Green Building, Materials and Civil Engineering – Kao, Sung & Chen (Eds) 2015 Taylor & Francis Group, London, ISBN 978-1-138-02669-8

635

1. INTRODUCTION

Production of plastic waste in Indonesia was ranked as the second producer of domestic waste that is equal to 5.4 million ton per year. Based on statistical data of domestic Indonesian waste, the amount of plastic waste that is 14% of the total waste production in Indonesia [1]. It comprises mostly plastics used in food packaging such as PET, PVC, LDPE, HDE, and PP. One of the most popular plastic packaging is plastic cup for sparkling beverages which is made from PP. Since Inci-neration method is not a good solution because it raises the pollutions, the only alternative left for easy disposal of this huge plastic waste is recycling to obtain value added products. Therefore, it is a promising way of use recycle PP (rPP) as matrix to obtain composite and a per-fect choice due to its low cost and the resulting protec-tion of environment. Plastic recycling is a process which basically comprises the following steps: collection, sepa-ration, cleaning and pelletizing. Adhikary [2] and Bhaskar [3] have published studies dealing with rPP composites.

On the other hand, in general the use of fillers in composites aim to reduce costs, provide color, strengthen or reinforce composite materials. As a filler, natural fi-bers have several advantages compared to inorganic fil-lers such as lower density, renewability, improvement in the mechanical properties, increase in range of application, biodegradability, greater deformability,

en-hanced energy recovery and relatively lower cost [4]. Several studies of natural fibers used as filler in compo-sites such as jute, kenaf, banana, and bamboo [5-8] has been done. One of natural fibers which can be potentially used is fiber of empty fruit bunch palm oil (EFBPO). The utilization of fiber of EFBPO as fillers had been stu-died using thermoplastic matrix [9-11].

However, the interfacial adhesion between natural fiber and thermoplastics is usually very weak due to the high interfacial tension. This leads to undesirable proper-ties of the composites. The process of modifying interfa-cial properties of an incompatible polymer blend leading to the creation of polymer blend is called compatibiliza-tion [12]. Physical compatibilizacompatibiliza-tion is a modificacompatibiliza-tion of polymeric structure to enhance miscibility, control of crystallization as a means to lock-in developed morphol-ogy and addition of compatibilizing agents [13]. Maleic anhydrate-g-polypropylene (MAPP) is the most common compatibilizer/coupling agent which is ex-pected to give good compatibility between the natural fiber and the thermoplastic by formation of stronger lin-kages in the interfaces and reducing filler-matrix surface tension. Some researchers have published studies dealing with MAPP addition on composites [10, 14-16].

In the present study the effect of MAPP addition on tensile properties and water absorption of rPP/OPEFB composites were investigated.

Tensile properties and water absorption of recycle polypropylene (rPP) / oil palm empty fruit

bunch (OPEFB) composites: the effect of maleic anhydrate-g-polypropylene (MAPP)

addition

Halimatuddahliana Nasution

Department of Chemical Engineering, Faculty of Engineering, Universitas Sumatera Utara,Medan, Indonesia

ABSTRACT:The effects of maleic anhydrate (MAPP) as compatibilizer on tensile properties and water absorption of recycle polypropylene (rPP)/oil palm empty bunch fruit (OPEFB) composites were investigated. Several contents of MAPP viz. 2, 4, 6, 8 wt.% were prepared. Corresponding rPP/OPEFB composite without MAPP addition was also made for comparison.The OPEFB composition was fixed at 30 wt.%, while rPP was 70 wt.% and reduced correspondingly on the addition of MAPP. Composites were prepared in extruder with temperatur of 190oC. Results indicated an improvement in tensile strength and elongation at break were obtained on the addition of MAPP up to 6 wt.%. It was also revealed that the water absorption was significantly decreased as the MAPP was increased up to 6%. However, the addition of 8 wt.% MAPP was found to reduce these properties. Scanning electron microscopy (SEM) images from the tensile fracture surface supported that the improvement on interface region between matrix and filler have occurred.

