FACTORS AFFECTING IN THE PREPARATION OF CONSTRUCTION WORK SCHEDULE

JUSTIN BONG CHUNN TAT

“I hereby declare that I have read this thesis and in my opinion this thesis is sufficient in terms of scope and quality for the award of the degree of Master of Science

(Construction Management)”

Signature : ………

Name of Supervisor : Prof. Dr. Muhd Zaimi Abdul Majid

FACTORS AFFECTING IN THE PREPARATION OF CONSTRUCTION

WORK SCHEDULE

JUSTIN BONG CHUNN TAT

A project report submitted in partial fulfillment of the requirements for the award of the degree of Master of Science (Construction Management)

Faculty of Civil Engineering Universiti Teknologi Malaysia

ii

“I declare that this project report entitled “Factors Affecting in the Preparation of

Construction Work Schedule” is the result of my own research except as cited in the

references. The report has not been accepted by any degree and is not concurrently submitted by any candidature of any other degree.”

iii

DEDICATION

Especially to my beloved father, mother, brother,

iv

ACKNOWLEDGEMENT

I wish to express my sincere appreciation to my supervisor Professor Dr. Muhd Zaimi Abdul Majid for his effort, encouragement and guidance.

In preparing this project, I was in contact with many industry practitioners. They have given me tips and useful information in order for me to complete the data sourcing. I am very thankful for them.

