'HVLJQDQG2SWLPL]DWLRQ

RI7KHUPDO6\VWHPV

A Series of Textbooks and Reference Books Founding Editor

L. L. Faulkner

Columbus Division, Battelle Memorial Institute and Department of Mechanical Engineering

The Ohio State University Columbus, Ohio

1. Spring Designer’s Handbook, Harold Carlson

2. Computer-Aided Graphics and Design, Daniel L. Ryan 3. Lubrication Fundamentals, J. George Wills

4. Solar Engineering for Domestic Buildings, William A. Himmelman 5. Applied Engineering Mechanics: Statics and Dynamics, G. Boothroyd

and C. Poli

6. Centrifugal Pump Clinic, Igor J. Karassik

7. Computer-Aided Kinetics for Machine Design, Daniel L. Ryan 8. Plastics Products Design Handbook, Part A: Materials

and Components; Part B: Processes and Design for Processes, edited by Edward Miller

9. Turbomachinery: Basic Theory and Applications, Earl Logan, Jr. 10. Vibrations of Shells and Plates, Werner Soedel

11. Flat and Corrugated Diaphragm Design Handbook, Mario Di Giovanni 12. Practical Stress Analysis in Engineering Design, Alexander Blake 13. An Introduction to the Design and Behavior of Bolted Joints,

John H. Bickford

14. Optimal Engineering Design: Principles and Applications, James N. Siddall

15. Spring Manufacturing Handbook, Harold Carlson

16. Industrial Noise Control: Fundamentals and Applications, edited by Lewis H. Bell

17. Gears and Their Vibration: A Basic Approach to Understanding Gear Noise, J. Derek Smith

18. Chains for Power Transmission and Material Handling: Design and Applications Handbook, American Chain Association 19. Corrosion and Corrosion Protection Handbook, edited by

Philip A. Schweitzer

20. Gear Drive Systems: Design and Application, Peter Lynwander 21. Controlling In-Plant Airborne Contaminants: Systems Design

and Calculations, John D. Constance

22. CAD/CAM Systems Planning and Implementation, Charles S. Knox 23. Probabilistic Engineering Design: Principles and Applications,

25. Finite Element Methods: An Introduction, Ronald L. Huston and Chris E. Passerello

26. Mechanical Fastening of Plastics: An Engineering Handbook, Brayton Lincoln, Kenneth J. Gomes, and James F. Braden

27. Lubrication in Practice: Second Edition, edited by W. S. Robertson 28. Principles of Automated Drafting, Daniel L. Ryan

29. Practical Seal Design, edited by Leonard J. Martini 30. Engineering Documentation for CAD/CAM Applications,

Charles S. Knox

31. Design Dimensioning with Computer Graphics Applications, Jerome C. Lange

32. Mechanism Analysis: Simplified Graphical and Analytical Techniques, Lyndon O. Barton

33. CAD/CAM Systems: Justification, Implementation, Productivity Measurement, Edward J. Preston, George W. Crawford, and Mark E. Coticchia

34. Steam Plant Calculations Manual, V. Ganapathy

35. Design Assurance for Engineers and Managers, John A. Burgess 36. Heat Transfer Fluids and Systems for Process and Energy

Applications, Jasbir Singh

37. Potential Flows: Computer Graphic Solutions, Robert H. Kirchhoff 38. Computer-Aided Graphics and Design: Second Edition,

Daniel L. Ryan

39. Electronically Controlled Proportional Valves: Selection and Application, Michael J. Tonyan, edited by Tobi Goldoftas

40. Pressure Gauge Handbook, AMETEK, U.S. Gauge Division, edited by Philip W. Harland

41. Fabric Filtration for Combustion Sources: Fundamentals and Basic Technology, R. P. Donovan

42. Design of Mechanical Joints, Alexander Blake

43. CAD/CAM Dictionary, Edward J. Preston, George W. Crawford, and Mark E. Coticchia

44. Machinery Adhesives for Locking, Retaining, and Sealing, Girard S. Haviland

45. Couplings and Joints: Design, Selection, and Application, Jon R. Mancuso

46. Shaft Alignment Handbook, John Piotrowski

47. BASIC Programs for Steam Plant Engineers: Boilers, Combustion, Fluid Flow, and Heat Transfer, V. Ganapathy

48. Solving Mechanical Design Problems with Computer Graphics, Jerome C. Lange

49. Plastics Gearing: Selection and Application, Clifford E. Adams 50. Clutches and Brakes: Design and Selection, William C. Orthwein 51. Transducers in Mechanical and Electronic Design, Harry L. Trietley 52. Metallurgical Applications of Shock-Wave and High-Strain-Rate

Phenomena, edited by Lawrence E. Murr, Karl P. Staudhammer, and Marc A. Meyers

55. Cam Design and Manufacture: Second Edition; with cam design software for the IBM PC and compatibles, disk included, Preben W. Jensen

56. Solid-State AC Motor Controls: Selection and Application, Sylvester Campbell

57. Fundamentals of Robotics, David D. Ardayfio

58. Belt Selection and Application for Engineers, edited by Wallace D. Erickson

59. Developing Three-Dimensional CAD Software with the IBM PC, C. Stan Wei

60. Organizing Data for CIM Applications, Charles S. Knox, with contributions by Thomas C. Boos, Ross S. Culverhouse, and Paul F. Muchnicki

61. Computer-Aided Simulation in Railway Dynamics, by Rao V. Dukkipati and Joseph R. Amyot

62. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, P. K. Mallick

63. Photoelectric Sensors and Controls: Selection and Application, Scott M. Juds

64. Finite Element Analysis with Personal Computers, Edward R. Champion, Jr. and J. Michael Ensminger

65. Ultrasonics: Fundamentals, Technology, Applications: Second Edition, Revised and Expanded, Dale Ensminger

66. Applied Finite Element Modeling: Practical Problem Solving for Engineers, Jeffrey M. Steele

67. Measurement and Instrumentation in Engineering: Principles and Basic Laboratory Experiments, Francis S. Tse and Ivan E. Morse 68. Centrifugal Pump Clinic: Second Edition, Revised and Expanded,

Igor J. Karassik

69. Practical Stress Analysis in Engineering Design: Second Edition, Revised and Expanded, Alexander Blake

70. An Introduction to the Design and Behavior of Bolted Joints: Second Edition, Revised and Expanded, John H. Bickford

71. High Vacuum Technology: A Practical Guide, Marsbed H. Hablanian 72. Pressure Sensors: Selection and Application, Duane Tandeske 73. Zinc Handbook: Properties, Processing, and Use in Design,

Frank Porter

74. Thermal Fatigue of Metals, Andrzej Weronski and Tadeusz Hejwowski 75. Classical and Modern Mechanisms for Engineers and Inventors,

Preben W. Jensen

76. Handbook of Electronic Package Design, edited by Michael Pecht 77. Shock-Wave and High-Strain-Rate Phenomena in Materials, edited by

Marc A. Meyers, Lawrence E. Murr, and Karl P. Staudhammer 78. Industrial Refrigeration: Principles, Design and Applications,

P. C. Koelet

79. Applied Combustion, Eugene L. Keating

82. Fundamental Fluid Mechanics for the Practicing Engineer, James W. Murdock

83. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, Second Edition, Revised and Expanded, P. K. Mallick

84. Numerical Methods for Engineering Applications, Edward R. Champion, Jr.

85. Turbomachinery: Basic Theory and Applications, Second Edition, Revised and Expanded, Earl Logan, Jr.

86. Vibrations of Shells and Plates: Second Edition, Revised and Expanded, Werner Soedel

87. Steam Plant Calculations Manual: Second Edition, Revised and Expanded, V. Ganapathy

88. Industrial Noise Control: Fundamentals and Applications, Second Edition, Revised and Expanded, Lewis H. Bell and Douglas H. Bell 89. Finite Elements: Their Design and Performance, Richard H. MacNeal 90. Mechanical Properties of Polymers and Composites: Second Edition,

Revised and Expanded, Lawrence E. Nielsen and Robert F. Landel 91. Mechanical Wear Prediction and Prevention, Raymond G. Bayer 92. Mechanical Power Transmission Components, edited by

