Volume 702 (2013) doi: 10.4028/www.scientific.net/AMR.702

ISSN: 1662-8985

TTP Trans Tech Publications

Paper Title Page Preface and Organizing Committee

Stability Analysis of Arch Dam Abutment

Authors: Ling Qiang Yang, Rui Gao 3

Adaptive Arithmetic of Rock and Concrete’s Crack Propagation

Authors: Rui Gao, Ling Qiang Yang, Xiang Dong Wang 7

Relibility Analysis of Hydrostructures Concrete Members

Authors: Yan Wang, Hong Wu Zhang, Rui Gao, Xiang Dong Wang, Ling Qiang

Yang 11

Rheological Analysis of Oceanic Concrete Structure

Authors: Rui Gao, Ling Qiang Yang 15

Creep of Dock Concrete In Situ Test

20

Rheological Property of Full-Mixed Concrete in Laboratory

23

Experiment Study on Stone Masonry Mechanical Properties

Authors: Ling Qiang Yang, Lu Ling Yang, Rui Gao 27

An Experimental Study on the Performance of Fixed-End Supported PFRP Channel Beams under Flexure

Authors: Jaksada Thumrongvut, Sittichai Seangatith 31

Numerical Simulation on Wave Force Acting on the Hollow Blocks

Authors: Xue Feng Chen, Kang Yang, Yu Cheng Li 37

A New Concrete Failure Phenomena Due to Sulfate Attack

Authors: Yan Wang, Rui Gao, Hong Wu Zhang, Ling Qiang Yang 44

SbVO4-TiO2 Cation Deficient Photocatalyst: Synthesis and Photocatalytic Investigation

Authors: Rahmatollah Rahimi, Masoumeh Mahjoub Moghaddas, Solmaz Zargari 51

Synthesis of Mesoporous V-TiO2 with Different Surfactants: The Effect of Surfactant Type on Photocatalytic Properties

Authors: Rahmatollah Rahimi, Masoumeh Mahjoub Moghaddas, Solmaz Zargari, Rahim Rahimi

Model Experiments with New Lance for Pneumatic Powder Injection

Authors: Jan Jezierski, Krzysztof Janerka 62

Synthesis of Surface Imprinted Polymer Microspheres with Ultrathin Polymer Shells via Surface-Initiated Iniferter Polymerization

Authors: Ren Yuan Song, Xiao Ling Hu, Ji Li, Ping Guan 68

Synthesis and Properties of Ionogels Based on 1-vinyl-3-alkylimidazolium Tetrahalogenidoferrate (III) [VAIM][FeClnBr4-n] and PMMA

Authors: Yi Mei Tang, Xiao Ling Hu, Li Wei Qian, Ping Guan 74

Design of Al2O3/CoAlO/CoAl Porous Ceramometal for Multiple Applications as Catalytic Supports

Authors: Andrey S. Andreev, Serguey F. Tikhov, Aleksey N. Salanov, Svetlana V. Cherepanova, Olga B. Lapina, Vasiliy A. Bolotov, Yuriy Yu. Tanashev, Jean Baptiste

d’Espinose de Lacaillerie, Vladislav A. Sadykov

79

The Effect of Deformation and Irradiation with High-Energy Krypton Ions on the Structure and Phase Composition of Reactor Steels

Authors: Alyona Russakova, Darya Alontseva, Tatyana Kolesnikova

88

The Structure-Phase Compositions and Properties of Plasma-Detonation Ni and Co-Based Powder Alloys Coatings

Authors: Darya Alontseva, Alyona Russakova 94

TiO2 and Metal-Doped TiO2 Performance for the 4-Chlorophenol Degradation in Batch and Continuous Reactors

Authors: Sitthichai Tangsatjatham, Pramoch Rangsunvigit, Sumaeth Chavadej 100

Water Absorption and Tensile Strength of Coconut Filter Fibers/Polypropylene Composites

Authors: N.P.G. Suardana, I.P. Lokantara, Y.J. Piao, J.K. Lim 207

A CDM Model and its FE Implementation for 2D C/SiC Composite under Tension and Shear Loads

