RFID IN THE FASHION INDUSTRY: EXPLORATORY CASE

STUDY AND IMPLICATIONS

Federico Pigni Aurelio Ravarini

Samuele Astuti Giacomo Buonanno

Luca Mari

Università Carlo Cattaneo - LIUC

CETIC –Centro per l’Economia e le Tecnologie dell’Informazione e della Comunicazione

22, C.so Matteotti

ABSTRACT

Radio Frequency Identification technologies (RFId) have the potential to reshape entire supply chains by univocally track down goods at item or part level and dramatically improve the efficiency of business process.

INTRODUCTION

Radio Frequency Identification technologies (RFId) have the potential to reshape

entire supply chains. The ability to univocally track down goods at an item or part

level could dramatically improve the efficiency of business process. Moreover,

even if generally compared to barcode, RFId applications provide an extended

flexibility being able to provide a standard, common platform on which users can

build their applications. However, the future of this technology is not yet clear.

RFId technological components are continuously being innovated, business cases

other than those referring to retail industry are very limited, standards are being

defined and literature on the subject is scarce.

Early studies by MIT Auto-ID Center outlined seven main foreseeable

applications of RFId technologies (Smith & Konsynski, 2003): inventory

management, product or asset identification, logistics and transportation,

healthcare, customer service, theft and waste prevention, personal and asset status.

Even though most of them are still in a pilot phase others have been already

deployed (Smith & Konsynski, 2003). It is clear that RFId technologies potentials

are huge and provide extensive flexibility than former barcode applications by

offering, if standardization limits are overcome, “a common platform on which

users could implement several applications simultaneously” (Sarma, Brock, & Engels, 2001). Despite these premises, RFId technologies are far from being

widely adopted (Smith & Konsynski, 2003). In the short term RFId technologies

seem to be a viable solution only for large companies. Moreover, the cost of the

single tag is difficult to justify for low value products whereas barcode could still

be applied. SMEs will probably benefit from these technologies only as a “second tier” adopter possibly forced by their supply chain leaders (Pigni et al., 2006). Furthermore, the lack of industry and application standards are limiting RFId

market expansion and diffusion (Liard, 2003; Micheal & McCathie, 2005).

Finally, some preliminary findings show that the total implementation cost is

discouraging firms to adopt RFId solutions in their supply chains, confining tags

to products batch and single warehouse internal automation (Osservatorio RFId,

However, the cost of the tag, the reader and direct costs in general, are just a part

of the total investment for RFId implementation. System integration, training,

reorganization and application implementation are necessary activities with a

wider scope and generally influenced by the company profile. On this issue any

reference is lacking. Moreover, given the limited number of RFId

implementations, very little is known on how all the information related to

product ID will be managed by companies (Leong, Ng, & Engels, 2004) or how it

could be integrated with their existing systems or again which effects could this

have on their supply chains (Curtin, Kauffman, & Riggins, 2006 - forthcoming;

Loebbecke, Palmer, & Huyskens, 2006; Micheal & McCathie, 2005; Pigni et al.,

2006). Finally, the interorganizational dimension should not be underestimated:

the possibility to track down the single product item along an entire supply chain

generates relevant information flows and requires efficient data management

among partners that should be supported by an adequate Interorganizational

System (IOS) (Cash & Konsynski, 1985; Chae, Yan, & Sheu, 2005; Pigni, Astuti,

& Buonanno, 2004).

Considering the lack of accepted models or frameworks taking into account the

cited specificities, this paper aims at providing an exploratory case study of RFId

implementation in the fashion industry (Yin, 2003). In particular it deals with the

development of an interorganizational system able to address the tedious issue of

counterfeited products. The case study deals with relevant research questions in

the RFId research agenda (Curtin, Kauffman, & Riggins, 2006 - forthcoming). By

assessing the main effects of the RFId system on the B2B logistics, on the internal

operations and by identifying the foreseeable B2C services the study discusses the

possible impacts of the technology on the business value. Finally, the paper covers

some of the typical issues regarding the interorganizational governance and

ownership of the system, such as the roles of the different players and the

increased cross-organizational control in the outsourced process.