v

ABSTRACT

vi

ABSTRAK

vii

TABLE OF CONTENTS

CHAPTER TITLE PAGE

DECLARATION ii

DEDICATION iii

ACKNOWLEDGEMENT iv

ABSTRACT v

ABSTRAK vi

TABLE OF CONTENTS vii

LIST OF TABLES xii

LIST OF FIGURES xiii

LIST OF APPENDIXES xiv

1 INTRODUCTION

1.1 Introduction 1

1.2 Background of Study 2

1.3 Problem Statement 4

1.4 Aim and Objectives of the Study 6

1.5 Scope of the Study 7

1.6 Significance of the Study 7

1.7 Research Methodology 8

viii

2.2.1 Benefits of Construction Work Schedule 12

2.2.2 Developing a Construction Work Schedule 13

2.3 Construction Work Scheduling Techniques 14

2.3.1 Bar Charts 15

2.3.2 Critical Path Method 15

2.3.3 Choosing the Right Scheduling

Method 18

2.4 Developing Scheduling Specifications 19

2.5 Responsibility of Schedule Preparation 20

2.5.1 The Clients / Owners 22

2.5.2 The Construction Manager 22

2.5.3 The Designers 24

2.5.4 The Contractor and Subcontractors 24

2.5.5 The Design-Build Firm 25

2.5.6 Fabricators and Vendors 25

2.6 Sources of Planning Work Schedule 26

2.6.1 Construction Materials 26

2.6.2 Machineries and Equipments 26

2.6.3 Labours and Manpower 27

2.6.4 Finance 27

2.6.5 Time 28

2.7 Control and Monitor Construction Work

Schedule 28

2.8 Characteristics of Good Construction Work

Schedule 29

2.8.1 The Plan 29

2.8.2 Subcontractor Input 30

ix

CHAPTER TITLE PAGE

2.8.4 Explicit Activities Name 31

2.8.5 The Right Level of Detail 32

2.8.6 Well Organized Activities

Groupings 33

2.8.7 Proper Consideration of Weather 33

2.9 Requirements of Successful Construction

Work Schedule 34

2.10 Factors Affecting Preparation of Better

Construction Work Schedule 36

2.10.1 Project Specific Factors 39

2.10.2 Project Management 40

2.10.3 Working Condition 41

2.10.4 External Environment 41

2.11 Summary 42

3 RESEARCH METHODOLOGY

3.1 Introduction 43

3.2 Literature Review 43

3.3 Methods of Data Collection 44

3.3.1 Primary Data Collection 45

3.3.2 Secondary Data Collection 45

3.4 Analysis Method 47

3.5 Reporting Results 48

3.6 Summary 49

4 DATA ANALYSIS AND FINDINGS

4.1 Introduction 50

4.2 Data Collection 50

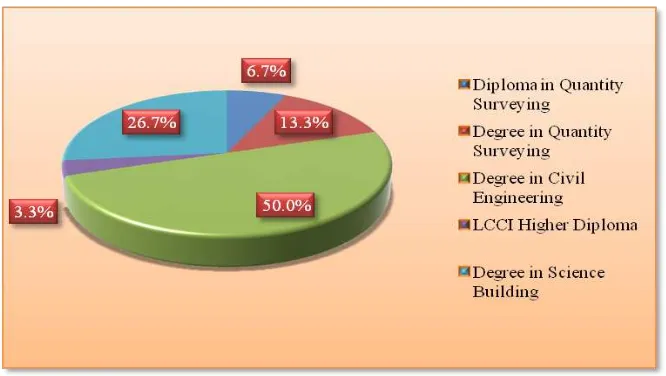

4.3 Demographic Profile of Respondents 51

x

CHAPTER TITLE PAGE

4.3.2 Respondent’s Experience 52

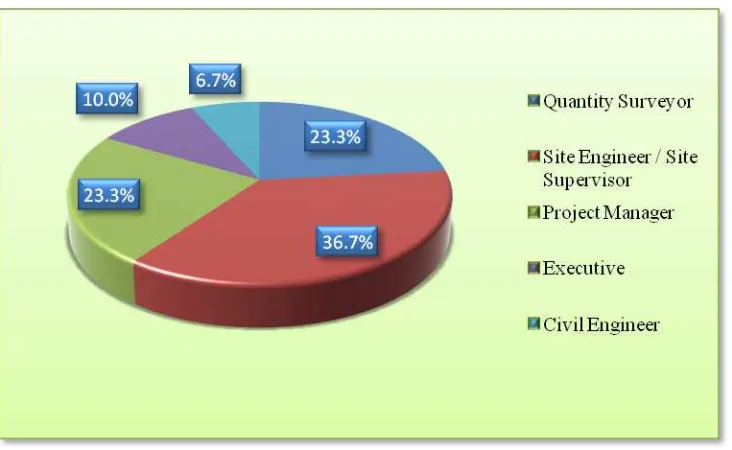

4.3.3 Current Working Position 53

4.4 The Analysis of the Factors 53

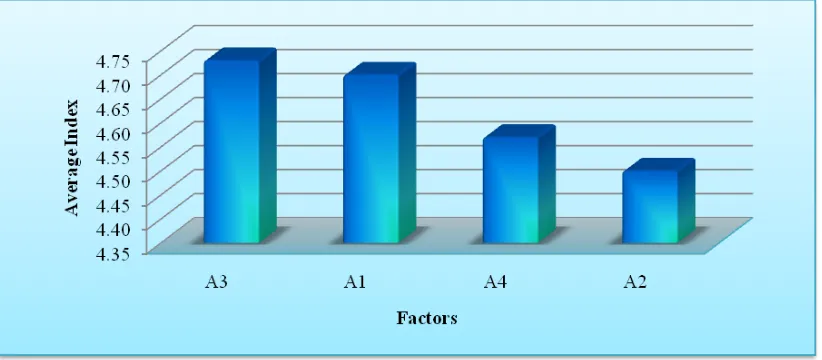

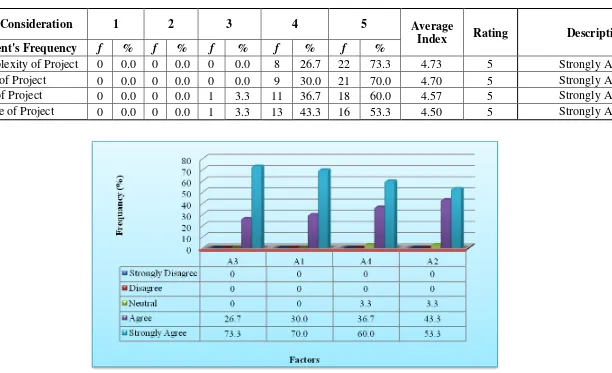

4.4.1 Analysis of Projects Specific Factors

Considered 54

4.4.1.1 Average Index Analysis 54

4.4.1.2 Frequency Analysis 55

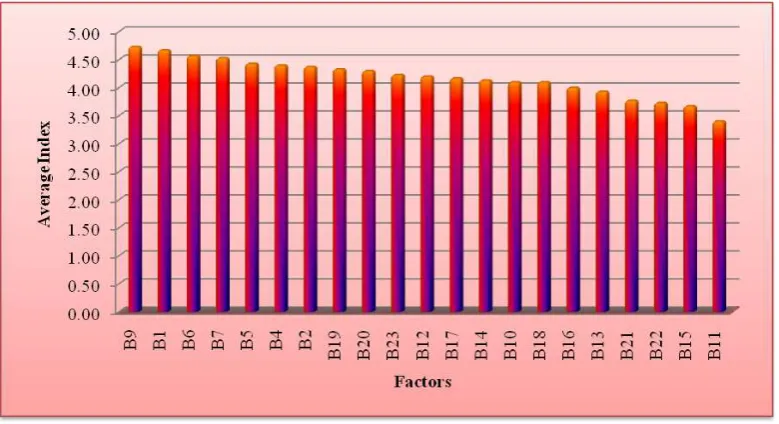

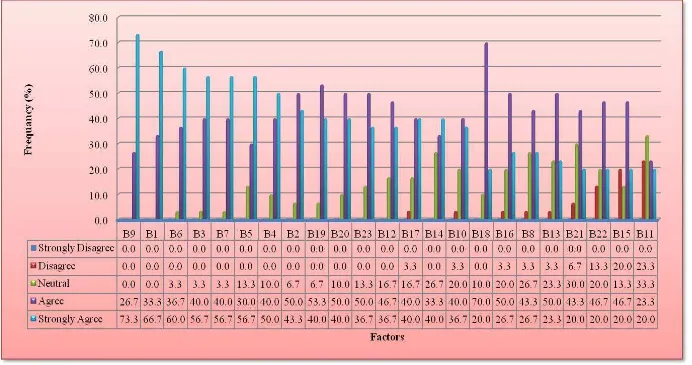

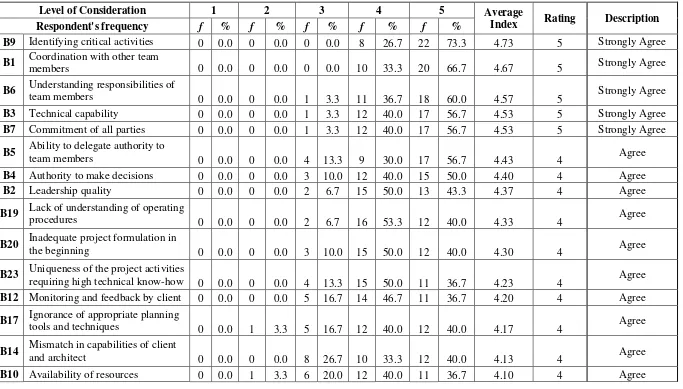

4.4.2 Analysis for Project Management Factors

Considered 57

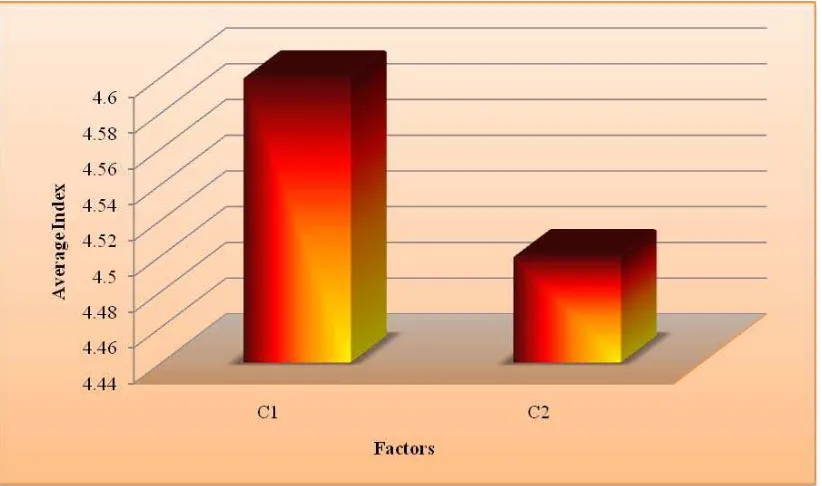

4.4.2.1 Average Index Analysis 57

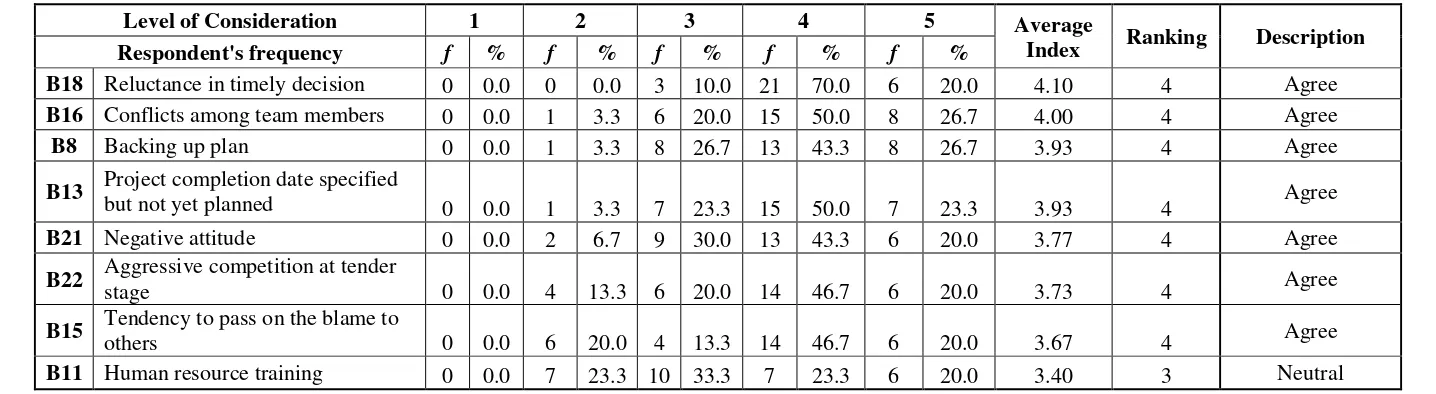

4.4.2.2 Frequency Analysis 59

4.4.3 Analysis for Working Condition Factors 63

4.4.3.1 Average Index Analysis 63

4.4.3.2 Frequency Analysis 64

4.4.4 Analysis for External Environment Factors 66

4.4.4.1 Average Index Analysis 66

4.4.4.2 Frequency Analysis 67

4.5 Analysis on Improvement Methods in

Preparing Better Construction

Work Schedule 68

4.6 Additional Suggested Factors Affecting

In the Preparation of Construction

Work Schedule 70

4.7 Discussion of Findings 70

4.8 Summary 73

5 CONCLUSION AND RECOMMENDATION

5.1 Introduction 75

5.2 Conclusion 75

5.3 Recommendations for future Study 79

xi

CHAPTER TITLE PAGE

REFERENCES AND BIBLIOGRAPHY 81

xii

LIST OF TABLES

CHAPTER TITLE PAGE

4.1 Project Specific Factors Considered in Preparing

Better Construction Work Schedule 56

4.2 Project Management Factors Considered in Preparing

Better Consruction Schedule 61

4.3 Working Condition Factors Considered in Preparing

Better Construction Work Schedule 65

4.4 External Environment Factors Considered in Preparing

Better Construction Work Schedule 65

4.5 Improement Methods in Preparing Better Construction

Schedule 69

5.1 Factors Affecting the Preparation of Better Construction

Work Schedule 76

5.2 Severity of Factors Affecting Preparation of Better

xiii

LIST OF FIGURES

CHAPTER TITLE PAGE

1.1 Research Framwork Flow Chart 9

4.1 Highest Qualification of Respondents 52

4.2 Working Experience of Respondents 52

4.3 Working Position of Respondents 53

4.4 Project Specific Factors 54

4.5 Tabulatin of Project Specific Factors 56

4.6 Project Management Factors 58

4.7 Tabulation of Project Management Factors 60

4.8 Working Condition Factors 63

4.9 Tabulation of Working Condition Factors 64

4.10 External Environment Factors 66

4.11 Tabulation of External Environment Factors 67

xiv

LIST OF APENDIXES

CHAPTER TITLE PAGE

CHAPTER 1

INTRODUCTION

1.1 Introduction

The construction development projects are vastly increasing in Malaysia as the Government is taking the initiative towards making Malaysia a developed country by 2020. In association to that, the construction arena became the catalyst for this development purpose. Malaysian today is mesmerized by the unique development today namely the Kuala Lumpur Tower, The Petronas Twin Tower, Kuala Lumpur International Airport in Sepang and The North-South Light-Way-Transit. These have become the Malaysian’s pride.

Nevertheless, in ensuring these massive projects to be completed and utilized, some important elements must be considered, such as cost, time period and design quality. Thus, in this research, time factor for the completion of a project is crucial.

2

Generally, the site supervisor will prepare scheduling reports to be evaluated and recommended by the client. The scheduling technique used will be the Precedence Diagram presented in the form of Microsoft Project or Primavera computer software.

This methods of scheduling is becoming more widely used in most of the construction projects especially Government projects. Thus, with this new technique, the process of construction in future can be identified and understood.

Therefore, research is done to identify factors affecting the preparation of a workable schedule of using Gantt chart, critical path method and other elements in the development projects in Malaysia. The usage of this method is predicted to reduce the problem of late possession of site and ensure that optimum cost, completion time and highest quality throughout the project.

1.2 Background of Study