2. EXPERIMENTAL

To carry out this experiment, fixed quantities of rPP, EPOFB, and calculated quantities of MAPP were measured. In the formulations where the MAPP had add-ed, the rPP mass was reduced correspondingly thus, the total proportion of the rPP and the MAPP was 70%. The composition of thesystems are shown in Table 1. The

mixture was fed into extruder machine, and processed at temperature of 190 oC. Composites were then compres-sion molded using hot press at 190oC. In hot press, com-posites were preheat for 5 minutes and followed by 5 mi-nutes compression time at the same temperature. The specimens were allowed to cool under pressure for another 5 minutes.

Table 1. Formulation of rPP/EPOFB composite

Sample EPOFB wt.% rPP wt% MAPP wt.%

1. 30 70 0

2. 30 68 2

3. 30 66 4

4. 30 64 6

5. 30 62 8

Tensile tests were carried out according to ASTM D638 using a Universal Testing Machine GOTECH AL-7000M. One mm thick dumbbell specimens were cut from the moulded sheets with a dumbbell cutter. The tensile test was performed at constant rate (20 mm/min) at room temperature. The results were quoted based on the average value of five specimens for each system.

For water absorption test, small blocks of 1×5×5 cm were cut from the sheet and oven dried at 103±2°C to determine dry weights. The blocks were immersed in dis-tilled water at room temperature and weighed after 2, 4, 6, 12 and 24 hours of soaking to determine their wet weights. Prior to weighed, speciments were wiped with tissue to make sure all their surfaces dried. Water absorp-tion was calculated according to Equaabsorp-tion (1).

where: w and woindicate wet weight and dry weight of the specimens (g), respectively.

3. RESULTS AND DISCUSSION

3.1The Effect of MAPP addition on the tensile strength and elongation at break of rPP/OPEFB composites.

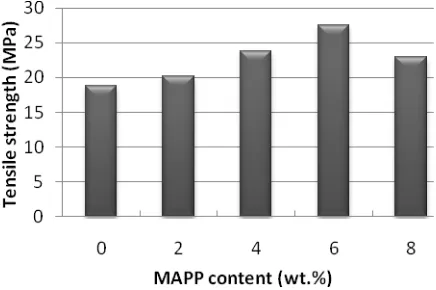

The effect of MAPP addition on tensile strength of rPP/OPEFB composites are shown in Figure 1. It was found that the addition of MAPP until 6 wt (%) resulted in an increase of tensile strength.

Figure 1. Plot of tensile strength versus MAPP content for rPP/OPEFB composites

The lowest tensile strength of composite without the addition of MAPP could be attributed to the poor interfacial interaction between the polymeric matrix dan filler, not allowing efficient stress transfer between the two phases of the material. Poor interfacial bonding causes partially separated micro-spaces between the filler particles and the polymer matrix, this causes stress prop-agation when tensile stress is loaded and induce in-creased brittleness [15]. This leads to undesirable tensile resistance of the composite.

Nevertheless, the addition of compatibilizer (MAPP) has improved interfacial bonding between the filler and the matrix and improved the tensile strength. The application of the MAPP as compatibilizer increased hydrophobicity of the composites. Other investigations noted, the increase in the tensile strength of the compo-sites on addition of MAPP was caused by maleic anhy-dride from the MAPP molecule which reacts with the hydroxyl groups (-OH) of cellulose or hemicellulose, the two main constituents in OPEFB [11]. The reaction of the hydrophilic –OH groups from the filler and the acid

637

However, the tensile strength reduction observed with 8 wt.% MAPP content. It could be attributed to a plasticizing effect exerted by MAPP on the composites since it is possible that MAPP has a lower molecular weight compared to the matrix PP [11].

The effect of MAPP additions on the elongation at break of RPP/OPEFB composites are showed in Figure 2.