CASE SETTING

The G company is a famous Italian brand in the fashion industry. It manufactures

more than 5 million articles per year generating revenues for 40 million euros. Its

activity: the production during the first year of operation was just of 250.000

articles. G has an agile organizational structure focusing only on product concept

and design, fabrics and materials selection, customers and suppliers management.

All the manufacturing and distribution activities are outsourced to external

companies.

G products are considered luxuries and consist of trousers, accessories, shirt and

sweatshirt on which the largest part of the revenues is generated. Like the majority

of its competitors G designs two main collections: Autumn/Winter and

Spring/Summer, plus another line of low cost accessories (around 3 euros).

G considers counterfeited items a very serious issue as they directly impact the

company image and risk to damage both sales and brand strength. The illegal

competition of low-cost fake products, in fact, directly hits sales and the trust that

the network of exclusivist shops have in G. Finally, consumers are damaged

because of the impossibility to have a status recognition granted by the ownership

of branded articles.

This study will focus on the RFId deployment on the two main collections

because of their unitary value and – obviously – because they are more subject to

counterfeiting.

G’s RFId solution against counterfeiting is designed to control both the parallel market of items and the zones of exclusive right, thus identifying that the articles

sold and legit shops, other than original, has been acquired through the official G

distribution channel (the so called “gray market”).

THE RFID ANTI-COUNTERFAITING PROJECT

The business case involves four main actors:

the tag supplier;

the outside contractor (referred to as “façonist”); the logistics provider;

In order to be an effective anti-counterfeiting measure, the RFId tags have to be

applied on items as unique recognizable labels and must remain readable till the

product reaches the final consumer. Consequently:

tags have to be applied on each article by the contractor and a management procedure for both the contractor and the point of sales has to be designed;

all the tags inserted in the articles require proper read and write operations;

consumers’ privacy has to be granted and managed;

logistics should take advantage of tags through proper automated procedures, thus:

o the warehouse management system (WMS) should be adopted in

order to manage the new information from the tags;

o through proper automated procedure tags on items should be

“checkable” on the market both at the points of sale or in other

organizations by sales agents;

Furthermore, the uniqueness of each tag applied to articles improves the shipment

control procedure as each shipment could be checked against the packing list at

item level and agents could better managed, at the points of sale, identifying

returned or defective products.

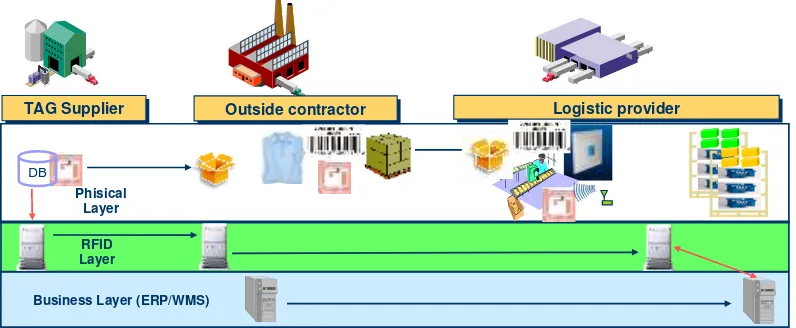

Three main logical levels are used to approach the case study and further analyze

the choices made to meet the project requirements:

the physical layer, where tags are applied, code are read and shipment executed;

the RFId layer, composed by both the RFId system hardware and archive;

the business layer, where the interactions among the RFId layer, the warehouse management system and the ERP system take place.