David W. South and Jon R. Mancuso

93. Handbook of Turbomachinery, edited by Earl Logan, Jr. 94. Engineering Documentation Control Practices and Procedures,

Ray E. Monahan

95. Refractory Linings Thermomechanical Design and Applications, Charles A. Schacht

96. Geometric Dimensioning and Tolerancing: Applications

and Techniques for Use in Design, Manufacturing, and Inspection, James D. Meadows

97. An Introduction to the Design and Behavior of Bolted Joints: Third Edition, Revised and Expanded, John H. Bickford

98. Shaft Alignment Handbook: Second Edition, Revised and Expanded, John Piotrowski

99. Computer-Aided Design of Polymer-Matrix Composite Structures, edited by Suong Van Hoa

100. Friction Science and Technology, Peter J. Blau

101. Introduction to Plastics and Composites: Mechanical Properties and Engineering Applications, Edward Miller

102. Practical Fracture Mechanics in Design, Alexander Blake 103. Pump Characteristics and Applications, Michael W. Volk

104. Optical Principles and Technology for Engineers, James E. Stewart 105. Optimizing the Shape of Mechanical Elements and Structures,

A. A. Seireg and Jorge Rodriguez

106. Kinematics and Dynamics of Machinery, Vladimír Stejskal and Michael Valásek

107. Shaft Seals for Dynamic Applications, Les Horve

111. High-Vacuum Technology: A Practical Guide, Second Edition, Revised and Expanded, Marsbed H. Hablanian

112. Geometric Dimensioning and Tolerancing: Workbook and Answerbook, James D. Meadows

113. Handbook of Materials Selection for Engineering Applications,

edited by G. T. Murray

114. Handbook of Thermoplastic Piping System Design, Thomas Sixsmith and Reinhard Hanselka

115. Practical Guide to Finite Elements: A Solid MechanicsApproach, Steven M. Lepi

116. Applied Computational Fluid Dynamics, edited by Vijay K. Garg 117. Fluid Sealing Technology, Heinz K. Muller and Bernard S. Nau 118. Friction and Lubrication in Mechanical Design, A. A. Seireg 119. Influence Functions and Matrices, Yuri A. Melnikov

120. Mechanical Analysis of Electronic Packaging Systems, Stephen A. McKeown

121. Couplings and Joints: Design, Selection, and Application, Second Edition,Revised and Expanded, Jon R. Mancuso

122. Thermodynamics: Processes and Applications, Earl Logan, Jr. 123. Gear Noise and Vibration, J. Derek Smith

124. Practical Fluid Mechanics for Engineering Applications, John J. Bloomer

125. Handbook of Hydraulic Fluid Technology, edited by George E. Totten 126. Heat Exchanger Design Handbook, T. Kuppan

127. Designing for Product Sound Quality, Richard H. Lyon

128. Probability Applications in Mechanical Design, Franklin E. Fisher and Joy R. Fisher

129. Nickel Alloys, edited by Ulrich Heubner

130. Rotating Machinery Vibration: Problem Analysis and Troubleshooting, Maurice L. Adams, Jr.

131. Formulas for Dynamic Analysis, Ronald L. Huston and C. Q. Liu 132. Handbook of Machinery Dynamics, Lynn L. Faulkner

and Earl Logan, Jr.

133. Rapid Prototyping Technology: Selection and Application, Kenneth G. Cooper

134. Reciprocating Machinery Dynamics: Design and Analysis, Abdulla S. Rangwala

135. Maintenance Excellence: Optimizing Equipment Life-Cycle Decisions, edited by John D. Campbell and Andrew K. S. Jardine

136. Practical Guide to Industrial Boiler Systems, Ralph L. Vandagriff 137. Lubrication Fundamentals: Second Edition, Revised and Expanded,

D. M. Pirro and A. A. Wessol

138. Mechanical Life Cycle Handbook: Good Environmental Design and Manufacturing, edited by Mahendra S. Hundal

139. Micromachining of Engineering Materials, edited by Joseph McGeough

142. Nondestructive Evaluation: Theory, Techniques, and Applications, edited by Peter J. Shull

143. Diesel Engine Engineering: Thermodynamics, Dynamics, Design, and Control, Andrei Makartchouk

144. Handbook of Machine Tool Analysis, Ioan D. Marinescu, Constantin Ispas, and Dan Boboc

145. Implementing Concurrent Engineering in Small Companies, Susan Carlson Skalak

146. Practical Guide to the Packaging of Electronics: Thermal and Mechanical Design and Analysis, Ali Jamnia

147. Bearing Design in Machinery: Engineering Tribology and Lubrication, Avraham Harnoy

148. Mechanical Reliability Improvement: Probability and Statistics for Experimental Testing, R. E. Little

149. Industrial Boilers and Heat Recovery Steam Generators: Design, Applications, and Calculations, V. Ganapathy

150. The CAD Guidebook: A Basic Manual for Understanding

and Improving Computer-Aided Design, Stephen J. Schoonmaker 151. Industrial Noise Control and Acoustics, Randall F. Barron

152. Mechanical Properties of Engineered Materials, Wolé Soboyejo 153. Reliability Verification, Testing, and Analysis in Engineering Design,

Gary S. Wasserman

154. Fundamental Mechanics of Fluids: Third Edition, I. G. Currie 155. Intermediate Heat Transfer, Kau-Fui Vincent Wong

156. HVAC Water Chillers and Cooling Towers: Fundamentals, Application, and Operation, Herbert W. Stanford III

157. Gear Noise and Vibration: Second Edition, Revised and Expanded, J. Derek Smith

158. Handbook of Turbomachinery: Second Edition,Revised and Expanded, edited by Earl Logan, Jr. and Ramendra Roy

159. Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair, George A. Antaki

160. Turbomachinery: Design and Theory, Rama S. R. Gorla and Aijaz Ahmed Khan

161. Target Costing: Market-Driven Product Design, M. Bradford Clifton, Henry M. B. Bird, Robert E. Albano, and Wesley P. Townsend 162. Fluidized Bed Combustion, Simeon N. Oka

163. Theory of Dimensioning: An Introduction to Parameterizing Geometric Models, Vijay Srinivasan

164. Handbook of Mechanical Alloy Design, edited by George E. Totten, Lin Xie, and Kiyoshi Funatani

165. Structural Analysis of Polymeric Composite Materials, Mark E. Tuttle 166. Modeling and Simulation for Material Selection and Mechanical

Design, edited by George E. Totten, Lin Xie, and Kiyoshi Funatani 167. Handbook of Pneumatic Conveying Engineering, David Mills,

Mark G. Jones, and Vijay K. Agarwal

170. Handbook of Lead-Free Solder Technology for Microelectronic Assemblies, edited by Karl J. Puttlitz and Kathleen A. Stalter 171. Vehicle Stability, Dean Karnopp

172. Mechanical Wear Fundamentals and Testing: Second Edition, Revised and Expanded, Raymond G. Bayer

173. Liquid Pipeline Hydraulics, E. Shashi Menon

174. Solid Fuels Combustion and Gasification, Marcio L. de Souza-Santos 175. Mechanical Tolerance Stackup and Analysis, Bryan R. Fischer 176. Engineering Design for Wear,Raymond G. Bayer

