I. Introduction

This thesis, "Pemanfaatan Material Daur Ulang Aspal Beton Untuk Material Aspal Beton Campuran Dingin Memakai Aspal Emulsi" (Utilization of Recycled Asphalt Pavements for Cold Mixture Asphalt Concrete with Bitumen Emulsion), investigates the feasibility of reusing reclaimed asphalt pavement (RAP) in cold mix asphalt concrete. The introduction establishes the context of road maintenance challenges in Indonesia, highlighting the high costs of conventional overlay methods and the scarcity of aggregate resources. It introduces the use of cold mix asphalt with bitumen emulsion as a sustainable and cost-effective alternative, setting the stage for the research objectives and its potential contributions to the field of civil engineering.

II. Literature Review and Theoretical Framework

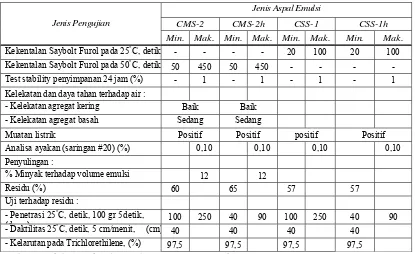

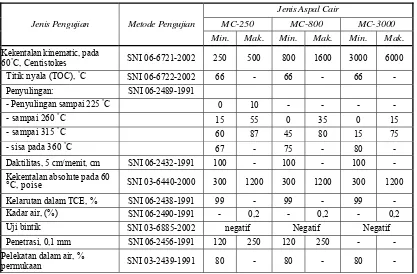

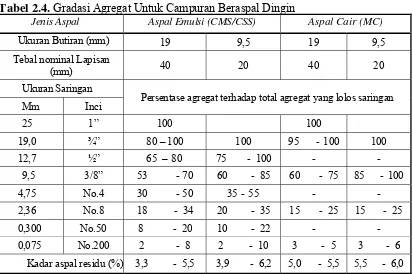

This section provides a comprehensive review of relevant literature and theoretical underpinnings. It covers the concepts of road rehabilitation and maintenance, focusing on the economic and environmental benefits of recycling techniques. The section also delves into the theory of asphalt concrete mixtures, including hot mix, warm mix, and cold mix asphalt, with a specific emphasis on cold mix asphalt using bitumen emulsion. Key material properties, such as the characteristics of asphalt (including bitumen emulsion), aggregates, and fillers, are examined. The principles of cold mix asphalt design and the relevant testing methods are explored, laying a strong theoretical foundation for the research.

III. Research Methodology

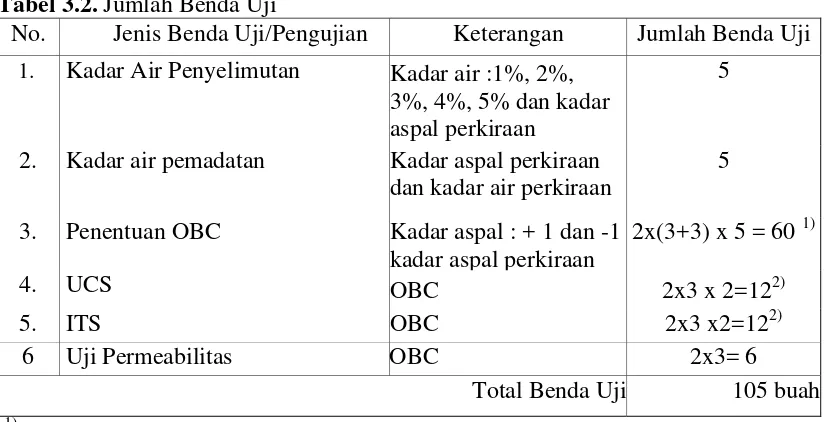

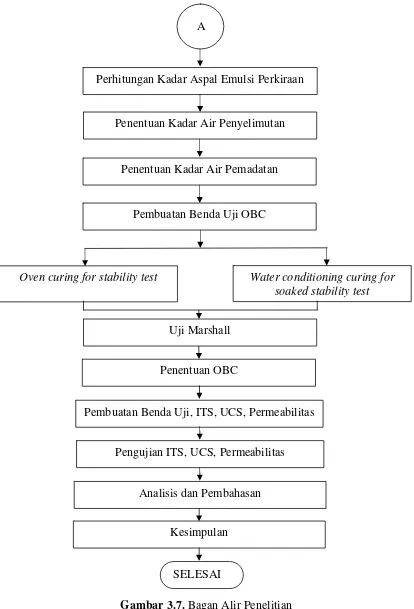

This section details the research methodology employed in the study. It outlines the research design, including the location (Yogyakarta-Prambanan road), timeframe, and data collection techniques. Specific details on the materials used (RAP from Yogyakarta-Prambanan, CSS-1H bitumen emulsion from PT. Hutama Prima) and the laboratory equipment are provided. The preparation of test specimens, including procedures for determining moisture content and compaction levels, is clearly described. Furthermore, the section specifies the testing procedures that were used: volumetric tests, Marshall tests, indirect tensile strength (ITS) tests, unconfined compressive strength (UCS) tests and permeability tests. This meticulous description ensures the reproducibility and validation of the research findings.

IV. Results and Discussion

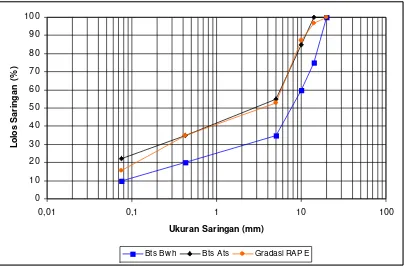

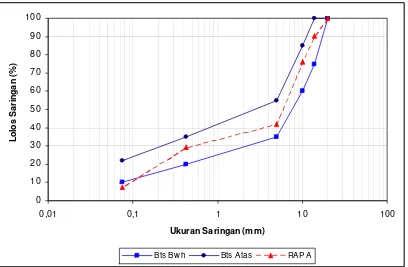

This extensive section presents the detailed results of the laboratory experiments and provides a thorough analysis and interpretation of the data. The results include the characterization of the RAP material (composition, gradation, and abrasion resistance), the properties of the rejuvenated aggregate and filler, and the characteristics of the CSS-1H bitumen emulsion. The section then presents the results of the mix design, using both extracted and unextracted RAP. Detailed analysis of Marshall properties (stability, flow, and voids), ITS, UCS, and permeability tests are shown and discussed, comparing the performance of mixes made with extracted and unextracted RAP. This section provides a comprehensive analysis of various factors impacting the cold mix asphalt properties.

V. Conclusion and Recommendations

This final section summarizes the key findings of the research, concluding on the feasibility of utilizing RAP in cold mix asphalt concrete. The conclusions draw on the data presented in the previous section and address the research objectives. The section also provides recommendations for future research and practical applications, potentially including adjustments to job mix formulas (JMF) for optimal performance. The overall impact and significance of the study's results are highlighted, emphasizing the contribution to sustainable road maintenance practices and knowledge advancement in the field.