/SBR blends containing silica, carbon black and titanium dioxide. Senna et al. (2012) and Almaslow et al. (2013) studied electron beam irradiated on natural rubber. Abou Zeid et al. (2008) investigated gamma irradiation on EPDM composites. The effect of radiation onto butyl rubber had been investigated by Scagliusi et al. (2012), and Khalid et al. (2010) evaluated the effect of radiation dose on the properties of natural rubber filled by CNT.

The present investigation is concern with the study of natural rubber latex that was prepared either by dipping or casting process, utilizing natural zeolite as filler in various concentrations. The prepared samples were subjected to gamma irradiation

effectiveness of the shielding material was evaluated from its half value layer (HVL). The effect of radiation on swelling ratio and crosslink density were also studied.

MATERIALS AND METHOD Materials

Concentrated natural rubber latex (NRL) with dry rubber content 60% and the additives including natural zeolite (purchased from local market), Ionol, zincdiethyldithiocarbamate (ZDEC), sulfur, ZnO, Darvan, Ammonium Chloride

(NH4Cl), Dipcal (calcium nitrate), ethanol 95%, calcium carbonate (CaCO3).

Additives Dispersion Preparation

Compounding is a mixing process between NRL and its additives. In order to get a homogeneous compound, both of them should be in the same phase. NRL is an emulsion, while the additives are powder. Thus, the additives should be emulsified before added into NRL. The emulsions or dispersions were prepared by using ball mill in the concentration of 50% w/w. The procedure to get 100 g, 50% w/w dispersion as follows: 50 g of each additive were mixed with 4 g Darvan (dispersing agent) and 46 g aquadest in a sealed-polyethylene bottle, which were filled by ceramic balls. Ceramic balls play a role as a grinding media. It is recommended to use three different diameters ceramic ball (e.g. 1, 2 and 3 cm) with the ratio of 1:2:1. The mixes in the sealed PE bottle were ball-milled for 24 h. The surface speed of ball mill was maintained on 60 rpm.

Compounding of NRL

Table 1. Composition of NRL compounds (in phr*)

Samples prepared by casting process were made into two different thicknesses, i.e. 0.5 and 1.0 cm. The procedures of casting process as follow: 20% v/v ammonium chloride aqueous 20% (w/v) was added into NRL compound (prepared in the previous step) and gently stirred. Immediately those mix casted into the square-mold such that the desired thickness achieved, and then let them hardened. Casted samples were vulcanized by steam 100ºC for 60 minutes. The samples thickness was measured using dial gauge three different area of sample.

Dipping Procedures

Coagulant dipping was employed to prepare the film sample using 30% ethanolic-calcium nitrate (Dipcal®) as coagulant and 30% calcium carbonate as parting agent. Cleaned and dried glass former were immersed in the coagulant solution for 10 s, followed by air-drying. The dried coated former were then dipped into the NRL compound with 10 s dwell time. After that, the former was withdrawn and the deposits on the surface were allowed to dry. Repeat the same procedure for double dipping. Vulcanization was conducted by steam at 100ºC for 30 minutes. The cured NRL film then stripped out from the former and stored in a sealed plastic. The samples thickness was measured using dial gauge at three different area of sample.

Attenuation Performance Measurement

The rubber specimens were exposed to gamma ray radiation for 30 s at room

temperature by 137Cs source with activity of 1 μCi and energy of radiation 780 keV.

………. (1)

The effectiveness of shielding material can be evaluated by its Half Value Layer (HVL) (Mheemeed et al. 2012). HVL describe the thickness of the material at which the intensity of the radiation after interacting with the absorber material is reduced to half of its energy before interaction (Eren Belgin et al., 2015). HVL is calculated after

obtaining the μL using Equation 2.

……… (2)

Swelling Test and Crosslink Density Measurement

Swelling experiment was performed on 2x2 cm cut sample prepared by either

the casting or dipping. The samples were immersed in toluene (ρ=0.867 g/cm3) at

25°C for 24 h. after the period was completed; the samples were taken out and

blotted with filter paper to remove liquid on the surface. Swelling ratio is defined on Equation 3,

……….. (3)

where w0 and wt are the mass of the test piece before swelling and after time “t”

immersion, respectively. The mass of the sample weighed using electronic balance

having precision 0.0001 g.