177. Vibrations of Shells and Plates: Third Edition, Revised and Expanded, Werner Soedel

178. Refractories Handbook, edited by Charles A. Schacht 179. Practical Engineering Failure Analysis, Hani M. Tawancy,

Anwar Ul-Hamid, and Nureddin M. Abbas

180. Mechanical Alloying and Milling, C. Suryanarayana

181. Mechanical Vibration: Analysis, Uncertainties, and Control, Second Edition, Revised and Expanded, Haym Benaroya

182. Design of Automatic Machinery, Stephen J. Derby

183. Practical Fracture Mechanics in Design: Second Edition, Revised and Expanded, Arun Shukla

184. Practical Guide to Designed Experiments, Paul D. Funkenbusch 185. Gigacycle Fatigue in Mechanical Practive, Claude Bathias

and Paul C. Paris

186. Selection of Engineering Materials and Adhesives, Lawrence W. Fisher

187. Boundary Methods: Elements, Contours, and Nodes, Subrata Mukherjee and Yu Xie Mukherjee

188. Rotordynamics, Agnieszka (Agnes) Muszn´yska

189. Pump Characteristics and Applications: Second Edition, Michael W. Volk

190. Reliability Engineering: Probability Models and Maintenance Methods, Joel A. Nachlas

191. Industrial Heating: Principles, Techniques, Materials, Applications, and Design, Yeshvant V. Deshmukh

192. Micro Electro Mechanical System Design, James J. Allen 193. Probability Models in Engineering and Science, Haym Benaroya

and Seon Han

194. Damage Mechanics, George Z. Voyiadjis and Peter I. Kattan 195. Standard Handbook of Chains: Chains for Power Transmission

and Material Handling, Second Edition, American Chain Association and John L. Wright, Technical Consultant

196. Standards for Engineering Design and Manufacturing, Wasim Ahmed Khan and Abdul Raouf S.I.

197. Maintenance, Replacement, and Reliability: Theory and Applications, Andrew K. S. Jardine and Albert H. C. Tsang

200. Fundamentals of Natural Gas Processing, Arthur J. Kidnay and William Parrish

201. Optimal Control of Induction Heating Processes, Edgar Rapoport and Yulia Pleshivtseva

202. Practical Plant Failure Analysis: A Guide to Understanding Machinery Deterioration and Improving Equipment Reliability,

Neville W. Sachs, P.E.

203. Shaft Alignment Handbook, Third Edition, John Piotrowski 204. Advanced Vibration Analysis , S. Graham Kelly

205. Principles of Composite Materials Mechanics, Second Edition, Ronald F. Gibson

206. Applied Combustion, Second Edition, Eugene L. Keating 207. Introduction to the Design and Behavior of Bolted Joints,

Fourth Edition: Non-Gasketed Joints, John H. Bickford 208. Analytical and Approximate Methods in Transport Phenomena,

Marcio L. de Souza-Santos

CRC Press is an imprint of the

Taylor & Francis Group, an informa business Boca Raton London New York

'HVLJQDQG2SWLPL]DWLRQ

RI7KHUPDO6\VWHPV

6HFRQG(GLWLRQ

CRC Press

Taylor & Francis Group

6000 Broken Sound Parkway NW, Suite 300 Boca Raton, FL 33487-2742

© 2008 by Taylor & Francis Group, LLC

CRC Press is an imprint of Taylor & Francis Group, an Informa business

No claim to original U.S. Government works

Printed in the United States of America on acid-free paper 10 9 8 7 6 5 4 3 2 1

International Standard Book Number-13: 978-0-8493-3753-6 (Hardcover)

This book contains information obtained from authentic and highly regarded sources. Reprinted material is quoted with permission, and sources are indicated. A wide variety of references are listed. Reasonable efforts have been made to publish reliable data and information, but the author and the publisher cannot assume responsibility for the validity of all materials or for the consequences of their use.

Except as permitted under U.S. Copyright Law, no part of this book may be reprinted, reproduced, trans-mitted, or utilized in any form by any electronic, mechanical, or other means, now known or hereafter invented, including photocopying, microfilming, and recording, or in any information storage or retrieval system, without written permission from the publishers.

For permission to photocopy or use material electronically from this work, please access www.copyright. com (http://www.copyright.com/) or contact the Copyright Clearance Center, Inc. (CCC) 222 Rosewood Drive, Danvers, MA 01923, 978-750-8400. CCC is a not-for-profit organization that provides licenses and registration for a variety of users. For organizations that have been granted a photocopy license by the CCC, a separate system of payment has been arranged.

Trademark Notice: Product or corporate names may be trademarks or registered trademarks, and are used only for identification and explanation without intent to infringe.

Library of Congress Cataloging-in-Publication Data Jaluria, Yogesh.

Design and optimization of thermal systems / Yogesh Jaluria. -- 2nd ed. p. cm. -- (Mechanical engineering)

Includes bibliographical references and index. ISBN 978-0-8493-3753-6 (alk. paper)

1. Heat engineering. 2. Engineering design. I. Title. II. Series.

TJ260.J353 2007

621.402--dc22 2007027214

Visit the Taylor & Francis Web site at http://www.taylorandfrancis.com and the CRC Press Web site at http://www.crcpress.com

Contents

Chapter 1 Introduction ... 1

1.1 Engineering Design ... 2

1.1.1 Design Versus Analysis ... 2

1.1.2 Synthesis for Design ... 6

1.1.3 Selection Versus Design... 7

1.2 Design as Part of Engineering Enterprise ... 9

1.2.1 Need or Opportunity ... 9

1.2.2 Evaluation and Market Analysis ... 10

1.2.3 Feasibility and Chances of Success ... 12

1.2.4 Engineering Design ... 14

1.2.5 Research and Development ... 15

1.2.6 Need for Optimization ... 16

1.2.7 Fabrication, Testing, and Production ... 18

1.3 Thermal Systems ... 19

1.3.1 Basic Characteristics ... 19

1.3.2 Analysis ... 22

1.3.3 Types and Examples ... 25

1.4 Outline and Scope of the Book ... 40

1.5 Summary ... 43

References ... 44

Chapter 2 Basic Considerations in Design ... 47

2.1 Formulation of the Design Problem ... 47

2.1.1 Requirements and Specifications ... 47

2.1.2 Given Quantities ... 50

2.1.3 Design Variables ... 51

2.1.4 Constraints or Limitations ... 53

2.1.5 Additional Considerations ... 55

2.2 Conceptual Design ... 58

2.2.1 Innovative Conceptual Design ... 58

2.2.2 Selection from Available Concepts ... 62

2.2.3 Modifications in the Design of Existing Systems ... 64

2.3 Steps in the Design Process ... 70

2.3.1 Physical System... 72

2.3.4 Evaluation: Acceptable Design ... 81

2.3.5 Optimal Design ... 83

2.3.6 Safety Features, Automation, and Control ... 86

2.3.7 Communicating the Design ... 90

2.3.8 Patents and Copyrights ... 92

2.4 Computer-Aided Design ... 97

2.4.1 Main Features ... 97

2.4.2 Computer-Aided Design of Thermal Systems ... 98

2.5 Material Selection ... 104

2.5.1 Different Materials ... 104

2.5.2 Material Properties and Characteristics for Thermal Systems ... 108

2.5.3 Selection and Substitution of Materials ...110

2.6 Summary ...113

References ...115

Problems ...116

Chapter 3 Modeling of Thermal Systems ... 125

3.1 Introduction ... 125

3.1.1 Importance of Modeling in Design ... 125

3.1.2 Basic Features of Modeling ... 125

3.2 Types of Models ... 128

3.2.1 Analog Models ... 129

3.2.2 Mathematical Models ... 130

3.2.3 Physical Models ... 130

3.2.4 Numerical Models ...131

3.2.5 Interaction Between Models ... 133

3.2.6 Other Classifications ... 133

3.3 Mathematical Modeling ... 134

3.3.1 General Procedure ... 134

3.3.2 Final Model and Validation ... 160

3.4 Physical Modeling and Dimensional Analysis ... 165

3.4.1 Dimensional Analysis ... 166

3.4.2 Modeling and Similitude ...176

3.4.3 Overall Physical Model ... 180

3.5 Curve Fitting ... 180

3.5.1 Exact Fit ...181

3.5.2 Best Fit ... 183

3.6 Summary ... 194

References ... 196

4.1 Numerical Modeling ... 208

4.1.1 General Features ... 208

4.1.2 Development of a Numerical Model ...210

4.1.3 Available Software ...211

4.2 Solution Procedures ... 212

4.2.1 Linear Algebraic Systems ... 213

4.2.2 Nonlinear Algebraic Systems ... 220

4.2.3 Ordinary Differential Equations ... 227

4.2.4 Partial Differential Equations ... 238

4.3 Numerical Model for a System ... 247

4.3.1 Modeling of Individual Components ... 248

4.3.2 Merging of Different Models ... 251

4.3.3 Accuracy and Validation ... 252

4.4 System Simulation ... 253

4.4.1 Importance of Simulation ... 254

4.4.2 Different Classes ... 256

4.4.3 Flow of Information ... 259

4.5 Methods for Numerical Simulation ... 264

4.5.1 Steady Lumped Systems ... 264

4.5.2 Dynamic Simulation of Lumped Systems ... 272

4.5.3 Distributed Systems ... 278

4.5.4 Simulation of Large Systems ... 282

4.5.5 Numerical Simulation Versus Real System ... 283

4.6 Summary ... 284

References ... 285

Problems ... 286

Chapter 5 Acceptable Design of a Thermal System: A Synthesis of Different Design Steps ... 299