Authors: Jun Li, Gui Qiong Jiao, Bo Wang 213

Biological Denitrification Using Slow-Release Carbon Source Composite Materials as Solid Carbon Source and Biofilm Carrier

Authors: He Ming Wang, Fan Yang 218

Paper Title Page Electrolyte

Authors: Min Zhang Zheng, Xiao Mei Liu

Electronic and Magnetic Properties of Li1.5Mn0.5As Alloys in the Cu2Sb Structure Authors: C.Y. Fong, Liam Damewood, L.H. Yang, C. Felser 231

The Electrical Characterization of p-CdTe/n-Si (111) Heterojunction Diode

Authors: Mohammed A. Razooqi, Ameer F. Abdulameer, Adwan N. Hameed, Rasha

A. Abdullaha, Ehsan I. Sabbar 236

A Study on the Bending Analysis of the Al Honeycomb Core Sandwich Composite Panel Bearing Large Bending Load

Authors: Hong Gun Kim, Young Jun Kim, Hee Jae Shin, Sun Ho Ko, Hyun Woo Kim, Young Min Kim, Yun Ju Cha, Woo Kum Lee, Lee Ku Kwac

245

Simulation of Movement of Drill Rods at Large Deformations

Authors: Lelya Khajiyeva, Almatbek Kydyrbekuly, Almaz Sergaliyev, Aliya

Umbetkulova 253

The Concrete Casting Matrixes Inserts Design Preparation Based on the Master Models

Authors: Cezary Grabowik, Witold Janik 259

Surface Roughness Characteristics of Polyamide APA after the Turning by Unconventional Cutting Tool

Authors: Katarina Monkova

Water Absorption and Tensile Strength of Coconut Filter

Fibers/Polypropylene Composites

NPG.Suardana

1,a, IP. Lokantara

1,b, YJ. Piao

2,c, and JK. Lim

2,d1

Department of Mechanical Engineering, Faculty of Engineering,

Udayana University, Bali Indonesia.

2

Automobile Hi-Technology Research Institute, Faculty of Mechanical & Aerospace System Engineering, Chonbuk National University, Deokjin 1-664-14, Jeonju, 561-756,

Republic of Korea.

a

[email protected], [email protected],

c

[email protected],[email protected]

Keywords: Coconut filter fiber, Surface treatment, Polypropylene, Composites, Water absorption, Tensile properties

Abstract. In this study, we evaluated water absorption and tensile properties of coconut filter fiber reinforced polypropylene composites. The fibers were subjected to various immersion times for 0.5, 1, and 3 h in 0.5 % acrylic acid solution at room temperature and 0.5 h at 70 oC. The treated fibers were used as reinforcement of polypropylene composites. Water absorption of treated fiber composites was lower than those of untreated fiber composite. Boiling in water significantly affect water absorption rate of the composites. The tensile strength and elastic modulus of treated fiber are higher than untreated fiber. They show a decrease in tendency when the immersion time increased. Tensile strength and elastic modulusof composites with AA-treated at 70 oC fiber are the highest.

Introduction

Coconut palm (Cocos nucifera) trees are found in the tropical countries, such as Indonesia, Malaysia, Philippine, India, Vietnam, Papua New Guinea, South America and so on [1]. One of the parts of the coconut trees is the coconut filter (Coconut fabric), which is present at the bottom of the leaves and growing from a young leaves sheath. It is abundantly available and presently wasted [2]. Coconut filter has enough strength, so it can be utilized to make other materials, which are more useable and profitable, for example, as an alternative for composite reinforcement, replacing glass fibers with natural fibers in the automobile industry can yield economic, environmental and social benefits.

Generally, alkalis and acids modify the properties of natural fibers like hemp, sisal, jute, rice straw, coir and so on. Kim and Lim [3] studied the rice straw fiber treatment by alkali and some acid solution. They found that the concentration of alkali and acid solution for surface treatment affect the tensile strength and elongation.