Crosslink density of rubber vulcanizates were determined from the equilibrium swelling measurements, and calculated using the Flory-Rehner (Equation 4) as follows:

……… (4)

Where Mc = the number average molecular weight of the rubber chains between

Vs=106.2 cm3 mol-1), Vr is molar volume of rubber, Χ=polymer-solvent interaction

parameter (for NR-toluene=0.42). The term Vr was calculated by using the relation as

expressed on Equation 5.

………… ...………. (5)

w1, ρ1 are the weight and density of rubber, while w2, ρ2 are the weight and density of

solvent. Swelling test and crosslink density measurement were performed before and after being radiated.

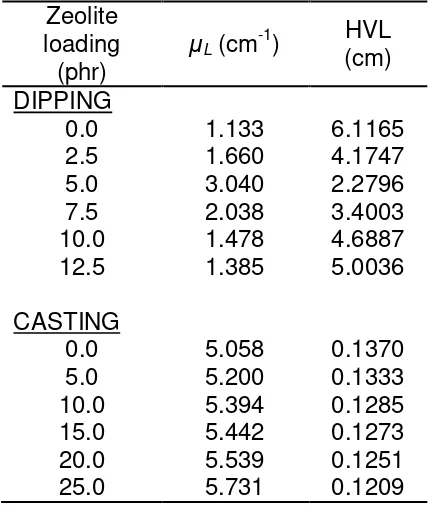

RESULT AND DISCUSSION Linear Attenuation Coefficient

Linear attenuation coefficient (μL) defines as the probability of a radiation

interacting with a material per unit path length. This parameter is the most important quantity characterizing the penetration and diffusion gamma radiation in medium

(Medhat, 2009). The magnitudes of measured μL and HVL of the dipped and casted

It is clearly seen that incorporation of zeolite into NRL matrix significantly affects the attenuation coefficient of dipping prepared samples. ANOVA result confirmed this

finding since F>Fcrit as shown at Table 3. The P-value lowers than α (0.05) means

that there is a strong correlation between zeolite loading and μL. The μL is increased

nearly three times with the incorporation of 5 phr zeolite, and then starts to decrease

with further addition. In contrast, μL of casted samples were independent to zeolite

loading and it has confirmed by ANOVA (Error! Reference source not found.).

Table 3. Single-way ANOVA

Source of

Variation SS df MS F P-value F crit

DIPPING Between

Groups 110.5748 1 110.5748 10.10754 0.009832 4.964603

Within Groups 109.3983 10 10.93983

Total 219.9731 11

CASTING Between

Groups 151.4928 1 151.4928 3.460421 0.092481 4.964603

Within Groups 437.7872 10 43.77872

Total 589.28 11

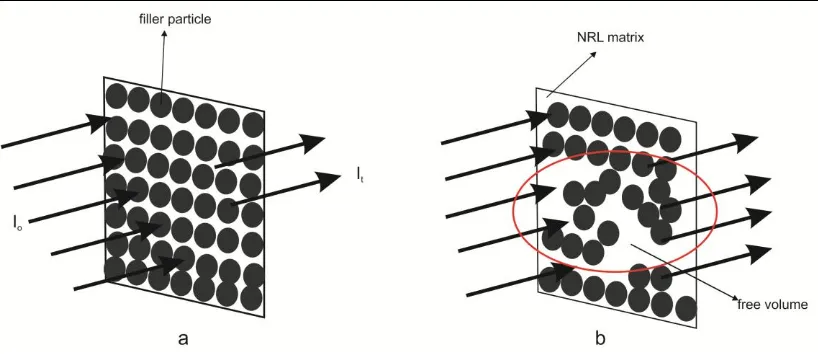

Gamma rays strike the material and their penetration are affected by the photon energies, thickness, density (Martínez-Barrera et al. 2013) and chemical composition (Erdem et al. 2010). The denser material will attenuate or absorb much radiation energy. Thus, homogeneous dispersion of the filler particle with less coagulation in the composites becomes the most important requirement. Coagulation or agglomeration of filler particle will generate a free volume in the NRL matrix. Figure 1

illustrates this phenomenon, where Io and It are the input and output intensity of the

Figure 1. Free volume creation as a result from agglomeration

In this study, lower zeolite concentration provides better filler particles dispersion. For dipped samples, critical zeolite loading was 5 phr, which provides better filler dispersion with less coagulation. Above this point, probability of coagulation is higher

exhibited by decreasing μL. Effective shielding material is provided by 5 phr zeolite

since it exhibit lowest HVL, while in casted samples HVL is found to be comparable. Zeolite dispersion was added into NRL in the concentration of 50% during compounding. This dispersion might be highly concentrated so that homogeneous compound was difficult to reach especially for higher loading. High-speed stirring can help homogenizing the NRL compound, but it is avoided because of frothing

tendency. This explains the independency of zeolite loading on μL of casted samples.