5.1 Introduction ... 299

5.2 Initial Design ... 300

5.3 Design Strategies ... 309

5.3.1 Commonly Used Design Approach ... 309

5.3.2 Other Strategies ... 309

5.3.3 Iterative Redesign Procedure ... 317

5.4 Design of Systems from Different Application Areas ... 322

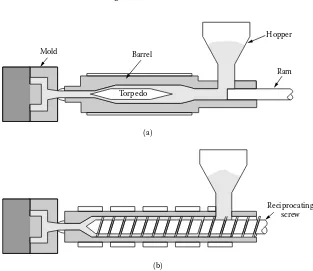

5.4.1 Manufacturing Processes ... 323

5.4.2 Cooling of Electronic Equipment ... 329

5.4.3 Environmental Systems ... 336

5.4.4 Heat Transfer Equipment ... 342

5.4.7 Design of Components Versus Design of Systems ... 361

5.5 Additional Considerations for Large Practical Systems ... 362

5.6 Summary ... 373

References ... 374

Problems ... 375

Chapter 6 Economic Considerations ... 383

6.1 Introduction ... 383

6.2 Calculation of Interest ... 385

6.2.1 Simple Interest ... 385

6.2.2 Compound Interest ... 385

6.2.3 Continuous Compounding ... 387

6.2.4 Effective Interest Rate ... 388

6.3 Worth of Money as a Function of Time ... 390

6.3.1 Present Worth... 390

6.3.2 Future Worth ... 391

6.3.3 Inflation ... 393

6.4 Series of Payments ... 396

6.4.1 Future Worth of Uniform Series of Amounts ... 396

6.4.2 Present Worth of Uniform Series of Amounts ... 397

6.4.3 Continuous Compounding in a Series of Amounts ... 399

6.4.4 Changing Amount in Series of Payments ... 400

6.4.5 Shift in Time ... 402

6.4.6 Different Frequencies... 403

6.4.7 Changes in Schedule ... 403

6.5 Raising Capital ... 405

6.5.1 Bonds ... 406

6.5.2 Stocks ... 408

6.6 Taxes ... 408

6.6.1 Inclusion of Taxes ... 409

6.6.2 Depreciation ...410

6.7 Economic Factor in Design ...413

6.7.1 Cost Comparison...413

6.7.2 Rate of Return ...417

6.8 Application to Thermal Systems ...419

6.9 Summary ... 421

References ... 421

Problems ... 422

Chapter 7 Problem Formulation for Optimization ... 429

7.1 Introduction ... 429

7.1.1 Optimization in Design ... 429

7.2.1 Objective Function ... 432

7.2.2 Constraints ... 434

7.2.3 Operating Conditions Versus Hardware ... 437

7.2.4 Mathematical Formulation... 438

7.3 Optimization Methods ... 440

7.3.1 Calculus Methods ... 440

7.3.2 Search Methods ... 441

7.3.3 Linear and Dynamic Programming ... 442

7.3.4 Geometric Programming ... 444

7.3.5 Other Methods ... 444

7.4 Optimization of Thermal Systems ... 447

7.4.1 Important Considerations ... 447

7.4.2 Different Approaches ... 448

7.4.3 Different Types of Thermal Systems ... 449

7.4.4 Examples ... 451

7.4.5 Consideration of the Second Law of Thermodynamics ... 455

7.5 Practical Aspects in Optimal Design ... 457

7.5.1 Choice of Variables for Optimization ... 457

7.5.2 Sensitivity Analysis... 459

7.5.3 Dependence on Objective Function: Trade-Offs ... 461

7.5.4 Multi-Objective Optimization ... 462

7.5.5 Part of Overall Design Strategy ... 464

7.5.6 Change of Concept or Model ... 465

7.6 Summary ... 466

References ... 467

Problems ... 468

Chapter 8 Lagrange Multipliers ... 473

8.1 Introduction to Calculus Methods ... 473

8.2 The Lagrange Multiplier Method ... 475

8.2.1 Basic Approach ... 475

8.2.2 Physical Interpretation ... 477

8.2.3 Significance of the Multipliers ... 485

8.3 Optimization of Unconstrained Problems ... 486

8.3.1 Use of Gradients for Optimization ... 487

8.3.2 Determination of Minimum or Maximum ... 487

8.3.3 Conversion of Constrained to Unconstrained Problem ... 489

8.4 Optimization of Constrained Problems ... 491

8.5 Applicability to Thermal Systems ... 494

8.5.1 Use of Curve Fitting... 494

8.5.2 Examples ... 495

8.5.5 Computational Approach ... 501

8.6 Summary ... 503

References ... 504

Chapter 9 Search Methods ...511

9.1 Basic Considerations ...511

9.1.1 Importance of Search Methods ... 512

9.1.2 Types of Approaches ...513

9.1.3 Application to Thermal Systems ...514

9.2 Single-Variable Problem ... 515

9.2.1 Uniform Exhaustive Search ...517

9.2.2 Dichotomous Search ...519

9.2.3 Fibonacci Search ... 521

9.2.4 Golden Section and Other Search Methods ... 523

9.2.5 Comparison of Different Elimination Methods ... 524

9.3 Unconstrained Search with Multiple Variables ... 527

9.3.1 Lattice Search ... 529

9.3.2 Univariate Search ... 530

9.3.3 Steepest Ascent/Descent Method ... 532

9.4 Multivariable Constrained Optimization ... 537

9.4.1 Penalty Function Method ... 537

9.4.2 Search Along a Constraint ... 542

9.5 Examples of Thermal Systems ... 547

9.6 Summary ...551

References ... 553

Problems ... 554

Chapter 10 Geometric, Linear, and Dynamic Programming and Other Methods for Optimization ... 559

10.1 Geometric Programming ... 559

10.1.1 Applicability ... 560

10.1.2 Unconstrained Optimization ... 561

10.1.3 Mathematical Proof ... 570

10.1.4 Constrained Optimization ... 573

10.1.5 Nonzero Degree of Difficulty ... 578

10.2 Linear Programming ... 579

10.3 Dynamic Programming ... 588

10.4 Other Methods ... 590

10.5 Summary ... 591

References ... 592

11.1 Knowledge-Based Systems ... 599

11.1.1 Introduction ... 600

11.1.2 Basic Components ... 602

11.1.3 Expert Knowledge ... 607

11.1.4 Design Methodology ... 609

11.1.5 Application to Thermal Systems ...610

11.2 Additional Constraints ... 621

11.3 Professional Ethics ... 623

11.4 Sources of Information ... 625

11.5 An Overview of Design of Thermal Systems ... 628

11.6 Summary ... 631

References ... 632

Problems ... 633

Design Projects ... 635

Appendix A Computer Programs ... 639

Appendix B Material Properties ... 659

Appendix C Interest Tables ... 679

Appendix D Heat Transfer Correlations ... 687

Preface to the First Edition

APPROACH

Design is an essential element in engineering education and practice. In recent years, there has been a growing emphasis on the design and optimization of sys-tems because of growing worldwide competition and the development of new processes and techniques. Design has long been very important in undergraduate mechanical engineering curricula around the country. However, the effort had been largely directed at mechanical systems, dealing with areas such as transmis-sion, vibrations, robotics, and controls, and at components such as gears, cams, springs, and linkages.