Construction scheduling has come a long way in the last 25 years. Unfortunately, despite the widespread use of computerized scheduling on construction projects today, there still exists a large disparity in the level of understanding in the proper use of this powerful tool. According to Frank (2004), some even say there is a crisis in the construction industry because they believe scheduling software is being misused to assert delay claims and there is, in their view, a predominance of poor quality schedules.

3

In association to that, the clients and contractors should be exposed to the importance and benefits of using work scheduling as an effective way to plan future work. The concept of work scheduling technique using critical path and Gantt chart gives a great impact on a project by assimilating every party involved in the construction project in reducing cost, shorten the time period and increase the quality of construction productivity.

Glenwright (2008) also stated that a characteristic of contemporary project scheduling is the over-simplification which stems from the inability of unaided human beings to cope with sheer complexity. Even though a detailed plan is necessary, the management also need only act when deviations from the plan occur. A technique can be developed to resolve this situation that would be very simple but yet rigorous in application. One of the difficulties in the traditional approach is that planning and scheduling are carried on simultaneously.

Besides that, according to Twomey (2006), delivering a project on time relies on managing the development process, choosing experienced professionals, assessing timeframes realistically, and anticipating that some unforeseen problems are likely to come up. Aggressive management of typical scheduling issues that occur throughout construction can help ensure that projects are completed within the intended timeframe.

Hendrikson (2008) mentioned that in developing a construction plan, it is common to adopt a primary emphasis on either cost control or on schedule control. Some projects are primarily divided into expense categories with associated costs. In these cases, construction planning is cost or expense oriented. Within the categories of expenditure, a distinction is made between costs incurred directly in the performance of an activity and indirectly for the accomplishment of the project. For other projects, scheduling of work activities over time is critical and is emphasized in the planning process.

4

resources over time (resulting in job shop scheduling procedures). Finally, most complex projects require consideration of both, cost and scheduling over time, so that planning, monitoring and record keeping must consider both dimensions. In these cases, the integration of schedule and budget information is a major concern.

According to Glenwright (2008), the first step was to separate the functions of planning from scheduling. The basic elements of a project are activities and resource expenditures and execution times are associated with each activity in the project. These factors, combined with technological relations, produce schedules proposing varying completion dates. Management comes into possession of a spectrum of possible schedules, each having an engineered sequence, a known elapsed time span, a known expenditure function, and a calendar fit.

In fact, Twomey (2006) stated that the key factors in keeping a project on track are to understand what causes delays and then to properly plan and manage schedule issues before they become problems. Delays of individual construction tasks may not be preventable. However, those that can’t be avoided do not necessarily have to hold up the entire project. The success of any construction project is based on balancing the resources of cost, quality, and schedule. All three of these issues are important. On many projects, however, time is the most critical issue for the overall success of the plan.

1.3 Problem Statement

5

throughout the duration of the project. This is most likely to happen when the schedule is realistic, useable, and understood by all of the project participants.

Besides, Harban Singh (2004) mentioned that work schedule submitted by the contractor should contain the main activities, sequence of activities, timing of activities, critical activities and critical path, and important milestones. Since there are no clear guidelines for the application of project scheduling in project management the current practice is entirely depending on the experience of the project manager. This has resulted in a lot of time wasting effort before parties involved in the project accept any work schedule.

Nevertheless, there are still weaknesses in term of formal guidelines for the preparation and submission of work schedule. Several problems associated with project scheduling are the inability to fully utilize the schedule, lack of understanding of scheduling techniques, and unable to see the importance of work schedule as stated by Mohamad Ibrahim et al (2006).

Furthermore, Jon et. al.(2002) said that as many contractors lack the skills necessary for successful scheduling, an owner may choose instead to provide to the contractor for successful scheduling consultant and may even pay for this service.

The participation of key subcontractors and suppliers to the development of a workable plan (detailed activity plans) is emphasized by Claugh and Sears (2000) and Walker (1996) who argues that construction planning and scheduling must be done by participation of people who are experienced in and familiar with the type of field work involved.

non-6

productive time. Problems will arise in sequencing decisions which was made by last planners based on their knowledge of working conditions and constructability issues, as well as, selecting the right amount of work which will use the labor and equipment capacity as directed by the schedule.

However, it appears that it is not how often the network is recalculated or updated but instead it is how well the plan and schedule continue to fit the actual conduct of the work. As many of the key problems of implementation lie in the general environment of the project and not under the direct control of the project, project managers must look outside the project and ahead to anticipate problems and develop contingency plans. Kiiras (2001) stated that this can only be achieved by means of continuous planning and steering during project life instead of the traditional detailed project planning before the start and reporting during execution.