Thus, it is recommended to reduce the zeolite dispersion concentration into lower level.

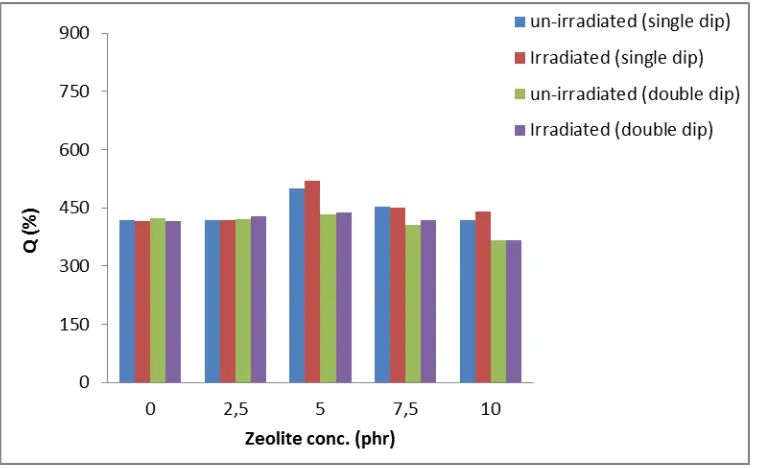

Swelling Ratio and Crosslink Density

The swelling phenomenon occurred in rubber can be describe as follows; the molecular chains in vulcanized rubber are usually loosely gathered that create a gaps in the molecular network (Lv et al. 2015). Thus, swelling test is often applied to predict the crosslink density of vulcanized rubber. Figure 2 and Figure 3 depict

Figure 2. Swelling ratio of dipped samples

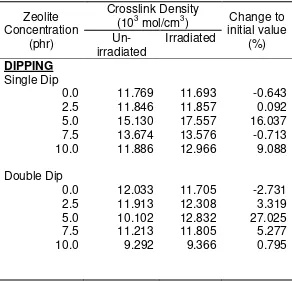

The Qt of the un- and irradiated of dipped samples show similar trend and the values

remain unchanged. It means that the gamma ray irradiation did not change the crosslink density of the vulcanizates, and confirmed by its changes as seen on Table 4. At the same zeolite concentration, single dipped samples provide denser crosslink than double dipped. The single dipped samples had lower thickness so that within the same vulcanization period will build denser crosslink in the rubber matrix, while the double dipped was insufficient.

Qt increased until reach a maximal value than start to decrease upon zeolite

concentration. Qt maximum was achieved at 5 phr of zeolite for both single and

double dipped samples. For single dipped samples, this finding is interesting since 5 phr of zeolite gave highest crosslink density. The denser crosslink on rubber matrices, the lower swelling because higher crosslink density will restrict swelling

(Samaržija-Jovanović et al. 2014). Interaction between filler particles and matrix also contribute to the gaps creation that will affect the extent of swelling. Solvent molecules penetrate into these gaps and causes a change in volumes and weight (Lv et al. 2015). Swelling of the polymer matrix by solvent depends on diffusivity and solubility of penetrating solvent molecule; which is a rate-dependent process

slower because at high filler loading the diffusion path of the penetrating solvent molecule will be longer and more tortuous.