In other study, combining treatment of bagasse can also be achieved by treatment of the fibers with 1 % NaOH solution for 30 min followed by 1 % acrylic acid for 1 h. This treatment method showed a better effect on improving mechanical properties in comparison to NaOH-treated of bagasse fiber-polyester composites [4]. Suardana, et al. [5] studied combining treatment of coir fiber. They found that 6% alkali treatment at 95oC for 3 h followed by acrylic acid (AA) treatment (0.5 % AA for 0.5, 1 and 3 h) of fiber reinforced PLA composites resulted in significant improvement of tensile and flexural strengths and less water sorption than untreated and alkali treated of the composites.

Though many fibers have been studied, there is a little known on the coconut filter fiber and its composite. In this study, we have tried to evaluate water absorption and tensile properties of their composites.

Advanced Materials Research Vol. 702 (2013) pp 207-212 © (2013) Trans Tech Publications, Switzerland

doi:10.4028/www.scientific.net/AMR.702.207

The objective of this study is to know the behavior of water absorption and tensile properties of the coconut filter fiber composites due to AA treatment of their fibers. The expectation of this study is to give a contribution of the abundant source of a raw material that could be utilized into Acrylic acid (CH2:CHCOOH) was produced by Junsei Chemical Co. Ltd Japan.

The coconut filter fibers were cut into 5-15 mm in length and washed with water to remove dust and impurities and then boiled in water (ratio fiber and water 1 gr fiber: 40 ml water) at 100 oC for 1 h. Finally, the fibers were rinsed with tap water and then dried in an oven at 70 oC for 12 h [6].

The fibers were subjected to various surface treatments as follows: the CF fibers were treated by 6 % NaOH immersion at 95 oC for 3 h (1 gr fiber in 40 ml solution) [8], and then washed with tap water to eliminate any NaOH solution remaining on the fibers surface and dried in the oven for 24 h at 70 oC. Subsequently, they were soaked in 0.5 % acrylic acid (AA) solution (1gr fiber in 40ml solution) at room temperature for 0.5, 1, 3 h, and at 70 oC for 0.5 h and then washed with distilled water. Finally, the fibers were dried in the oven at 70 oC for 72 h [6].

The compounded materials were molded from a stack of eight PP films interleaved with CF fibers (35% volume fraction). The mold and specimen were placed into hot press machine (Carver #3912) that was used for compression molding. The specimen was heated until 200 oC without pressure, subsequently the pressure was increased to 1.5 MPa for 15 min at that temperature. It was cooled down to room temperature with load 40 Kg. The nominal thickness of the specimens was 3-5 mm.

Water absorption experiments were carried out according to ASTM D570. Before specimens testing, all specimens were dried at 50 oC for 6 h to reduce the moisture content. First, the specimens were immersed in water for 6, 18 and 48h, respectively, at room temperature. In the

following step, the specimen’s surface was dried with tissue papers and weighed immediately to

measure their wet weight. Then, the specimens were dried at 50 oC for 6 h and immersed again and the surface was dried with tissue papers as stated before. Finally, the specimens were dried at 50 oC for 6 h and repeated immersion in water at 70 oC for 6, 18 and 48 h, respectively. Water absorption (WA) was calculated by the formula [5]:

The composites tensile tests were performed using an Instron Universal Testing Instrument model 4206 and carried out in accordance with ASTM D3039.