1.4 Aim and Objectives of the Study

The aim of this study is to identify the factors affecting in the preparation of construction work schedule.

To achieve the aim, the main objectives of this study are outlined as follows:

(1) To investigate the factors affecting in the preparation of better construction work schedule;

(2) To establish the severity of these factors; and

7

1.5 Scope of the Study

The scope of study is confined to building projects undertaken by contractors registered with class G5 to G7 under Construction Industry Development Board (CIDB) in the locality of Johor.

1.6 Significance of the Study

8

1.7 Research Methodology

In achieving the results of this study, a pilot study is done to obtain opinion from various parties involved in the construction projects. From this study, a hypothesis shows that the schedules normally given to clients from the contractors are done using the critical path method or precedence diagram method rather than bar charts.

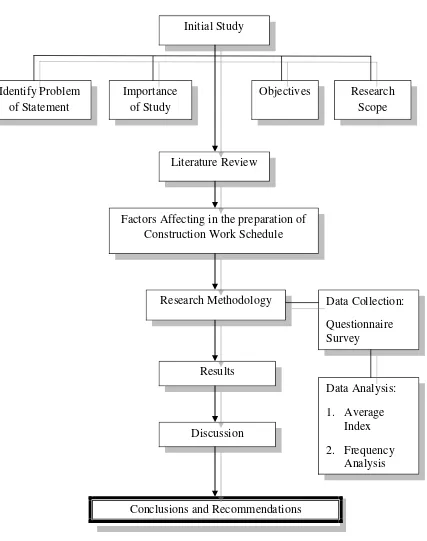

The approach for implementing this research is divided into a few categories. The purpose of this methodology is to simplify the process of data collection and other relevant information which is obtained throughout this research. The research framework flow chart is illustrated as show in Figure 1.1.

1.8 Summary

9

Figure 1.1: Research Framework Flow Chart Initial Study

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

This chapter covers the introductory of construction work schedule. The last

part of this chapter will focus on the factors affecting in the preparation of

construction work schedule with listing of all the possible factors adopted according

to the suitability of the local construction industry.

2.2 Importance of Construction Work Scheduling

The importance of planning and scheduling in construction cannot be

overestimated. The US Department of Labor, Bureau of Statistics, includes an

industry definition of a Construction Manager (CM) that states they will typically

schedule and coordinate all design and construction processes (USDL, 2005). In a

study entitled “What does a Construction Manager really do?” performed by the

11

most important general areas was time management, in which CMs reported their

most important function is to develop a construction schedule, followed by

developing and managing a critical path schedule for the job (CMAA, 2005).

Glavinich (2004) answers the question, “Why Schedule the Construction Project?”

with the following: to communicate the construction plan, establish production goals,

monitor and establish progress, and to manage change.

The construction schedule is one of the most powerful management tools at

the service of the construction manager. A well-planned and realistic schedule that

takes into account as many variables as possible will help keep a construction

project moving along smoothly, alert the construction manager when the project is

about to run into snags, and help make needed adjustments when unforeseen

circumstances arise. In order to do all that, though, the plan must have the input and

some degree of ownership from everyone who will have to live by it. Otherwise,

there is risk of having workers and subcontractors who are working against the

construction schedule rather than with it.

The schedule is prepared by the scheduler and/or planner. In preparing a

schedule, the scheduler or planner may meet or discuss with some people for crucial

information, e.g. estimator, manager, superintendent, sub-contractor, architect,

engineer, owner, and materials' suppliers. They may need to study the contract,

drawings, specification, and perhaps, conduct site reconnaissance. Further, they need

to know about manpower and productivity. Apart from the schedule, it is also

necessary to prepare systematic monitoring to provide early warning of restraints as

well as imaginative action to overcome them.

According to Jon et. al. (2002), the scheduling consultant should strive to develop a trusting relationship with the different participants to develop a workable

plan and project schedule. Proper scheduling provides the best opportunity for a

well-coordinated and well-sequenced project that is delivered on time and within all

participants’ budget. This is because a well-coordinated and well-sequenced project is

often difficult to achieve. He must work diligently with the project stakeholders who

are the general contractor, the subcontractors, the construction manager, and the owner,

agreed-12

on objectives. These objectives usually involve completion of performance in the time

allotted and delegated responsibility for maintaining the schedule utilizing the

methodology reflected in the project schedule.

2.2.1 Benefits of Construction Work Schedule

The Construction schedule major purpose is to map out the progress

expected on a construction project in a timeline that is the most efficient and cost

effective possible. It does this through various means, and serves a number of

subsidiary purposes as well. These include:

(1) The original conceptual plan can help determine the feasibility of the project

and give an idea of the estimated cost of the project;

(2) It serves as a reasonable, understandable document upon which contractors

and subcontractors can make realistic bids on the project;

(3) It makes binding agreements with subcontractors. When a subcontractor

signs the agreed-upon construction schedule, they are committing to meeting

its terms;

(4) It gives the owner of the project a realistic timeline by which he can expect

his project to be completed. It lays out the sequence of events and the

process that will be followed by the construction company and

subcontractors, making it easier for him to monitor;

(5) It serves as a map and scheduling tool for the project manager, who can use

it to schedule work crews, time deliveries and equipment rentals and monitor

the progress in case of needed changes;

(6) It becomes a daily, weekly and monthly benchmark of the actual progress on

the project as the construction subcontractors and crew leaders enter finished

13

(7) It serves as a base plan for any changes that might have to be made due to

unforeseen circumstances, unexpected delays (or completion ahead of

schedule – it can happen!), or owner changes and additions;

(8) When coupled with communication and project management software, it is

an effective, efficient way to track progress, and flag trouble spots before

they become critical.;

(9) It serves as documentation of work completed as the concerned parties sign

off on agreed upon completion;

(10)In the event of dispute or questions, it can serve as legal documentation of

the actual history and events of the construction; and

(11)After project completion, it can serve as a guide in future projects through

post-completion analysis.

2.2.2 Developing a Construction Work Schedule

Construction schedule specifications are all over the map. According to the

committees of the Association for the Advancement of Cost Engineering (AACEI)

and the Project Management Institute College of Scheduling (PMICoS) (2005),

there is no consistency in arrangement, focus or language. Some specifications start

right off with the software to be used along with the requirements for reports and

updates. Others start with scheduler qualifications while still others introduce the

purpose of the schedule and the schedule scope of work. Frequently, however, these

procedures, processes and technical details are completely intermingled. At the

same time, there are variances in common details, such as determination of lost

weather days and the maximum duration of an activity. Some specs specifically

require the qualification of the scheduler, while one owner offers to fund the

14

The idea is that processes and procedures that are common to many

specifications will be independent of the technical portions of the specifications.

The mechanical details of the schedule and specific software requirements can

reside in a technical section of the specification. Time extension requirements

should be separate as well. Having a common framework of schedule specifications

will lead to more consistency across contracts and will reduce confusion among the

contractor community. Accomplishing general industry agreement on the

procedures and process should be more achievable. Having a separate technical

section may not necessarily lead to agreement on many details, but will at least lead

to development of a checklist for owners to consider in their schedule specifications.

If today’s construction schedules are properly prepared, construction

managers, owners, suppliers, and sub-contractors have an efficient and effective

management tool to control complex construction projects accomplished by a

diverse array of designers, engineers, suppliers, and specialty subcontractors.