With the growth of thermal systems, such as those related to materials pro-cessing, energy conversion, pollution, aerospace, and automobiles, the need to design and optimize thermal systems has also grown. In mechanical engineer-ing programs around the country, courses have been developed on the design of thermal systems. These are often elective courses, or, in many schools, such courses form the final capstone design course, often alternated with a design course on mechanical systems. Invariably, optimization is an important element in such courses because of the crucial need to optimize systems in practical applications.

This book is written as a textbook at the senior undergraduate or the first-year graduate level. It can also be used as a reference book for other thermal sciences courses, such as those on heat transfer, fluid mechanics, and thermodynamics, and for courses in applied areas, such as power plants, environmental control of buildings, and solar energy systems. It can be used for reference by practicing engineers as well. Although the book is written for engineering education curri-cula in the United States, the material and treatment can easily be used in various countries around the world. The book is largely written for mechanical engineers. However, the material is suitable for courses in other engineering disciplines, such as chemical, aerospace, industrial, and materials engineering.

presented as an essential element in the design and optimization process.

The basic approach to the development of a suitable model is discussed in Chapter 3 in detail since this forms the most crucial step in the design of a sys-tem. Various approximations and idealizations that can be used for modeling are presented, along with examples of mathematical modeling of practical systems. This is followed in Chapter 4 by detailed discussions of numerical modeling and simulation, again linking these to the mathematical model and experimental data. These results then form the basis for creative design of thermal systems and for the evaluation of the designs obtained.

The development of a workable, or acceptable, design, one which satisfies the requirements and constraints of the problem, is discussed as a synthesis of the different design steps. Several examples are given in Chapter 5 to illustrate the overall procedure. This is followed in Chapter 6 by a discussion of economic factors in design since these often guide system design and optimization. The for-mulation of the optimization problem is explained in Chapter 7. The presentation on optimization includes several applicable methods such as calculus methods, search methods, and linear, dynamic, and geometric programming. These topics are covered in Chapter 8 through Chapter 10. Again, thermal systems found in several important and relevant areas are used as examples to illustrate the ideas presented. Solved examples and problems strengthen the presentation and allow the important concepts to be assimilated by the readers. Recent trends, such as knowledge-based design methodology, are included in Chapter 11. Additional practical considerations, such as economic, safety, and materials, are also dis-cussed at various stages of the presentation.

ations that arise in the design and optimization of thermal systems, as well as the appropriate methodology. Readers are encouraged to use their own backgrounds, imaginations, and available literature for designing different types of systems. Since simple closed-form, analytical, solutions are rarely obtained in practical thermal systems, clear and concise answers are not readily available in many cases. A consideration of several practical systems makes this aspect of thermal system design clear.

The material included in this book has been used in courses for undergraduate seniors at Rutgers University and at the Indian Institute of Technology, Kanpur, India. The topics, examples, and problems have, therefore, been largely tested in a classroom environment. Various design projects and examples emerged from these courses, and some of them are included in the text. In keeping with the basic design process, many of the problems are open-ended and a unique solution is not obtained.

SUPPLEMENT

A solutions manual, prepared by me in order to ensure the problem-solving meth-odology is the same as that in the book, is available to text adopters. This manual contains possible solutions to most of the problems in this book (since many prob-lems are open-ended and thus do not have a unique solution).

ACKNOWLEDGMENTS

encouragement, support, and inspiration. Certainly, the greatest contribution to this work has been the unqualified support and encouragement of my wife, Anuradha, and the patience and understanding of our children, Pratik, Aseem, and Ankur. Without their support, it would not have been possible for me to meet the strong demands placed on my time by this book.

Preface to the Second Edition

The second edition of this book follows the basic principles, approaches, and treatment presented in the first edition. The focus is clearly on systems in which thermodynamics, fluid flow, and thermal transport form the main considerations. However, the ideas, methodology, and pedagogy are applicable to a wide variety of engineering systems. The main thrust is to design and optimize systems based on inputs from simulation and experimental data on materials and on components that constitute the system. A systematic approach is followed to finally obtain an optimal design, starting with conceptual design and proceeding through mod-eling, simulation, and design evaluation to choose a feasible design. Additional aspects, such as system control, communicating the design, financial consider-ations, safety, and material selection, that arise in practical systems are also pre-sented. A wide range of examples from many different applied areas, such as energy, environment, heating, cooling, manufacturing, aerospace, and transpor-tation systems, are employed to explain the various elements involved in model-ing, simulation, and design. Even though there are many significant differences between such a diversity of systems, the basic approach is still very similar and can be used for relatively simple systems with few components to large, com-plex systems with many components and subsystems. A large number of solved examples and exercises are included to supplement the discussion and to illustrate the ideas presented in the text.

The book is appropriate as a textbook for engineering senior undergraduate or first-year graduate level courses in design, as well as for capstone design courses taught in most engineering curricula. It is also appropriate as a reference book in courses at this level in heat transfer, fluid mechanics, thermodynamics, and other related basic and applied areas in mechanical engineering and other engineering disciplines. The book would also be useful as a reference for engineers working on a wide range of problems in industry, national labs, and other organizations.

then be extended to systems that are more complicated. Additional exercises and examples are included in all the chapters, as well as additional projects at the end of the book. Extra information is added at various places, as appropriate; for instance, in materials and in optimization. Much of the presentation has been revised and, in several cases, simplified and clarified to make it easier to follow.

The presentation has also been updated to include recent advances in design and optimization. Among the additional topics included are artificial-intelligence-based techniques like genetic algorithms, fuzzy logic, and artificial neural net-works. Response surfaces and other optimization techniques are included in the discussion, along with effective use of concurrent experimental and numerical inputs for design and optimization. Multi-objective optimization is particularly important for thermal systems, since more than one objective function is typically important in realistic systems, and a detailed treatment is included. Other strate-gies to optimize the system are presented. Additional references have been added on these topics, as well as on the others that were covered in the first edition. Previ-ous references have been updated. The application of these ideas to the optimiza-tion of thermal systems is reiterated with examples of actual, practical systems.

The material presented in this textbook is the outcome of many years of teaching design of thermal systems, in elective courses and in capstone design courses. The inputs from many colleagues and former graduate and undergradu-ate students have been valuable in selecting the topics and the depth and breadth of coverage. Discussions with colleagues outside Rutgers University, particularly at the conferences of the American Society of Mechanical Engineers, have been important in understanding the instruction and concerns at other universities. Inputs from reviewers of the first edition were also useful in fine-tuning some of the presentation. The support and assistance provided by the editorial staff of Taylor & Francis, particularly by Jessica Vakili, have been valuable in the devel-opment of the second edition. Finally, I would like to acknowledge the encour-agement and support of my wife, Anuradha, and of our children, Ankur, Aseem, and Pratik, as well as Pratik’s wife, Leslie, and son, Vyan, for this effort. It did take me away from them for many hours and distracted me at other times. Their patience and understanding is thus greatly appreciated.

The Author

Yogesh Jaluria, M.S., Ph.D., is currently Board of Governors Professor at Rutgers, the State University of New Jersey, New Brunswick, and the chairman of the Department of Mechanical and Aerospace Engineering. He received his B.S. degree from the Indian Institute of Technology, Delhi, India, in 1970. He obtained his M.S. and Ph.D. degrees in mechanical engineering from Cornell University.

Jaluria has contributed more than 400 technical articles, including over 160 in archival journals and 16 chapters in books. He has two patents in materials pro-cessing and is the author/co-author of six books. Jaluria received the 2003 Robert Henry Thurston Lecture Award from the American Society of Mechanical Engineers (ASME), and the 2002 Max Jakob Memorial Award for eminent achievement in the field of heat transfer from ASME and the American Institute of Chemical Engineers (AIChE). In 2002, he was named Board of Governors Professor of Mechanical and Aerospace Engineering at Rutgers University. He was selected as the 2000 Freeman Scholar by the Fluids Engineering Division, ASME. He received the 1999 Worcester Reed Warner Medal and the 1995 Heat Transfer Memorial Award for significant research contributions to the science of heat transfer, both from ASME. He also received the 1994 Distinguished Alumni Award from the Indian Institute of Technology, Delhi.