Figure 2. Plot of elongation at break versus MAPP content for rPP/OPEFB composites

An examination of Figure 2 reveals that the elon-gation at break of rPP/OPEFB composites were signifi-cantly improved as content of MAPP increase until 6 wt. %. This could be related to improvement adhesion between OPEFB fiber and rPP. Without addition of MAPP, the elongation at break of composite shows the lowest value. This could be attributed to the lack adhesion on filler-matrix interface. On the addition of MAPP, as in the case of tensile strength, improving the adhesion between OPEFB and rPP has enhanced the elongation at break. At high MAPP content (8 wt.%), de-creases on elongation at break were however observed for the rPP/OPEFB composite. This could be related to the migration of too much of the compatibilizer around the fibers, causing self entanglement among the compati-bilizers rather than the polymer matrix, resulting in slip-page [11].

3.2 The Effect of MAPP Addition on Water Absorption of rPP/OPEFB Composites

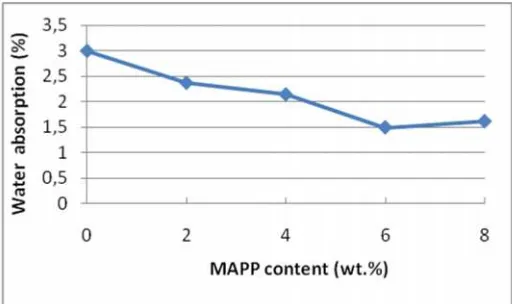

Figure 3 shows the effect of MAPP addition on water absorption of rPP/OPEFB composites. It shows the water absorption was decreased due to the addition of compatibilizer (MAPP) to the rPP/OPEFB composites.

Figure 3. Plot of water absorption versus MAPP content for rPP/OPEFB composites

The current composite consists of hydrophilic (OPEFB) and hydrophobic (rPP) parts. The hydrophilici-ty of cellulose and hemicellulose within the OPEFB is the main cause of water absorption. They contain numer-ous hydroxyl groups (–OH) and carboxyl groups (–

COOH) which had tendency to interact with water mole-cules via hydrogen bonding. Under water immersion, the water molecules resided in the unfilled pores and voids in the composites, and formed hydrogen bonds with the components of cellulose and hemicellulose. On the addition of MAPP, the anhydride moieties in the MAPP reacted with the surface hydroxyl groups of OPEFB (ester linkage). Therefore, application of the MAPP de-creased the surface tension in composites and it caused the hydrophilic part less accessible for the water mole-cules due to good encapsulation of the OPEFB by the hydrophobic part as well as decreased number of hy-droxyl groups in the OPEFB part. Similar to our findings, Chinomso et.al [11] who studied OPEFB Filled HDPE reported that the amount of water absorbed was found to decrease with increase in MAPP content.

However, the composites containing 8 wt. % MAPP exhibited slightly higher water absorption com-pared with the composites with 6 wt. % MAPP. It is possible that unreacted MAPP increased the hydrophilic-ity of the composites since the MAPP contains a low content of polar groups in contrast to the non-polar rPP matrix.

3.3 Morphology

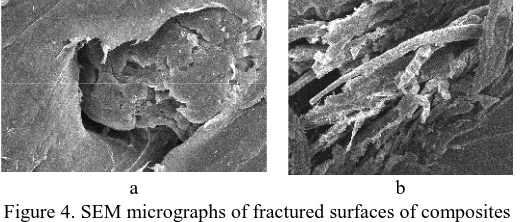

a b

Figure 4. SEM micrographs of fractured surfaces of composites rPP/EPOFB. a) without MAPP addition; b) with MAPP

addition (6 wt.%)

Figure 4a shows there was fiber pull out leaving holes behind on uncompatibilized rPP/OPEFB composite. It is clearly indicating weak interfacial region and damage mainly occured along the loose and weak interface between OPEFB fiber and rPP matrix. As mention before, the hydrophilic nature of OPEFB fiber filled hydropobic rPP is believed to be responsible for the poor interfacial adhesion between OPEFB and rPP.This image has become evidence the low value ten-sile strength and high degree of water absorption of com-posite. However, as seen on Fig 4b, the presence of MAPP in rPP/EPOFB composite reduced the holes turned more difficult fiber pull-out during brittle fracture. The surface of fiber displayed a rough morphology con-firming its effect on promoting adhesion in the interfacial region, indicating stress transfer from the matrix to the fiber, resulting in enhanced tensile in response to stress. Interface bonding between the fillers and the matrix is the key to transfer the stress from the matrix into the fil-lers across the interface [11].