Tag application and RFId layer management

The RFId tags operates in the HF – 13,56 Mhz – and stores a 64 bit unique, read

only, identification code (Leong, Ng, & Engels, 2004; Sarma, Brock, & Engels,

2001) set by the manufacturer (2 blocks of data) and 896 bit (28 blocks of 32 bit

50cmx50cmx70cm assorted items boxes. In order to avoid additional costs the

contractor is directly supplied by the tag manufacturer with chip integrated in the

labels describing the materials used. Tags are sent in the exact quantity required

by the order placed to the contractor by G, and their unique codes are stored in the

RFId layer (see Figure 1). Eventually, excess tags have to be sent back to G and

re-allocated to new orders. Once received by the logistics provider, products are

checked for authenticity and put in stock keeping unit (SKU) composed by boxes

of homogenous products (color, size and type). During this operation, each tag is

read and associated with the box and the product code. Both barcode and UPC are

used to manage the stocks in order to minimize the impacts on current practices.

This information is finally transferred to the ERP system updating the inbound

bill.

TAG Supplier Outside contractor Logistic provider

DB

Business Layer (ERP/WMS) RFID

Layer Phisical

Layer

Figure 1: Inbound RFId architecture

The RFId layer requires the management of these new codes and should grant its

accessibility outside company boundaries. Furthermore, it should manage:

Tags shipment from the manufacturer to the contractor;

WMS data integration of:

inbound logistics information regarding the tagged articles received from the contractor;

outbound logistics information of the articles sent to customers;

supplier, customers and articles data.

data on products that should be present in the points of sales, thus acquired from the legit distribution channel;

data on exceptions like products in the points of sale that should not be present;

exception reporting.

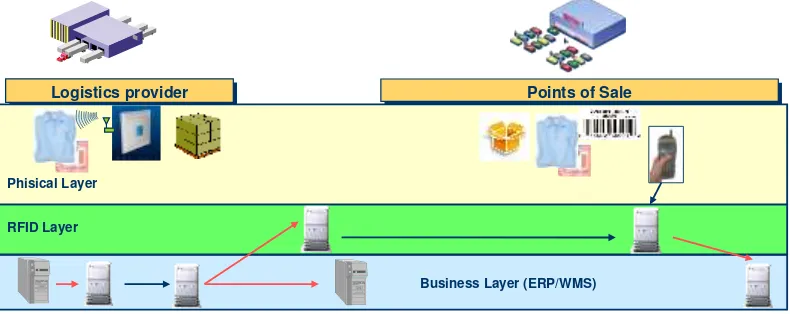

Logistics management (picking and shipping)

The integration of the RFId system with the warehouse management system is

designed to limit the impacts of the new technology. The shipping procedure

remains unchanged thus each shipment is identified both at box level through

barcode with the associated picking list and at item level through the RFId tags

(see Figure 2). The warehouse management system will associate to each

box/barcode the proper article code and quantities. During shipment, the box

barcode is used to retrieve the picking list from the WMS and then to check this

list against tag’s readings. The matching of tag’s readings with product codes is

obtained accessing the RFId tags code archive. Any discrepancy is managed as

exception and manually handled. Once tags reading operations are finished the

processing data is sent back to the WMS, thus information redundancy is greatly

reduced.

Logistics provider Points of Sale

Phisical Layer

Business Layer (ERP/WMS) RFID Layer

Figure 2: Outbound RFId architecture

Market control (Sale agents)

Sale agents are used to control the consistencies of point of sales’ articles display

Agents are equipped with a portable RFId reader device, interfaced with the

business layer and able to access all shipment data to the point of sales. In this

first stage, data are not directly sent to the integrated PDA device, but is the sale

agent that has to update this information manually by uploading the “update file”

received periodically by email.

The agent will not directly deal with the possible exceptions encountered: the

PDA generates an exception file that will be sent back by email to G.

Future development of the RFId application will be able to manage defective

products in order to authorize returning these articles.

Privacy issue

Customer’s privacy concerns need to be dealt carefully both for the obvious issues

and actions that could emerge and for the possible marketing opportunity.