Results and discussions

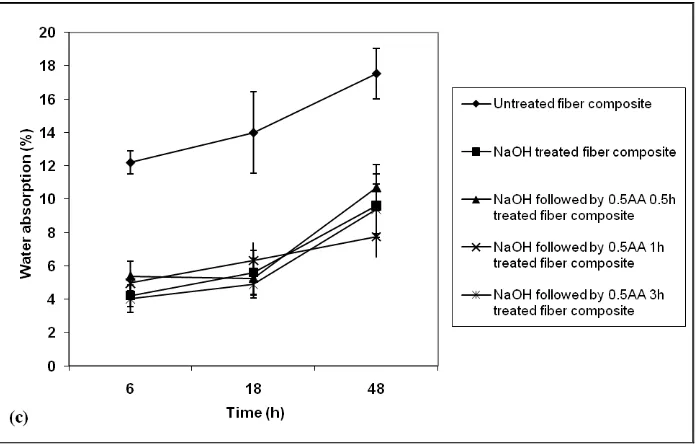

Water Absorption of Composites. Water Absorption of the untreated and treated coconut filter fiber composites were monitored at room temperature and at 70 oC. The results are shown in Figs. 1(a-c) where water absorption is plotted against soaking time. These figures show that water-uptake for all specimens increased when the soaking time are increased. Water absorption of untreated fiber composite was the highest in all cases. This may be attributed to the lignocelluloses absorbing water by forming hydrogen bonding between water and hydroxyl groups of cellulose, hemicelluloses in the cell wall [5.7]. The cellulose and hemicelluloses in the untreated fiber are more than 50 % [8,9], leading to the poor wettability and weak adhesion between untreated fiber and PP, therefore, the fiber can behave like capillary flow of the water along the fiber-matrix

interface. For surface modified CF fiber composites, the alkali treatment of natural fiber can reduce the hydroxyl group from surface fiber [4], and also the fibers get masked with the polypropylene which is hydrophobic and strong adhesion each other, hence water absorption is less than untreated fiber composites.

The effect of AA-treated fibers reinforced PP composites on water absorption was better than those of the untreated fiber composites. This is due to AA coating on the fiber surface, resulting in decrease of the water absorption of composites [10].

The initial water absorption rate is the lowest for 3h-AA-treated fiber composites followed by alkali-treated fiber composites for all cases. Similar trends were observed in water absorption rate value between Fig. 1a and Fig. 1b, but water absorption rate with immersion in boiling water at 70

o

C significantly increased for all specimens (Fig. 1c). From this Figure, it is evident that initial water absorption rate increased to about 100 % for all composites. Similar results are observed by Sreekala et al. [11] and Patel et al. [12]. Temperature is one of the parameters to give effect of water uptake in fibrous composite besides of the presence of hydrophilic groups, fiber loading, orientation of fiber, permeability of fiber, etc. Water absorption increases with increasing temperature, because of the deterioration of adhesive bonding.

Fig. 1. Water absorption of CF/PP composites of: (a) the first time at room temperature; (b) the second time after re-drying and immersing at room temperature; (c) the third time after re-drying and immersing at 70oC.

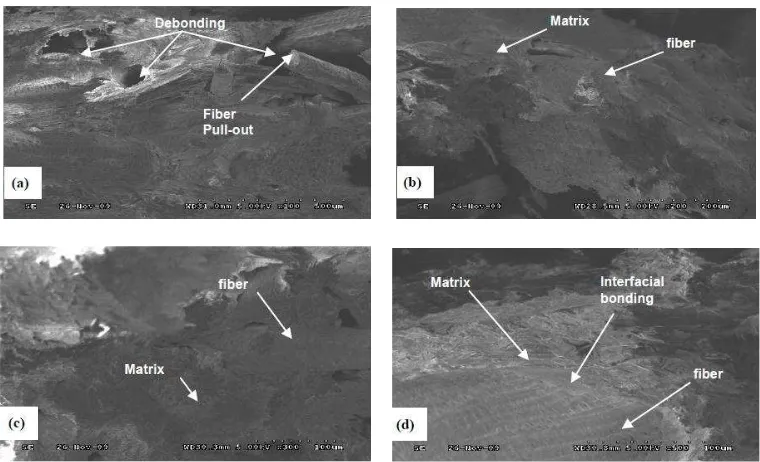

Tensile Properties of Composites. Tensile strength (σt) and modulus of elasticity (Et) of the CF/PP composites with different fiber treatment are presented in Fig. 2. The σt and Et of untreated fiber composites are the lowest as in comparison to those of treated fiber/PP composites. Fig. 3a shows the tensile fracture surface of this composite. It can also be seen that CF fibers debonded easily and pullout from PP when stress is applied, so some holes are created in the fracture surface, which indicates poor adhesion at the interface between fibers and PP. Therefore, the σtand Etbecome low.