1

1

Introduction

Design is generally regarded as a creative process by which new methods, devices, and techniques are developed to solve new or existing problems. Though many professions are concerned with creativity leading to new arrangements, struc-tures, or artifacts, design is an essential element in engineering education and practice. Due to increasing worldwide competition and the need to develop new, improved, and more efficient processes and techniques, a growing emphasis is being placed on design. Interest lies in producing new and higher quality products at minimal cost, while satisfying increasing concerns regarding the environmen-tal impact and safety. It is no longer adequate just to develop a system that per-forms the desired task to satisfy a recognized need of the society. It is crucial to optimize the process so that a chosen quantity, known as the objective function, is maximized or minimized. Thus, for a given system, the output, profit, produc-tivity, product quality, etc., may be maximized, or the cost per item, investment, energy input, etc., may be minimized.

The survival and growth of most industries today are strongly dependent on the design and optimization of the relevant systems. With the advent of many new materials, such as composites and ceramics, and new manufacturing processes, several classical industries, such as the steel industry, have diminished in impor-tance in the recent years, while many new fields have emerged. It is important to keep abreast of changing trends in these areas and to use new techniques for product improvement and cost reduction. Even in an expanding engineering area, such as consumer electronics, the prosperity of a given company is closely linked with the design and optimization of new processes and systems and optimiza-tion of existing ones. Consequently, the subject of design, which had always been important, has become increasingly critical in today’s world and has also become closely coupled with optimization.

those arising in different fields of engineering, for example, civil, chemical, elec-trical, and industrial engineering.

In this chapter, we shall first consider the main features of engineering design, its importance in the overall context of an engineering enterprise, and the need to optimize. We will also examine design in relation to analysis, synthesis, selection of equipment, and other important activities that support design. This discussion will be followed by a consideration of systems, components, and subsystems. The basic nature of thermal systems will be outlined, and examples of different types of systems will be presented from many diverse and important areas.

1.1 ENGINEERING DESIGN

One of the most important tasks confronted by engineers is that of design. It may be the design of an individual component, such as a thermostat, flow valve, gear, or spring, or it may be the design of a system, such as a furnace, air conditioner, or an internal combustion engine, which consists of several components or constituents interacting with each other. It is, therefore, fair to ask what design is and what distinguishes it from other activities such as analysis and synthesis with which engineers are frequently con-cerned. However, design has come to mean different things to different people. The perception of design ranges from the creation of a new device or process to the routine calculation and presentation of specifications of the different items that make up a system. However, design must incorporate some element of creativity and innovation, in terms of a new and different approach to the solution of an existing engineering problem that has been solved by other methods or a solution to a problem not solved before. The process by which such new, different, or improved solutions are derived and applied to engineering problems is termed design.

1.1.1 DESIGNVERSUSANALYSIS

We are all quite familiar with the analysis of engineering problems using infor-mation derived from basic areas such as statics, dynamics, thermodynamics, fluid mechanics, and heat transfer. The problems considered are often relevant to these disciplines and little interaction between different disciplines is brought into play. In addition, all the appropriate inputs needed for the problem are usually given and the results are generally unique and well defined, so that the solution to a given problem may be carried out to completion, yielding the final result that satisfies the various inputs and conditions provided. Such problems may be termed as closed-ended.

such analyses for a variety of physical circumstances. Many courses are directed at engineering analysis and students are taught various techniques to solve simple as well as complicated problems in fundamental and applied areas. Most students thus acquire the skills and expertise to analyze well-defined and well-posed prob-lems in different engineering disciplines.

The design process, on the other hand, is open-ended, that is, the results are not well known or well defined at the onset. The inputs may also be vague or incomplete, making it necessary to seek additional information or to employ approximations and assumptions. There is also usually considerable interaction between various disciplines, particularly between technical areas and those con-cerned with cost, safety, and the environment. A unique solution is generally not obtained and one may have to choose from a range of acceptable solutions. In addition, a solution that satisfies all the requirements may not be obtained and it may be necessary to relax some of the requirements to obtain an acceptable solution. Therefore, trade-offs generally form a necessary part of design because certain characteristics of the system may have to be given up in order to achieve some other goals such as greater cost effectiveness or smaller environmental impact. Individual or group judgment based on available information is needed to decide on the final design.

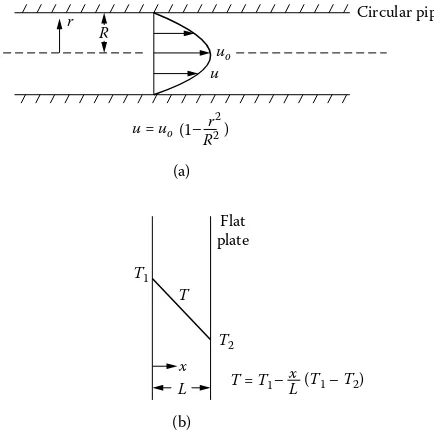

FIGURE 1.1 Analytical results for (a) developed fluid flow in a circular pipe and

(b) steady-state one-dimensional heat conduction in a flat plate.

Circular pipe R

uo u

u = uo r

r2 R2 (1–

(a)

(b) Flat plate

T

T=T1 (T1–T2) T1

T2

x L L

x

A Few Examples

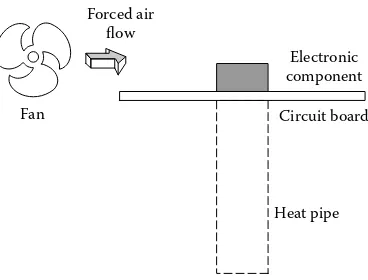

Consider the example of an electronic component located on a board and being cooled by the flow of air driven by a fan, as shown in Figure 1.2. The energy dissipated by the component is given. If the temperature distributions in the com-ponent, the board, and other parts of the system are to be determined, analysis or numerical calculations may be used for the purpose. Even though the numerical procedure for obtaining this information may be quite involved, the solution is unique for the given geometry, material properties, and dimensions. Different methods of solution may be employed but the problem itself is well defined, with all the input quantities specified and with no variables left to be chosen arbitrarily. There are no trade-offs or additional considerations to be included.

Let us now consider the corresponding design problem of finding the appro-priate materials, geometry, and dimensions so that the temperature Tc in the component remains below a certain value, Tmax, in order to ensure satisfactory performance of the electronic circuit. This is clearly a much more involved problem. There is no unique answer because many combinations of materials, dimensions, geometry, fan capacity, etc., may be chosen to satisfy the given requirement Tc < Tmax. There is considerable freedom and flexibility in choos-ing the different variables that characterize the system. Such a problem is, thus, open-ended and many solutions may be obtained to satisfy the given need and constraints, if any, on cost, size, dimensions, etc. It is also possible that a sat-isfactory solution cannot be found for the given conditions and an additional cooling method such as a heat pipe, which conveys the heat dissipated at a much higher rate by means of a phase change process, may have to be included, as shown by the dotted lines in Figure 1.2. Then the design process must consider the two cooling arrangements and determine the relevant characteristic param-eters for these cases. Thus, different approaches, often known as conceptual designs, may be considered for satisfying the given requirements.

Fan

Forced air flow

Electronic component

Circuit board

Heat pipe

FIGURE 1.2 An electronic component being cooled by forced convection and by a heat

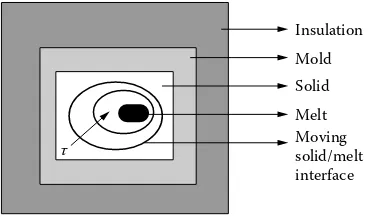

Another example that illustrates the difference between analysis and design is that of a casting process, as sketched in Figure 1.3. Molten material is poured into a mold and allowed to solidify. If the properties of the material undergoing solidification and of the various parts of the system, such as the mold wall and the insulation, are given along with the relevant dimensions, the initial temperature, and the convective heat transfer coefficient h at the outer surface of the mold, the problem may be solved by analysis or numerical computation to determine the temperature distributions in the solid material, liquid, and various parts of the system, as well as the rate and total time of solidification for the casting (Flemings, 1974). The problem can often be simplified by using approximations such as constant material properties, negligible convective flow in the melt, uni-form heat transfer coefficient h over the entire surface, etc. But once the problem is posed in terms of the governing equations and appropriate boundary condi-tions, the results are generally well defined and unique.