Figure 3. Swelling ratio of casted samples

Table 4. Crosslink density of prepared samples

Zeolite Concentration

(phr)

Crosslink Density

(103 mol/cm3) Change to

initial value (%)

Un-irradiated Irradiated

DIPPING

Single Dip

0.0 11.769 11.693 -0.643

2.5 11.846 11.857 0.092

5.0 15.130 17.557 16.037

7.5 13.674 13.576 -0.713

10.0 11.886 12.966 9.088

Double Dip

0.0 12.033 11.705 -2.731

2.5 11.913 12.308 3.319

5.0 10.102 12.832 27.025

7.5 11.213 11.805 5.277

CASTING

Different thickness of casted samples gives different Qt response upon zeolite

increment as seen on Figure 3. Qt tends to increase upon zeolite concentration when

the samples thickness is 0.5 cm, while 1.0 cm-samples firstly increases until obtaining an optimum value and starts to decrease with further addition of zeolite.

Gamma rays radiation significantly reduces Qt and marked reduction in crosslink

density (Table 4) are also found. In this case, radiation has led to network degradation through chain scission. Ionizing energy of gamma rays radiation absorbed by the polymer backbone initiates a free radical substance; subsequently polymer then undergoes a chain scission and crosslinking, both of which alter the polymer characteristic (Nambiar & Yeow, 2012). Typically chain scission and crosslinking are coexist, the prevalence of each depending on many factors. A key role parameter can be played by irradiation parameters, such as the total absorbed dose and irradiation dose rate, because they affect the concentration of the reactive

species formed (Samaržija-Jovanović et al., 2014). Crosslink density reduction after

irradiation probably resulted by chain scission which is predominant than other mechanism. In the other side, radiation provides better filler-polymer matrix

CONCLUSION

Zeolite-filled natural rubber latex film has been prepared by either dipping or casting process for gamma rays radiation shielding. The linear attenuation coefficient

(μL) of the prepared dipped samples were dependent on the increment of zeolite

concentration, while of casted samples were independent. The most effective shielding material was given by 5-phr zeolite dipped sample. Agglomeration of filler

particles in the polymer matrix affected the μL. The concentration of zeolite dispersion

used in this study was too high and it was recommended to reduce it in order to get homogeneous filler dispersion. Gamma rays radiation did not affect the swelling ratio

(Qt) and crosslink density of the dipped samples, and both parameters were affected

by zeolite concentration. In contrast, the radiation greatly changed the Qt and

crosslink density of the casted samples. Chain scission plays a dominant role than other mechanism and contributing to the crosslink density reduction.

ACKNOWLEDGEMENT

The author will express their thanks to the management of Sekolah Tinggi Teknologi Nuklir, Yogyakarta for facilitating the gamma ray radiation experiment.

REFERENCES

Abdel-Aziz, M. M., & Gwaily, S. E. (1997). Thermal and mechanical properties of styrene-butadiene rubber/lead oxide composites as gamma-radiation shields. Polymer Degradation and Stability, 55(3), 269–274.

Abdel-Aziz, M. M., Gwaily, S. E., Makarious, A. S., & El-Sayed Abdo, A. (1995). Ethylene-propylene diene rubber/low density polyethylene/boron carbide

composites as neutron shields. Polymer Degradation and Stability, 50(2), 235–

240.

Abou Zeid, M. M., Rabie, S. T., Nada, A. A., Khalil, A. M., & Hilal, R. H. (2008). Effect of gamma irradiation on ethylene propylene diene terpolymer rubber composites. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 266(1), 111–116.

Akkurt, I., Akyildirim, H., Karipçin, F., & Mavi, B. (2012). Chemical corrosion on

gamma-ray attenuation properties of barite concrete. Journal of Saudi Chemical

Akkurt, I., Akyildirim, H., Mavi, B., Kilincarslan, S., & Basyigit, C. (2010). Radiation

shielding of concrete containing zeolite. Radiation Measurements, 45(7), 827–

830.

Almaslow, A., Ratnam, C. T., Ghazali, M. J., Talib, R. J., & Azhari, C. H. (2013). Effects of electron-beam and sulfur crosslinking of epoxidized natural rubber on

the friction performance of semimetallic friction materials. Composites Part B:

Engineering, 54, 377–382.

Chen, S., Bourham, M., & Rabiei, A. (2014). Novel light-weight materials for shielding

gamma ray. Radiation Physics and Chemistry, 96, 27–37.

Erdem, M., Baykara, O., Doĝru, M., & Kuluöztürk, F. (2010). A novel shielding

material prepared from solid waste containing lead for gamma ray. Radiation

Physics and Chemistry, 79(9), 917–922.