Planning, coordination, and communication of the work plan, schedule, performance,

and control are then greatly facilitated in the efforts to achieve projects successfully

and profitably. However, the ‘if’ needs to become ‘when’. And this means all of

the underlying aspects need to be checked by an independent, qualified and

experienced master construction scheduler and the validation-auditing team as stated

by Glenwright (2008).

2.3 Construction Work Scheduling Techniques

The advantages to using a complete construction scheduling package include:

immediate field updates; realistic revisions; input from those actually completing the

work; and a stronger investment in completing the work according to schedule and

on time. Onsite internet access to the construction schedule and communication

capabilities give the project leadership the tools they need to provide onsite

15

The nature of the project schedule will normally depend on the cost of the

project. A bar chart is usually used on smaller projects. As the cost of the project

increases owner’s start to demand a schedule that is based on a critical path method

network.

2.3.1 Bar Charts

A bar chart simply indicates when specific activities will start date, their

duration and finish date. The activities are plotted on a time scale. Since each

specific activity on a bar chart is depicted as a straight line on the schedule, a bar

chart is easy to understand. A bar chart does not indicate the interrelationship

between different activities nor does indicate that the commencement of one activity

is dependent on the completion of a predecessor activity.

2.3.2 Critical Path Method

It is important to understand the relationship between the commencement

and completion of the various activities which comprise a construction project.

Critical path method (CPM) network and Program Evaluation Review Technique

(PERT) are the two scheduling devices which indicate the dependencies and

interrelationships between different activities. Those interrelationships between

activities are indicated as a network.

Over the years, the CPM has become the common construction network

16

dependence of that activity on the completion of a preceding activity, and how the

completion of that activity will restrict the commencement of subsequent activities.

The CPM is graphical model of a project. The basic components of the

network are individual arrows which represent specific activities. The activity can

be any aspect of the project that requires either time or resources. The project

activities are indicated by a logical flow of the work from the left hand side of the

schedule to the right hand side. At each end of the arrow are activity numbers. The

numbers are referred to as “i-j” designations. The letter “i” represents the start of the activity and the letter “j” represents the finish of the activity. At some place along the arrow and between the “i-j” designations is a number which represents the number of days that activity will require. The schedule also has a time scale. Finally,

the critical path is shown as darker or different colored line that runs through the

critical activities.

According to William (2009), the basic steps in creating a CPM schedule

include: (1) identification of the basic tasks or activities that must be performed to

complete the project; (2) estimation of the duration of the specific activities; (3)

making a determination of the logical flow of the work, which includes a

determination of which activities must be completed before the subsequent ones can

commence; and (4) inputting the information into the computer so that it can make

the numeric calculations that lead to the formulation of the schedule.

Terms that are used in context of a CPM network include:

(1) An Arrow or line is used to represent one activity;

(2) A Node or Event which represents the beginning and ending point of an activity;

(3) A Milestone is typically a significant event that the owner or contractor wants to track;

(4) A Link which represents the path between two Nodes;

(5) A Dependency is the relationship between two different activities as

17

(6) A Predecessor activity is an activity that restrains ( refer to as a restrain) a subsequent depend activity;

(7) A the restrained activity that follows a Predecessor activity is a

Successor activity;

(8) Job logic refers to the necessary time and order of specific activities in relationship to the whole project; and

(9) Float represents the number of days an activity can be delayed without delaying the project, with a critical activity having no float.

The critical path is computed in two steps. The first step involves a forward

pass calculation of the activities; starting with the first activity on day one of the project. During the forward pass calculation the early start and early finish for that

activity is calculated. The early start is the earliest time an activity can start and is

based on the completion of predecessor activities. The early finish is the earliest

time an activity can finish, assuming it starts on time and takes no longer than was

planned. The second step is the backward pass calculation. It involves calculating

the late start dates and late finish dates for each activity. While the late start date is

the latest date an activity can start without delaying the project completion, the late

finish date is the latest date an activity can finish without delaying the project.

Scheduling software automatically completes these two calculation passes then

prepares a report with the dates and a graphic network portrayal of the schedule.

The Critical Path is the longest continuous chain or series of activities through the CPM network. In essence, the critical path is the shortest period of time

it will take to complete all the activities that comprise the project. The completion

of project is delayed when one of the critical path activities is not started on time,

not finished within the allotted time, or not finished on time. If a non-critical

18

2.3.3 Choosing the Right Scheduling Method

Jon et. al. (2002) mentioned that one of the key decisions to be made before a project begins is which scheduling method is best suited to the project.

Frequently, the owner and the designer decide on scheduling requirements as a part

of the planning process for a project and the process of drafting specifications for

bidding or negotiating. In making this decision, considerations were given to;

(1) The size, complexity, and location of the project;

(2) Project phases and timing;

(3) The number of parties that will act as prime contractors;

(4) The need date for completion of certain milestones and of the project;

(5) The experience of the owner, the architect/engineer, or the construction

manager in the use of specific scheduling techniques;

(6) The capabilities and experience of the prime contractor(s) in preparing

and implementing the project schedule required;

(7) The type and quality of data desired by the owner, architect/engineer,

construction manager, or contractor to effectively plan, schedule,

coordinate, monitor, appraise, and document the progress of the project;

and

(8) The amount of owner-furnished or third-party-furnished material and

equipment involved.

Regardless of the scheduling system chosen, the owner or the owner’s agent

responsible for managing the project should have experience with the scheduling

19

2.4 Developing Schedule Specifications

After an owner or agent has chosen the proper scheduling technique, either

the critical path method (CPM) or the bar chart method, it is important to the success

of the project that specifications outlining the scheduling requirements be carefully

prepared and incorporated into the contract. Including such requirements enables

an owner to more effectively control and enforce the scheduling obligations of the

parties involved.

Schedule specifications should be clear and concise, avoiding ambiguities

and potential misunderstanding. Unfortunately, this is not often the case.

Frequently, specifiers have little knowledge of the scheduling technique being

specified and the responsibilities and liabilities they can incur.

Experience has shown that it is very difficult to establish standard schedule

specifications for use by the construction industry today. For example,

specifications may range from one paragraph to five or ten pages. The short

specifications are dangerous, and the long ones are expensive. However, experience

has shown that the more detail included in the specifications, the better chance there

is to eliminate misunderstandings.

Hence, Jon et. al. (2002) stated that good Construction work schedule specifications set forth the type of schedule that will be in effect for the project.

Specifically, they address:

(1) The scheduling method and techniques to be used;

(2) Which party has the responsibility for preparing the schedule;

(3) Coordination of any multiple-contract situations that will exist on the

project;

(4) The amount or level of schedule detail required by the specification;

(5) The need to incorporate all contractually specified milestones. This may

include completion dates for critical components of work, deliveries of

20

layouts), dates for access to the prject, and availability dates for key work

areas (where renovbation proceed in existing facilities);

(6) The need for the contractor to identify dependencies that will restrain

performance;

(7) Processing procedures for shop drawings (preparation, submission, and

approval);

(8) Processing procedures for submittals (initial and updates, plus frequency);

(9) Procedures for review and approval of the schedule;

(10)Remedies for noncompliance (for initial schedule as well as updates);

(11)Updating procedures (specifying frequency, requirements for joint

updating meetings between parties, the keeping of meeting minutes, data

requirements and methods for incorporating time-impact analyses and

time extensions as part of the updating process);

(12)Progress reports;

(13)Whether or not the schedule will be used for determining progress

payments;

(14)Procedures for justification of time extensions (using time impact

analysis);

(15)Float utilization and availability to project and parties; and

(16)Involvement of subcontractors in the scheduling process.