We may now pose a corresponding design problem by allowing a choice of the materials and dimensions for the mold wall and insulation and of the cooling conditions at the outer surface, in order to reduce the solidification time below a desired value cast. Then, many combinations of wall material and thickness, cool-ing parameters, insulation parameters, etc., are possible. Again, there is no unique solution and, indeed, there is no guarantee that a solution will be found. All that is given is the requirement regarding the solidification time and quantities that may be varied to achieve a satisfactory design. In other cases, the requirements may be specified as limitations on the temperature gradients in the casting in order to improve the quality of the product. Clearly, we are dealing with an open-ended problem without a unique solution.

It is largely because of the open-ended nature of design problems that design is often much more involved than analysis. Consequently, while extensive infor-mation is available in the literature on the analysis of various thermal processes and on the resulting effects of the governing variables, the corresponding design problems have received much less attention. However, even though design and analysis are very different in their objectives and goals, analysis usually forms

Insulation

Mold

Solid

Melt Moving solid/melt interface

the basis for the design process. It is used to study the behavior of a given sys-tem, choose the appropriate variables for the desired effects, and evaluate various designs, leading to satisfactory and optimized systems.

1.1.2 SYNTHESIS FORDESIGN

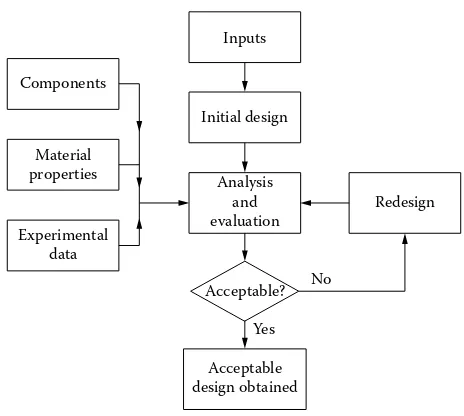

Synthesis is another key element in the design process, since several components and their corresponding analyses are brought together to yield the characteristics of the overall system. Results from different areas have to be linked and synthe-sized in order to include all of the important concerns that arise in a practical system (Suh, 1990; Ertas and Jones, 1996; Dieter, 2000). We cannot consider only the heat transfer aspects in the casting problem while ignoring the strength of materials and manufacturing aspects. Information from different types of mod-els, including experimental and numerical results, and from existing systems are incorporated into the design process. The cost, properties, and characteristics of various materials that may be employed must also form part of the design effort, since material selection is a very important factor in obtaining an acceptable or optimal system. Additional aspects, such as safety, legal, regulatory, and envi-ronmental considerations, are also synthesized in order to obtain a satisfactory design. Figure 1.4 shows a sketch of a typical design process for a system, involv-ing both analysis and synthesis as part of the overall effort.

Acceptable design obtained

Yes No Acceptable?

Analysis and evaluation Experimental

data Material properties

Redesign Initial design

Components

Inputs

1.1.3 SELECTIONVERSUSDESIGN

We are frequently faced with the task of selecting parts in order to assemble a system or a device that will perform a desired duty. In several cases, the entire equipment may be selected from what is available on the market, for instance, a heat exchanger, a pump, or a compressor. Even though selection is an important ingredient in engineering practice, it is quite different from designing a component or device and it is important to distinguish between the two. Selection largely involves determining the specifications of the item from the requirements for the given task. Based on these specifications, a choice is made from the various types of items available with different ratings or features. Design, on the other hand, involves starting with a basic concept, modeling and evaluating different designs, and obtaining a final design that meets the given requirements and constraints. The system may then be fabricated and tests carried out on a prototype before going into production. Therefore, design is directed at creating a new process or system, whereas selection is concerned with choosing the right item for a given job.

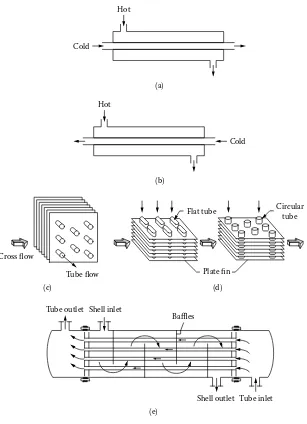

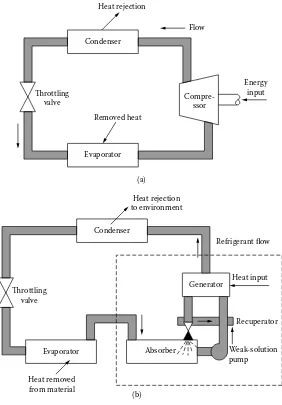

Selection and design are frequently employed together in the development of a system, using selection for components that are easily available over the ranges of interest. Standard items such as valves, control sensors, heaters, flow meters, and storage tanks are usually selected from catalogs of available equipment. Sim-ilarly, pumps, compressors, fans, and condensers may be selected, rather than designed, for a given application. Obviously, design is involved in the develop-ment of these components as well; however, for a given system, the design of these individual components may be avoided in the interest of time, cost, and conve-nience. For instance, a company that develops and manufactures heat exchangers would generally design different types of heat exchangers for different fluids and applications, achieving different ranges in heat transfer rate, area, effectiveness, flow rate, etc. Different configurations such as counter-flow and parallel-flow heat exchangers, compact heat exchangers, shell-and-tube heat exchangers, etc., as shown in Figure 1.5, may be considered for a variety of applications. These may then be designed to obtain desired parametric ranges of heat transfer rate, output temperature, size, etc. (Kays and London, 1984). Design engineers working on another thermal system, such as air conditioning or indoor heating, may simply select the condenser, evaporator, or other types of heat exchangers needed, rather than design these.

(a) Hot

Cold

(b) Hot

Cold

(c)

Tube flow

Cross flow

(d)

Flat tube Circular

tube

Plate fin

(e) Shell inlet

Shell outlet Tube inlet Tube outlet

Baffles

FIGURE 1.5 Common types of heat exchangers. (a) Concentric pipe parallel-flow,

1.2 DESIGN AS PART OF ENGINEERING ENTERPRISE

Before proceeding to a discussion of the characteristics and types of thermal systems, it will be instructive to consider the position occupied by design and optimization in the overall scheme of an engineering undertaking. The planning and execution of such an enterprise involve many aspects that are engineering based and several that are not, for example, economic and market considerations. Engineering design is one of the key elements in the development of a product or a system and is coupled with the other considerations to obtain a successful ven-ture. Let us follow a typical engineering undertaking from the initial recognition of a need for a particular item or process to its final implementation.

1.2.1 NEED OR OPPORTUNITY

Defining a need or opportunity is always the first step in an engineering undertak-ing because it provides the impetus to develop a product or system. Need refers to a specific requirement and implies that a suitable item is not available and must be developed for the desired purpose. The need for a given item may be felt at vari-ous levels, ranging from the consumer and the retailer to the industry itself, and may involve developing a new system or modifying and improving existing ones.

Opportunity is the recognition of a chance to develop a new product that may be superior to existing ones or less expensive. It may also be an item for which the market is expected to develop as it becomes available.