4. CONCLUSION

Tensile strength and elongation at break of oil palm empty fruit bunch (OPEFB) fiber filled recycle polypropylene (rPP) have shown improvement with in-creasing of maleic anhydrate g-polypropylene (MAPP) up to 6 wt.% content. The addition of MAPP into rPP/OPEFB composites was found to significantly im-prove surface adhesion between filler and matrix. SEM images of the fractured surfaces confirmed that an addi-tion of the MAPP compatibilizer improved the interfacial bonding between the rPP and the OPEFB fiber for the

2. Adhikary, K. B. 2008.Wood flour recycled polymer composite panels as building materials. Thesis. Chem-ical and Process Engineering, University of Canter-bury

3. Bhaskar, J. Haq, S. Pandey, A. K. & Srivastava, N.

2012. Evaluation of properties of propylene-pine

wood Plastic composite J . Mater. Environ. Sci. 3(3):605-612

4. Bos, H. 2004. The Potential of Flax Fibres as Rein-forcement for Composite Materials, Thesis. University Press Facilities, Eindhoven, the Netherlands

5. Verma,B. B. 2009. Continuous jute fibre reinforced laminated paper composite and reinforcement-fibre free paper laminate. Bull. Mater. Sci. 32: 589–595. 6. Akil, H.M. Omar, M.F. Mazuki, A.A.M. Safiee, S.

Ishak, Z.A. & Abu Bakar, M.A. 2011. Kenaf fiber reinforced composites. A Review, Materials and

De-sign 32: 4107–4121.

7. Ghosh, R. Reena, G. Krishna, R. A. & Raju, L. 2011. Effect of fibre volume fraction on the tensile strength of banana fibre reinforced vinyl ester resin composites. International Journal Of Advanced

Engi-neering Sciences And Technologies 4: 089–091. 8. Ochi, S. 2012. Tensile properties of bamboo fiber

rein-forced biodegradable plastics. International Journal

of Composite Materials 2: 1-4.

9. Khalid, M. Ratnam, C.T. Chuah, T.G., Ali, S. & Choong T.S.Y. 2006. Comparative study of polypro-pylene composites reinforced with oil palm empty fruit bunch fiber and oil palm derived cellulose.

El-sevier Materials & Design 29: 173-178.

10. Khalid,. M. Ali, S. Abdullah, L.C. Ratnam, C.T. & Choong T.S.Y. 2006. Effect of MAPP as coupling agent on the mechanical properties of palm fiber emp-ty fruit bunch and cellulose polypropylene biocompo-sites, International Journal of Engineering and

Tech-nology 3(1): 79-84.

11. Chinomso, M. Ewulonu. & Igwe, I. O. 2012. Proper-ties of oil palm empty fruit bunch fibre filled high den-sity polyethylene. International Journal of

Engineer-ing and Technology 3(6): 458-471.

12. Utracki, L.A. (1990). Polymer Alloys and Blends:

Thermodynamics and Rheology. New York: Hanser

Publications.

13. Xanthos, M. (1988). Interfacial Agents for Multiphase Polymer Systems: Recent Advances. Polym. Eng. Sci. 28(21), 1392-1340.

14. Kim, H. S. Lee, B. H. Choi, S. W. Kim, S & Kim, H. J. 2007. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene compo-sites. Composites: Part A 38(6):1473-1482.

15. Martí-Ferrer, F. Vilaplana, F. Ribes-Greus, A. Benedi-to-Borrás, A. & Sanz-Box, C. 2006. Flour rice husk as filler in block copolymer polypropylene: Effect of dif-ferent coupling agents. Journal of Applied Polymer

Science 99(4):1823-1831.

16. Rosa, S. M. L. Santos, E. F. Ferreira, C. A. & Nachtiga, S. M. B. 2009. Studies on the Properties Rice-Husk-Filled-PP Composites–Effect of Maleated PP. Materials Research 12(3), 333-338,