2.5 Responsibility for Schedule Preparation

In order for the construction plan to meet all these requirements, though, it

must have the willing cooperation and buy-in of the owner, construction manager,

sub-contractors and designers. In short, everyone needs to have some degree of

ownership in the plan. For that reason, it’s important that the owner or construction

manager to have the input of every major player in the project during the design

21

As early as the bidding stage, it pays to be open to suggestions and

communication. Being open to input from bidding subcontractors allows the plan to

be refined based on the experience and capabilities of those who have tackled

similar work in the past. If those lines of communication are open from the very

start, every subcontractor who makes a successful bid has a realistic stake in the

project because they feel they helped define the tasks and timetable. Without it,

updating the schedule regularly becomes a time-wasting chore in their minds. When

a contractor and his crew have an investment in the plan, they feel they are helping

to manage it rather than being a slave to it.

As quoted by Willis (1986), most of the following parties will be participants

in a typical construction project. Women now play significant roles in all sectors of

the construction industry, and it is expected that their participation in the industry

will continue to increase.

Once the project delivery system and scheduling methods have been selected,

the party responsible for preparing the project schedule must be designated. In the

traditional approach, for example, an owner requires a general contractor to prepare

the schedule. In addition, the owner has the option to require the general contractor

to submit the schedule either for formal approval or for informational purposes only.

Under such circumstances, the general contractor also had options. For

example, the general contractor may choose to prepare the schedule in-house or may

contract the services of a scheduling consultant to provide technical assistance if the

required skills and experience are not available in the general contractor’s

organization. On occasion, an owner may specify that the general contractor hire a

scheduling consultant and may even insist on approving the use of any consultant

selected by the contractor.

As many contractors lack the skills necessary for successful scheduling, an

owner may choose instead to provide to the contractor for successful scheduling

consultant and may even pay for this service as referred by Jon et. al. (2002). This

option also offers alternatives. For example, the scheduling consultant can work

22

contracted; the resultant schedule can then be submitted by the contractors to the

owner for formal approval or informally agreed to by the owner. The scheduling

specifications should include information on whether the schedule submittal

required formal approval by the owner.

2.5.1 The Clients / Owners

This is the individual, the firm, or the organization that funds the construction

project and will own the completed facilities. The owner, perhaps assisted by

consultants, specifies the scope of the construction project.

In some instances, the owner may specify the detailed layout of the facility,

the type of materials to be used, and so forth. The owner, perhaps assisted by some

of the parties described below, and depending on the technical expertise of his or her

own staff, may inspect the project work as it is being performed and on its completion.

The golden rule in the construction process is: "He who has the gold makes the

rules." Because the owner controls the purse strings, he or she dictates the kind of

contract that will be used and selects the other parties to the project.

2.5.2 The Construction Manager

He or she is an employee of a professional construction management firm that

may be retained by the owner to perform predesigned planning, to help select the

designer, to help select contractors, and to perform post-contract award functions. The

construction management firm may perform all or some of these functions in return

23

employee of such a firm. The term construction manager can also be applied to

many other management level personnel within the construction industry.

When an owner contracts the services of a construction manager as his agent,

the construction manager is frequently responsible for overall scheduling and

coordination when multiple trade or multiple prime contracts are used. As a result,

the construction manager has several options schedule development and

implementation.

The construction manager may prepare an overall detailed master schedule

for the project. This type of schedule usually be supported by milestone schedules

and/or prebid integrated schedules for each of the key multiple prime or trade

contracts that are anticipated to be let with this method of the project delivery.

As trade contractors are let, the construction manager has the option to

require each trade contractor to participate jointly in the development of the trade

contract schedule. The objective is to reflect the trade in the development of the

trade contract schedule. The objective is to reflect the trade contractors’ plans and

intentions to execute their work and to coordinate their dependencies with others.

The alternative to this procedure is to require trade contractors to prepare

their own schedules, based on certain basic information provided by the construction

manager, and submit them to the construction manager for approval. After approval,

the construction manager has the option to incorporate the trade contractors’

schedulers into the detailed master schedule or to maintain them separately. From

the detailed information, a time-scaled master summary control schedule may be

developed by the construction manager to provide management with overall project

visibility and a management tool for use in periodic briefings and reports.

When design-build construction manager project delivery systems are used,

the scheduling options available to the design-build contractor construction manager

24

2.5.3 The Designers

They may be employees of the owner, but are more often the employees of

an architect-engineer (AE) firm. In addition to designing a facility that meets the

expressed needs of the owner and that complies with applicable building codes, the

AE may be retained by the owner to act as his or her representative in

inspecting the project work, to review and approve materials that the contractor

proposes to use in the work, to review and recommend contractor requests for progress

payments, and to perform other functions on behalf of the owner.

2.5.4 The Contractor and Sub-contractors

These are individuals or firms that undertake to perform required

construction work in return for a contract price. Contractors may be categorized

as prime contractors and subcontractors. Prime contractors have a contractual

relationship with the owner, whereas subcontractors have a contractual relationship

with the prime contractor or with another subcontractor. General contractors are

prime contractors who contract to perform ail of the required work, possibly

excluding some specialty items such as electrical and mechanical work that the

owners desire to contract directly with the specialty contractors. Subcontractor s

are sometimes referred to as first-tier subcontractors, second-tier subcontractors, and

so on. A first-tier subcontractor has a contractual relationship with a prime

contractor. A second-tier subcontractor has a contractual relationship with a

first-tier subcontractor, and so forth. A typical construction contractor, regardless of

whether a prime contractor or a subcontractor, will perform certain functions, either

personally or by use of his staff. These functions include the following:

A. Home Office Functions. These include the selection of potential

25

bids or negotiating construction contracts, the procurement of

construction materials, the management and maintenance of

contractor-owned equipment, and personnel and financial

management. The titles of home office contractor staff members

might include: estimators, schedulers, procurement specialists,

accountants, counsel, project managers, fleet managers, safety

officer, quality control officer, and others.

B. Field Functions. The contractor's principal field function is project

management. The contractor may have a project manager, a

project superintendent, or both as his field supervisors at the project

site. Other contractor field personnel may include office engineers,

office clerks, time-keepers, clerks, inspectors, and foremen.

2.5.5 The Design-Build Firm

The term is usually reserved for firms that perform both design and

construction functions, but such a firm may also perform planning functions.

2.5.6 Fabricators and Vendors

These terms apply to firms that contract with the owner or with the

contractor, to fabricate and deliver fabricated or off-the-shelf construction

materials to be used in the project. The construction contract may call for the

contractor to purchase and install all of the material, or it may call for the owner to

purchase some of the material for installation by the contractor. Material that has

been procured by the owner is termed owner-furnished material (OFM). If the owner

26

2.6 Sources of Planning Work Schedule

When everyone is together, it is more possible to identify needs for

additional manpower, added equipment, and potential time loss and gain. If a delay

has caused the loss of time, the entire team can work on recovering the lost time. If

there is a gain, the team can come up with the best way to use the gain.

There are many method employed in project planning. Many project

planners were used to table form which comprises from a date list, starting or

completed information, which are provided by the management. Regardless of the

methods employed, the decisions made will require the collection of data on

materials, machineries, equipments, manpower, finance and time.