Customers have the possibility to detach the RFId tag from the label and are

invited do to that if for any reason privacy is one of their concerns. The advice to

remove the tag is sufficient to protect G against any action for privacy concerns.

However, by suggesting to customers that the label grants the originality of the

products, tags could be used for marketing purposes.

PROJECT RESULTS AND LESSONS LEARNED

One of the most recent authoritative study on RFId application is Loebbecke et al.

(2006). In the analysis of the results of their case study the authors identified three

main relevant aspects of their application:

The physics involved, and the need to fine tune readers, tags and packaging to reach the 99% readability;

The processes affected by the RFId implementation “from tagging,

packing, and shipping logistic units and items through distribution and

warehousing on to display, sales, and theft prevention at the stores”;

The price and performance of the application and the different scenarios and choices regarding the RFId tag selection.

Despite all these elements provide interesting views of a case study, we suggest

stated before, an instance of IOS). The study of the IOS level is proposed to

isolate RFId effects on business processes’ information dimension. This is

especially useful for the present case study because of the limited impacts on

processes purposely planned in the design phase of the project.

The physics

As RFId applications are based on radio signals they are obviously subjected to

interferences that could thwart its feasibility (Finkenzeller, 2003; Loebbecke,

Palmer, & Huyskens, 2006; Micheal & McCathie, 2005; Pigni et al., 2006). The

effective scanning distance of RFId tags is affected by the composition of nearby

objects or simply by the material the tag is applied to. One of the most critical

aspects of any RFId project implementation is thus the understanding of the RFId

environment. High-moisture materials and metals can reduce the scanning

distance, as confirmed by several studies.

The pilot study was used to fine tune the application in order to attain the

application readability requirements. In particular, the scanning process required

special attention during the installation of the equipments both for the pilot and for

the actual deployment of the solution. The main obstacle was posed by the relative

short distance between tags applied on folded products, in several cases to small to

grant a perfect readability. Despite the encountered difficulties, product

readability was reached quite easily by studying a convenient packaging and

procedure in a pilot phase with the support of an RFId solution provider that

already developed expertise in this field.

The processes

The entire project was studied to minimize the effects on current business process

and it mainly affected logistics’ and sales’ ones. Despite the limited impacts all

the supply chain actors (Contractor, Logistics Provider and POS) experienced

changes in the way products are handled.

Outside Contractor: Tag application is totally transferred to façonists that have to

receive the RFId tags, apply them to products and handle both the outbound and

shipment. Tags application had only minimal impacts as it is stitched to the items

the outside contractors but checked by the logistics provider to verify legit

products.

Logistics provider: tags streamline logistics operations producing relative increase

in performance and accuracy through automation of inbound and outbound items

check.

Point of Sales: the single item tracking impacts sales agents jobs as they are

responsible for grey market/counterfeited items checking at the POS. Moreover,

POS are supplied with a proper PDA to verify sales and check inventory on a

daily basis. Actually, no action is formally undertaken when discrepancy between

items expected and found at the POS are notified, since the case study is still in an

early stage.

Finally, despite the project identified possible added value services to be provided

to customers, none of them was put into place, yet.

The Supply Chain Management System (IOS)

The RFId project posed multiple challenges in terms of IS design because of its

interorganizational nature. The first problem to address was related to the

“architecture” of the IOS supporting the RFId system. Generally, RFId

architectures range from centralized to fully decentralized and interoperable

systems, depending on where the information is stored: a central database or the

tag itself (Pigni et al., 2006). The solution developed by G mainly leverages the

benefits from the first scenario by directly managing the system, thus reducing the

impacts and the costs on the supply chain partners. The drawback is the obvious

“cost” to set-up the RFId layer, to grant its interoperability with both G’s current

ERP system and the logistics provider’s WMS, and the design of POS’ PDA application. Finally, to improve the traceability of gray market product, in each

tag is sored in other than the Electronic Product Code, the Stock Keeping Unit

Identifier: an 8 characters code that identifies the box used to store items in the

logistics provider’s warehouse. Thus the RFId layer manages the correspondence

between the SKU and the single items associated, whereas the WMS was only

capable to identify the class of products within each SKU.