Fig. 2 exhibits that the tensile strengths of the treated CF fiber composites increase 36.14, 44.03, 32.7, 35.98 and 45.66 % in comparison to those of untreated CF fiber composite when the fibers being treated with alkali, alkali followed with 0.5 % AA-treated for 0.5 h, 1 h, 3 h at room temperature and 0.5 h at 70 oC, respectively. Fig. 2 also shows that the elastic modulus increases by 20.42, 26.88, 11.42, 17.78 and 38.33 % in comparison to those of untreated CF fiber composite when the same treatment was for them, respectively. SEM photographs that are shown in Fig. 3b-3d supported those results. These Figures show that are good interface bonding between fibers and matrix without any debonding and pullout.

The trend of composites tensile properties has a little difference with their single fibers [6]. These may be due to the reinforcing ability of the fibers not just depending upon the mechanical strength of the fibers but some factors affect the interfacial interaction between the matrix and the fibers surface like polarity of the fiber, surface characteristics and the presence of reactive centers of functional groups [13,14].

The enhancement of σt and Et of composite with AA at 70 oC indicates the effectiveness of the reinforcement because of heating as an initiator system to induce any chemical changes.

Fig. 2. Graph of Tensile strength and Elastic modulus of the untreated and treated fiber composites.

Fig. 3. SEM of tensile fractured surface of: (a) untreated; (b) alkali-treated; (c) and (d) alkali followed by 0.5%AA for 0.5h at room temperature and at 70oC treated fiber composites, respectively.

Conclusions

Based on this study, the following conclusions are drawn:

1. Treated fiber composites have lower water absorption than those of untreated fiber composite. 2. Boiling in water significantly affect water absorption rate of coconut filter/polypropylene

composites.

3. Tensile strength and elastic modulus of treated fiber composites are higher than those of untreated fiber composite.

4. Tensile strength and elastic modulus of composites with AA-treated at 70 oC fiber are the highest in this study. This indicates that heating as an initiator system to induce any chemical changes.

References

[1] J.G. Ohler: Modern Coconut Management; palm cultivation and products, EcoPort version by Peter Griffee, Food and Agriculture Organization of the United Nations ID: 127

[2] K.G. Satyanarayana, C.K.S. Pillai, K. Sukumaran, S.G.K. Pillai: J. Mater. Sci. Vol. 17 (1982), p. 2453.

[3] H.J. Kim, J.K. Lim: Int. J. Mater. Product Tech. Vol.36.Nos.1/2/3/4 (2009).

[4] V. Vilay, M. Mariatti, R. M. Taib, M. Todo: Compos. Sci. and Technol. Vol. 68 (2008), p. 631

[5] N.P.G. Suardana1, I.P. Lokantara, J. K. Lim: Mater. Physics and Mechanics Vol.12 (2011),p. 113

[6] N.P.G. Suardana, H. Ruihua, H.C. Yoon, C.I. Kim, Y.J. Piao, J.K. Lim: Proceeding of the KSME 2009, Spring annual meeting, Jeju Korea, p.430

[7] A.K. Bledzki and J. Gassan: Prog. Polym. Sci. Vol. 24 (1999),p. 221.

[8] K. Bilba, M-A. Arsene, A. Ouensanga, Biores. Technol.Vol. 98(2007),p.58

[9] K.O. Reddy, G.S. Reddy, C.U. Maheswari, A.V. Rajulu, K.M. Rao: J. of Forestry Research

[12] V.A. Patel, B.D. Bhuva and P.H. Parsania: J. of Reinf. Plastics and Compos. Vol.28 (2009),p. 2549

[13] M. S., Sreekala, M. G., Kumaran, S. Joseph and M. Jacob, Appl. Compos. Mater. Vol.7(2000), p.295

[14] M. M Rahman and M. A. Khan: Compos. Sci. and Technol. Vol. 67 (2007), p. 2369