2.6.1 Construction Materials

The measurement of quantities by the quantity surveyors from building plans

and specifications can be summarized to determine the particular quantity and types

of materials to be used to perform a work. The availability and delivery period for

these materials should be obtained and from suppliers or according to experience.

2.6.2 Machineries and Equipments

The machineries and equipment which are required to complete a

construction project will definitely depend on the suitable types and the method of

27

machineries or equipments is made, the availability and delivery time must be

determined.

Heavy machineries such as cranes, cement mixers, steel bar cutter and steel

bar bending machines for structural works are required during the execution of the

work scheduling. These matters are important to prevent machineries from idling

which induce will induce a high cost.

2.6.3 Labours and Manpower

Labours and manpower are important assets in construction projects.

Without labours, a project can become abandoned and the contractor will need to

terminate the contract. Thus, labours should be taken into account when scheduling

work to ensure that the participation of the labours is at the maximum standard.

The numbers of skilled workers should also be considered in the work

performed. It should be adequately sufficient to meet expected workload and work

tasks. A mistake in this planning will result in late submission of works.

2.6.4 Finance

The allocation of finance must be scrutinized to reimburse for the cost of the

supply of construction materials, labours and machineries. Any financial difficulties

28

2.6.5 Time

The most crucial element which must be carefully monitored is time. The

owners will normally check for starting dates, completed dates and other relevant

yet important dates in contract submissions by the contractors. Besides, there are

also time limits which must be obeyed by construction organizations during

planning stage.

The time require for the construction materials to be delivered to site should

follow a specified schedule. This is to fulfill worker’s demand and reduce wastage.

A proper understanding of the project requirements will enable a more effective and

efficient materials handling at site.

2.7 Control and Monitor Construction Work Schedule

Communication remains vital once construction begins. Keeping the lines of

communication open involves making regular updates on progress both ways. It’s

up to the crew leaders to be sure that progress is tracked regularly in the scheduling

software. Any possible delays need to be noted, as well as finished work flagged.

Making the means to communicate instantly available on site provides both

incentive and opportunity to keep the schedule properly maintained.

In addition to daily updates, regular weekly meetings of the team leaders are

vital as well. These meetings should include the project manager, an owner

representative, and representatives of the subcontractors. Update meetings can

provide a look-ahead on the project’s progress and possible difficulties or gains. By

breaking down the schedule into smaller blocks, weekly meetings can help make the

29

upcoming week. Again, including all interested parties makes use of the expertise

of everyone concerned, and fosters the team attitude that keeps the project on track.

2.8 Characteristics of a Good Construction Schedule

According to Frank (2204), the best approach is for all project participants to

join in the scheduling process and develop a meaningful schedule, and then use it

throughout the duration of the project. This is most likely to happen when the

schedule is realistic, useable, and understood by all of the project participants.

2.8.1 The Plan

All good schedules start with a well thought out planned work sequence.

The plan should consider factors that could impact the timing of the work such as

site access, access to work areas, long lead time equipment and materials, labor

availability, and which areas of the work will take the longest. Once this plan has

been established, it should be clearly communicated to all project participants. It is

important to make sure that those not working on site, such as the engineer

reviewing shop drawings or material fabricators, understand the priorities and

30

2.8.2 Subcontractor Input

Generally, construction managers and general contractors are capable of

putting together a schedule without subcontractor input. However, it is the

subcontractors who are in the best position to know their durations and plan their

work sequences. For this reason, I have found that a detailed schedule planning

meeting with the major or early subcontractors is one of the best ways to ensure the

schedule has appropriate work activity durations and sequencing.

Subcontractor input will also confirm durations for shop drawing submittals

and material deliveries. How long will shop drawings take? What time has the

manufacturer indicated for fabrication of materials? The initial schedule will

include these activities, but the subcontractor can help "tune up" the schedule with

more accurate information. Subcontractors can also assist in the schedule updating

process, since they are closest to the actual work. Often they can suggest

"work-arounds" or alternate sequences to mitigate delays or other field problems.

2.8.3 Schedule Card Trick

One method for coordinating the schedule input of large groups of

contractors is a meeting called the "Schedule Card Trick." The contractors prepare

their activities and durations in advance of the meeting on different colored 3 x 5

cards. Several large calendar sheets with weekly time increments are also prepared

before the meeting. During the "card trick" meeting, you "build the building,"

starting with the earliest work areas. The activities for each work area are sequenced

and arranged by placing the cards on the calendar sheets and connecting related

31

In this way, the construction schedule is created in front of the

subcontractors. This is a great opportunity to hash out key sequencing and planning

issues. For example, which subcontractor goes first inside the building, ductwork,

or masonry? Will the finishes go from the bottom floor up or the top floor down?

The "Schedule Card Trick" gives all the subcontractors a chance to see the big

picture, as well as where and when their work fits in the schedule. There is also the

added benefit of "buy in" of the schedule by the subcontractors because they helped

put it together.

2.8.4 Explicit Activity Names

Work activities in the schedule should have names that are clear and specific.

Explicit work activity names make it easy to understand what is included (and not

included) in the work activity and when they start and finish. In order to properly

track work progress, the schedule needs separate activities for each trade contractor

even if the activities are scheduled to occur at the same time. The plan may be for

them to start and finish together, but you will never be able to identify the contractor

responsible for delaying the activity if they are combined in a single activity in the

schedule. Similarly, it is good practice to separate activities that a certain trade

contractor may do in different time periods or with different crews, such as "framing

32

2.8.5 The Right Level of Detail

When construction is just getting started on a project, it is not unusual to find

the project team focused on the earlier parts of the work. As a result, they may not

want to take the time to develop a detailed schedule for work that is a year or more

in the future. On many projects, a detailed schedule will be developed for the site

work, structure and enclosure, and a single long duration activity will be allocated

for "interior finish work." This will work, as long as enough time is allocated in the

schedule for the later work and a future schedule details this work.

A schedule may not be used if it is cluttered with too much detail. Generally,

activity durations should range between one and four weeks. How much to "break

down" individual work activities also depends on how large the work areas are and

if a set of activities will always be done in sequence. It may be all right to combine

"form/reinforce/place footing - east side" if the duration is one or two weeks. One

day activities or milestones signifying the completing of key project activities (i.e.

permanent power available, roof tight, completion of a work stage) are also useful.

Even a large, detailed schedule may not provide all the specific activities needed in

the field or may be too cumbersome to use on a daily basis. For these reasons, field

staff often develops short-term, hand drawn schedules to coordinate day to day

activities among subcontractors. This is an acceptable practice if the durations and

sequencing in these short-term schedules are consistent with the "official" project

schedule. Significant differences between the two schedules are indications that

there may be a problem with the overall schedule because it is not accurately

33

2.8.6 Well Organized Activity Groupings

The typical construction schedule on a large project will include hundreds or

even thousands of activities. To make the schedule useable, it should be structured

so these activities can be sorted and grouped, making it easy to find desired schedule

information. Generally, activities can be separated by phases, such as bid/award,

shop drawing/fabrication, new construction and renovation. It is helpful if the

activities can be sorted by bid package or specification section within these

categories. It works best if the groupings of activities correspond to the planned

work areas and sequences (i.e. how you are planning to "build the project"). For

example, if the interior work on the floor of a building will be completed all at once

or in two halves, or by specific functional areas (Administration Area, Classrooms,

Library, etc.), it is important to create schedule activities for each work area.