Eren Belgin, E., Aycik, G. A., Kalemtas, A., Pelit, A., Dilek, D. A., & Kavak, M. T. (2015). Preparation and characterization of a novel ionizing electromagnetic radiation shielding material: Hematite filled polyester based composites. Radiation Physics and Chemistry, 115, 43–48.

Galamboš, M., Suchánek, P., & Rosskopfová, O. (2012). Sorption of anthropogenic

radionuclides on natural and synthetic inorganic sorbents. Journal of

Radioanalytical and Nuclear Chemistry, 293(2), 613–633.

Gwaily, S. E. (2002). Galena/(NR+SBR) rubber composites as gamma radiation

shields. Polymer Testing, 21(8), 883–887.

Khalid, M., Ismail, A. F., Ratnam, C. T., Faridah, Y., Rashmi, W., & Al Khatib, M. F. (2010). Effect of radiation dose on the properties of natural rubber

nanocomposite. Radiation Physics and Chemistry, 79(12), 1279–1285.

Kurudirek Murat, M., Özdemir, Y., Türkmen, I., & Levet, A. (2010). A study of chemical composition and radiation attenuation properties in clinoptilolite-rich

natural zeolite from Turkey. Radiation Physics and Chemistry, 79(11), 1120–

1126.

Lv, X. R., Wang, H. M., & Wang, S. J. (2015). Effect of swelling nitrile rubber in

cyclohexane on its ageing, friction and wear characteristics. Wear, 328-329,

Mann, K. S., Rani, A., & Heer, M. S. (2015). Shielding behaviors of some polymer

and plastic materials for gamma-rays. Radiation Physics and Chemistry, 106,

247–254. 5

Martínez-Barrera, G., Menchaca-Campos, C., & Gencel, O. (2013). Polyester polymer concrete: Effect of the marble particle sizes and high gamma radiation

doses. Construction and Building Materials, 41, 204–208.

Medhat, M. E. (2009). Gamma-ray attenuation coefficients of some building materials

available in Egypt. Annals of Nuclear Energy, 36(6), 849–852.

Mheemeed, A. K., Hasan, H. I., & Al-Jomaily, F. M. (2012). Gamma-ray absorption

using rubber-lead mixtures as radiation protection shields. Journal of

Radioanalytical and Nuclear Chemistry, 291(3), 653–659.

Mohamed, M. A., Mounir, R., & Shaltout, N. A. (2012). Radiation vulcanization of

filler-reinforced natural rubber/styrene butadiene rubber blends. Journal of

Reinforced Plastics and Composites, 31(9), 597–604.

Nambiar, S., Osei, E. K., & Yeow, J. T. W. (2013). Polymer nanocomposite-based

shielding against diagnostic X-rays. Journal of Applied Polymer Science, 127(6),

4939–4946.

Nambiar, S., & Yeow, J. T. W. (2012). Polymer-composite materials for radiation

protection. ACS Applied Materials and Interfaces, 4(11), 5717–5726.

Onjun, O., Laothong, N., Picha, R., Ratanathongchai, W., & Onjun, T. (2014). Natural

rubber blocks as thermal neutron shields. Progress in Nuclear Science and

Technology, 4, 631–634.

Puiso, J., Jakevicius, L., Vaiciukyniene, D., Vaitkevicius, V., Kantautas, A., &

Baltusnikas, A. (2015). X-RAY shielding zeolite containing lead. In Proceeding of

International Conference “Medical Physics in the Baltic States” (pp. 119–123).

Samaržija-Jovanović, S., Jovanović, V., Marinović-Cincović, M., Budinski-Simendić,

J., & Marković, G. (2014). Comparative study of radiation effect on rubber–

carbon black compounds. Composites Part B: Engineering, 62, 183–190.

Senna, M. M., Mohamed, R. M., Shehab-Eldin, A. N., & El-Hamouly, S. (2012). Characterization of electron beam irradiated natural rubber/modified starch

composites. Journal of Industrial and Engineering Chemistry, 18(5), 1654–1661.

Shoushtari Zadeh Naseri, A., & Jalali-Arani, A. (2015). A comparison between the effects of gamma radiation and sulfur cure system on the microstructure and crosslink network of (styrene butadiene rubber/ethylene propylene diene

monomer) blends in presence of nanoclay. Radiation Physics and Chemistry,