Logistics provider: a procedure was setup to remotely exchange data from G’s

ERP system to logistics provider WMS providing RFId identification data,

exceptions, orders and packing lists.

Point of Sales: a PDA application should be designed to check daily sales at POS

and provide a proper interface with G’s ERP system. A similar application was

designed for G’s salespersons to check items’ RFId tags against the legit ID stored

in the central database.

Price and performance

G products benefits of a high unitary value minimizing tags’ cost incidence on the

final price of the branded items. Despite this, their value, on the total amount of

both investment and variable costs, represents the most relevant voice totaling (at

fixed quantities) more than 150.000€/yr. Investments in the RFId antennas, related

installation and configuration services where in the order of the 20.000€. Higher

costs (30.000€) were sustained for the acquisition, configuration and integration of the RFId software layer in G and the logistics provider. Finally, 20.000€ had to be

invested for the development of PDA software and partially committed to the POS

sales tracking system.

Benefits originated both from increased revenues and costs savings. It is estimated

that counterfeited products hit revenues by 8% and through the use of RFId this

plague was at least contained. The institution of a new item tracking procedure

through the RFId system dramatically reduced the costs of the services provided

by those agencies responsible for the inspection of customs’ confiscated products

(around 100.000€/yr.). Moreover, the finer tracking greatly impacted the gray

market increasing customers’ trust on the company as legit products are now

available only through G distribution channel as all the others are persecuted.

Consequently, the company exposure to customer’s claims, that generated legal

costs of over 200.000€/yr, are effectively eliminated.

Logistics benefits from the RFId project are related to returned goods

management. The ability to check the items composing each shipment reduced the

possibility of errors that generally translated in missed sales. Therefore, the costs

In summary, this case study showed a very successful example of RFId

implementation. The project payback was lower than a year and despite a limited

investment, great benefits were achieved. Harder to determine are the indirect

effects of the projects both in term of benefits and costs, despite the fact that the

latter were purposely contained. The effects on brand and customers’ trust are

surely important, but hardly referable to monetary values or performance indexes

and generally were not explicitly considered during project design. Finally,

despite its evident relevance the RFId contribute to G’s competitive advantage

was not assessed as the main project success criteria were directly related to

correspondent elements in the company budget.

CONCLUSIONS AND FURTHER RESEARCH

The RFId project had the precise purpose to limit the impacts on current business

processes and systems since its limited deployment on the company’s product

range. If changes were limited, the B2B logistics experienced positive efficiency

and efficacy effects, enabling full tracking of the gray market. Similarly, the

company has developed strong interest in the B2C logistics to strategically use

tags for “after sales” management and brand recognition among the consumers. The increased control on manufactured and delivered products reshaped the

internal process of G allowing new control opportunities on the distribution

channel, increasing market perception.

Furthermore, compared to the findings of Loebbecke et al. (2006) in the same

industry, the standardization did not constituted a real issue: despite the fact that

the application has an interorganizational scope and involves multiple players it is

directly owned and managed by G. G is the initiator and the owner of the system

and was able, reducing the impacts of the RFId solution and properly

communicating the attainable benefits, to engage all the relevant partners in its

supply chain. The main integration efforts were focused on the logistics provider

both for the inbound and outbound activities, but the impacts on the WMS were

extremely reduced. The entire implementation, in fact, was supported by a parallel

“RFId application layer” designed to be interoperable with both the logistics provider WMS and G’s ERP system and responsible for the management of

Further research should deepen the understanding of the price and performance

concept by referring to a more comprehensive one like the “business value” of the

RFId application. This concept should comprehend additional aspects other than

operational measures, generally adopted because of their direct “measureability” and their use of the ROI ratio (Gebauer & Buxmann, 2000). Moreover, RFId

projects have a strong interorganizational component involving partners with the

different role of initiators and participants and interorganizational investments

tend to be oriented to the long term, thus requiring an adequate evaluation

perspective (Gebauer & Buxmann, 2000; Pigni, Astuti, & Buonanno, 2004).