Breaking work into smaller pieces in the schedule also allows better tracking (for

starts and finishes) and better logic (the following activity will probably start sooner).

Areas on bridge and road projects are often sub-divided by survey stations or work

phases.

2.8.7 Proper Consideration of Weather

Once a detailed schedule has been developed and the expected start date for

the work is known, the project team should review the activities in relation to the

time of year in which they are scheduled. In cold weather climates, activities which

fall in the winter months may need to be shifted, or it may be necessary to plan for

temporary enclosure and heating. Similarly, the schedule may need to allow more

time for certain activities or show them being done on a limited basis because of

weather considerations. Similar issues may arise in extremely warm areas or areas

which have a rainy season. If a revised project start date or other delays shift the

34

shifted into bad or difficult weather periods should be looked at closely and adjusted

as needed to reflect the effect of weather.

This is one of the most often ignored aspects of preparing and updating

project schedules; when not considered and planned for, seasonal effects can

significantly impact the project cost and schedule. Finally, use the schedule. Hang

a large plot on the wall at the jobsite. Write on it, noting actual starts and finishes,

and make notes about changes and new issues. Put the new updates on top of older

versions (which are very likely to be referred to by those who are really watching

the schedule). Refer to it daily with the subcontractors. Formally review current

activities at all regular subcontractor meetings. Awareness of the schedule and

delays will allow for better planning and a smoother job. Throughout the project, be

"schedule conscious." The schedule itself may experience delays, but time will

move on.

2.9 Requirements of Successful Construction Work Schedule

There are advantages and disadvantages to each of the methods of schedule

preparation and implementation. Although success has been achieved using all of

these methods, each has had its own failures, due primarily to various user-oriented

reasons.

According to Jon et. al. (2002), experience has shown that on fixed-price or lump-sum contracts, the best results have been achieved when the contractor is

responsible for schedule preparation and maintenance, with the owner or the

owner’s agent reserving the right to approve the initial schedule.

This assignment of responsibility makes a good deal of sense, considering

the risks involved. On a fixed-price or lump-sum contract, the general contractor, in

35

it can perform the required work at a cost lower than the competition. Therefore, the

general contractor is in the best position to plan and schedule its work and the work

of the subcontractors and suppliers. If the general contractor lacks the technical

capability to develop this information, there is always the option of hiring a

scheduling consultant to convert the plans and intentions to the scheduling technique

specified in the contract.

When multiple prime contracts are involved in project delivery, the

responsibility for overall schedule preparation is best left to the owner or the

owner’s agent. The owner is the only party with the authority and economic power

to schedule and coordinate the multiple prime contractors involved. This does not,

of course, preclude specifying and allowing the prime contractors to develop their

own schedules for their own portions of the work and then monitoring them

separately or on an integrated basis, throughout the life of the project.

When a design-build contractor is involved, the contractor or construction

manager should be directly responsible for scheduling and coordination of the work.

Regardless of the schedule preparation method chosen, the degree of success will

depend on five conditions (Jon M. W. et. al., 2002):

(1) All parties need to commit to making the schedule work;

(2) A good scheduling specification must be prepared to properly

communicate to all parties their contractually required responsibilities,

methods, and procedures for scheduling;

(3) Once the schedule is agreed on, it must be implemented and periodically

updated to reflect current status and how the remaining work is to be

completed;

(4) Timely and accurate submissions of delay analyses by all parties

involved are a must to keep the schedule properly adjusted for excusable

delay. Each party should strive to maintain a correct posture for the time

of performance; and

(5) The owner, or the party having the responsibility for overall schedule and

36

ensure schedule compliance by the various parties involved so as not to

delay another party.

2.10 Factors Affecting in the Preparation of Better Construction Work

Schedule

According to Mohamad Ibrahim et. al. (2006), they believed that four areas should be properly investigated prior to the development of the project scheduling

procedures. The critical areas that have been identified are process of acceptance,

responsibilities of contracting parties, application of work schedule, and

implications of work schedule.

According to Jon et. al. (2002), clear and concise schedule specifications outlining the responsibilities for scheduling and the requirements for preparation,

approval, participation, use, maintenance, and reporting are essential for timely and

successful completion of most projects. Unfortunately, poor scheduling especially in

terms of its specifications, have contributed to the downfall of many projects. Some of

the common problems associated with the poor construction work schedule include:

(1) Not being specific about the method of scheduling required.

Whatever the scheduling method chosen, it should be stated clearly and

eliminate any opinions or ambiguities;

(2) Not requiring contractors to involve subcontractors in schedule development and implementation.

This is compounded by the problem of prime contractors;

(3) Specifying only a maximum number of activities required.

The level of detail required should be based on specific criteria. Based

on experience, a minimum number of activities should be specified to

37

(4) Owners not approving or rejecting a contractor’s schedule in a timely manner and not stating reasons for rejecting when formal approval of a schedule is required.

Owner should state clearly in the specification how long he intends to

take to review and approve the contractor’s schedule or reject it as

unreasonable or not feasible;

(5) Stating that the schedule will be periodiacally updated, but not being specific about the frequency of such updates.

The frequency of updating should be clearly stated, such as mothly or

bi-weekly. If the specified freuquency becomes unnecessary, the

requirement can always be reduced to a lesser frequency, either

temporarily or permanently;

(6) Not requiring joint updates.

Joint updates involving all key parties are encouraged to maximize

communication abouyt schedule, performace, problems, actions reuired,

and intended plans for completion. The objective is to eliminate the

surprises that can result when a single party independently prepares an

update and distributes the updated version of the schedule to all other

project participants;

(7) Not requiring that all physical access and availability restraints be incorporated into the project schedule.

The party responsible for preparing the schedule should include this

information in the schedule and define the relationship of each restraint

to the sequence of work planned to accomplish the required scope of

work within the time period specified;

(8) Not specifying an explicit period for review and approval of shop drawings and other contractual submittals.

Many contracts simply state that shop drawings will be submitted

within a reasonable period of time. Define reasonable by stating

specifically when submittals are to be made at the duration of their

review and submittal periods;

(9) Not requiring owner-furnished equipment to be incorporated into a

38

This is essential for identifying proper dependency and time impact

when delivery delays occur;

(10) Not specifying in the contract all contractual dependencies with proceeding, concurrent, and follow-on contractors in a multi-prime contractor project.

Additionally, not requiring prime contractors to define other key points

of interface, particularly with the subcontractors and suppliers on which

they are dependent;

(11) Allowing manpower and equipment restraints to create critical and near-critical paths.

These situations may be the result of float abuses, which attempt to hide

float that normally exists. Critical or near-critical paths are those with

less than two weeks of contingency;

(12) Not giving specific instructions for graphic techniques to be used for

network or bar-chart construction.

The failure to require readable time-scaled diagrams for the original

plan and updates can result in schedules that are useless and effectively

unintelligence to the owner, subcontractors, architect/engineer, and

contractor;

(13) Not including in the specifications remedies for noncompliance of initial schedule submittal and subsequent update information;

(14) Not including a narrative reporting requirement as part of the update process;

(15) Not including a remedy for schedule-specification discrepancies.

Most specifications include a statement that, in the event of

discrepancies, the specifications shall govern the development and

utilization of the project schedule;

(16) Stating a maximum duration requirement for activities.

Keeping durations to a minimum, along with criteria for levels of

indenture, is appropriate;

(17) Not requiring time extensions to be justified by proper documentation (such as the use of time-impact analyses and fragnets) and not