Consumers’ need for a new or improved product is often discovered through surveys conducted by the sales division and through consumer interactions with salespersons. In some cases, individual consumers and consumer groups may also provide information on their needs and requirements. The problems or limitations in existing products may become evident from such inputs, indicating the need for developing a new or improved item. The development of the hard disk in personal computers arose mainly because of consumers’ need for larger data storage capac-ity. Similarly, CD-ROM and memory sticks were introduced because of the need to store and transfer data and information. Anti-lock brakes, air bags, computer-controlled fuel injection, and streamlining of the body have been introduced in automobiles in response to safety and efficiency needs. The need for specific com-ponents or systems may also arise in auxiliary industrial units that are dependent on the main industry. For instance, the development of larger and improved television systems, such as the high definition television, has generated demand for a range of electronic products and systems that will be met by other specialized industries.

computer is an interesting example of such an opportunity-based development. An opportunity was perceived by the industry, mainly by Apple Computers Inc., and adequate technical expertise was available to develop a personal computer. This led to an expanding market and the use of the personal computer in a variety of applications, ranging from word processing, information storage, and account-ing to instruction and data acquisition. The video cassette recorder, fiber-optics cable, compact disc player, microwave oven, and the Apple iPod and iPhone represent new products that were developed in recent years with possible oppor-tunities and expanding markets in mind.

The industry today is very dynamic and is always on the lookout for opportu-nities where the available technical know-how can be used effectively to develop new ideas, leading to new products and systems. The research and development division of a given industrial concern is often the source of such opportunities because of its interest in new materials and techniques being developed in the academic, industrial, and research environments outside the firm. However, a new idea may also arise from other divisions in the company based on their involve-ment with various processes and products.

1.2.2 EVALUATION ANDMARKETANALYSIS

An important consideration in the development of a new concept is its evalua-tion for economic viability, since profit is usually the main concern in engineer-ing undertakengineer-ings. Even if need and opportunity have indicated that a particular product or system will be useful and will have a secure market, it is necessary to determine how big the market is, what price range it will bear, and what the possible expenses involved in taking the concept to completion are. The sales and marketing division of the company could target typical consumers, who may be individuals, organizations, or other industries. The information regarding price, consumption level, desired characteristics of the product, and nature of the intended application could be gathered through surveys, mail, telephone or individual contact, interactions with product outlets and sales organizations, and inputs from consumer groups. Earlier studies on similar products may also be used to provide the relevant information for evaluating the proposed venture. For instance, many products have recently been reduced in size and weight because of consumer demand. These include camcorders, laptop computers, digital cam-eras, and even cars. In each case, a market analysis was carried out to ensure that the price and the demand were satisfactory to justify the time, money, and effort spent in developing these items. Of course, in the case of cars, the need to reduce fuel consumption was one of the main motivations for size reduction.

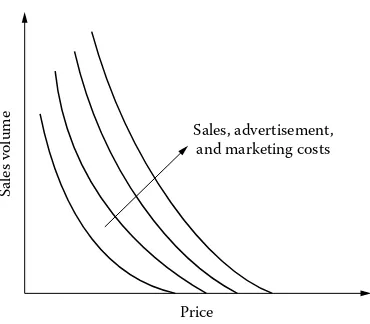

demand for hot water, though desirable, would require larger heaters, leading to higher costs. Better safety and durability features will also raise the price. Clearly, additional features and higher quality make it attractive to various con-sumers and may open additional markets. However, as the price continues to increase, the sales volume will generally decrease, partly because of less frequent replacement, resulting from improved quality, and partly due to loss in sales to less expensive versions. Very selective models may have a small volume of sales but a large profit, or return, per unit. Figure 1.6 shows typical sales volume versus price curves. The curves are separated by differences in the expenditure involved in marketing, advertising, and sales. The profit per item is smaller at a given price if the expense in advertising is increased. However, it is expected that the total volume will increase due to better advertising, making the overall venture more profitable (Stoecker, 1989).

The evaluation of the enterprise must include all expenses that are expected to be incurred. Besides the cost of manufacture of the given item and the expense of advertising and sales, the cost of designing and developing the system, from the initial concept to the prototype, must also be considered. The cost must include both labor and the capital investment needed for equipment and supplies. Considering all the relevant costs and the anticipated sales volume (employing economic concepts as outlined in Chapter 6), the given undertaking may be eval-uated to determine the profit or the percentage return on the investment. If the return is too low, the process may be terminated at this stage. Several new ideas and concepts are evaluated by typical industries, and many of these do not go much farther because of an expected small volume of sales or a large investment needed for development and manufacture. In several cases, specialized compa-nies exist in order to fabricate custom-made or one-of-a-kind products at the spe-cific request of a client. The price may be exorbitant in these cases, but only one or two systems are made, providing a satisfactory return because of the high price rather than the large sales volume.

Price

Sales, advertisement, and marketing costs

Sales volume

1.2.3 FEASIBILITY AND CHANCES OF SUCCESS

It is important to determine if a particular enterprise is feasible. It is also neces-sary to evaluate the chances of success. These considerations are usually brought in early in the project, though inputs from research, development, and design may be needed to make a reliable judgment. The future of the project is strongly influenced by the results obtained from this study.

Measure of Success

The basis for evaluating success must be defined first. This would depend on the nature of the enterprise and the product under consideration. The return on investment is the criterion used by most engineering companies to determine if an undertaking is successful. The dividends paid to investors or the value in the stock market are also important measures of success of an enterprise. Sometimes, other considerations are more important than profit for a given undertaking. Pollution and environmental requirements due to government regulations may be a crucial factor. For instance, the deterioration of the ozone layer has made it necessary to seek alternatives to traditional refrigerants, such as refrigerant 12 (Freon 12), which is a chlorofluorocarbon (CFC), and considerable effort is directed at the development and testing of other fluids for this purpose. Satisfactory hazardous waste disposal similarly may be the dominant consideration in a chemical plant. Cooling towers may have to be used instead of an available lake for cooling the condensers of a power plant, again because of the unde-sirable environmental impact on the lake. The desire to reduce the dependence on imported oil has similarly led to work on synthetic fuels and nonconventional energy sources. Safety aspects may also be used as criteria to evaluate success, particularly in nuclear reactors. National defense may require the indigenous development of certain components or systems, even though these may be procured cheaply abroad. Thus, even though profit is usually the main criterion of success, other considerations may also be used to evaluate the success of an engineering venture.

Chances of Success

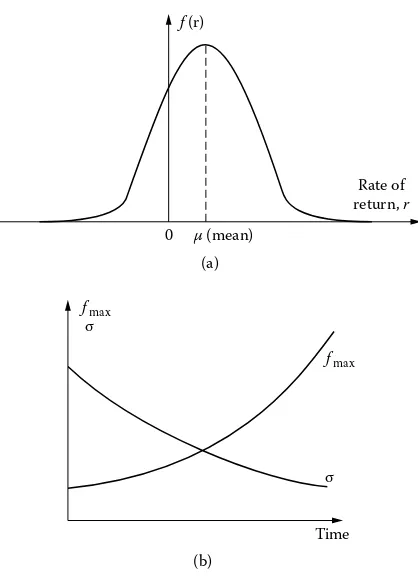

Once the basis for evaluating success is chosen, the next step is to determine the chances of success. Since success depends on many events in the future that can-not be predicted with certainty, evaluation of the chances of success is based on a probabilistic analysis of the various items that are involved in the enterprise, such as financing, design, research and development, manufacturing, testing, govern-ment approvals, sales, advertising, and marketing. The probability of success must be considered over the entire duration of the project and may be expressed in terms of the probability of achieving the chosen measure of success. Suppose the rate of return r is taken as the criterion of success for a given undertaking. The probability

P of achieving a return between r1 and r2 is given in terms of the probability func-tion f (r), which gives the probability of the return lying between r and r dr as

P f r dr

r r

( ) 1

2

with

f r dr( ) 1 (1.2)

indicating that the probability of the return lying somewhere between –∞ and ∞ is 1, or 100%. The probability distribution is often a normal distribution curve given by

f r( ) r

( )/ exp

1 2

1 2 1 2

2

(1.3)

This distribution has a maximum, which occurs at the mean value , and a stan-dard deviation , which gives the spread of the curve, as shown in Figure 1.7. Thus, a larger maximum indicates a higher probability of attaining values around and a larger deviation indicates a larger spread or uncertainty. Other distribu-tions also arise in different cases and the corresponding characteristics may be determined. The probabilities of the occurrence of various events that make up

Rate of return,r

0

(a)

μ(mean)

f(r)

fmax fmax

σ

σ

Time (b)

FIGURE 1.7 Probability distribution curve for the rate of return r, along with anticipated