Lastly, this paper provides a preliminarily positive answer to an interesting

research question: do RFId use impact IOS adoption and creation? The RFId

project determined the adoption and creation of an IOS (Morrel & Ezingeard,

2002) because it resulted to perfectly fit company’s needs to track items along the

supply chain to fight the counterfeiting plague. The main reasons behind this

project development are attributable to efficiency and effectiveness drivers, more

than an accurate understanding of G’s competitive positioning, that seems to experience benefits, too. The development the RFId systems enabled the adoption

of an IOS along the supply chain, fostered by the ability of G to manage the

organizational challenge posed by the technology itself and the coordination of

multiple partners. Likewise all the inhibitors that generally hinder IOS

development were avoided thanks to G commitment to the project and the

decision to support all the costs by itself, greatly reducing the partners’

REFERENCES

Cash, J. I., & Konsynski, B. R. (1985). IS Redraws Competitive Boundaries. Harvard Business Review, 63(2), 134-142.

Chae, B., Yan, H. R., & Sheu, C. (2005). Information Technology and Supply Chain Collaboration: Moderating Effects of Existing Relationships Between Partners. IEEE Transaction on Engineering Management, 52(4), 440-448.

Curtin, J., Kauffman, R. J., & Riggins, F. J. (2006 - forthcoming). Making The ‘Most’ Out of RFId Technology: A Research Agenda for the Study of the Adoption, Usage and Impact of RFId Information Technology and Management.

Finkenzeller, K. (2003). RFID Handbook : Fundamentals and Applications in Contactless Smart Cards and Identification (R. Waddington, Trans.): Hardcover.

Gebauer, J., & Buxmann, P. (2000). Assessing The Value Of Interorganizational Systems To Support Business Transactions. International Journal of Electronic Commerce, 4(4), 61.

Leong, K. S., Ng, M. L., & Engels, D. W. (2004). EPC Network Architecture. In the proceedings of the Auto-ID Lab Research Workshop, Zurich, CH, 23 September.

Liard, M. J. (2003). The Global Markets and Applications for Radio Frequency Identification and Contactless Smartcard Systems, 4th Edition. Natick, MA: Venture Development Corporation.

Loebbecke, C., Palmer, J., & Huyskens, C. (2006, June 5 - 7). RFID's Potential in the Fashion Industry: A Case Analysis. Paper presented at the 19th Bled eConference, Bled, Slovenia.

Micheal, K., & McCathie, L. (2005). The Pros and Cons of RFID in Supply Chain Management. Paper presented at the International Conference on Mobile Business (ICMB'05), Sydney, NSW.

Morrel, M., & Ezingeard, J. (2002). Revisiting adoption factors for interorganizational information systems in SME's. Logistic Information Management.

Osservatorio RFId. (2005). RFId tra presente e futuro - I risultati 2004-2005 dell’Osservatorio RFId. Milano, IT: Politecnico di Milano.

Pigni, F., Astuti, S., & Buonanno, G. (2004). An evaluation framework for RFId Adoption. In the proceedings of the XLII Congresso Annuale AICA, Benevento, Italy, 28 - 30 Settembre.

Sarma, S., Brock, D., & Engels, D. (2001). Radio Frequency Identification and the Electronic Product Code. IEEE Micro, 21(6), 50-54.

Smith, H., & Konsynski, B. (2003). Developments in Practice X: Radio Frequency Identification (RFID) - An Internet for Physical Objects. Communications of the Association for Information Systems, 12(19), 301-311.